Issue 06/2018

bioplasticsMAGAZINE_1806

bioplasticsMAGAZINE_1806

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ISSN 1862-5258<br />

Nov / Dec<br />

<strong>06</strong> | <strong>2018</strong><br />

Compostable<br />

sanitary napkin<br />

project wins<br />

13th Global<br />

Bioplastics Award<br />

| 10<br />

bioplastics MAGAZINE Vol. 13<br />

Highlights<br />

Bioplastics from waste streams | 20<br />

Films, flexibles, bags | 12<br />

... is read in 92 countries

BIO-FLEX ®<br />

AS VERSATILE AS YOUR REQUIREMENTS<br />

Biobased up to 85 %<br />

Certifi ed home compostable<br />

Certifi ed industrial compostable<br />

Heat resistant<br />

Food contact approved<br />

Easy processable on existing equipment

Editorial<br />

dear<br />

readers<br />

As you read these lines, the 13 th European Bioplastics Conference in Berlin is over<br />

or – for some of you – still going on. And as always, we are grateful to European<br />

Bioplastics for giving us the opportunity to present the Annual Global Bioplastics<br />

Award at this prestigious event. For those of you who missed it, turn to page 10,<br />

where we present this year’s winner. We had already reported about the project<br />

earlier this year, and it so happened that the development was anonymously<br />

proposed for the award – and won.<br />

Films, Flexibles, Bags is traditionally the first highlight topic of every December<br />

issue of bioplastics MAGAZINE. And the other this year is Bioplastics made from<br />

waste streams.<br />

It is also interesting to see that in the aftermath of our 1 st PHA platform World<br />

Congress , the response continues. A group of four experts have now come<br />

together to found GO!PHA - the Global Organization for PHA - a global initiative to<br />

accelerate the development of the PHA-platform industry.<br />

As always, we’ve rounded up some of the most recent news items on materials<br />

and applications to keep you abreast of the latest innovations and ongoing<br />

advances in the world of bioplastics.<br />

Lastly, I’d like to remind you of the 3 rd bio!PAC conference on biobased<br />

packaging in Düsseldorf next May – the call for papers is still open. If you have<br />

an interesting topic to report on, please let us know. The same goes for the<br />

first international bio!TOY conference. At the end of March, we are going to bring<br />

together raw material suppliers and toy manufacturers in Nürnberg, Germany, the Toy<br />

City. See pages 11 and 13 for details.<br />

Let me take this opportunity to wish you all a relaxing time over the holidays as this<br />

year comes to an end. Together with you, our readers, we look forward with confidence<br />

to a new year of challenges, innovations - and events. On our calendar, we’ve already<br />

marked down Chinaplas, taking place next year at a new location in Guangzhou and<br />

of course the K’show in Düsseldorf in October and a host of other events. We’ll be<br />

covering as many of these events as possible - and we hope to see you there, too.<br />

