WIR 02/2019 [EN]

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The Customer Magazine of the Doppelmayr/Garaventa Group Issue 2/<strong>2019</strong> 45th Year/No. 208<br />

Mobility at the<br />

next level<br />

The ropeway as an urban<br />

transport solution<br />

Cabin with<br />

vision<br />

ATRIA, the new 3S cabin<br />

Ropeway technology<br />

for the<br />

whole world<br />

The Hohe Brücke plant<br />

in Wolfurt<br />

10-MGD Línea Plateada, El Alto (BOL)

2 Contents<br />

6<br />

16<br />

Means of transport for the future<br />

Urban ropeways supplement and relieve urban transport networks.<br />

For passengers, they offer sustainable and comfortable mobility.<br />

12<br />

ATRIA<br />

Coherent design throughout: CWA’s new 3S cabin impresses with new technology,<br />

modularity and premium-quality materials.<br />

Top skiing enjoyment<br />

The new D-Line gondola lifts Natrun and<br />

Sonnberg bring enhanced comfort for<br />

guests in the Hochkönig ski region.

Foreword<br />

3<br />

11<br />

Developments for the future<br />

Close collaboration with our customers continues to<br />

be a major factor in the further development of our<br />

products and our company. This is what enables<br />

us to identify requirements and to generate new<br />

ideas. We then develop technology as well as new<br />

business models and fields of application where<br />

we can utilize our know-how.<br />

In Maria Alm, two new ropeways have transformed an entire resort. The ski<br />

trail now virtually starts at the front door. The tenth line has been completed<br />

in La Paz. Over 30 kilometers of ropeway network are now an important<br />

part of daily mobility for its citizens. This new mode of transport saves<br />

them a lot of time on their way to work. Time that can be used for other<br />

things. The Ramcharger 8 is setting new trends in North America – the<br />

comfort of the D-Line technology has been very well received by guests<br />

at Big Sky.<br />

The fi rst 8-seater chairlift for North America<br />

The D-Line Ramcharger 8 is the new gold standard in aerial lift<br />

technology at Big Sky Resort.<br />

Continuous development enables us to meet this wide range of expectations.<br />

We launch new products onto the market that systematically drive<br />

forward our chosen strategy. The ATRIA cabin for tricable gondola lifts<br />

addresses the need for modular design and individual styling, which have<br />

already been implemented on the D-Line and very successfully put to the<br />

test. At INTERALPIN, visitors were able to board the ATRIA for the first<br />

time; the first visionary trip will be taking place shortly on the Kitzsteinhorn<br />

in Salzburg.<br />

24<br />

Investments in our own infrastructure remain a key building block of our<br />

entrepreneurial success. At our Hohe Brücke plant, we have purchased<br />

two new machining centers for handling large parts. The manufacturing<br />

processes for D-Line components are also being continuously expanded.<br />

Highly skilled and experienced employees ensure the highest quality<br />

standards with great precision and a strong sense of responsibility. Today<br />

and in the future.<br />

Michael Doppelmayr<br />

Executive Director<br />

The Doppelmayr/Garaventa Group’s<br />

biggest production facility<br />

Up to 25,000 tons of steel are processed annually at the<br />

Hohe Brücke plant in Wolfurt – a glimpse behind the scenes.

4 Facts & Figures<br />

International tourism continues to grow<br />

According to the latest issue of the World<br />

Tourism Barometer from UNWTO – the United<br />

Nations agency responsible for the promotion<br />

of responsible, sustainable and universally<br />

accessible tourism – the number of international<br />

tourist arrivals (overnight visitors)<br />

increased 6 percent to 1.4 billion in 2018. This<br />

puts the sector clearly above the 3.7% growth<br />

registered in the global economy. The growth<br />

trend in tourism is continuing, as expected. The<br />

results are attributable to stronger economic<br />

growth, more affordable air travel and greater<br />

visa facilitation around the world. 1 “The growth<br />

of tourism in recent years confirms that the<br />

sector is today one of the most powerful<br />

drivers of economic growth and development.<br />

It is our responsibility to manage it in a sustainable<br />

manner and translate this expansion into<br />

real benefits for all countries, and particularly,<br />

to all local communities, creating opportunities<br />

for jobs and entrepreneurship and leaving no<br />

one behind,” 2 said UNWTO Secretary-General<br />

Zurab Pololikashvili. Doppelmayr’s emissionfree,<br />

virtually soundless ropeways make an<br />

important contribution to environmentally friendly<br />

mobility and therefore to sustainable and barrier-<br />

free tourism, both in natural settings and in<br />

urban areas.<br />

INCREASE IN INTERNATIONAL<br />

TOURIST ARRIVALS 2018:<br />

Americas<br />

3 %<br />

6 %<br />

Europe<br />

10 %<br />

Middle East<br />

7 %<br />

Africa<br />

6 %<br />

Asia/<br />

Pacific<br />

1 http://www2.unwto.org/press-release/<strong>2019</strong>-05-21/international-tourism-numbers-and-confi dence-rise<br />

2 Cf. http://www2.unwto.org/press-release/<strong>2019</strong>-01-21/international-tourist-arrivals-reach-14-billion-two-years-ahead-forecasts<br />

