CPT International 04/2018

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

www.cpt-international.com<br />

4<br />

December<br />

<strong>2018</strong><br />

CASTING<br />

PLANT AND TECHNOLOGY<br />

INTERNATIONAL<br />

State-of-the-art<br />

induction furnace<br />

technology

Reports and<br />

product news on<br />

GIFA 2019<br />

in CASTING PLANT &<br />

TECHNOLOGY (CP+T)<br />

It’s It’s time again in in Düsseldorf,<br />

from 25 25 - 29 - 29 June 2019: the foundry<br />

sector once more presents itself as as<br />

a a high-tech industry.<br />

We look forward to to your press releases and<br />

specialist reports for for GIFA 2019!<br />

PHOTO: FOTOLIA<br />

PHOTO: FOTOLIA<br />

e-mail address: redaktion@bdguss.de<br />

We We would be be pleased to to receive<br />

questions by by phone:<br />

Contact: Robert Piterek<br />

e-mail: robert.piterek@bdguss.de<br />

Tel.: +49 (0)211 6871-358<br />

More than 2,000 exhibitors from over 30 30 countries are expected<br />

at at the 14th GIFA international foundry trade fair with<br />

WFO Technical Forum. In In the News section, among other places,<br />

the editorial staff at at CP+T will report on on innovations, new products<br />

and new technical processes in in advance of of GIFA. Please<br />

send press releases and specialist reports for for GIFA 2019 to to the<br />

editorial office via via e-mail under the heading “GIFA 2019”.

EDITORIAL<br />

The range of casting<br />

applications is increasing!<br />

GIFA is approaching, so the sector is increasingly expressing views about the<br />

expectations, previous planning and coming trends that will play a role at the<br />

world’s largest casting trade fair. The man who knows best which new chapters<br />

of foundry history will be opened at the upcoming 14th <strong>International</strong> Foundry<br />

Trade Fair (GIFA) has his say in this issue of CP+T: Heinz Nelissen, Managing<br />

Director of Vesuvius GmbH, Foseco Foundry Division, was appointed President<br />

of GIFA and NEWCAST 2019 a few months ago. In an interview with our magazine<br />

he discusses hot topics such as additive manufacturing, Industry 4.0 and<br />

e-mobility, as well as the market situation facing the various product segments<br />

in casting, potential substitutions by competing production processes, and<br />

how to ensure the recruitment and advancement of skilled labor and mana gers<br />

(more on this from P. 6).<br />

Consistent with the trends and directions of development in the sector, this<br />

final issue of <strong>2018</strong> is also dedicated to the future of casting with examples of<br />

best practice from Germany and the USA. The casting process is one of the<br />

world’s oldest production techniques – ancient Egyptian hieroglyphics show<br />

that it was already being used many thousands of years ago. The reason why<br />

the technique has lasted so long can be traced back to its high level of design<br />

freedom. This can be even further expanded with the help of state-of-the-art<br />

‘additive’ technology, considerably broadening the range of casting applications<br />

and making the process even more attractive. The American Foundry<br />

Society has now selected its Casting of the Year. It was created using a combination<br />

of additive and foundry practice. Bionic production aspects were also<br />

involved. In the article from P. 35, we reveal what the workflow looked like and<br />

the challenges that had to be overcome.<br />

The other topics covered in this issue are just as exciting: CP+T reports on<br />

melting technology and the range of competences of the globally active industrial<br />

furnace constructor Otto Junker. We also describe the experiences<br />

gained with a high-tech sand preparation plant in Bavaria, as well as with the<br />

latest simulation software for optimizing product design and casting technology.<br />

There are also company reports on investments in Industry 4.0 at Ortrander<br />

Eisenhütte, as well as on Modulcast, a combination of high-bay storage,<br />

molding plant and the casting process – a first in the foundry sector!<br />

Merry Christmas and a happy New Year!<br />

Have a good read !<br />

Robert Piterek<br />

e-mail: robert.piterek@bdguss.de<br />

Casting Plant & Technology 4 / <strong>2018</strong> 3

FEATURES<br />

INTERVIEW<br />

Nelissen, Heinz<br />

“The foundries will stand up to new challenges and solve the problems” 6<br />

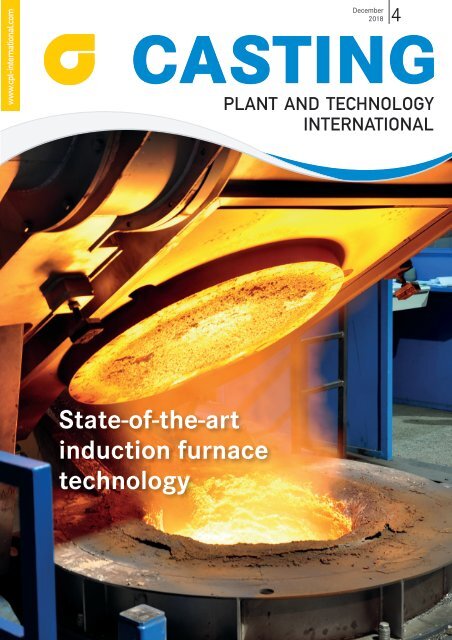

Cover-Photo:<br />

Otto Junker GmbH<br />

Jägerhausstr. 22<br />

52152 Simmerath-Lammersdorf<br />

sales@otto-junker.com<br />

+49-2473-601-0<br />

One of two Otto Junker induction crucible<br />

furnaces installed at Fima-Olimpia<br />

Fonderie S.p.A. in Barberino val d’Elsa,<br />

Italy. The ovens hold a weight of 6 tons<br />

and melt with a capacity of 4 MW. The<br />

furnaces were delivered in 2011 and<br />

since then provide reliable service. In<br />

particular, the IGBT converter ensures<br />

high reliability and excellent network<br />

performance (Photo: Fima-Olimpia<br />

Fonderie S.p.A.)<br />

MELTING SHOP<br />

Niklaus, Steffen; Reiermann, Joachim; Schmitz, Wilfried<br />

20 Years of Otto Junker Melting Technology Centre – state-of-the-art<br />

induction technology 12<br />

AUTOMATION<br />

Meier, Wolfgang<br />

The latest generation of sand preparation at Isar Metallgusswerk 22<br />

SIMULATION<br />

Pretzell, Anja<br />

Magmasoft - Autonomous Engineering 26<br />

RESOURCE EFFICIENCY<br />

Klingauf, Peter<br />

Refiner optimizes yield by briquetting 32<br />

12 35<br />

Otto Junker has been operating a Technology Centre for<br />

melting and casting trials for 20 years – the birthplace of<br />

many innovations (Photo: Otto Junker)<br />

The uniquely shaped motorcycle swing arm portrays the<br />

possibilities available when combining additive manufacturing,<br />

simulation and innovative design (Photo: AFS/TEI)

CASTING<br />

4 | <strong>2018</strong><br />

PLANT AND TECHNOLOGY<br />

INTERNATIONAL<br />

3-D-PRINTING<br />

Wetzel, Shannon<br />

TEI swing arm wins Casting of the Year 35<br />

INDUSTRY 4.0<br />

Vehreschild, Michael<br />

Investments in Industry 4.0 have paid off for the<br />

Ortrander Eisenhütte 38<br />

COMPANY<br />

Vehreschild, Michael<br />

Achieving top form 42<br />

COLUMNS<br />

Editorial3<br />

News in brief 48<br />

Brochures56<br />

Fairs and congresses / Ad Index 58<br />

Preview / Imprint 59<br />

42<br />

The Friedrich Lohmann foundry now has “a lot in stock” thanks to the new high-bay storage system which is called Modulcast.<br />

Casting takes place at a height of four meters. Employees literally operate at top form here.The connection of high-bay storage<br />

system, molding plant and casting process is a novelty in the foundry industry (Photo: Friedrich Lohmann GmbH)

INTERVIEW<br />

“The foundries will stand up<br />

to new challenges and solve<br />

the problems”<br />

Dipl.-Ing. Heinz Nelissen, President GIFA 2019 and NEWCAST, Managing Director Vesuvius<br />