Until then, please enjoy reading bioplastics MAGAZINE.<br />

bioplastics MAGAZINE Vol. 13<br />

ISSN 1862-5258<br />

Compostable<br />

sanitary napkin<br />

project wins<br />

13th Global<br />

Bioplastics Award<br />

| 10<br />

Highlights<br />

Bioplastics from waste streams | 20<br />

Films, flexibles, bags | 12<br />

Nov / Dec<br />

<strong>06</strong> | <strong>2018</strong><br />

... is read in 92 countries<br />

Follow us on twitter!<br />

www.twitter.com/bioplasticsmag<br />

Michael Thielen<br />

Like us on Facebook!<br />

www.facebook.com/bioplasticsmagazine<br />

bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13 3

Content<br />

Imprint<br />

Nov / Dec <strong>06</strong>|<strong>2018</strong><br />

3 Editorial<br />

5 News<br />

10 Events<br />

36 Application News<br />

41 Brand Owner<br />

45 10 years ago<br />

46 Basics<br />

50 Suppliers Guide<br />

53 Event Calendar<br />

54 Companies in this issue<br />

Bioplastics Award<br />

10 And the winner is..<br />

Films/Flexibles/Bags<br />

12 What’s new for cellulose based films<br />

14 That’s not my bag<br />

From Science & Research<br />

18 PLA in the post-consumer-recycling stream<br />

28 Improved biobased fibres for clothing applications<br />

29 New method for high yield FDCS production<br />

30 Compostable plastics behaviour<br />

42 Land use<br />

Report<br />

32 Go!PHA<br />

39 Tui-Cruises<br />

Bioplastics from waste streams<br />

20 Waste cooking oil as source for PHA<br />

22 Is Algae a sustainable feedstock<br />

24 Valorizing side stream<br />

Materials<br />

26 Calcium Carbonate opens new<br />

opportunities for the use of PLA<br />

Applications<br />

34 PLA in the fridge<br />

Publisher / Editorial<br />

Dr. Michael Thielen (MT)<br />

Samuel Brangenberg (SB)<br />

Head Office<br />

Polymedia Publisher GmbH<br />

Dammer Str. 112<br />

41<strong>06</strong>6 Mönchengladbach, Germany<br />

phone: +49 (0)2161 6884469<br />

fax: +49 (0)2161 6884468<br />

info@bioplasticsmagazine.com<br />

www.bioplasticsmagazine.com<br />

Media Adviser<br />

Samsales (German language)<br />

phone: +49(0)2161-6884467<br />

fax: +49(0)2161 6884468<br />

sb@bioplasticsmagazine.com<br />

Michael Thielen (English Language)<br />

(see head office)<br />

Layout/Production<br />

Kerstin Neumeister<br />

Print<br />

Poligrāfijas grupa Mūkusala Ltd.<br />

1004 Riga, Latvia<br />

bioplastics MAGAZINE is printed on<br />

chlorine-free FSC certified paper.<br />

Print run: 3.400 copies<br />

bioplastics magazine<br />

ISSN 1862-5258<br />

bM is published 6 times a year.<br />

This publication is sent to qualified subscribers<br />

(169 Euro for 6 issues).<br />

bioplastics MAGAZINE is read in<br />

92 countries.<br />

Every effort is made to verify all Information<br />

published, but Polymedia Publisher<br />

cannot accept responsibility for any errors<br />

or omissions or for any losses that may<br />

arise as a result.<br />

All articles appearing in<br />

bioplastics MAGAZINE, or on the website<br />

www.bioplasticsmagazine.com are strictly<br />

covered by copyright. No part of this<br />

publication may be reproduced, copied,<br />

scanned, photographed and/or stored<br />

in any form, including electronic format,<br />

without the prior consent of the publisher.<br />

Opinions expressed in articles do not<br />

necessarily reflect those of Polymedia<br />

Publisher.<br />

bioplastics MAGAZINE welcomes contributions<br />

for publication. Submissions are<br />

accepted on the basis of full assignment<br />

of copyright to Polymedia Publisher GmbH<br />

unless otherwise agreed in advance and in<br />

writing. We reserve the right to edit items<br />

for reasons of space, clarity or legality.<br />

Please contact the editorial office via<br />

mt@bioplasticsmagazine.com.<br />

The fact that product names may not be<br />

identified in our editorial as trade marks<br />

is not an indication that such names are<br />

not registered trade marks.<br />

bioplastics MAGAZINE tries to use British<br />

spelling. However, in articles based on<br />

information from the USA, American<br />

spelling may also be used.<br />

Envelopes<br />

A part of this print run is mailed to the<br />

readers wrapped sponsored bioplastic<br />

envelopes<br />

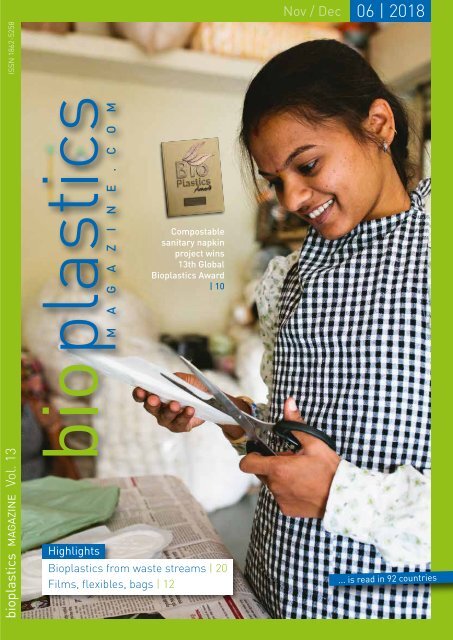

Cover<br />

Aakar Innovations<br />

Follow us on twitter:<br />

http://twitter.com/bioplasticsmag<br />

Like us on Facebook:<br />

https://www.facebook.com/bioplasticsmagazine

daily upated news at<br />

www.bioplasticsmagazine.com<br />

Novamont opened new<br />

Origo-Bi production site<br />

News<br />

The official inauguration of Mater-Biopolymer, Novamont’s newly refurbished<br />

site for the production of its biodegradable biopolyester Origo-Bi, took place on<br />