The biggest Doppelmayr plant in figures<br />

The Hohe Brücke plant in Wolfurt is the<br />

Doppelmayr/Garaventa Group’s biggest production<br />

facility and its competence center for<br />

continuous-movement ropeways. It is here that<br />

a wide range of steel parts are manufactured,<br />

such as bullwheels, support structures and<br />

parts for sheave assemblies and grips, which<br />

are destined for ropeways around the entire<br />

globe. Go to page 26 for a glance behind the<br />

scenes; an initial overview of the plant’s<br />

dimensions is given here.<br />

Steel processed p.a.:<br />

22,000 – 25,000 tons<br />

Headcount: 350<br />

Of which<br />

apprentices: 100<br />

Total area:<br />

12.2 hectares<br />

including external<br />

warehouse, office<br />

annexes, parking lot<br />

Steel manufacture: 12,200 m²<br />

Mechanical production: 5,800 m²<br />

Apprentice workshop: 850 m²<br />

Offices: 1,800 m²<br />

Apprentice break room: 150 m²<br />

Testing hall: 1,700 m²<br />

Maintenance: 600 m²

...<br />

Facts & Figures<br />

5<br />

20 years of year-round attractions<br />

from Input ®<br />

Doppelmayr subsidiary Input ® Projektentwicklungs<br />

GmbH has now been in existence for<br />

20 years. Input ® works with customers to<br />

develop individual year-round attraction concepts<br />

for tourist destinations. The goal is to<br />

create ways of having fun in natural surroundings<br />

365 days a year – for families, people<br />

seeking relaxation and those who like being<br />

active. From the outset, the main focus has<br />

been on concepts for “snow-free periods”,<br />

which is where Input ® has been a pioneer.<br />

Nowadays, the company also works on many<br />

projects for winter tourism. Networked thinking,<br />

integrated analysis and the authentic<br />

presentation of destinations are what set the<br />

work of the team and the concepts it develops<br />

apart. “We can look back on many fantastic<br />

projects around the entire globe, such as<br />

those in the Spain, United Arab Emirates, Hong<br />

Kong, Iraq, Lebanon, Mexico and, needless<br />

to say, in our magnificent Alps. We also look<br />

forward to developing new creative concepts<br />

with our customers and are excited to see<br />

what the future will bring,” says long-standing<br />

Input ® employee Hannes Triebnik, who took<br />

over the post of managing director from<br />

company founder Helmut Müller in April 2016.<br />

input-projekt.com<br />

Amazed and delighted<br />

countless<br />

families and children<br />

Concepts in 65<br />

Alpine destinations<br />

Developed more than<br />

150<br />

projects<br />

30<br />

Projects in over<br />

countries on 3 continents<br />

Wholly owned subsidiary<br />

of Doppelmayr – Founded<br />

20<br />

years’ experience<br />

in the design of<br />

experiential concepts<br />

Lebanon<br />

Mexico<br />

Oman<br />

Qatar<br />

Russia<br />

Saudi Arabia<br />

Slovakia<br />

South Korea<br />

Spain<br />

Sri Lanka<br />

Italy<br />

Switzerland<br />

Iran<br />

Tajikistan<br />

Trinidad & Tobago<br />

Iraq<br />

UAE<br />

Turkey<br />

Hong Kong<br />

India<br />

1999<br />

Venezuela<br />

Ukraine<br />

Germany<br />

Georgia<br />

...<br />

France<br />

...<br />

Planned<br />

and designed 9<br />

indoor ski centers<br />

Colombia<br />

China<br />

Brazil<br />

Austria<br />

Argentina<br />

Summer outpaces winter on<br />

Luftseilbahn Wengen-Männlichen<br />

The 2018 summer season was more than<br />

gratifying for the aerial tramway operators<br />

Luftseilbahn Wengen-Männlichen AG in the<br />

Swiss canton of Bern. The panoramic Royal<br />

Ride reopened on June 1 of last year following<br />

extensive refurbishment. Its crowning glory is<br />

the viewing platform on each of the cabins,<br />

which offers stunning vistas of the Jungfrau<br />

massif for up to ten passengers. During the<br />

summer half year, 139,863 passengers were<br />

carried, a 14-percent increase over the previous<br />

year. The ride on the upper deck was enjoyed<br />

by almost 16,000 passengers. For the first time<br />

in the 65-year history of the aerial tram, higher<br />

revenues were achieved in the summer than in<br />

the winter. While the difference only amounts to<br />

several thousand Swiss francs, it does point to<br />

a definite trend toward perception of the tram<br />

as a ride experience rather than merely as a<br />

feeder ropeway. This enables the operators to<br />

develop further offers and attractions.<br />

FACTS & FIGURES:<br />

Increase in summer<br />

revenues 2018:<br />

261,000 Swiss francs –<br />

19-percent increase<br />

Passengers carried in summer half year:<br />

139,863 – 17,155 more passengers – 14-percent increase<br />

Compared with 5-year average for the summer season:<br />

29,055 more passengers

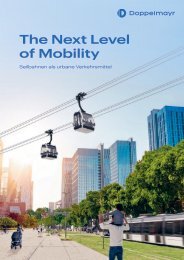

6 The Next Level of Mobility<br />

The Next Level of Mobility<br />

Ropeways in the city<br />

Urban ropeways are far more than a practical addition to car, bus and rail<br />

travel. They harbor huge potential as a cost-effective and environmentally<br />

friendly means of transport. With their small structural footprint for the towers<br />

and stations, ropeways are a valuable extension of the urban infrastructure<br />

and simultaneously open up a new transport plane.

The Next Level of Mobility<br />

7<br />

Our living spaces are developing, and ever more people<br />

are moving away from the countryside and into the city.<br />

Urban areas are growing and face new challenges.<br />

Traffic volumes are increasing, cities are getting louder, the<br />

streets more congested and the air more polluted. These are<br />

factors which make a noticeable impact on people’s quality of<br />

life. Mobility is essential to us – because we all need to get from<br />

A to B, whether it’s going to work, in our leisure time or part of<br />

everyday life.<br />

A future-proof, functional and efficient transport system has to<br />

meet a whole series of criteria. Ideally, means of transport<br />

should offer a high level of availability and a high transport capacity,<br />

guarantee on-time arrival and comfortable travel for all<br />

passengers, and operate independently of obstacles or traffic<br />

jams. They should also have low exhaust and noise emissions.<br />

In a densely populated city, available space is limited and<br />

should preferably be used as living space. How can mobility<br />

meet such requirements?<br />

Combining the advantages of the individual means of transport<br />

available for urban or transport planning will be crucial.<br />

Because different means of transport have individual features<br />

that enable their use to solve different problems.

8 The Next Level of Mobility<br />

The ropeway – a new transport level<br />

In cities, the ropeway can meet transport challenges<br />

on an entirely new level. It possesses<br />

a whole series of features and benefits that<br />

harmonize very well with other means of transport.<br />

Ropeways can expand a city’s transport<br />

infrastructure as well as linking up the network<br />

with major hubs or hotspots. This makes them<br />

an ideal complement to the existing transport<br />

system. The ropeway accesses a completely<br />

new level above the existing infrastructure,<br />

which can continue to be used for city life. It<br />

can cross obstacles such as rivers or hills with<br />

ease. Ropeway passengers enjoy a silent trip<br />

as they glide above the city, leaving the street<br />

noise and the hustle and bustle behind them.<br />

A new perspective opens up as they take their<br />

seats and enjoy the ride in comfort.<br />

Space-saving and barrier-free<br />

Vacant areas for transport are rare in urban<br />

areas. Here again, the ropeway has the<br />

answer: The small structural footprint for towers<br />

and stations means that ropeways do not<br />

require much space. In addition, they offer<br />

barrier-free access for everyone, enabling<br />

wheelchairs, baby strollers and bicycles to be<br />

carried with ease. Level entry to the cabins in<br />

the stations means problem-free boarding for<br />

all.<br />

Another advantage: Short planning and construction<br />

times make the ropeway an interesting<br />

option for urban planners and investors.<br />

Ropeway projects can therefore be implemented<br />

extremely quickly in comparison with other<br />

infrastructure projects. This modern mode of<br />

transport has a successful track record in<br />

mountain areas that goes back decades, and

The Next Level of Mobility<br />

9<br />

carries millions of people on a daily basis.<br />

Ropeways boast remarkable achievements<br />

not only in the mountains but also in the urban<br />

environment.<br />

Environmentally friendly and effective<br />

There are many areas where a mobility<br />

solution can help to protect the environment.<br />

With an electric motor housed in the station,<br />

which quietly and continuously propels the<br />

cabins along the aerial rope, the ropeway is<br />

energy-efficient and effective – with no exhaust<br />

and no particulates.<br />

World’s biggest ropeway network in La Paz<br />

Since 2014, aerial ropeways have been part of<br />

everyday life for the citizens of La Paz and El Alto<br />

in Bolivia. These installations make it easier for<br />

people to get around, shorten traveling times and<br />

guarantee that they will get where they want to go<br />

on time – with a means of transport that is environmentally<br />

friendly and efficient. The ropeway<br />

network is the principal mode of transport for the<br />

two adjacent metropolises and encompasses ten<br />

lines with an overall length of approximately<br />

33 kilometers. Every day, Mi Teleférico is used by<br />

some 300,000 people – as a means of getting to<br />

work, going shopping, going to school or accessing<br />

leisure-time activities. The ropeways are<br />

also very popular with tourists. Over 200 million<br />

passengers have been carried to date. The<br />

world’s biggest ropeway network has had a<br />

positive impact on the many people who live<br />

and work in La Paz and El Alto. It provides an<br />

outstanding example for many other visionary<br />

mobility solutions around the globe to follow.

10 Interview<br />

Designed for our guests<br />

and operators<br />

<strong>WIR</strong> spoke with Stephen Kircher, President of Boyne Resorts, and Mike Unruh,<br />