GmbH, Foseco Foundry Division, Borken, Germany, spoke with the technical journal CP+T.<br />

FOTO: ULI ZILLMANN<br />

What can visitors expect from the upcoming<br />

GIFA trade show? What will<br />

be different compared to last GIFA in<br />

2015?<br />

The megatrend of the moment and the<br />

topic of the future in production technology<br />

is additive manufacturing. Also<br />

the digital transformation is an issue<br />

for foundries. 3-D printing has been<br />

gaining in importance alongside traditional<br />

manufacturing techniques. 3-D<br />

printing has already proved its worth<br />

in practice in a wide range of high-end<br />

sectors such as in medical engineering<br />

as well as in the automotive and aerospace<br />

industries. Meanwhile also the<br />

foundry industry and the steel and aluminium<br />

sectors have recognized the<br />

potential of 3-D printing. GIFA is going<br />

to dedicate due attention to this topic,<br />

among others by a special show featuring<br />

the great potential this technology<br />

provides. I am sure that we will see<br />

3-D solutions and products not only at<br />

the special show, but also at numerous<br />

exhibitor stands. We are very likely to<br />

come across exciting approaches to designing<br />

self-optimizing systems as part<br />

of the “digital transformation”.<br />

Who should visit GIFA?<br />

Everybody active in the foundry industry<br />

or in related sectors should see<br />

GIFA as an opportunity to get a personal<br />

impression of the state of the<br />

art and current development trends.<br />

The main target groups of GIFA are<br />

employees and managers of iron, steel<br />

and malleable iron foundries, as well<br />

as non-ferrous metal foundries. The<br />

trade show also addresses mechanical<br />

and apparatus engineering companies<br />

and manufacturers of equipment for<br />

the automotive and gear engineering<br />

sectors as well as the supply industry.<br />

Recent development trends like 3-D<br />

printing and digital technology are<br />

characterized by much shorter innovation<br />

cycles than those we know<br />

from classical foundry equipment suppliers.<br />

Competitive events such as the<br />

biennial Euroguss become bigger and<br />

more international, and new trade<br />

fairs with new focuses, like CastForge<br />

in Stuttgart, have emerged. How is<br />

GIFA positioned within this competitive<br />

landscape?<br />

Events with a regional or national<br />

scope fulfill an important role, as they<br />

cover topical issues from the expert angle<br />

and address a regional audience.<br />

However, GIFA – and METEC, THERM-<br />

PROCESS and NEWCAST alike – showcase<br />

innovations, products and services<br />

on a global scale. No other trade<br />

show provides such a wide-ranging<br />

and far-reaching picture of the complete<br />

range of foundry technology,<br />

cast products, metallurgy and thermal<br />

processing technology. It is a forum for<br />

both the big players of the foundry industry<br />

and the smaller, highly innovative<br />

champions to present themselves<br />

to large audience. The big equipment<br />

suppliers often time their research and<br />

development projects around the fouryear<br />

cycle of the show. The key to the<br />

success of this trade fair quartet is that<br />

it covers the complete market of both<br />

the demand and supply side. This also<br />

mirrors in the decision-making responsibility<br />

represented by the GIFA<br />

visitors: In 2015, more than half of the<br />

about 50,000 visitors held top management<br />

positions and correspondingly<br />

high decision-making responsibilities.<br />

In terms of internationality, the trade<br />

fair quartet GMTN is second to none:<br />

In 2015, 58% of the visitors came from<br />

112 different countries. And the fouryear<br />

cycle ensures that the event does<br />

not loose any vigour.<br />

Is it true that apart from new topics<br />

such as additive manufacturing and<br />

the digital transformation the overall<br />

concept of the fair has remained<br />

the same?<br />

Obviously GIFA comes up to the visitors’<br />

expectations. For example, in<br />

2015, 97% of the about 50,000 visitors<br />

gave a very high rating to the event<br />

and stated that their expectations had<br />

been fulfilled. Every second one stated<br />

that they had established new supplier<br />

relations. GIFA is certainly an ideal<br />

platform to meet customers, colleagues<br />

and junior staff. We expect<br />

young talent to visit the trade show in<br />

great number again next year.<br />

In which way has the economic landscape<br />

changed versus 2015?<br />

A key criterion for the assessment of<br />

the foundry market is the cast output.<br />

NF-metals foundries have seen a<br />

constant rise in production and, with<br />

lightweight construction and e-mobility<br />

gaining in importance, their prospects<br />

for the future are also excellent,<br />

especially in pressure and low-pressure<br />

die casting ...<br />

But not for the iron foundries ...<br />

... the iron foundries in Germany – and<br />

elsewhere in Western Europe – experienced<br />

a rather moderate development<br />

from 2011 until recently. However,<br />

Casting Plant & Technology 4/ <strong>2018</strong> 7

INTERVIEW<br />

since 2017 and the first half of <strong>2018</strong>,<br />

they have been feeling a clear upturn.<br />

This was triggered by the growing demand<br />

in the mechanical engineering<br />

sector as a result of a catch-up effect<br />

and a booming phase in all its subsegments,<br />

with the exception of wind<br />

power. Although the current market<br />

situation is very positive, there is a dark<br />

cloud on the horizon. This is due to<br />

the dramatically changing eco-political<br />

environment. Just take the anti-free<br />

trade measures implemented by the US<br />

Administration, the unsolved Brexit or<br />

the increase in sanctions. The reliability<br />

of business relations has definitely<br />

not improved. Let’s hope that the all in<br />

all positive climate will persist beyond<br />

next year’s GIFA.<br />

What will be the main top issue at<br />

next GIFA?<br />

I do not see one single, overwhelming<br />

topic, but several interrelating and interdependent<br />

issues. As well as additive<br />

manufacturing, topics like lightweight<br />

construction in automotive<br />

engineering, Industry 4.0, the digital<br />

transformation, energy and resource<br />

efficiency, and sustainability will play<br />

central roles at next GIFA – not forgetting<br />

e-mobility.<br />

Do you see additive manufacturing<br />

and casting as partners or competitors?<br />

They are two complementary trends.<br />

Generative processes currently represent<br />

one of the most important and<br />

intensive research areas of the global<br />

industry. Products for specific applications,<br />

prototypes and parts for<br />

airplanes are already being produced<br />

by 3-D printing, replacing castings in<br />

these areas. However, for large series<br />

production, casting still is the most<br />

economical process – also according to<br />

statements by major OEMs. With computers<br />

becoming increasingly more efficient<br />

and faster, costs decreasing and<br />

the quality of metal powders improving,<br />

this balance may, however, slightly<br />

shift towards 3-D printing in the future.<br />

There are already examples of application<br />

where 3-D printing and casting<br />

complement each other. These will be<br />

featured in a special show at GIFA.<br />

Is 3D printing also an interesting option<br />

for your company?<br />

We already produce prototype tools<br />

by 3-D printing. This allows us to test<br />

the tools under manufacturing conditions<br />

before kicking off the cost-intensive<br />

production of metal tools in large<br />

series. We know that some pressure die<br />

casting shops use extremely complex<br />

tools which they can produce only by<br />