19 October, in Patrica, Italy.<br />

At the end of the preceding "The Regeneration continues" conference, the guests,<br />

including representatives of institutions, local administrations, universities and<br />

research and industrial partners of the Group, were given a tour of the plant to have<br />

an opportunity to take a closer look at the production process.<br />

In line with Novamont’s strategy of revitalizing sites that have become old and<br />

obsolete, the new Mater-Biopolymer has been converted from a former PET<br />

production plant into a modern facility for the production of biopolyesters based<br />

on renewable raw materials, using a more sustainable and low-emission process.<br />

The highly efficient plant is equipped with a complex system of utilities to minimize<br />

costs and waste through the recovery and enhancement of waste. In 2016, the site<br />

started the construction of a waste water distillation section from the process that<br />

made it possible to recover the tetrahydrofuran (THF) that is generated during the<br />

polymerization reaction, which, once distilled, is destined for the chemical and<br />

pharmaceutical industries, among other things. MT<br />

www.novamont.com<br />

Think Sustainable<br />

M·VERA ®<br />

Bioplastics<br />

With our M·VERA® range of<br />

biobased and biodegradable<br />

plastics (certified according<br />

to EN 13432), we provide you<br />

with customised solutions<br />

for your application:<br />

• Film<br />

Such as shopping bags,<br />

fruit and vegetable bags<br />

or agricultural films<br />

• Injection Moulding<br />

Such as packaging, coffee<br />

capsules, cutlery and others<br />

• Color, Carbon Black and<br />

Additive Masterbatches<br />

Our team of highly experienced<br />

plastic specialists is pleased to<br />

help you – contact us!<br />

Braskem joins Europe’s Bio-based<br />

Industries Consortium (BIC)<br />

Chemicals company Braskem announces it has joined European network Biobased<br />

Industries Consortium (BIC) as a full member.<br />

BIC represents the private sector in the Bio-based Industries Joint Undertaking<br />

(BBI JU), a public-private partnership (PPP) with the EU worth €3.7 billion. By<br />

joining BIC, Braskem has become part of a wider network committed to bringing<br />

bio-based products to market.<br />

Established as a pillar of the European Commission Bioeconomy Strategy, BBI JU<br />

operates under EU research and innovation programme Horizon 2020. It supports<br />

the development and production of bio-based products in Europe via biorefining<br />

research and demonstration projects, including large-scale commercialisation,<br />

through investment in innovative manufacturing facilities and processes. MT<br />