VP Mountain Operations, Big Sky Resort.<br />

<strong>WIR</strong>. Ramcharger 8 is a one-of-a-kind ski<br />

lift. In North America, it is not only the first<br />

8-seater chair lift but also the first D-Line<br />

installation. What do these firsts mean to<br />

Boyne Resorts, Big Sky and the industry?<br />

Stephen Kircher: Ramcharger 8 reinforces<br />

our long-standing reputation over the past<br />

70 years of being first to adopt the next generation<br />

of chairlift technology – being the<br />

first ski company to install triple, quad and<br />

6-place chairlifts. We are proud to help move<br />

the industry forward again with what is, without<br />

a doubt, the most advanced and comfortable<br />

chairlift technology ever conceived in<br />

Ramcharger 8. Doppelmayr over the past four<br />

decades has become the international leader<br />

in creating mountain transport systems. We<br />

have treasured having them as our preferred<br />

vendor over this period. We believe that<br />

Doppelmayr continues to lead in all the important<br />

categories – safety, reliability, aesthetics<br />

and guest comfort.<br />

<strong>WIR</strong>. The 8-seater chairlift debuted in<br />

December 2018. What is your résumé of the<br />

first winter season with this installation?<br />

Stephen Kircher: Our guests were literally<br />

blown away, an experience level that most<br />

Americans have never imagined in a lift.<br />

Ramcharger 8 immediately became the most<br />

popular lift on the mountain, drawing volumes<br />

of people to that part of the mountain and, at<br />

the same time, handling the volumes like no<br />

other lift on the planet. Families especially<br />

appreciated the extra safety features and the<br />

ultimate comfort on cold days.<br />

<strong>WIR</strong>. Boyne Resorts is known for its pioneering<br />

spirit and its pursuit of enhancing<br />

guest experience. Do you already have new<br />

projects for your skiers in mind?<br />

Stephen Kircher: Yes, indeed. We are<br />

working with the Doppelmayr team on many<br />

new exciting lift projects across North America.<br />

We believe this is going to be soon known as<br />

the second golden age in lift installations –<br />

certainly it is likely to be for our company with<br />

the help of Doppelmayr’s superior technology.<br />

<strong>WIR</strong>. D-Line is the next generation of<br />

ropeways. How did the ropeway employees,<br />

the operators, maintenance crews, etc. experience<br />

this technology?<br />

Mike Unruh: All aspects of the lift appear<br />

to be designed not only with the guest in<br />

mind but also with the operators and maintenance<br />

techs in mind as well. Terminals are<br />

more spacious, allowing easier and safer<br />

access to components. Controls are simplified<br />

and labeled in a manner which makes operation<br />

of the lift more intuitive than lifts of just a<br />

few years ago. Everyone from lift operators to<br />

lift maintenance technicians was able to<br />

quickly learn and adapt to the new controls<br />

Doppelmayr Connect. Touch screen technology,<br />

drop-down menus, along with on-screen<br />

troubleshooting guidance were a boon to all.<br />

The ability to have mechanical and electrical<br />

schematics available at each terminal sped<br />

the learning process and any troubleshooting<br />

activities. The ability to have Doppelmayr technicians<br />

and engineers log into the lift at any<br />

hour of the day and from any location including<br />

Austria was tremendously helpful and<br />

efficient as well.<br />

<strong>WIR</strong>. What are the biggest advantages<br />

and comfort features for your guests that<br />

Ramcharger 8 has to offer?<br />

Mike Unruh: The lift is very easy to load,<br />

starting with the load gates, progressing onto<br />

the conveyor carpet and finishing at a load table<br />

that is height-adjustable at the touch of a button.<br />

These features combine to make for a smooth<br />

and safe loading process that greatly reduces<br />

the likelihood of misloads. The ride is the<br />

smoothest and most comfortable experience<br />

available. This experience starts with the wide,<br />

heated seats and continues through the blue<br />

bubble, extending into the shape and size of the<br />

grip and other line equipment. The suspension<br />

system of the carrier itself is the final touch of<br />

excellence in the ride quality. Top terminal design<br />

along with a wide, gentle unload ramp<br />

resulted in a very low number of unloading issues<br />

for guests as well.<br />

<strong>WIR</strong>. Do you have a special experience or<br />

story in connection with the lift you would like<br />

to share?<br />

Mike Unruh: Not one in particular. However,<br />

ski enthusiasts and “lift geeks” alike are all<br />

amazed when given the opportunity to learn<br />

more about the inner workings and designs of<br />

Ramcharger. They all start by being blown<br />

away with the look and feel of the lift, and then<br />

are truly amazed when they learn more about<br />

the real tech advances.<br />

<strong>WIR</strong>. Many thanks for taking the time out to<br />

talk to us!

Flagship project: The first 8-seater<br />

chairlift in North America<br />

8-CLD-B Ramcharger 8 | Big Sky, Montana (USA)<br />

Boyne Resorts<br />

1,332 m 354 m 3,200 PPH 5.1 m/s 65 December 2018 D-Line<br />

Boyne Resorts is driving forward development at Big Sky with a world-class<br />

D-Line lift installation.<br />

The ropeway operating company Boyne<br />

Resorts is a popular vacation provider in<br />

North America’s all-year recreation segment and<br />

is regarded as a pioneer in winter tourism. At Big<br />

Sky Resort in Montana, the company is once again<br />

consolidating its position as a trailblazer in the<br />

sector with the completion of its new D-Line<br />

8-seater chairlift, which is now the new gold<br />

standard in aerial lift technology. Boyne Resorts<br />

and Doppelmayr have jointly implemented many<br />

innovative projects in a collaboration spanning<br />

more than 40 years. With the construction of the<br />

Ramcharger 8, the ski area is raising the bar in<br />

terms of passenger comfort, safety and quality.<br />

The completion of the new ropeway project takes<br />

Big Sky, also known as “America’s Alps”, another<br />

step closer to the same league as top European<br />

ski destinations.<br />

Mountain. With the Doppelmayr Direct Drive, up<br />

to now the only one of its kind in North America,<br />

a height-adjustable loading conveyor, locking<br />

restraining bars and the Doppelmayr Connect<br />

control system, the operating company has the<br />

full spectrum of cutting-edge D-Line ropeway<br />

technology in operation. This new lift enables<br />

Big Sky to offer its guests maximum ride comfort<br />

and top safety standards. All 65 chairs feature<br />

the new Ramcharger 8 logo and different printed<br />

designs on the chairbacks, creating visual<br />

interest and distinctive styling for the overall<br />

look of the installation.<br />

Leading the way in North America<br />

The Ramcharger 8 is one of the continent’s<br />

most technologically advanced installations.<br />

The new 8-seater chairlift, which incorporates<br />

ergonomically shaped individual heated seats<br />

and bubbles in Big Sky’s signature blue, replaces<br />

a detachable quad chairlift on Andesite<br />

Many market firsts<br />

A particular eye-catcher at the bottom station<br />

is the huge HD video screen providing winter<br />

sports enthusiasts with the latest information<br />

on trails and weather conditions. Another<br />

practical feature of the new installation is the<br />

chair parking facility, which is fully automated.

ATRIA<br />

At INTERALPIN in May <strong>2019</strong>, the Doppelmayr/Garaventa Group presented the new<br />

3S cabin, ATRIA, from CWA. This cabin impresses with plenty of transparency and<br />

vision, and offers passengers an exceptional ropeway experience. It also features<br />

the latest technology. Its modularity opens up a wide range of possibilities and<br />