3-D printing. Additive manufacturing<br />

provides much more design options,<br />

for example, as it can produce parts<br />

with undercuts.<br />

What will be Foseco’s main focus at<br />

GIFA?<br />

Foseco is going to feature the main<br />

R&D areas in foundry technology. Energy<br />

and resource efficiency can be significantly<br />

improved by specific products<br />

and technologies. Visitors may<br />

look forward to our presenting innovations<br />

in gating technology. We will<br />

introduce a new technology allowing<br />

virtually turbulence-free casting of medium-heavy<br />

steel castings. In non-ferrous<br />

metals treatment, we have long<br />

been active in developing products<br />

and processes for optimized melt refining.<br />

At our booth we will showcase<br />

new technologies for our FDU<br />

and MTS equipment in combination<br />

with innovative solutions for the metal<br />

transport. Innovative coating and<br />

binder systems will round out our exhibits.<br />

Do you think there is potential for<br />

the casting process to substitute any<br />

of its competing manufacturing techniques?<br />

Do you expect any new casting<br />

solutions and new markets for<br />

castings to occur?<br />

We are in competition with hybrid<br />

metal/metal and metal/plastics<br />

components, with 3-D printing,<br />

with high-performance machining<br />

techniques, and with our traditional<br />

“competitors” forging and welding.<br />

We don’t see the new technologies<br />

take over significant market<br />

shares from the foundries or vice versa<br />

during the next five years. However,<br />

this does not mean that the new<br />

technologies will not position themselves<br />

in the market as solutions for<br />

certain niche applications or applications<br />

that require a very specific range<br />

of properties. By further sophisticating<br />

the technology of thin-wall casting<br />

not only in pressure die casting<br />

but also in iron and steel casting, the<br />

foundries may open new application<br />

opportunities. Also the development<br />

of new casting materials and the further<br />

development of existing ones<br />

will provide new options. Generally,<br />

due to the advance of e-mobility, we<br />

will see a number of entirely new components<br />

in the market, mainly made<br />

of aluminium.<br />

8 Casting Plant & Technology 4 / <strong>2018</strong>

Yet, a growing mix of materials is being<br />

used in automotive engineering.<br />

This further intensifies the competition<br />

between materials and production<br />

processes. Are structural components<br />

made of fibre reinforced<br />

composite materials a threat to structural<br />

aluminium castings?<br />

The plastics industry has been dedicating<br />

great efforts to achieving an even<br />

deeper penetration of the automotive<br />

market. Thermoplastics and fibre reinforced<br />

plastics are used in technologically<br />

highly demanding solutions.<br />

However, casting alloys, in the here<br />

described case especially high-strength<br />

aluminium alloys for the production<br />

of safety-critical components, provide<br />

better strength and elongation properties.<br />

Only casting alloys can be 100 percent<br />

recycled and reused to produce a<br />

casting of the same high quality. Plastics<br />

manufacturers still haven’t solved<br />

the issue of recycling. And the current<br />

discussion about plastics contaminating<br />

the environment is likely to serve<br />

as a promoter of cast products.<br />

Are the players in the markets relevant<br />

and with a potential for castings<br />

aware of the advantages of cast<br />

products? Or is this an area where the<br />

foundry industry needs to become<br />

more active?<br />

Our big customer segments are passenger<br />

car and utility vehicle producers<br />

and the mechanical engineering sector<br />

with its numerous subsegments.<br />

Alongside these, there are many more<br />

specialized segments. The main customer<br />

groups of the foundry industry<br />

know the advantages of castings very<br />

well. However, I believe that spreading<br />

the word about the foundries’ performance<br />

capacities more widely and intensively<br />

would open new application<br />

potential for castings also among our<br />

traditional customers. Despite the Internet,<br />

websites and search engines,<br />

the lack of knowledge about the performance<br />

features of cast components<br />

is surprisingly great in many potential<br />

customer segments. Nevertheless, the<br />

foundries should not start to take over<br />

the job of the universities.<br />

Up until the present, iron castings<br />

have always succeeded in defending<br />

their position in automotive engineering<br />

against non-ferrous metals<br />

castings, even in lightweight solutions.<br />

Is this going to change in the<br />

future against the backdrop of e-mobility?<br />

Weight reduction of castings for automotive<br />

applications will remain a key<br />

development target among OEMs, independent<br />

of e-mobility. We can see<br />

today that castings will continue to<br />

be indispensible in both fully electrically<br />

and conventionally propelled vehicles.<br />

Lightweight construction with<br />

cast iron components, and with thinwalled<br />

steel castings, will also be needed<br />

in the future alongside further op-<br />

Competence in<br />

Shot Blast Technology<br />

We offer a complete service in surface preparation technology,<br />

not just as machine designers and manufacturers.<br />

Our emphasis is on providing reliable service on:<br />

• Wear and Spare Parts<br />

• Repair and (remote) maintenance<br />

• Inspection and process advice<br />

• Machine upgrades and performance<br />

enhancement<br />

• Upgraded used machines<br />

AGTOS<br />

Gesellschaft für technische Oberflächensysteme mbH<br />

Gutenbergstraße 14 · D-48282 Emsdetten<br />

Tel. +49(0)2572 96026-0 · info@agtos.de<br />

www.agtos.com<br />

151-11/13-4c-GB<br />

Casting Plant & Technology 4/ <strong>2018</strong> 9

INTERVIEW<br />

GIFA 2019 and NEWCAST – Foundry technology<br />

at global scale<br />

NEWCAST: Registrations will be accepted beyond the official deadline!<br />

GIFA 2019, the world’s biggest and most important trade fair for foundry machinery,<br />

casting processes and cast products, follows seamlessly in the footsteps<br />

of the previous shows. More than 900 exhibitors – including numerous<br />

market leaders – from all countries relevant for the foundry industry will present<br />

their products and technologies in halls 10 to 13 and 15 to 17. The 14th edition<br />

of GIFA will provide a concise overview of topical issues such as energy<br />

and resource efficiency and present advanced, future-oriented innovations and<br />

world’s firsts for the entire process and value chain of casting.<br />

NEWCAST, launched in 2003, has since evolved into an international event<br />

representing current market trends. In 2019, more than 400 exhibitors are expected<br />

to present their competence and products in halls 13 and 14. The participation<br />

of international market leaders, including Bosch Rexroth AG (Germany),<br />

GF Casting Solutions AG (Switzerland), GOM GmbH (Germany), Kimura<br />

Foundry Co., Ltd. (Japan), Kutes Metal Inc. (Turkey), Finoba Automotive GmbH<br />

(Germany) and Siempelkamp Giesserei (Germany) highlights the growing importance<br />

of NEWCAST. Countries like China, India and Turkey will present<br />

themselves with big pavilions. Other highlights will be the NEWCAST Award<br />

and the NEWCAST Forum, sponsored and organized by the Germany Foundry<br />

Association (BDG). Foundries interested in using the Forum as an active marketing<br />

platform can still register.<br />

Although the official registration period has expired, the trade fair organizer<br />

Messe Düsseldorf will be accepting registrations until the start of the event.<br />

NEWCAST provides participating foundries an excellent platform for promoting<br />