www.braskem.com<br />

BIO-FED<br />

Branch of AKRO-PLASTIC GmbH<br />

BioCampus Cologne · Nattermannallee 1<br />

50829 Cologne · Germany<br />

Phone: +49 221 88 8894-00<br />

Fax: +49 221 88 88 94-99<br />

info@bio-fed.com<br />

www.bio-fed.com<br />

bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13 5

News<br />

daily upated news at<br />

www.bioplasticsmagazine.com<br />

Unilever and Bio-on work together<br />

Unilever (headquartered in Rotterdam, The Netherlands)<br />

and Bio-on (Bologna, Italy) recently announced the start of a<br />

strategic partnership to develop, produce and sell personal<br />

hygiene and care products that guarantee a smaller or no<br />

environmental impact. Using patented bio-technologies<br />

for natural, biodegradable microplastics (PHA) production,<br />

Unilever and Bio-on are taking an important step towards<br />

building a more sustainable economy and more responsible<br />

consumption in the personal care sector.<br />

This collaboration is designed to meet the demands<br />

of consumers, who are increasingly concerned about<br />

sustainability and making purchasing choices that respect<br />

the environment, whilst making the most of the skills and<br />

excellence at both companies.<br />

Unilever's knowledge and large-scale presence on the<br />

personal care market with noted brands such as Mentadent,<br />

Dove, Zendium, Glysolid, and Sunsilk, teams up with the<br />

exclusive know-how of Bio-on, specialised in biotechnologies<br />

applied to widely used materials, to create completely natural<br />

products and solutions.<br />

"For Unilever, developing a partnership with such an<br />

excellent Italian company as Bio-on is an important step<br />

towards the goals we have set ourselves with the Unilever<br />

Sustainable Living Plan, primarily to halve the environmental<br />

impact of our products by 2030," claims Fulvio Guarneri,<br />

Chairman & CEO of Unilever Italia. "This collaboration<br />

makes us very proud because it is one of the most important<br />

examples through which Unilever is making concrete moves<br />

towards sustainability in our business strategy."<br />

"Research into innovative products and cutting-edge<br />

formulations that respect the environment and people is<br />

now a priority in the personal care sector," explains Marco<br />

Astorri, Chairman and CEO of Bio-on. "We are very pleased<br />

to work alongside such a major player as Unilever, with<br />

which we will have the great opportunity to introduce real<br />

sustainable innovation whilst reaching an increasingly broad<br />

consumer base." Bio-on will work with Unilever through two<br />

new companies, which will focus 100% on exploiting exclusive<br />

technologies to develop, produce and supply personal care<br />

products. MT<br />

www.bio-on.it | www.unilever.it<br />

Dupont completes expansion of Sorona production<br />

DuPont Industrial Biosciences has completed the expansion<br />

of their Kinston, NC manufacturing facility, which produces<br />

bio-based, high-performance DuPont Sorona ® polymers<br />

From the expansion, DuPont has increased the facility’s<br />

capacity to produce Sorona polymer by 25%. This investment<br />

is reflective of the growing demand for Sorona polymer<br />

throughout the carpet and apparel markets and an emerging<br />

global focus on building the circular economy.<br />

“This expansion is a direct result of the significant growth<br />

in global demand for Sorona polymer and a testament to<br />

DuPont’s commitment to manufacturing innovative products in<br />

North Carolina,” says Michael Saltzberg, Ph.D., global business<br />

director of DuPont Biomaterials. “We are grateful for the support<br />

from partners that made this project possible including: Lenoir<br />

County Economic Development, North Carolina Community<br />

College System, Lenoir Community College, Duke Energy<br />

Corporation, North Carolina Department of Commerce and<br />

North Carolina Department of Transportation.”<br />

DuPont Sorona polymer is made from 37 % renewable<br />

plant-based ingredients and has many versatile applications.<br />

As compared to similar materials, like nylon 6, Sorona<br />

polymer uses 30 % less energy and releases 63 % fewer<br />

greenhouse gas emissions. In addition to reducing its reliance<br />

on fossil fuels, Sorona polymer combines eco-efficiency with<br />

function, as its high-performance qualities can be used in<br />

a variety of applications. Fibers made with Sorona polymer<br />

exhibit exceptional softness, inherent stain resistance and<br />

uncompromising durability, offering a sustainable, highperforming<br />

material option for customers throughout the<br />

supply chain.<br />

DuPont Industrial Biosciences employs more than 90<br />

workers in Kinston through the manufacturing of Sorona<br />

polymer. With the startup of the line, four additional employees<br />

also are being recruited. MT<br />

tinyurl.com/sorona<br />

Magnetic<br />

for Plastics<br />

www.plasticker.com<br />

• International Trade<br />

in Raw Materials, Machinery & Products Free of Charge.<br />

• Daily News<br />

from the Industrial Sector and the Plastics Markets.<br />

• Current Market Prices<br />

for Plastics.<br />

• Buyer’s Guide<br />

for Plastics & Additives, Machinery & Equipment, Subcontractors<br />

and Services.<br />

• Job Market<br />

for Specialists and Executive Staff in the Plastics Industry.<br />

Up-to-date • Fast • Professional<br />

6 bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13

daily upated news at<br />

www.bioplasticsmagazine.com<br />

News<br />

EU Parliament's single-use plastics ban -<br />

Bioplastics can provide an alternative, EUBP says<br />

The European Parliament recently approved its report on the draft Directive on Marine Pollution and Single-use Plastics.<br />