styling options for ropeway operators.<br />

The first thing you notice when you take<br />

your seat in the ATRIA is its transparency.<br />

Generously proportioned panorama<br />

windows consisting of over 26 m² of real glass<br />

ensure a perfect all-round view. CWA’s new<br />

3S cabin creates a sense of lightness and<br />

provides passengers with an impressive experience<br />

as they glide up the mountain in a ski area<br />

or over the streets in a city.<br />

Modularity creates scope<br />

An important feature of the ATRIA is its modularity,<br />

which addresses the need for maximum<br />

individual styling. Ropeway operators can configure<br />

the 3S cabin to suit their requirements<br />

and add a host of features by means of simple<br />

retrofits and conversions for years to come:<br />

for the transportation of skiers and their sports<br />

equipment in winter regions, to ensure the right<br />

ventilation in warmer climates, and for carrying<br />

people with a wide range of needs in urban<br />

environments. Absolute disabled friendliness<br />

and convenient access ensure that passengers<br />

with impaired mobility can also enjoy a<br />

top ropeway experience. The new 3S cabin<br />

enables the carriage of wheelchairs, strollers,<br />

a wide range of sports equipment and freight.<br />

The ATRIA impresses with its harmonized<br />

design language: rounded forms and<br />

consistent styling – from the elegant underbody<br />

to the roof with integrated cabin suspension.<br />

Sustainable, premium-quality materials<br />

such as wood and fabrics are used for the<br />

interior. Pleasant acoustics and ergonomic<br />

fittings ensure a comfortable ride experience<br />

for the passengers.<br />

Sophisticated and connected<br />

The topic of digitalization was also of major<br />

importance when developing the ATRIA. Entirely<br />

in line with SMART Ropeway, the Doppelmayr/<br />

Garaventa Group’s strategic approach to digital<br />

technology, the ATRIA is also connected<br />

and integrated into the Doppelmayr Connect

Technology & Innovation<br />

13<br />

Acoustics<br />

The continuous acoustic ceiling<br />

and the quiet running ensure<br />

a pleasant sound environment<br />

and enhance the wellbeing of<br />

the occupants.<br />

Views<br />

The generously proportioned<br />

panorama glazing and the slender<br />

dimensions of the fittings<br />

allow maximum transparency.<br />

Technology<br />

The ATRIA is also connected and integrated<br />

into the Doppelmayr Connect ropeway<br />

control system. This means the ropeway<br />

operative can control cabin functions such<br />

as lighting, ventilation, air-conditioning<br />

and seat heating as well as one- and<br />

two-way communications simply and<br />

centrally through Doppelmayr Connect.<br />

Entrance<br />

The wide electromechanical doors<br />

allow several passengers to enter<br />

the cabin simultaneously – for swift<br />

boarding and disembarkation. The<br />

entrance also provides plenty of<br />

room for passengers with impaired<br />

mobility and for baby strollers.<br />

Underbody<br />

Attractive design also embraces elements<br />

that are only noticed at second<br />

glance. In the case of the ATRIA, that<br />

applies to the elegant underbody panel<br />

that forms a consistent finishing touch<br />

to the overall styling.<br />

ropeway control system. This means the ropeway<br />

operative can control cabin functions<br />

such as lighting, ventilation, air-conditioning<br />

and seat heating as well as one- and two-way<br />

communications simply and centrally through<br />

Doppelmayr Connect. The carriage wheel generator,<br />

which was developed by Doppelmayr/<br />

Garaventa and has been in successful use for<br />

many years, provides a constant power supply<br />

to the 3S cabin during the trip.<br />

The electromechanical door drive system is<br />

state of the art and all part of the basic cabin<br />

equipment. It enables the reversal of door<br />

movement as well as audiovisual signals to<br />

indicate opening and closing – an essential<br />

safety feature for passengers with visual or<br />

hearing impairments.<br />

Tricable gondola lift – the ropeway system<br />

of superlatives<br />

Top achievements and records are part of<br />

the DNA of 3S systems from the Doppelmayr/<br />

Garaventa Group. Their journey leads over<br />

tall towers and long rope spans; with every<br />

trip they carry large numbers of passengers<br />

in comfort. With its modern design and technology,<br />

the ATRIA harmonizes perfectly with<br />

the overall concept of the tricable gondola lift.<br />

For the Doppelmayr/Garaventa Group, the new<br />

3S cabin represents a development milestone<br />

that is set to inspire passengers and customers<br />

alike for a long time to come.<br />

The first 3S systems to go into operation with<br />

ATRIA cabins will be the 3K Kaprun-Kitzsteinhorn-K-onnection<br />

in Kaprun at the end of<br />

November <strong>2019</strong> and the Eigerexpress Grindelwald<br />

Grund-Eigergletscher belonging to<br />

Jungfraubahn AG in December 2<strong>02</strong>0.<br />

View the ATRIA<br />

video here:

14 International Projects<br />

From motorcycle museum to freeride paradise<br />

10-MGD Kirchenkar Lift II | Hochgurgl, Tyrol (AUT)<br />

Hochgurgler Lift GmbH & Co. KG<br />

519 m 210 m 2,400 PPH 6.0 m/s 1.6 min 17 10-passenger cabins November 2018 D-Line<br />

The fi rst D-Line gondola lift from Doppelmayr/<br />

Garaventa went into operation in Hochgurgl<br />

in 2015. Construction of the Kirchenkar Lift II<br />

now marks the completion of the project.<br />

Since last winter season, freeriders and skiers<br />

opting for the groomed trails have been able to<br />

travel from the bottom station at 2,147 m directly<br />

up to 2,839 m. The addition of the second<br />

section – the Kirchenkar Lift II – following on<br />

from the fi rst, which was built in 2015, provides<br />

access to more ski trails and, in particular, to<br />

many new freeride possibilities at the Austrian<br />

resort of Obergurgl-Hochgurgl in Tyrol.<br />

The D-Line gondola lift has a transport capacity<br />

of 2,400 passengers an hour. The OMEGA IV<br />

cabins are fi tted with heated seats, and the large<br />

panorama windows provide guests with fantastic<br />

views of the Ötz Valley’s breathtaking mountain<br />

scenery. The spectacular route up to the top<br />

station passes over steep terrain and large<br />

ridges, turning the trip into an impressive experience.<br />

The cabins feature images of classic<br />

motorbikes – as a reminder of Europe’s highest<br />

motorcycle museum, which is located directly at<br />

the bottom station. The bottom station and the<br />

museum are integrated into the Top Mountain<br />

Crosspoint, a multifunctional complex that also<br />

includes a large restaurant with table service as<br />

well as the toll station.<br />

We’re very proud of the fact that we<br />

implemented Doppelmayr’s first D-Line<br />

gondola lift with the Kirchenkar Lift I in 2015.<br />

What has impressed us most has been its<br />

reliability as we haven’t had a single shutdown<br />

in these four years. The Kirchenkar Lift II<br />

now marks the successful completion of the<br />

project. Alban<br />

and Attila Scheiber,<br />

Managing Directors,<br />

Hochgurgler Lift<br />

GmbH & Co. KG.<br />

© ötztal Tourismus<br />

Avalanche blasting ropeways ensure safety<br />

Since last winter season, two avalanche blasting<br />

ropeways from Doppelmayr located at the<br />

elevation of the top station of the Kirchenkar Lift II<br />

ensure the artificial triggering of controlled<br />

avalanches throughout the ski area. The two installations<br />

– Kirchenkar A and B – impress above<br />

all with their lengths of 1.6 and 2.3 kilometers<br />

respectively as well as the automatic control<br />

system and a special multiple-charge carrier. This<br />

confi guration signifi cantly reduces the workload<br />

for the blaster. The steep, high alpine terrain<br />

made the task of installing the towers particularly<br />

difficult – the walkover assessment during the<br />

planning phase already proved to be a challenge<br />

for the surveyors, geologists and Doppelmayr<br />

project managers. Operation of these ropeways<br />

is straightforward and safe. The explosive charges<br />

can be precisely positioned at points along the<br />

ropeline, while the choice of positions is fl exible. If<br />

a charge fails to detonate, it can be run back to<br />

starting position. Thanks to Doppelmayr’s many<br />

years of experience and the advanced technolo-<br />

gy employed, these avalanche blasting ropeways<br />

also impress with top availability. The<br />

installations in Hochgurgl not only ensure safe,<br />

avalanche-free downhill skiing but also safeguard<br />

the popular freeride slopes.

Aerial tram facilitates access<br />

to Hindu shrine<br />

45-ATW Vaishno Devi | Katra, Jammu/Kashmir (IND)<br />

SMVD Shrine Board<br />

441 m 237 m 800 PPH 6.0 m/s 2.0 min 2 45-passenger cabins December 2018<br />

In India, a reversible aerial tramway up to<br />

Mount Vaishno Devi close to the border with<br />

Pakistan now makes it easier for Hindus to visit<br />

one of their most important pilgrimage sites.<br />

Mount Vaishno Devi, in Northern India, is the<br />

location of several sacred temples devoted to<br />

the Hindu goddess Shakti – the primal feminine<br />

force that moves throughout the universe.<br />

Thousands of mostly Indian pilgrims start<br />

out on their journey from the town of Katra<br />

13 kilometers away to make their offerings<br />

at the temples. The route they have to cover<br />

to get there, particularly the last section, is<br />

winding, long and arduous. The vehicles used<br />

to take travelers to their destination are sometimes<br />

unreliable, frequently break down and<br />

then get stuck on the steep road. Today, all<br />

the pilgrims can take the new aerial tram from<br />

Doppelmayr/Garaventa to climb the last strenuous<br />

237 vertical meters up to the temples,<br />

hotels and restaurants in comfort – with a trip<br />

that takes just a few minutes rather than an<br />

hour, as in the past.<br />

The 45-passenger cabins were manufactured<br />

by CWA; Garaventa supplied the electrome-<br />

chanical components and conducted the<br />

evacuation drills with the Indian operators. “It<br />

was an honor for us to build our tramway on this<br />

sacred mountain. What’s special about this<br />

project is that in India, this is the fi rst installation<br />

based entirely on European technology”,<br />

says Garaventa CEO Arno Inauen. Satya Malik,<br />

Governor of Jammu and Kashmir and Chairman<br />

of the Shri Amarnathji Shrine Board, praised<br />

the engineers who “accomplished this mega<br />

project”. Now older and mobility-impaired<br />

pilgrims can fulfi ll their wish to visit the temple.