themselves and meeting new customers.<br />

timized solutions based on light-metal<br />

castings. Iron and steel castings owe<br />

their relevance to their excellent fatigue<br />

strength properties and the<br />

great flexibility in designing bionic<br />

constructions. The production of<br />

thin-walled iron and steel castings requires<br />

high capital investments in machinery,<br />

above all in core and mould<br />

making equipment, fettling machines,<br />

robotic equipment for automatic handling<br />

and, last but not least, machining<br />

systems.<br />

Where do you see potential for steel<br />

casting?<br />

We expect a great deal from steel casting.<br />

The last few years have seen a<br />

strong demand for lightweight castings,<br />

especially of ferrous materials.<br />

One can generally state that casting is<br />

an ideal process for bionic constructions.<br />

Here, we expect new opportunities<br />

for steel castings. Currently, thinwall<br />

casting of steel is being further<br />

developed with a view to new applications<br />

triggered by e-mobility but only<br />

feasible thanks to thin-walled steel<br />

castings. An example is the development<br />

of spring supports for chassis.<br />

Should foundries get more involved<br />

with IT-related topics and new, data-driven<br />

business models?<br />

Foundries are familiar with data-driven<br />

business models because many of<br />

their customers operate on this basis.<br />

The customers usually define the requirements<br />

and the foundries have to<br />

comply with them in due time. Every<br />

foundry should carefully consider up<br />

to which point it is willing to disclose<br />

their processes and operating procedures<br />

to their customers. There is no<br />

need to lay the entire production process<br />

open because there are other options.<br />

In no way should the foundries<br />

adopt a defensive attitude. They are<br />

way ahead of many other industries<br />

and boast excellent skills and competences.<br />

For 5,000 years, progress has<br />

been tradition in the foundry industry.<br />

And I am confident that the foundries<br />

will come up with exciting solutions in<br />

response to the digital transformation.<br />

Is Industry 4.0 a chance for foundries?<br />

In order to improve their competitiveness<br />

and make processes more consistent,<br />

foundries are urged to invest even<br />

more in automation and process control.<br />

There are concrete plans to build<br />

new foundries here in western Europe.<br />

These projects derive their profitability<br />

from much improved productivity,<br />

reduced maintenance needs and lower<br />

energy costs. This entails very high<br />

capital investment. But capital costs<br />

are low at the moment. Many foundries<br />

have reacted to the new situation<br />

and started to dedicate resources to<br />

making their operations more digital<br />

and smarter. The casting process is<br />

still held as being not fully controllable.<br />

Current computer capacities and<br />

the possibility to measure an increasing<br />

number of casting parameters and<br />

feeding them into process control<br />

loops via dedicated software programs<br />

opens many new opportunities.<br />

Where in the foundry world will the<br />

most important developments in digital<br />

transformation take place?<br />

Generally speaking, all activities in<br />

connection with customer relations<br />

will to an increasing degree be handled<br />

electronically and via the Internet. Designing,<br />

quotations, coordination of<br />

deadlines, meetings via Skype or video<br />

conferences – all this has become<br />

so much easier thanks to the highspeed<br />

Internet. And internally, there<br />

are digitized processes like simulations,<br />

patternmaking and, in the meltshop,<br />

charging and furnace control. Or<br />

let’s take the optimization of machine<br />

control in the core and mould making<br />

shops, in the fettling shop and, if<br />

applicable, in the machining area.<br />

Whether in the acquisition of operating<br />

data, quotation preparation and<br />

pricing, quality data collection and<br />

10 Casting Plant & Technology 4 / <strong>2018</strong>

evaluation, in all these areas the use<br />

of Big Data and digital solutions will<br />

increase dramatically. In the future,<br />

many new foundry and casting parameters<br />

will be collected and fed back into<br />

the systems for process optimization.<br />

More and more robotic systems will be<br />

used in mould and core making, for fettling<br />

and machining operations down<br />

to the dispatch of the castings. In other<br />

words: in all process steps with a potential<br />

to control or reduce costs and<br />

make the processes faster and more<br />

consistent. Administrative procedures<br />

such as procurement and accounting<br />

are in many cases already digitalized<br />

to a high degree. Also after-sales services<br />

and the spare parts business will<br />

become more digital.<br />

Are the classical business models in<br />

place in the foundries at stake due to<br />

digital disruption?<br />

Looking back, there have been very few<br />

dispruptive developments. Therefore<br />

we should avoid calling every development<br />

a disruption or revolution. Especially<br />

the fact that most of the foundries<br />

are medium-sized businesses will<br />

allow them to quickly adjust to changing<br />

circumstances. The flexibility and<br />

agility are lived reality in our industry.<br />

Don’t you think that the growing digitalization<br />

will change the working<br />

environment in the foundries?<br />

Being a classical supply industry,<br />

foundries have always been extremely<br />

flexible in adjusting to customer wishes<br />

and deadlines. Communications<br />

technology has been advancing with<br />

rapid strides. The “new generation” of<br />

foundrymen has grown up with modern<br />

communication devices. Therefore<br />

it is normal for them to use them on<br />

the job. The foundryman of the near<br />

future will certainly control its moulding<br />

line via an app. We will see this<br />

happen very soon. But there is no reason<br />

to be concerned because: “A foundryman<br />

can handle everything!”<br />

What new challenges will the foundries<br />

be confronted with in the future?<br />

All kinds of challenges are possible:<br />

profitability, technology, customer relations,<br />

competition, environmental<br />

regulations, technophobia, human<br />

resources, regulation, and many more.<br />

And we will certainly also be presented<br />

with challenges that are unimaginable<br />

today and that will come as a<br />

surprise. Not very long ago, nobody<br />

expected that we would so soon see<br />

trade barriers being set up everywhere<br />

in the world. No matter what challenges,<br />

the foundries will stand up to them<br />

and come up with solutions – worked<br />

out in cooperation with their customers<br />

and suppliers.<br />

What do you think will be the biggest<br />

challenges for the foundries during<br />

the next five years?<br />

Every company must be ready to permanently<br />

fight for their survival. There<br />

is often not one single front line, but a<br />

fight at many different fronts. As well<br />

as the economic constraints and the<br />

technological challenges, safeguarding<br />

a qualified human resource base<br />

will become increasingly important<br />

and mission-critical. The generational<br />

change in all areas of the foundries<br />

will lead to a shortage of skilled labour.<br />

In your opinion, what is the currently<br />

the most exciting development in the<br />

world of casting?<br />

Our industry can only prosper in the<br />

long run when we succeed in attracting<br />

and training foundry specialists of<br />

the next generation – now! Our trade<br />

associations BDG and VDG as well as<br />

universities and companies have undertaken<br />

great efforts to improve our<br />

industry’s image and make the foundry<br />

trade attractive for more young people.<br />

We see first positive results of this<br />

campaign. An increasing number of<br />

university graduates have followed<br />

the invitation to our annual foundry<br />

conferences in recent years. At next<br />

GMTN we will offer a special program<br />

for school students, giving them the<br />

opportunity to learn about the vast<br />

range of highly attractive technology-related<br />

jobs.<br />

The interview with GIFA and NEWCAST<br />

President Heinz Nelissen was conducted<br />

by Gerd Krause, Mediakonzept, Düsseldorf,<br />

Germany.<br />

NEW<br />

multiPulse<br />

160 °C.

MELTING SHOP<br />

Medium frequency induction crucible furnace when tapping an aluminum master alloy (Photos and graphics: Otto Junker)<br />

Steffen Niklaus, Joachim Reiermann, Wilfried Schmitz, Otto Junker GmbH, Simmerath<br />

20 Years of Otto Junker Melting<br />

Technology Centre – state-of-theart<br />

induction technology<br />

For 20 years, Otto Junker, Simmerath, Germany, has been operating a Technology Centre for<br />

carrying out melting and casting trials in cooperation with customers and for internal development<br />

projects. The heart of this facility always has been a coreless medium-frequency induction<br />

furnace of close-to industrial size. In 2015 the originally used 750 kg furnace (related to iron)<br />

was replaced by a new furnace with a capacity of 1,700 kg which incorporates all the latest developments<br />

and innovations and is thus from unmatched flexibility. The article summarizes the<br />

work carried out in the Technology Centre over the years. Also, there is a detailed explanation<br />

of the technical innovations implemented in the new furnace plant.<br />

12 Casting Plant & Technology 4 / <strong>2018</strong>

Introduction and<br />

retrospective<br />

For 20 years, Otto Junker GmbH has<br />

been operating a Technology Centre in<br />

Lammersdorf, Germany, to carry out<br />

R&D projects in the fields of melting,<br />

holding and pouring equipment. In<br />

all, the facility comprises a surface area<br />

of approx. 450 m 2 . The relevant building<br />

features a crane with max. payload<br />

capacity of 3.2 tonnes, an array of indispensable<br />

machine tools, a welding<br />

station, several annealing furnaces, a<br />

dedicated forklift truck and other miscellaneous<br />

equipment. In addition, an<br />

extensive array of advanced measuring<br />

equipment is available. The core<br />

of the Technology Centre, however, is<br />

a medium-frequency coreless induction<br />

furnace, originally with a capacity<br />

of 750 kg (related to iron alloys), a<br />

power rating of 400 kW and an operating<br />

frequency switchable between 250<br />

and 500 Hz (Multi-Frequency Technology).<br />

The Multi-Frequency Technology<br />

will be explained in detail later in<br />

this paper. One crucial benefit is that<br />

the Technology Centre holds an operating<br />

permit for melting all common<br />

wrought, cast and special alloys.<br />

This pilot system has been employed<br />

in diverse customer projects aimed at<br />

investigating metallurgical and process<br />

engineering issues. A number of<br />

specific applications are listed by way<br />

of example:<br />

- Determination of melting behaviour<br />

and collection of melting<br />

data for small-sized silicon for the<br />

solar cell industry (numerous trial<br />

series for multiple customers)<br />

- Recycling of silicon dust from wafer<br />

slicing processes<br />

- Trials investigating the smelting<br />

reduction of filter dusts from highgrade<br />

steelmaking processes<br />

- Trials on the smelt reduction of<br />

electric arc furnace (EAF) dusts<br />

- Recycling of aluminium chips<br />

- Testing of crucible materials for silicon<br />

melting<br />

- Determination of melting behaviour<br />

and collection of melting<br />

data for ferrosilicon<br />

- Pouring trials relating to a copper<br />

anode casting process<br />

Figure 1: Bath movement and meniscus<br />

Carbon content in %<br />

3.55<br />

3.45<br />

3.35<br />

3.25<br />

3.15<br />

3.05<br />

2000 kW-125 Hz<br />

1000 kW-125 Hz<br />

2500 kW-250 Hz<br />

2000 kW-250 Hz<br />

2.95<br />

0 15 30 45 60<br />

Time in s<br />

Figure 2: Multi-Frequency Technology - carburization behaviour of cast iron melts at<br />