“European Bioplastics fully supports the transition from a linear to a circular economy. Bioplastics enable more sustainable<br />

solutions for a range of products“, says François de Bie, Chairman of European Bioplastics (EUBP).“We agree on the importance<br />

of reducing single-use plastic products where feasible, but hygiene and food safety cannot be compromised. With regard to<br />

some of the concerned single-use products – such as e.g. plates and cutlery –, biodegradable certified compostable plastics<br />

provide an organically recyclable alternative“.<br />

EUBP considers the Parliament’s decision to restrict the use of single-use cutlery and plates as not sufficiently considering<br />

the reality of food consumption in Europe. In certain closed-loop contexts, such as canteens, air travel, or sport and music<br />

events, these are an indispensable and efficient solution to guarantee safety and hygiene for food and drinks while ensuring at<br />

the same time waste collection and recycling.<br />

Biodegradable certified compostable plastics fulfil Europe’s rigorous requirements and standards for health and safety and<br />

can be recycled organically together with the food waste.<br />

EUBP fully supports the Parliament’s suggestion to restrict products made from oxo-degradable plastics, which is in line<br />

with earlier statements by the Parliament and the European Commission in the context of the EU Plastics Strategy.<br />

Concerning biodegradability in the marine environment, EUBP stresses that it is an interesting property. However, it needs<br />

to be clearly defined for which materials, products and under which circumstances this property is of added value. Improving<br />

waste management on land and building efficient mechanical and organic recycling infrastructures across Europe remain a<br />

priority when it comes to fighting marine pollution.<br />

EUBP looks forward to further constructive discussions with the European Commission, the Parliament, and the Council<br />

during the upcoming trilogues in order to realise a truly sustainable, no-litter, circular economy for Europe. MT<br />

www.european-bioplastics.org<br />

HIGH WE DRIVE THROUGHPUT. THE<br />

DIAMEETS CIRCULAR ECONOMY. QUALITY.<br />

Whether it is inhouse, postconsumer<br />

or bottle recycling:<br />

you can only close loops in a<br />

precise and profitable way if<br />

machines are perfectly tuned<br />

for the respective application.<br />

Count on the number 1<br />

technology from EREMA<br />

when doing so: over 5000<br />

of our machines and systems<br />

produce around 14 million<br />

tonnes of high-quality pellets<br />

like this every year –<br />

in a highly efficient and<br />

energy-saving way.<br />

That’s Careformance!<br />

CAREFORMANCE<br />

We care about your performance.<br />

1710013ERE_ins_bioplastics magazine.indd 1 bioplastics MAGAZINE 18.10.17 [<strong>06</strong>/18] Vol. 14:313 7