16 International Projects<br />

A vision becomes reality<br />

10-MGD Sonnberg Lift | Maria Alm, Salzburg (AUT)<br />

Aberg – Hinterthal – Bergbahnen AG<br />

1,260 m 332 m 2,000 PPH 6.0 m/s 4.8 min 32 D-Line<br />

10-MGD Natrun Lift | Maria Alm, Salzburg (AUT)<br />

Aberg – Hinterthal – Bergbahnen AG<br />

1,450 m 357 m 2,200 PPH 6.0 m/s 5.3 min 39 D-Line<br />

A long-cherished dream has come true with<br />

the opening of the two D-Line gondola lifts<br />

Natrun and Sonnberg in Maria Alm.<br />

With two new 10-passenger gondola lifts, the<br />

village of Maria Alm in Austria’s Salzburg province<br />

has created a new infrastructure that<br />

takes the opportunities for skiing enjoyment to<br />

a whole new level. Since the 2018/<strong>2019</strong> winter<br />

season, the Natrun lift has run from Maria Alm<br />

up to the local Natrun mountain; on the sunny<br />

side of the mountain, the new Sonnberg lift<br />

provides the connection to Hochkönig, the<br />

main ski area. For skiers, this opens up direct<br />

access to the popular Königstour ski circuit.<br />

Until now, this could only be reached by ski<br />

bus or car from Maria Alm, whereas today the<br />

skiing can begin almost from the front door.<br />

The bottom station of the Sonnberg lift is now<br />

located immediately next door to the Aberg<br />

lift, which was formerly the main point of access<br />

for the ski circuit. Creating this connection<br />

nevertheless called for a large amount of<br />

planning ingenuity. Available space at the<br />

bottom station was severely restricted by the<br />

existing building, a parking lot, the federal<br />

road and the local Urslau river. In addition,<br />

the route of the Sonnberg lift had to go past a<br />

farm holding and a residential area further<br />

up. This was the only way to bring the top<br />

stations of the new lifts together at one level.<br />

As a consequence, the lift incorporates some<br />

special technical and structural features. The<br />

Sonnberg lift not only includes a curve along<br />

its route but also an unusual station construction:<br />

The loading area is located on the<br />

upper level; the first tower is anchored to the<br />

station building and projects at an angle over<br />

the Urslau.<br />

Village improvements<br />

Guests and local residents alike are pleased<br />

about the direct access to the ski area. The<br />

reduction in traffic in the village has also had a<br />

very positive impact on quality of life. This is<br />

attributable to the greatly improved parking<br />

situation at Aberg, previously the main point<br />

of access, and the good accessibility, which<br />

benefits day visitors in particular.<br />

Family-friendly summer offer<br />

The drives of the two lifts are housed in the top<br />

stations, in the immediate vicinity of the new<br />

restaurant, which also provides the venue for<br />

regular events. This is where the D-Line really<br />

scores highly as the new technology and the<br />

Doppelmayr Direct Drive are very quiet. In<br />

Maria Alm, the offer for summer operations is<br />

being continuously extended. Alongside the<br />

forest slide park, adventure play area, bike<br />

trails and hiking routes, the new culinary offer<br />

has something for everyone. For this reason,<br />

the Natrun lift is also open from mid-May<br />

through to the beginning of November.<br />

The new concept has provided a strong<br />

boost for the entire region,<br />

which has also been very<br />

well rceived by our<br />

guests. Hartwig<br />

Moßhammer, CEO of<br />

Aberg – Hinterthal –<br />

Bergbahnen AG<br />

© Aberg – Hinterthal – Bergbahnen AG

International Projects<br />

17<br />

One tramway, many perspectives<br />

70-ATW Salins-Cungieri-Cuolm da Vi | Disentis, Switzerland (CHE)<br />

Bergbahnen Disentis AG<br />

2,262 m 724 m 4 590 PPH 8.0 m/s 5.6 min 2 70-passenger cabins<br />

The new reversible aerial tramway Salins-<br />

Cungieri-Cuolm da Vi in Sedrun opens up several<br />

possibilities at the same time – by linking<br />

ski resorts and integrating existing offers.<br />

The merger of the Swiss ski resorts Disentis-<br />

Sedrun-Andermatt ensures that the entire<br />

region on the Oberalp Pass is equipped to<br />

meet the future requirements of tourism. The<br />

aerial tram Salins-Cungieri-Cuolm da Vi operated<br />

by Bergbahnen Disentis will serve several<br />

functions simultaneously. On the one hand, it<br />

will provide a new boost for the Cungieri area,<br />

which up until 2005 was a popular recreation<br />

destination – in particular the toboggan run<br />

from Cungieri to Sedrun. On the other hand,<br />

the new aerial tram closes the gap between<br />

Sedrun and Disentis. With the intermediate<br />

unloading at the second of the four towers, the<br />

tramway operators have made the high alpine<br />

landscape with additional offers in summer<br />

and winter accessible to guests – the new tram<br />

will therefore be operating all year round.<br />

Marcus Weber, chairman of the board of Bergbahnen<br />

Disentis AG, is delighted about the new<br />

installation: “The new aerial tramway closes the<br />

last gap in our three ski areas and meets all<br />

the requirements that we, as ropeway operators,<br />

stipulated for the installation. The innovative<br />

tramway offers our guests plenty of space and<br />

comfort, and will also transport important freight<br />

for the envisaged mountaintop restaurant.”<br />

Tough job for the installation team<br />

Construction of the new aerial tramway posed<br />

numerous challenges for the Doppelmayr/<br />

Garaventa installation team. The upper terminal<br />

and towers 3 and 4 can only be reached on<br />

foot or by air. This meant having to fly in all the<br />

materials and equipment by helicopter. For<br />

three of the towers, needle assembly had to be<br />

used due to the poor accessibility. Tight road<br />

bends and the low headroom at the underpass<br />

of the Matterhorn-Gotthard railroad signifi<br />

cantly restricted material transport to the<br />

lower terminal and to tower 1. Delivering the<br />

two cabins required millimeter precision. The<br />

headroom problem had to be overcome by<br />

shifting the cabin sideways on the truck’s<br />

semi-trailer to gain two centimeters of clearance<br />

at critical points. The successful completion<br />

of the tramway construction project was<br />

made possible by the professionalism and<br />

excellent collaboration of all the parties involved.<br />

The minimalist architecture of the upper and<br />

lower terminals – both of which take the form of<br />

a glass cube – harmoniously blends in with the<br />

natural landscape and allows passengers to<br />

see the entire ropeway technology.<br />

The new aerial tramway was officially opened<br />

on June 7.