different operating frequencies and power input levels<br />

Hier kommuniziert<br />

die Gießereibranche<br />

AKTUELL<br />

IM WORLD WIDE WEB<br />

www.giesserei.eu<br />

Casting Plant & Technology 4/<strong>2018</strong> 13

MELTING SHOP<br />

a<br />

b<br />

- Trial series relating to melt refining<br />

of silicon melts<br />

- Determination of melting behaviour<br />

and collection of melting<br />

data for ferrochrome<br />

- Investigation of the carburization<br />

characteristics of cast iron melts<br />

- Sponge iron meltdown experiments<br />

- Melting of copper-zinc alloys for<br />

low pressure die casting<br />

- Furnace engineering for the Vacural<br />

die casting process<br />

Figure 3: a) Influence of a 0° and b) 60° phase offset on the melt flow pattern, shown<br />

on the example of a five-tonne furnace for zinc alloys (numerical calculation of flow<br />

field, laminar, stationary)<br />

Figure 4: Tapping of a copper melt<br />

Of course, this pilot system has also<br />

been used extensively for in-house development<br />

tasks, such as testing of<br />

temperature and melt level sensors, development<br />

of crucible monitoring systems,<br />

refractory testing, and the like. It<br />

is worth mentioning here that numerous<br />

trial series conducted as part of customer<br />

projects have ultimately led to orders<br />

for corresponding furnace systems.<br />

When conducting extensive melting<br />

trials, the melting process is of course<br />

the first step, but then invariably<br />

comes the problem of providing a sufficient<br />

number of suitable containers to<br />

receive the molten metal. Metal molds<br />

are a perfectly good solution for individual<br />

trials, but trial series stretching<br />

over several days or even weeks would<br />

necessitate a high number of these<br />

costly molds, as the cooling times need<br />

to be taken into account. This is where<br />

another advantage comes into play,<br />

namely that Otto Junker also operates<br />

a sand casting foundry for high-grade<br />

steel at its Lammersdorf site, so that<br />

the required number of sand molds<br />

can be turned out without much trouble.<br />

In this case, the molten metal is<br />

cast into formats that can easily be recharged<br />

into the furnace.<br />

In all, experience has shown that a<br />

furnace of the size mentioned above<br />

constitutes the minimum size required<br />

for extrapolating the results of melting<br />

trials to our customer’s larger industrial<br />

installations. Mere laboratory-scale<br />

coreless induction furnaces of the type<br />

commonly found in research institutions<br />

and universities can only yield<br />

findings of very restricted information<br />

value in this regard. The reasons will be<br />

explained below.<br />

14 Casting Plant & Technology 4 / <strong>2018</strong>

Meanwhile, the state of the art in<br />

medium-frequency coreless induction<br />

furnaces, especially in the field of<br />

converter technology, had evolved so<br />

much that the decision was taken in<br />

2012 to replace the old well-tried system<br />

by a new furnace which was to be<br />

outfitted with everything Otto Junker<br />

has to offer in this segment. This system<br />

was commissioned on October<br />

21, 2015. But before presenting this<br />

system, let us first look more closely<br />

at one of the key technical aspects of<br />

induction melting, i.e., the melt bath<br />

agitation caused by electromagnetic<br />

forces.<br />

Figure 5: IGBT frequency converter<br />

Figure 6: Furnace visualisation and automation system JOKS 4.0<br />

The medium-frequency coreless<br />

induction furnace – cause<br />

and importance of bath<br />

movement<br />

One key property of the coreless induction<br />

furnace which distinguishes<br />

it fundamentally from other melting<br />

resources is the melt bath agitation<br />

caused by the electromagnetic forces.<br />

This is illustrated in some detail in Figure<br />

1, which depicts the current-carrying<br />

water-cooled induction coil and<br />

symbolically indicates the direction of<br />

the current flow. It also shows the refractory<br />

crucible which contains the<br />

melt and is placed inside the coil. The<br />

inductor current produces a magnetic<br />

field which in turn induces ring currents<br />

in the molten metal. It should<br />

be noted here that the current density<br />

is highest, due to the skin effect, in<br />

the rim zone of the melt directly adjoining<br />

the crucible wall. Because the<br />

currents are short-circuited, Joulean<br />

heat is generated in the melt, mainly<br />

in the boundary layer close to the crucible<br />

wall. In addition, these currents<br />

– extending in a direction opposed<br />

to that of the inductor current – produce<br />

a secondary magnetic field. Due<br />

to this effect, the coil exerts repelling<br />

forces on the melt. With a coil of infinite<br />

length, the magnitude of these<br />

forces would be the same at all places<br />

over the coil height. In a finite coil as<br />

encountered in practice, the electromagnetic<br />

force density is variable over<br />

the height of the coil (Fig. 1). Hence,<br />

melt volumes situated at the centre of<br />

the coil encounter a more intense repellent<br />

force and hence, are accelerated<br />

more strongly in the direction of the<br />

coil axis than melt regions located near<br />

the edge of the coil.<br />

One consequence of this situation is<br />

that a flow pattern resembling two rotational<br />

toroids will form in the melt.<br />

In a high-power furnace, the local flow<br />

velocity may amount to as much as 1 -<br />

2 m/s. Moreover, a so-called bath meniscus<br />

will form at the surface of the<br />

melt due to the equilibrium between<br />

the repelling electromagnetic force<br />

and the force resulting from the metallostatic<br />

pressure.<br />

The intensity of this bath movement<br />

firstly depends on the furnace<br />

power; the higher the power input,<br />

the more vigorous the bath movement<br />

will be. In addition, the melt<br />

flow intensity varies with the frequency<br />

of the alternating current<br />

(a.c.) feeding the coil: the lower this<br />

frequency, the more vigorous the bath<br />

movement. It follows, first of all, that<br />

for a given fixed frequency the heat<br />

input into the melt and the intensity<br />

of the bath movement are always<br />

correlated. Furthermore, bath movement<br />

intensity can be selectively controlled<br />

at a given required furnace out-<br />

Casting Plant & Technology 4/<strong>2018</strong> 15

MELTING SHOP<br />

a<br />

b<br />

Figure 7: Control cabinet on furnace platform; a) general view; b) detailed view<br />