News<br />

thyssenkrupp commissions first commercial<br />

PLA plant for COFCO in China<br />

To reduce reliance on petroleum-based plastics,<br />

thyssenkrupp has developed a manufacturing process<br />

for the bioplastic PLA. The world’s first commercial plant<br />

based on the patented PLAneo ® technology recently started<br />

production in Changchun, China. It is operated by the Jilin<br />

COFCO Biomaterial Corporation, a subsidiary of COFCO,<br />

China’s largest food and beverage group. The new plant with<br />

an initial capacity of 10,000 tonnes, produces all standard PLA<br />

types, among other things for the production of eco-friendly<br />

packaging, fibers, textiles and engineering plastics.<br />

the technology, thyssenkrupp’s subsidiary Uhde Inventa-<br />

Fischer profited from decades of expertise gained from the<br />

construction of more than 400 polymerization plants and<br />

extensive experience in the scale-up of new technologies.<br />

For the new plant in Changchun thyssenkrupp provided<br />

the engineering, key plant components and supervision of<br />

construction and commissioning. MT<br />

www.thyssenkrupp-industrial-solutions.com<br />

Sami Pelkonen, CEO of the Electrolysis & Polymers<br />

Technologies business unit of thyssenkrupp Industrial<br />

Solutions: “The bioplastics market will continue to grow in the<br />

coming years, not least due to the increasing environmental<br />

awareness of industry, governments and consumers. With our<br />

PLAneo technology we want to do our bit to make the plastics<br />

sector more sustainable and resource-friendly. With it we<br />

enable our customers to produce high-quality bioplastics with<br />

a wide range of properties – at a price that is competitive with<br />

conventional plastics.”<br />

PLAneo technology converts lactic acid into PLA in a<br />

particularly efficient and resource friendly way. Another<br />

advantage is its transferability to large-scale plants with<br />

capacities of up to 100,000 tons per year. In developing<br />

Neste and Clariant will collaborate<br />

Neste, the world’s leading provider of sustainable renewable<br />

diesel and an expert in delivering drop-in renewable chemical<br />

solutions, and Clariant, a world leader in specialty chemicals,<br />

have signed an agreement to collaborate on the development<br />

of new sustainable material solutions targeted at a range of<br />

industries.<br />

In the first phase of the partnership, the companies will<br />

start replacing fossil-based ethylene and propylene used in<br />

Clariant’s top-quality hot-melt adhesives, with monomers<br />

derived from renewable feedstock. This is enabled by turning<br />

Neste’s renewable hydrocarbons – produced 100 % from<br />

renewable raw materials, such as waste and residue fats and<br />

oils as well as vegetable oils – into ethylene and propylene for<br />

Clariant’s products.<br />

In a later phase, the companies will also develop other<br />

sustainable additive solutions derived from renewable raw<br />

materials for plastics and coatings applications. This will<br />

enable the two companies to help various sustainabilityfocused<br />

brand owners – such as those producing furniture,<br />

sporting goods, hygiene products, electronics, and cars – to<br />

increase their bio-based offering while also reducing crude oil<br />

dependency and climate emissions.<br />

“We are proud to join forces with Clariant, one of the<br />

most innovative players in the specialty chemicals industry.<br />

Collaboration marks an essential step forward in Neste’s<br />

quest to become a preferred partner as a provider of<br />

sustainable chemicals solutions for forerunner brands”, says<br />

Peter Vanacker, President & CEO from Neste.<br />

“Combining Clariant’s in-depth knowhow in the varying<br />

applications of adhesives, plastics, and coatings, with Neste’s<br />

extensive knowledge and experience in working with biobased<br />

materials to produce a variety of drop-in renewable<br />

solutions, enables both companies to develop their sustainable<br />

material offering to provide maximum added value not only<br />

to sustainable brands in varying industries but also to their<br />

customers,” Vanacker adds.<br />

“For society, our environment, and future generations, it is<br />

our responsibility to improve sustainability performance and<br />

reduce our carbon footprint and dependency on crude oil. As<br />

a result of Clariant’s partnership with Neste, we can progress<br />

our goal to become a true sustainable solution provider in<br />

the additive market, offering our customers products and<br />

solutions that can make a positive contribution towards their<br />

targets and enhance end applications,” continues Gloria<br />

Glang, Vice President, Head of Global Advanced Surface<br />

Solutions Business at Clariant. MT<br />

www.neste.com | www.clariant.com<br />

8 bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13

Picks & clicks<br />

Most frequently clicked news<br />

Here’s a look at our most popular online content of the past two months.<br />

The story that got the most clicks from the visitors to<br />

bioplasticsmagazine.com was:<br />

re:thinking<br />

plastic<br />

UK judge finds the case for oxo-degradable plastic ‘compelling’<br />

(05 November <strong>2018</strong>)<br />

In a further twist of the oxy-degradable plastics saga, Symphony Environmental<br />

Technologies PLC today (5th November <strong>2018</strong>) heard the news that lawyer and<br />

former deputy Judge of the High Court in England, Peter Susman QC, has declared<br />

the scientific case for oxo-biodegradable technologies to be “clear and compelling”.<br />

A commentary by bioplastics MAGAZINE.<br />

Produced<br />

exclusively from<br />

pure plant-based,<br />

renewable<br />

resources!<br />

Biome Bioplastics'<br />

educational channel<br />

Biome Bioplastics, Southampton, UK, has launched a digital educational channel,<br />

#ThinkBioplastic. The platform aims to help government, media and the public<br />

better understand the complexities of plastics and plastic pollution and learn more<br />

about available alternatives.<br />

#ThinkBioplastic will share content about the whole plastic life cycle (production,<br />

use and disposal) and investigate the science behind recent plastic’s headlines.<br />