Three high-speed lifts<br />

for Whistler Blackcomb<br />

10-MGD Blackcomb Gondola | Blackcomb, British Columbia (CAN)<br />

Whistler Blackcomb<br />

Section 1 1,956 m 487 m 4,000 PPH 6.0 m/s 6.8 min 90<br />

Section 2 2,1<strong>02</strong> m 697 m 4,000 PPH 6.0 m/s 7.2 min 95<br />

Guests at the Canadian ski resort Whistler<br />

Blackcomb can now enjoy even faster access<br />

to the slopes thanks to three new ropeways.<br />

The Whistler Blackcomb ski resort in Canada’s<br />

province of British Columbia has accomplished<br />

the biggest investment program in its<br />

history, with three new lifts going into service<br />

in the 2018/19 winter season. A two-section<br />

gondola lift and two chairlifts will in future<br />

enable visitors to access Whistler Mountain<br />

and Blackcomb Mountain in less time than<br />

ever before. The three lift installations optimally<br />

meet the investment goal of improving traffic<br />

flow and expanding upload capacity.<br />

Highest transport capacity in North America<br />

The construction of the Blackcomb Gondola<br />

marks the greatest innovation for the ski resort.<br />

This lift replaces the Wizard and Solar chairlifts,<br />

which up to now provided the main transport<br />

corridor to Blackcomb Mountain. Both staff and<br />

guests now enjoy a faster trip up the mountain<br />

and arrive warm and dry thanks to the new<br />

10-passenger gondola. In comparison with the<br />

two chairlifts, the new installation has increased<br />

transport capacity by 47 percent. It carries up<br />

to 4,000 passengers an hour, which makes it<br />

the ropeway with the highest transport capacity<br />

in North America. The lift’s higher capacity<br />

is also set to bring a signifi cant improvement<br />

for summer operations. With the expansion of<br />

the Whistler Mountain Bike Park, the resort is<br />

boosting its attractions outside the ski season.<br />

The gondola’s top station connects up with the<br />

PEAK 2 PEAK tricable gondola, the region’s<br />

centerpiece that links the two mountains.<br />

Two chairlift upgrades<br />

The Catskinner chairlift represents another<br />

upgrade for Blackcomb Mountain. Four passengers<br />

can now ride on each chair rather<br />

than three, as was previously the case. Travel<br />

speed has also been significantly increased,<br />

providing a 59-percent boost in transport capacity.<br />

On Whistler Mountain, mountain enthusiasts<br />

are awaited by the new Emerald Express<br />

6-seater chairlift offering comfort and top performance.<br />

The new lift replaces a quad chairlift<br />

in the popular Family Ski Zone and can move<br />

almost 30 percent more passengers.<br />

This transformative investment brings a<br />

dramatically improved<br />

mountain experience<br />

for all our guests. Pete<br />

Sonntag, Senior Vice<br />

President and Chief<br />

Operating Officer,<br />

Whistler Blackcomb

International Projects<br />

19<br />

6-CLD Emerald Express | Blackcomb, British Columbia (CAN)<br />

Whistler Blackcomb<br />

1,791 m 425 m 3,600 PPH 5.1 m/s 6.2 min 124 6-seater chairs<br />

4-CLD Catskinner | Blackcomb, British Columbia (CAN)<br />

Whistler Blackcomb<br />

1,168 m 339 m 2,800 PPH 5.1 m/s 4.2 min 97 quad chairs

© Hofer Wolfgang<br />

D-Line in yellow<br />

10-MGD Mösl Lift | Hippach, Tyrol (AUT)<br />

Mayrhofner Bergbahnen AG<br />

1,660 m 557 m 2,000 PPH 6.0 m/s 6.9 min 44 10-passenger cabins December 2018 D-Line<br />

The Mösl lift on the Hochschwendberg provides<br />

a faster route into the Mayrhofen ski area<br />

The new 10-passenger gondola lift from<br />

Doppelmayr/Garaventa has connected the<br />

Mösl district on the Hochschwendberg with the<br />

Mayrhofen ski area since December 2018. The<br />

lift serves an important feeder function as, up<br />

to now, local residents and guests had to take<br />

a bus from Hochschwendberg to reach the ski<br />

area. The Mösl lift creates a new and, above<br />

all, faster connection. The sunshine yellow and<br />

bright blue design of the D-Line gondola lift is<br />

in line with the corporate colors of the operating<br />

company Mayrhofner Bergbahnen – just like<br />

the 3S Penken lift or the Ahorn lift.<br />

Comfort and quiet running<br />

The Mösl lift has two sections. The lower<br />

section is used for the return trip, the upper<br />

section for repeat trips up the mountain. Passengers<br />

enjoy the comfort of the OMEGA IV<br />

cabins during the ride. And they also benefit<br />

from the quiet running of the D-Line. The gearless<br />

DDD drive (Doppelmayr Direct Drive) in the<br />

top station is very low-noise and particularly<br />

low-maintenance. In addition, the ropeway<br />

control system Doppelmayr Connect ensures<br />

efficient operation and a perfect overview<br />

of the entire installation. A parking lot and a<br />

bus stop are immediately adjacent to the bottom<br />

station – so the lift is well integrated into<br />

the local infrastructure. The high-capacity and<br />

comfortable D-Line gondola lift is another<br />

highlight for Mayrhofen. To coincide with the<br />

construction of the Mösl lift, a ski trail expansion<br />

complete with ski movie run – a timed ski<br />

run with video cameras – was also implemented<br />

in this section of the ski area.<br />

It’s great that we now have a D-Line lift with<br />

the Doppelmayr Direct Drive – that means<br />

a considerable reduction in maintenance<br />

work. In addition, the installation is very<br />

quiet in operation. The first winter season<br />

with this new lift has proved our decision in<br />

favor of this ropeway type<br />

to be the right one, and<br />

we’re very pleased<br />

with it.<br />

Andreas Rauch,<br />

Operations Manager,<br />

Horberg Mayrhofner<br />

Bergbahnen AG.

International Projects<br />

21<br />

Haifa’s historic Carmelit<br />

funicular reopens<br />

340-FUL Carmelit–Haifa | Haifa (ISR)<br />

The Carmelit Haifa Ltd.<br />

1,745 m 267 m 2,970 PPH 8.0 m/s<br />

Originally built in the 1950s, Israel’s first<br />

and only funicular railway subway was damaged<br />

by a fire in 2017 but has shone in a new<br />

splendor since fall 2018.<br />

The Carmelit funicular in Haifa – which takes its<br />

name from Mount Carmel – has had an eventful<br />

history. It was built from 1956 to 1959 and<br />

served as an important means of public transport<br />

up until 1986. Following an extensive<br />

rebuild carried out by Von Roll, the Carmelit<br />

funicular resumed operations in 1992. In<br />

January 2017, it was integrated into Haifa’s<br />

public transport network. On February 4 of the<br />

same year, one of the two trains caught fire<br />

outside of operating hours, resulting in severe<br />

damage to several cars and parts of the track.<br />

Doppelmayr/Garaventa then refurbished the<br />

funicular in the shortest possible time frame.<br />

Since fall 2018, the Carmelit has been back<br />

in service, carrying passengers in comfort to<br />

Haifa’s hotspots.<br />

New cars and intuitive skill<br />

The Carmelit is a subway and a ropeway system<br />

at the same time. Following the damage<br />

caused by the fire, it received two completely<br />

new trains, each consisting of two cars, plus<br />

new electrical equipment. The new cars are<br />

state of the art in terms of fire protection. Both<br />

trains are fitted with sprinklers. While the track<br />

has been partially replaced, the haul rope and<br />

counter rope are entirely new. The funicular<br />

runs in a tunnel over its entire length, which<br />

posed a particular challenge when it came to<br />

installing the new components. Lowering the<br />

cars onto the track and introducing them into<br />

the tunnel called for great skill and instinct due<br />

to the tight space available.<br />

The funicular is 1.8 kilometers long and services<br />

a total of six stations: two terminals and four<br />

intermediate stations. As a means of transport<br />

in Haifa, it offers one of the most attractive<br />

ways to explore the city. Most of the sites are<br />

located just a few minutes’ walk from the stations.<br />

The urban means of transport, with a<br />

maximum trip time of 8 minutes, provides<br />

residents and tourists with a convenient way of<br />

accessing Haifa’s three main centers without<br />

the hassles of traffic jams and hunting for a<br />

parking space: downtown, which is the active<br />

business center; Hadar neighborhood, a<br />

young and vibrant residential area; and Central<br />

Carmel, where most of the hotels and many<br />

places of entertainment are located.<br />

Operating hours<br />

The Carmelit subway operates Sunday through<br />

Thursday from 6 am to midnight, Friday only<br />

until 3 pm, and Saturday from 8 pm to midnight.<br />

The Carmelit subway is an environmentally<br />

friendly and simple transport solution for<br />

Haifa’s citizens and tourists. It enables passengers<br />

to get to work and<br />

places of entertainment in<br />

the city without the problem<br />

of traffi c congestion<br />

and fi nding a parking<br />

space. Avishay Hadar,<br />

CEO Carmelit Haifa Ltd.