put by selecting the proper operating<br />

frequency.<br />

Finally, at a given power and frequency,<br />

the intensity of the bath<br />

movement depends on the furnace<br />

filling level; and this is particularly<br />

true for the melt flow in the bath surface<br />

region. The higher the filling level<br />

at a given power and frequency, the<br />

less vigorous will be the bath movement.<br />

In the above considerations we have<br />

assumed laminar flow conditions for<br />

reasons of descriptive simplicity. In reality,<br />

however, a substantial turbulent<br />

flow portion will be superimposed over<br />

the laminar flow. This will be the more<br />

pronounced the lower the furnace’s<br />

operating frequency.<br />

Bath movement is very important<br />

from a technological viewpoint since<br />

it facilitates optimum melt homogenization<br />

and stir-down of constituents<br />

and thus ensures a uniform melt composition<br />

and temperature at the same<br />

time. Also, without this forced convection,<br />

the coreless induction furnace<br />

simply wouldn’t work because most of<br />

the heat input takes place via a boundary<br />

layer situated close to the crucible,<br />

as explained earlier. If there were no<br />

bath movement to distribute this heat<br />

to the entire charge, strong overheating<br />

of the melt close to the furnace wall<br />

would inevitably occur within a very<br />

short time, causing a failure of the refractory<br />

lining.<br />

Finally, it is important to remember<br />

that for induction furnaces which are<br />

operated at a fixed nominal frequency,<br />

which is the majority of furnaces so far,<br />

Figure 8: General view of furnace platform<br />

heat input into the melt and the intensity<br />

of bath movement are always correlated.<br />

Special circuit techniques<br />

From a metallurgical point of view,<br />

the ideal induction melting process is<br />

one in which both the input of thermal<br />

power and the melt flow can be<br />

controlled to match given technological<br />

needs. Therefore it is desirable to<br />

decouple heat power input and bath<br />

movement from each other, i.e., the<br />

desired melt movement in the furnace<br />

should be adjustable independently of<br />

the respective heat input. While controlling<br />

electrical power – and hence,<br />

the input of thermal energy into the<br />

melt – poses no major problem to the<br />

furnace engineer, it takes very special<br />

circuit technology to control the melt<br />

movement independently of the power<br />

input.<br />

To achieve this objective, Otto Junker<br />

had initially developed the special<br />

circuit variants known as Power Focus<br />

Technology and Multi-Frequency<br />

Technology, both of which have been<br />

successfully deployed in a large number<br />

of furnace systems.<br />

Power Focus Technology permits<br />

an automatic or freely selectable concentration<br />

of power in the coil region<br />

where it is most needed (i.e., the upper<br />

or lower section of the coil). Thus, on a<br />

half-filled furnace, the power input can<br />

16 Casting Plant & Technology 4 / <strong>2018</strong>

e focused in the lower crucible area to<br />

make more energy available there. On<br />

the other hand, when the furnace is<br />

filled to capacity, the operator can raise<br />

the power input in the upper coil section<br />

to agitate the bath more intensely<br />

and thus improve stir-down, e.g., of<br />

metal chips.<br />

Multi-Frequency Technology provides<br />

a means of changing the operating<br />

frequency either manually or automatically<br />

during the melting process.<br />

With cast iron, for instance, a suitable<br />

frequency of 250 Hz is used for melting<br />

down the charge materials. A lower frequency<br />

– e.g., 125 Hz – is then selected<br />

for introduction of the carburizing<br />

agents and alloying additives. Practical<br />

experience shows that this changeover<br />

to a lower frequency greatly accelerates<br />

the carburization process performed to<br />

adjust the melt composition (Figure 2).<br />

At the same time, burn-off of carburizing<br />

agent is reduced.<br />

It should be noted here that these<br />

two circuit technologies can also be<br />

combined for even greater effect. This<br />

approach has proven its merits, e.g., in<br />

melting furnaces used for the recycling<br />

of aluminium chips, which are always<br />

molten with a liquid heel. Here, on the<br />

one hand, the filling-level-related surface<br />

bath movement must be reduced<br />

as far as possible in order to minimize<br />

oxidation and melting loss, while on<br />

the other hand it must always remain<br />

sufficient to ensure a rapid stir-down<br />

of the chip material. This is achieved<br />

via an automatic use of the Power Focus<br />

and Multi-Frequency Technology<br />

functions [1].<br />

These options are substantially expanded<br />

by the newest developments<br />

relying on the special technical advantages<br />

of IGBT converter technology:<br />

Apart from proven thyristor-based<br />

frequency converters, the successful<br />

development of special IGBT converters<br />

has gained increasing importance<br />

in electrothermal processes. These systems<br />

involve the use of Insulated Gate<br />

Bipolar Transistors (IGBTs) instead of<br />

thyristors in the inverter.<br />

A special design of the IGBT converter<br />

with two separate inverters and<br />

a system providing phase-shifted power<br />

supply to two furnace coil sections<br />

Figure 9: Existing filtration system<br />

creates the technical prerequisites for<br />

an even broader control of the bath<br />

movement. In the charge melt-down<br />

phase the furnace can thus be operated<br />

at an appropriate nominal frequency<br />

of, e.g., 250 Hz and to increase the<br />

bath agitation at low power the frequency<br />

can be controlled steplessly<br />

below 100 Hz. The amount of phase<br />

offset between the two coil sections is<br />

likewise adjustable to provide a more<br />

selective control of the flow pattern<br />

(i.e., direction of rotation and velocity),<br />

as illustrated in Figure 3. In this example,<br />

illustrating a 0° offset vs. a +60°<br />

offset, the second offset section permits<br />

the region of maximum flow velocity<br />

to be moved to the centre of the<br />

molten metal bath to obtain more effective<br />

intermixing of the entire melt.<br />

In addition, the turbulent portion of<br />

the melt flow is increased substantially<br />

with this circuit technology, especially<br />

at low frequencies, so that the mixing<br />

effect can be maximized with minimum<br />

heat input.<br />

The technical options available for<br />

influencing bath movement in a coreless<br />

induction furnace can be implemented<br />

and combined in manifold<br />

ways to address specific metallurgical<br />

tasks. The decisive factor is that the development<br />

of said circuit technologies<br />

(stepless frequency variation, phase<br />

shift) has made it possible for the first<br />

time to largely decouple heat input<br />

from the intensity and pattern of bath<br />

movement.<br />

One typical application for this technology<br />

is for example the production<br />

Casting Plant & Technology 4/<strong>2018</strong> 17

MELTING SHOP<br />

Otto Junker’s furnace control system<br />

for visualisation and automation is installed,<br />

which is currently JOKS 4.0.<br />

Figure 7 shows the control cabinet for<br />

manual furnace operation installed on<br />

the furnace platform. A complete view<br />

of the furnace platform is provided in<br />

Figure 8. Figure 9 shows the filtration<br />

system and Figure 10 the existing vibratory<br />

feeder for charging of fine materials<br />

such as chips, for example.<br />

Figure 10: Existing vibratory charging system for continuous feeding fine-sized charge<br />