It will highlight the role of bioplastic in reducing the negative impact of polymer<br />

manufacture and disposal. All content will be in an easily digestible form.<br />

Biome Bioplastics CEO Paul Mines explains the motivation behind the channel:<br />

“The recent extensive coverage on plastic, while increasing awareness of the<br />

problem, has also increased people’s confusion about the existing solutions. We<br />

decided to take the matter into our own hands and form a necessary back-to-basic<br />

approach that puts the emphasis on science and fact. We hope to cut through some<br />

of the noise in this debate and empower people to make their own choices.”<br />

The channel has already received support from experts in the biobased industry.<br />

Professor Adrian Higson, Director at NNFCC, said the #ThinkBioplastic platform<br />

will help inform individuals about the ‘already available solutions’ to the plastic<br />

problem. He added: “In turn, this can shine a new light on the opportunity that<br />

biobased and biodegradable plastics represent, to shift towards a sustainable<br />

bioeconomy - a move that could eliminate dependency on fossil fuels.”<br />

#ThinkBioplastic will also be working with ambassadors, such as award-winning<br />

wildlife photographer Sue Flood, who has spent almost 30 years as a wildlife<br />

filmmaker and photographer, among others as a member of the team that produced<br />

the acclaimed Blue Planet and Planet Earth documentaries. MT<br />

www.thinkbioplastic.com<br />

Our premium range from<br />

renewable raw materials<br />

With Joma Nature® we offer a select<br />

range of our Spice Grinders and our<br />

Securibox® as an environmentally<br />

conscious alternative to conventional<br />

products – sustainable and CO 2-neutral.<br />

For our environment, we aim to<br />

protect our natural surroundings<br />

and secure a livable world for our<br />

children.<br />

www.jomapackaging.com<br />

bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13 9

Award<br />

And the winner is ...<br />

The 13 th Global Bioplastics Award <strong>2018</strong> was<br />

given to Aakar Innovations for their biobased<br />

sanitary pads for girls and women in rural India<br />

Aakar Innovations Pvt. Ltd. from Belapur, Mumbai,<br />

India developed a fully compostable sanitary pad for<br />

girls and women in rural India. The pads are manufactured<br />

in local decentralized workshop locations by the local<br />

women of the region.<br />

Arunachalam Murugananphan is the social entrepreneur<br />

that made this all happen and received the innovation<br />

award from the President of India. Aakar Innovations<br />

follows in those pioneering footsteps and takes it a step<br />

further by introducing the element of environmental and<br />

social responsibility. Using biobased and fully compostable<br />

materials, Aakar is manufacturing sanitary pads using<br />

rural, low cost manufacturing and also providing jobs to<br />

women in rural villages.<br />

Aakar is a hybrid social enterprise that enables women<br />

to produce and distribute affordable, high-quality, 100 %<br />

compostable sanitary napkins within their communities<br />

while simultaneously raising awareness and sensitization<br />

of menstrual hygiene management. That’s why Aakar<br />

launched a 100 % compostable sanitary pad under the<br />

brand name Anandi.<br />

Anandi is a 100 % compostable sanitary napkin using<br />

biobased compostable polymer film. It uses virgin soft<br />

pine wood pulp containing more than 97 % of cellulose and<br />

hemi-cellulose. The wood pulp as used has pure cellulose<br />

materials with complete uniformity of fibers allowing it to<br />

decompose easily. Activated by an only eco-friendly ozone<br />

treatment process and using compostable bioplastic. The<br />

root sources of the material used is from naturally available<br />

corn starch.<br />

The judges were impressed with the holistic concept,<br />

addressing the social, economic and environmental<br />

elements at the same time. A perfect example of what<br />

sustainability is all about! It is tangible, helping millions<br />

of women in rural India, and shows how bioplastics can<br />

advance the cause of environmental and social justice in a<br />

responsible manner. All bioplastic components are certified<br />

compostable as per EN 13432 or ASTM D6400. A certification<br />

for soil degradability is being awaited and will complete a<br />

truly remarkable story of empowerment, social justice and<br />

environmental responsibility<br />

The prize was awarded to the winning company on<br />

December 4 th , <strong>2018</strong> during the 13 th European Bioplastics<br />