22<br />

News from Around the World<br />

Gondola ride to university<br />

Doppelmayr/Garaventa is building Israel’s<br />

first urban gondola lift – to resolve a pressing<br />

traffic problem.<br />

Israel’s first urban gondola lift is to be implemented<br />

in Haifa by Doppelmayr/Garaventa.<br />

Construction of the new 8-passenger gondla lift<br />

will resolve a pressing traffic problem. The<br />

University of Haifa is located at the city’s highest<br />

point (470 m) and has limited car parking<br />

facilities. The new ropeway, which will be fully<br />

integrated into the city’s public transit network,<br />

is aimed at relieving the situation. The<br />

university’s 20,000 students can look forward<br />

to a comfortable ride from the central railroad<br />

and bus terminal along a direct route to the<br />

campus, with its various research institutes<br />

and halls of residence. The four-kilometer-long<br />

gondola lift will also be used by tourists – the<br />

university’s elevated location makes it a popular<br />

viewing point as it offers attractive vistas of<br />

the city and the sea.<br />

The ropeway installation has been designed<br />

to accommodate the numerous specifications<br />

required by the customer. The gondola<br />

lift will run up to 17 hours a day and has<br />

to meet particular requirements in terms<br />

of noise emissions. For this reason, the ropeway’s<br />

support structures – i.e. towers and<br />

foundations – will be isolated from the<br />

building structure at each of the six stations.<br />

Completion of the installation is scheduled<br />

for August 2<strong>02</strong>0.<br />

Four Funifors and one of the<br />

steepest aerial tramways<br />

Doppelmayr/Garaventa is to build fi ve new<br />

ropeways in the Swiss resort of Lauterbrunnen<br />

near Interlaken by 2<strong>02</strong>6.<br />

In order to optimize access to the popular<br />

mountain Schilthorn-Piz Gloria, the operating<br />

company Schilthornbahn AG, which always<br />

has the interests of its guests at heart, is replacing<br />

its existing aerial ropeways with new<br />

installations. This major contract for the construction<br />

of fi ve ropeways from Stechelberg up<br />

to the Schilthorn – which provided the setting<br />

for the 1969 James Bond fi lm “On Her Majesty’s<br />

Service”– has been awarded to the Doppelmayr/<br />

Garaventa Group.<br />

The planned infrastructure of the aerial tramway,<br />

which will operate all year round, encompasses<br />

three sections (Stechelberg–Mürren–<br />

Birg–Schilthorn). By 2<strong>02</strong>6, one of the world’s<br />

steepest aerial tramways with a maximum<br />

grade of 160 percent is to be built in the lower<br />

section. The upper sections will consist of<br />

four Funifors, which offer particularly high<br />

wind stability thanks to their wide rope gauge.<br />

Each of these single-track installations will run<br />

independently – i.e. two alongside of each<br />

other and two one behind the other. The<br />

Funifors will be equipped with four drives and<br />

can therefore be run separately. This has a positive<br />

impact on the availability of the installations<br />

when maintenance work has to be carried out.<br />

The Funifor technology was developed and<br />

patented by Doppelmayr Italy, and the specialists<br />

in Lana will also be providing their<br />

support for engineering and production of the<br />

Funifor installations for the Schilthorn project.<br />

Schilthornbahn AG was also impressed by<br />

the sophisticated energy management concept<br />

jointly developed by Garaventa and<br />

Frey AG Stans, which enables the operating<br />

company to dispense with very cost-intensive<br />

new power supply systems. The groundbreaking<br />

ceremony for the project is planned<br />

for 2<strong>02</strong>1.

News from Around the World<br />

23<br />

Russia’s first D-Line<br />

Rosa Khutor Resort is to build its 30th ropeway<br />

– which will be supplied by Doppelmayr/<br />

Garaventa.<br />

Doppelmayr is to implement the first D-Line<br />

generation ropeway project in Rosa Khutor<br />

Resort in time for the <strong>2019</strong>/2<strong>02</strong>0 winter season.<br />

The new installation, a 10-passenger detachable<br />

gondola lift on the southern slope of the<br />

Aibga crest in the Western Caucasus, will be<br />

the 30th ropeway in Rosa Khutor. For the customer,<br />

a main priority in awarding the contract<br />

was to improve guest services and infrastructure.<br />

The new D-Line with its many innovations<br />

will open up entirely new possibilities for the<br />

resort. The vast majority of the lifts in the ski area<br />

were supplied by Doppelmayr/Garaventa.<br />

Olympic region as popular ski destination<br />

The resort was the biggest venue for the<br />

2014 Winter Olympic Games. In the <strong>2019</strong>/2<strong>02</strong>0<br />

season, Rosa Khutor is to host a stage of the<br />

women’s downhill and super-G events for<br />

the FIS World Cup. As an all-year mountain<br />

vacation resort, Rosa Khutor attracts some<br />

20,000 visitors on a daily basis; in the 2017/18<br />

winter season, the number of visitors was<br />

almost 1 million and that figure is set to rise.<br />

The additional lift on the southern slope will<br />

reduce waiting times and speed up passenger<br />

flows.<br />

UN-Habitat:<br />

Collaboration extended<br />

New ropeway films<br />

In spring <strong>2019</strong>, Thomas Pichler, managing<br />

director of Doppelmayr Seilbahnen GmbH,<br />

signed the agreement to extend the highly<br />

successful collaboration with UN-Habitat, the<br />

United Nations Human Settlements Program.<br />

The two organizations, which have been collaborating<br />

since 2016, are expanding their<br />

agendas with respect to the challenges in the<br />

area of mobility and taking another large step<br />

toward the future. As the global leader in the<br />

area of rope-propelled transport systems,<br />

Doppelmayr is delighted to provide its expertise<br />

with a view to driving forward new mobility<br />

solutions for the urban environment of<br />

the future and contributing to the development<br />

of new ideas.<br />

Exciting new ropeway films are available<br />

on the Doppelmayr/Garaventa YouTube<br />

channel. The Saanersloch lift in Gstaad is<br />

Switzerland’s first D-Line gondola lift and<br />

the world’s first ropeway installation with<br />

elegant real-glass facades on the station<br />

buildings. The important issue of wheelchair<br />

accessibility on D-Line chairlifts is<br />

highlighted in the film on the new Gampen<br />

lift in Ischgl. The Kohlmais lift in Saalbach<br />

is the first continuous-movement installation<br />

to be equipped with the new OMEGA<br />

V cabins. In Booysendal, South Africa, a<br />

RopeCon ® system transports 909 tons of<br />

platinum ore an hour. China’s first 3S lift<br />

crosses the national park in Lushan – a<br />

UNESCO World Heritage Site.<br />

View the new<br />

fi lms here:

Ropeway technology<br />

for the entire world<br />

Components for a wide range of ropeway systems are manufactured<br />

at the Hohe Brücke plant. Precision and top quality standards at<br />

Doppelmayr’s biggest production facility are key to satisfied customers.<br />

The Hohe Brücke plant in Wolfurt, the home<br />

base for the family-run business, has been<br />

operating at its current location since 20<strong>02</strong><br />

and is the Doppelmayr Group’s biggest production<br />

facility. The entire site covers an area of over<br />

12 hectares. A wide variety of steel parts are<br />

made here, such as bullwheels, support structures<br />

or parts for sheave assemblies and grips.<br />

In some cases, the components are manufactured<br />

manually; in others, using cutting-edge robots<br />

and machine tools.<br />

The plant’s 350-strong workforce processes<br />

between 22,000 and 25,000 tons of steel on an<br />

annual basis. The production methods used include<br />

plasma and flame cutting, MAG welding<br />

and stress-free annealing as well as machining<br />

methods such as boring, turning and milling. “We<br />

work in shifts as well as normal working hours,<br />

while our factory loading is now high over the entire<br />

year,” says production manager Karl-Heinz Zündel.

Doppelmayr/Garaventa Group<br />

25<br />

Top requirements for quality and on-time delivery<br />

Doppelmayr makes to order as well as to stock.<br />

Ropeway manufacture frequently takes the form<br />

of a “modular system”. This enables optimal<br />

capacity utilization and on-time delivery. It<br />

goes without saying that the quality has to be<br />

right for all parts used in ropeway systems. For<br />

this reason, products have to undergo a wide<br />

range of inspections and testing before they<br />

leave the factory. All components are subject to<br />

continuous monitoring during production, which<br />

is performed by skilled employees with the aid<br />

of precision measuring equipment. Specially<br />

trained employees are responsible for nondestructive<br />

testing for cracks and surface fl aws<br />

as well as for weld testing, and are required to<br />

take part in regular training and certifi cation.<br />

The machine infrastructure used at the plant<br />

is designed for Doppelmayr’s special requirements<br />

– in particular the machine peripherals.<br />

The new assembly lines for the D-Line were<br />

actually developed in-house.<br />

Apprentices integrated into the production<br />

process<br />

The family-run company attaches great importance<br />

to the education and training of its<br />

production employees. This includes flexible,<br />

cross-departmental offers within the company<br />

as well as external courses. Apprentice training<br />

is a major priority. At the present time, over<br />

100 apprentices are being trained in Wolfurt in<br />

the fields of steel construction engineering,<br />

mechanical engineering, machining or electrical<br />

engineering. The youngsters work on genuine<br />

customer orders, which means they are<br />

fully integrated into the manufacturing process.<br />

“For our apprentices, this is very interesting<br />

and valuable. That motivates them and they<br />

are proud when they can then marvel at the<br />

finished ropeway installation they worked on,”<br />

says Karl-Heinz Zündel.<br />

In spite of the size that we have now reached,<br />

the family atmosphere is very important to<br />

us in addition to quality – because satisfied<br />

and motivated employees are our most<br />

valuable asset.<br />

Production Manager Karl-Heinz Zündel

Even better service<br />

quality worldwide<br />

With the development of its customer support strategy 2030, Doppelmayr is setting<br />

the benchmark for a harmonized service package for customers around the globe.<br />