material<br />

The capabilities of the furnace system<br />

in terms of influencing the melt flow<br />

via power, frequency and phase-shift<br />

control are demonstrated in a video<br />

(see QR-Code).<br />

of master alloys presenting high concentrations<br />

of alloying elements. In<br />

this application, production rate is<br />

determined mostly by the dissolution<br />

kinetics of the respective alloying<br />

agent. This is why this process calls for<br />

a strong stirring action along with very<br />

low heat input, so that the melt temperature<br />

remains constant and does<br />

not rise excessively. Such alloys are<br />

also often prone to separation or gravitational<br />

segregation, so that a certain<br />

amount of bath movement is necessary<br />

during the pouring process, which<br />

takes some time also. During this time<br />

the melt temperature, in turn, is not allowed<br />

to rise. Said circuit technologies<br />

are also used to improve the reaction<br />

kinetics in vacuum induction furnaces<br />

for melt distillation, as well as in other<br />

special applications [2, 3, 4].<br />

The new melting system in<br />

Otto Junker GmbH’s Melting<br />

Technology Centre<br />

The new system (Figure 4) is equipped<br />

with all three of the circuit variants described<br />

above and thus offers unique<br />

flexibility when it comes to selective<br />

control of the melt bath movement.<br />

Here are some key specifications:<br />

- Capacity, related to iron materials:<br />

1,700 kg<br />

- Power rating, related to iron materials:<br />

600 kW<br />

- Nominal melting frequency<br />

in melting mode (switchable):<br />

200/100 Hz<br />

- Operating frequency during stirring<br />

at reduced power, steplessly<br />

variable: 30-100 Hz<br />

- Two coil sections (top/bottom) with<br />

independent inverters, providing<br />

different power input into the respective<br />

sections.<br />

- Phase-shifted operation of the coil<br />

sections within the range of: -90° to<br />

+90°<br />

- JOKS furnace control system with<br />

touch screen.<br />

- Furnace weighing system<br />

- Optical Coil Protection (OCP) system<br />

- Radio remote control of power input<br />

and furnace tilting operation<br />

- Full cooling circuit instrumentation<br />

for calorimetric measurements<br />

- Ring-type exhaust system and filter<br />

system<br />

- Diverse charging equipment<br />

- Operation under protective gas atmosphere<br />

Figure 5 shows the converter cabinet,<br />

Figure 6 the graphic user interface implemented<br />

on a touch screen. Care is<br />

taken that always the latest version of<br />

The video shows the bath surface<br />

(molten aluminium) and bath surface<br />

movements at following conditions<br />

(power and frequency, as indicated):<br />

400 kW/200 Hz; 200 kW/100 Hz, 100<br />

kW, 35 Hz. The objective is to demonstrate<br />

that the apparent bath movement<br />

has nearly the same intensity in<br />

each of the three cases, even though<br />

heat input is halved from case to case.<br />

The fourth example illustrates the influence<br />

of a +90° phase shift at a frequency<br />

of 35 Hz and an even lower<br />

power setting (60 kW). It is clearly visible<br />

that bath agitation is somewhat<br />

more intensive than in the previous<br />

examples. Especially, it is apparent that<br />

the turbulent portion of the melt flow<br />

emerges here. In the Otto Junker Academy<br />

courses held twice annually, this<br />

trial series is demonstrated “live” – i.e.,<br />

using actual molten metal – to the participants.<br />

Needless to say, the system has also<br />

been used for numerous trials carried<br />

out as part of customer projects. Examples<br />

include the following:<br />

- Implementation of copper melt refining<br />

trials using selective oxidation<br />

- Melting trials with introduction of<br />

silicon flakes into an aluminium<br />

melt<br />

18 Casting Plant & Technology 4 / <strong>2018</strong>

1<br />

MEDIA DATA<br />

For Your Successful Planning of GIFA 2019<br />

FOTO: PIXABAY<br />

Media-Informationen 2019<br />

CASTING<br />

www.giesserei.eu<br />

www.giesserei.eu<br />

GIESSEREI 1<strong>04</strong> (2017) Nr. 6<br />

Die Zeitschrift für Technik, Innovation und Management<br />

PLANT AND TECHNOLOGY<br />

INTERNATIONAL<br />

SINCE 1914<br />

So haben wir das Kern!<br />

Umweltschutz / Nachhaltigkeit / Material- und Energieeffizienz<br />

Die LHL-Serie – Massiv. Schnell. Präzise.<br />

50 Liter Schussvolumen in weniger als 15 Sekunden – das geht nicht? Wir können das:<br />

Unsere LHL-Kernschießautomaten ermöglichen extrem schnelle Taktzeiten und können noch viel mehr.<br />

Wir zeigen Ihnen, was in der LHL steckt.<br />

FRP – the digital transformation<br />

of metal casting industry<br />

Nehmen Sie mit uns Kontakt auf: www.laempe.com/kontakt<br />

Laempe. Der Kern.<br />

zur<br />

GIFA<br />

2019<br />

01.06.17 14:58<br />

Entscheider lesen die Marktführer<br />

www.giesserei.eu/<br />

mediadaten<br />

AMF<br />

Markus Winterhalter<br />

T +49 211 1591-142 | E-Mail: markus.winterhalter@dvs-hg.de<br />

DVS Media GmbH<br />

Aachener Str. 172 | 40223 Düsseldorf | www.dvs-media.eu

MELTING SHOP<br />

- Melting trials aimed at producing<br />

aluminium-titanium-boron grain<br />

refinement alloys<br />

- Melting down of aluminium returns<br />

contaminated with ceramic<br />

filter residue<br />

- Production of complex aluminium<br />

alloys for plain bearings<br />

- Recycling of zinc-containing zinc<br />

dross<br />

- Melting and foaming trials with<br />

special glass<br />

- Melting experiments related to the<br />

production of ultra-pure aluminium<br />

Figure 11: Automatic ladle pouring machine, type PUMA, during pouring tests<br />