Doppelmayr offers comprehensive customer<br />

service anywhere in the world.<br />

An in-depth survey of customer requirements<br />

was conducted to identify further<br />

improvement potentials. This revealed a desire<br />

for a service spectrum of greater depth<br />

and breadth in some regions. The goal that<br />

Doppelmayr sets itself is the capability to offer<br />

all customers – irrespective of their geographical<br />

location – the same high quality of service.<br />

That is why the company developed its customer<br />

support strategy 2030. The prime objective<br />

is for customers around the globe to be able<br />

to access harmonized service packages that<br />

meet Doppelmayr’s usual high quality standards.<br />

Same quality standards<br />

The quality process is aimed at a precise internal<br />

and external definition of services so<br />

that customers worldwide always know what to<br />

expect from a service and how to ensure<br />

they are optimally prepared, i.e. how long the<br />

service will take, how many people they have<br />

to provide, how the process should take place<br />

and how it must be documented in detail. In<br />

other words: full transparency. This relates,<br />

for example, to sheave assembly services,<br />

ropeway inspections or repairs, and electrical<br />

services.<br />

SMART Ropeway in customer support<br />

Digitalization plays a key role when it comes<br />

to internationalizing services. In line with<br />

Doppelmayr’s approach to digitalization under<br />

the heading of SMART Ropeway, knowledge<br />

management is employed on a cross-organizational<br />

and cross-border basis. Digital<br />

platforms improve direct communication and<br />

information interchange, and systematically<br />

focus operational know-how. The current<br />

customer support website will be redesigned<br />

to provide greater transparency, more download<br />

options and a host of new features. This<br />

will guarantee a more mobile, more flexible and<br />

faster service. And customers will have faster<br />

and easier access to important advisory services.<br />

Another measure is the training drive. Doppelmayr<br />

customers and personnel around the globe will<br />

undergo in-depth training to ensure the same<br />

high level of ropeway expertise worldwide.<br />

The customer support strategy 2030 offers genuine<br />

value added for customers. This will not<br />

only simplify the collaboration with Doppelmayr<br />

but also provide assistance for interactions with<br />

government agencies.

In Brief<br />

27<br />

University course in Ropeway Engineering<br />

& Management kicks off<br />

Understanding the technology of ropeway<br />

systems and managing ropeway operations<br />

– these are the skills you will acquire<br />

from a university course in ropeways that is<br />

unique in Europe.<br />

For the fourth time, the Vorarlberg University<br />

of Applied Sciences (AUT) and Schloss Hofen<br />

(AUT) are about to start the degree course<br />

developed jointly with the Doppelmayr Group.<br />

The course is based on the concept of 12-week<br />

study blocks and has been designed in line<br />

with the industry’s seasonal orientation. The<br />

lectures are always held from September<br />

through November and from April through<br />

July of the respective semester. This enables<br />

the students to combine work and education.<br />

For the first time, as part of the fourth<br />

degree course, one week out of one 12-week<br />

block will be spent in Hallein, Salzburg, and<br />

one week out of the other block in Bolzano<br />

in South Tyrol.<br />

INTERESTED?<br />

Applications are possible<br />

at short notice – the course<br />

begins in September.<br />

Further information at<br />

seilbahnlehrgang.at<br />

OMEGA V among<br />

the best of the best<br />

CWA has every reason to feel honored at receiving<br />

the Red Dot Award: Product Design <strong>2019</strong>. Its<br />

new OMEGA V cabin for continuous-movement<br />

gondola lifts was awarded the Red Dot: Best of<br />

the Best, which is the competition’s top accolade.<br />

The OMEGA V convinced the jury with its clean<br />

lines, its timeless, puristic shape and the premium<br />

quality of its elegant interior. For the fi rst<br />

time, the cabin suspension has been integrated<br />

into the overall design of this latest generation,<br />

which sets entirely new benchmarks. The optimal<br />

ergonomics inside and the generously proportioned<br />

glass construction ensure an exceptional<br />

ride experience for passengers.<br />

Winning the Red Dot: Best of the Best is a special<br />

achievement. Only 1.5 percent of the submitted<br />

products received this year’s award. The<br />

Red Dot Award: Product Design is one of the<br />

biggest design competitions worldwide, with<br />

designers and manufacturers from 55 nations<br />

entering over 5,500 products in <strong>2019</strong>. The international<br />

jury comprised of experienced experts<br />

places the emphasis on criteria such as level of<br />

innovation, functionality, formal quality, longevity<br />

and ergonomics as part of its assessment.<br />

red-dot.org/pd/winners<br />

Legend<br />

INTERALPIN <strong>2019</strong><br />

Inclined length<br />

Vertical rise<br />

Number of towers<br />

Capacity<br />

Speed<br />

Trip time<br />

Carriers<br />

Opened<br />

D-Line<br />

Max. inclination<br />

Summer operation<br />

Winter operation<br />

The Doppelmayr/Garaventa Group showcased a<br />

host of product highlights at INTERALPIN <strong>2019</strong>.<br />

The many visitors to the exhibition stand were<br />

able to experience interactive exhibits and the<br />

latest innovations, including a world premiere:<br />

CWA’s new 3S cabin, ATRIA, was presented for<br />

the first time. The new OMEGA V cabin for<br />

continuous-movement ropeways, on show with<br />

a wide range of styling options, also attracted<br />

many admirers. The “Motion Cube” enabled<br />

visitors to immerse themselves in a digital<br />

world of experience and enjoy the cabin’s<br />

many facets. The modular design of both the<br />

OMEGA V and the ATRIA make them ideally<br />

suited to winter or summer use as well as for<br />

urban applications.<br />

SMART Ropeway, the digital future, was presented<br />

as a hands-on experience. Trade fair visitors<br />

had the opportunity to try out the Doppelmayr<br />

Connect ropeway control system live. The<br />

D-Line ropeway generation was also extensively<br />

showcased at INTERALPIN. The various material<br />

and design samples as well as the many chair<br />

exhibits impressively demonstrated its benefi ts<br />

and the high level of customizing available.<br />

Imprint<br />

Proprietor, editor and publisher: Doppelmayr Seilbahnen<br />

GmbH, Postfach 20, Konrad-Doppelmayr-Straße 1, 6922<br />

Wolfurt, Austria, dm@doppelmayr.com, doppelmayr.com;<br />

text and editing: ikp Vorarlberg GmbH, www.ikp.at; graphics<br />

and layout: KONZETT BR<strong>EN</strong>NDÖRFER, www.agenturkb.com;<br />

photos: Doppelmayr; printing: Thurnher, Rankweil; editorial<br />

policy pursuant to §25 Media Act: up-to-date information for<br />

customers, partners and employees of the Doppelmayr/<br />

Garaventa Group; publication frequency: the magazine is<br />

published three times a year and distributed free of charge to<br />

customers and partners of the Doppelmayr Group. Reprinting<br />

only permitted with statement of source and explicit written<br />

authority; status: September <strong>2019</strong>; errors and omissions<br />

excepted; General Terms and Conditions apply.<br />

doppelmayr.com

Service & Applications<br />

Mobility & Experience<br />

Advanced Connectivity<br />

Service & Applications<br />

Digital Services & Applications make the daily work routine easier<br />

for our customers. The operation and maintenance of a ropeway<br />

installation are optimized and assisted by intelligent functions.<br />

Relations & Reliability<br />

Technology & Innovation<br />