In those examples, the pilot system was<br />

used to determine optimum design parameters<br />

for the respective coreless induction<br />

furnace. Also, customer objectives<br />

were addressed in trials requiring<br />

the full range of capabilities (e.g., phase<br />

shift) in the context of sophisticated<br />

industrial process sequences. In the<br />

meantime, eleven furnaces so equipped<br />

have been sold, nine of which featuring<br />

steplessly variable frequency adjustment.<br />

At this point, it is important to<br />

reiterate that in the systematic elaboration<br />

of solutions for metallurgical tasks,<br />

a supplier-customer relationship built<br />

on communication and trust is the<br />

most important key to success, just as<br />

much as the actual equipment. In this<br />

context, it is standard practice to sign<br />

a Non-Disclosure Agreement up front.<br />

Of course, the system has also been<br />

routinely employed for in-house trials,<br />

e.g., in refining pouring technology<br />

and designing new equipment.<br />

These activities are related mainly to<br />

aspects of pressurized pouring and automatic<br />

tilt-pouring of cast iron. As for<br />

the latter method, extensive trial campaigns<br />

were conducted at the Melting<br />

Technology Centre in the past two<br />

years using a PUMA-type automatic ladle<br />

pouring system developed by Induga<br />

GmbH, Simmerath, Germany (Figure<br />

11). Here, the medium-frequency<br />

furnace served as a melt source and<br />

buffer vessel. The aim of the trials was<br />

to optimize pouring parameters as well<br />

as the underlying mathematical models<br />

[5].<br />

To come back to what was said earlier:<br />

A system of the dimensions and capabilities<br />

discussed here is indispensable<br />

if the results are to be extrapolated<br />

to a large furnace, having a capacity of<br />

10 t for example. This implies in particular<br />

that power density and intensity<br />

of bath movement must be transferable.<br />

This brings us directly to the<br />

aforementioned problem with small<br />

lab furnaces (with capacities between<br />

1 and 50 kg) as used in research institutions<br />

and universities. They are mostly<br />

operated at high frequencies in the kHz<br />

range and offer comparably high power<br />

densities, so that the relation between<br />

heat input and bath movement is far removed<br />

from the real-world conditions<br />

in actual industrial furnaces. For example,<br />

250 Hz is a typical nominal operating<br />

frequency of standard coreless induction<br />

furnaces used to melt cast iron.<br />

On the other hand, melting experiments<br />

with the above-mentioned<br />

furnace (which, after all, has a capacity<br />

of 1.7 tonnes) take a not inconsiderable<br />

effort with regard to refractory<br />

materials, charge material logistics<br />

and pouring operations. In 2017, therefore,<br />

the Melting Technology Centre’s<br />

equipment pool was completed with<br />

the addition of a smaller furnace and<br />

frequency converter that allows reduced-scale<br />

trials to be realized more<br />

flexibly and with less cost and effort.<br />

The unit has a capacity of 100 kg (related<br />

to iron materials) and a power rating<br />

of 60 kW. Its operating frequency<br />

can be selected in steps between 350 Hz<br />

and 1,000 Hz, i.e., close to the range<br />

encountered in industrial practice.<br />

Heat treatment research and<br />

development systems<br />

Although the present paper deals<br />

mainly with the company’s Melting<br />

Technology Centre, it should be<br />

mentioned here that Otto Junker<br />

GmbH also maintains an extensively<br />

equipped Thermoprocessing Technology<br />

Centre.<br />

In addition to a series of test set-ups,<br />

several of which were built to customer<br />

order with a view to investigating<br />

special application issues, a hot dip<br />

tinning line and a strip flotation furnace<br />

with cooling section deserve special<br />

mention.<br />

These last two units serve primarily<br />

for systematic development and improvement.<br />

In this regard the use of<br />

simulation techniques has proven its<br />

worth: Firstly, they make it possible<br />

to select a number of particularly suitable<br />

test variants beforehand. Secondly,<br />

empirical data obtained through<br />

experiments permit continuous improvements<br />

to the simulation models.<br />

The HiPreQ mist quench (Figure 12),<br />

already established in the marketplace,<br />

and the proprietary blow-off system for<br />

20 Casting Plant & Technology 4 / <strong>2018</strong>

Figure 12: HiPreQ mist quench<br />

hot dip tinning lines are examples of<br />

whole new equipment components developed<br />

from the combination of simulation<br />

and measurements, which create<br />

major advantages for our customers,<br />

such as the planarity of strips, which<br />

are cooled down only as fast as is necessary<br />

from a metallurgical viewpoint, or<br />

the unmatched visual and dimensional<br />

uniformity of tin-coated strips. As a<br />

useful side effect, numerous parameter<br />

variations in the empirically proven<br />

simulations also permit complex interactions<br />

to be coordinated such that the<br />

mathematical models used in the thermoprocessing<br />

equipment offer sufficient<br />

accuracy and real-time capability.<br />

All these possibilities are also benefits<br />

for our customers to the extent that<br />

heating or cooling processes can be verified<br />

and, where necessary, optimized<br />

already during the planning stage.<br />

This not only ensures that the potential<br />

investment into new equipment<br />

will ultimately yield products with the<br />

required metallurgical properties. The<br />

findings also contribute to achieving<br />

maximum economic efficiency as expressed<br />

by productivity and energy efficiency.<br />

And in cases where a problem<br />

cannot be solved with ‘forced convection’,<br />

e.g., due to requirements for very<br />

short heat-up times or locally limited<br />

heating, it is always possible to use the<br />

synergy with the Melting Technology<br />

Centre and fall back on inductive heating<br />

processes [6].<br />

Conclusion<br />

The new melting system in Otto Junker<br />

GmbH’s Melting Technology Centre<br />

provides an ideal basis for addressing<br />

metallurgical and process engineering<br />

tasks via melting trials performed<br />

jointly with the customer to define the<br />

optimum parameters and equipment<br />

level of any future melting system. In<br />

addition, a multitude of circuit configuration<br />

options form a perfect toolset<br />

for exploring complex metallurgical<br />

processes involving different operating<br />

sequences. Finally, it should be noted<br />

that Otto Junker offers the use of this<br />

melting system, complete with peripheral<br />

equipment and operating personnel,<br />

not only in melting furnace projects<br />

but also as a contract service on<br />

attractive terms.<br />

References:<br />

www.cpt-international.com<br />

ww.otto-junker.com<br />

THE MILLENNIUM EVENT<br />

THE ALUSPECIALISTS' MEETING<br />

11 TH ALUMINIUM TWO THOUSAND<br />

WORLD CONGRESS<br />

9 - 13 April 2019<br />

BHR Treviso Hotel<br />

Treviso - Italy<br />

WHERE INNOVATION MEETS BUSINESS<br />

Conferences, Technical Tours, Social Events<br />

www.aluminium2000.com<br />

Event organized by:<br />

INTERALL<br />

<strong>International</strong> Aluminium Publications<br />

Interall Srl: Via Gino Marinuzzi- 38 - 41122 Modena - Italy - Tel. +39-059-282390 - Fax +39-059-28<strong>04</strong>62<br />

aluminium2000@interall.it - www.aluminium2000.com<br />

CONFERENCE TOPICS: Main subjects (but not limited to):<br />

Markets & strategies, alloys billets & related equipment, Rolling technology,<br />

architecture & special uses, transport & automotive industry, anodizing,<br />

coating, nano technologies, automation, measuring, testing & quality<br />

techniques, advanced applications & research, environmental protection &<br />

recycling, waste water treatment, foundry, casting & die casting, extrusion<br />

session<br />

EVENT HIGHLIGHTS<br />

120 highly specialized technical papers, expected 500 delegates from 55<br />

different countries, 4 parallel sessions running throughout the 3 days event,<br />

Social Program for all participants, Sponsorship opportunities<br />

Official language: ENGLISH<br />

Casting Plant & Technology 4/<strong>2018</strong> 21

Double belt conveyor for transporting sand vertically (left) and to the polygonal sieve for ejection of lumps of sand from the process<br />

(right) during installation at Isar Metallguss (Photos: Isar Metallguss)<br />

Wolfgang Maier, Managing Partner at Isar Metallgusswerk, Geretsried<br />

The latest generation of<br />

sand preparation at Isar<br />

Metallgusswerk<br />

Isar Metallgusswerk, an SME based in Geretsried, Germany, has invested in state-of-the-art<br />

molding sand preparation in order to meet the highest of quality demands in ever-harsher international<br />

competition. Electronically controlled, the plant consistently supplies an optimally coordinated<br />

and reproducible sand quality. In addition, electronic documentation enables precise<br />

traceability for every casting batch.<br />

Every caster knows that high-quality<br />

molding sand is one of the decisive<br />

prerequisites for good casting<br />

quality. Grain size, moisture and<br />

the proportion of bentonite must be<br />

exactly right in order to prevent inclusions<br />

and achieve clean surfaces. “And<br />

the best quality – ‘Made in Germany’<br />

– is precisely what we guarantee our<br />

customers and what our partners can<br />

expect from us. Whereby it plays no<br />

role whatsoever whether we produce<br />

one casting, hundreds of castings, or<br />

thousands,” according to the credo of<br />

the management at Isar Metallgusswerk.<br />

For more than four decades, the<br />

SME and its employees have stood for<br />

reliable production of precise components<br />

made of aluminum alloys, aluminum<br />

bronzes, tin bronzes and gunmetal<br />

alloys using the sand casting<br />

22 Casting Plant & Technology 4 / <strong>2018</strong>

AUTOMATION<br />

Figure 1: Molding sand mixer from Eirich in Geretsried. The homogenization<br />

of old sand, new sand and bentonite takes place<br />

in the mixing system<br />

Figure 2: Metal frame of the molding sand preparation plant<br />

during installation. From the start of construction until commissioning<br />

of the plant took a total of six weeks<br />

process and permanent mold casting.<br />

“We are recognized specialists for complex<br />

shapes with high dimensional accuracy,<br />

as well as for pressure-tight,<br />

highly stressed parts,” according to<br />

Works Manager Thomas Sandner,<br />

who mentions the company’s DIN EN<br />

ISO 9001:2015 process-oriented quality<br />

management. A quality standard<br />

that is appreciated by customers in<br />

machine construction, the automotive<br />

sector, the electrical industry, the<br />

production of optical and medical devices,<br />

hospital technology, general engine<br />

construction, the lighting industry,<br />

catenary construction and traffic<br />

technology.<br />

Fully automatic molding sand<br />

preparation<br />

Isar Metallgusswerk has been operating<br />

a fully automatic sand preparation<br />

plant for the last 30 years in order<br />

to meet customers’ demands. The<br />

equipment, however, slowly reached<br />

the end of its useful life and no longer<br />

met the management’s quality requirements.<br />

The tour of the works reveals an<br />

orderly and efficient company. The<br />

management is particularly proud of<br />

the state-of-the-art molding plant, integrated<br />

in the production process almost<br />

five years ago. The plant, however,<br />

requires a continuous supply of<br />

high-quality molding sand. By 2016,<br />

the Geretsried executives had gradually<br />

come to the conclusion that<br />

is was essential to further modernize<br />

production by installing a completely<br />

new high-quality molding<br />

sand preparation plant that would<br />

also meet the requirements of Industry<br />

4.0. A step that involves substantial<br />

costs. And smaller operations<br />

like Isar Metallgusswerk often shrink<br />

from such major investments in view<br />

of the fluctuating orders situation, as<br />

well as shrinking and volatile markets.<br />

But those who really want to supply<br />

high-quality products must also work<br />

with high-quality sand.<br />

Order placed with Maschinenfabrik<br />

Gustav Eirich and VHV<br />

The specialist expertise of the project<br />

partners, and the proven quality<br />

of the individual components of<br />

the molding sand preparation plant,<br />

played a decisive role in the decision<br />

to award contracts to Maschinenfabrik<br />

Gustav Eirich (Figure 1), in Hardheim,<br />