Conference in Berlin, Germany. MT<br />

www.aakarinnovations.com<br />

10 bioplastics MAGAZINE [<strong>06</strong>/17] Vol. 12

Events<br />

bioplastics MAGAZINE presents a first of its kind:<br />

call for papers<br />

Conference on Biobased Materials in Toy Applications<br />

27 - 28 March 2019 - Nürnberg, Germany<br />

The biobased polymer supply chain meets the toy maker industry and trade.<br />

• More than 20 presentations with focus on suitable materials and user experiences<br />

• Background information on regulation / policy, and funding opportunities in EU<br />

• Table-top exhibition of business and technology leaders<br />

• Time and atmosphere supporting business development through dialog<br />

• Media and PR programme to spread the news<br />

• Supported by the German Toy Maker Association DVSI<br />

Driving innovation, sustainability and product safety to the next level.<br />

Explore new ways with biobased plastics.<br />

Confirmed speakers include:<br />

Lego, Bioseries, Bioblo, eKoala, Braskem, FKuR, Tecnaro, Hexpol TPE,<br />

nova-Institute and DVSI<br />

Call for Papers is still open. For updated information and opportunities on programme,<br />

exhibiting, sponsoring, etc. visit the website or contact mt@bioplasticsmagazine.com<br />

Gold Sponsor<br />

Silver Sponsor<br />

Coorganized by<br />

Innovation Consulting Harald Kaeb<br />

supported by<br />

Media Partner<br />

1 st Media Partner<br />

#bio-toy<br />

www.bio-toy.info

Films/Flexibles/Bags<br />

What’s new in<br />

cellulose based films<br />

When Futamura<br />

acquired its<br />

cellulose films<br />

business in 2016, including<br />

the trademark brands<br />

Cellophane and NatureFlex, the<br />

business was already braced for positive change,<br />

with early investment from owners Futamura, the cellulose<br />

films business based in Wigton (Cumbria, UK) and Tecumseh<br />

(Kansas, USA), strengthened its core production facilities<br />

and planned for strategic growth. Then who could have<br />

foreseen that the broadcast of one BBC nature documentary,<br />

Sir David Attenborough’s Blue Planet II, would put the<br />

metaphorical cat amongst the pigeons (or catfish amongst<br />

the shrimp?) turning this plastic world as we know it upside<br />

down and placing a spotlight on bio-material alternatives to<br />

single-use conventional plastics.<br />

Traditionally, renewable and compostable NatureFlex<br />

films are in popular with ethical companies wanting to do<br />

the right thing with their packaging, and increasingly from<br />

new business start-ups who want to get their sustainable<br />

packaging journey kicked off on the right foot, right through<br />

to retailers and large brand owners who are more and more<br />

considering bio-alternatives to conventional plastic films<br />

for main stream brands.<br />

NatureFlex is ideal for flexible applications packaging<br />

fresh produce, as well as dry products such as tea and<br />

coffee. However, there are great success stories when<br />

laminated to other bio-materials such as; The Curiosity<br />

Co. bacon, which has received much attention following<br />

the launch of the UK’s first so-called PLASTIC FREE ® aisle<br />

at the Thornton’s Budgens Bellsize park store in early<br />

November. In addition to bacon packs, NatureFlex was<br />

used by Budgen’s to replace cling film for wrapping their<br />

deli cheese, and could be found in numerous flexible packs<br />

in store ranging from the recently launched Two Farmer’s<br />

crisp range to Tea Pigs.<br />

The Plastic Free Trustmark, created by A Plastic Planet,<br />

states in its criteria that a flexible package must be certified<br />

to the EN13432 standard and / or TÜV Austria Home<br />

compost, making NatureFlex the ideal solution either<br />

on its own or laminated to other certified compostable<br />

biomaterials.<br />

Other applications using NatureFlex films include<br />

pouches, cereal liners, coffee capsules (lidding), and<br />

sachets for tea, coffee, herbs and spices and flow wraps for<br />

chocolate bars, overwrap for yeast, tea cartons and many<br />

more everyday items. MT<br />

www.futamuragroup.com<br />

12 bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13

Automotive Events<br />

bioplastics MAGAZINE presents:<br />

bio PAC<br />

call for papers<br />

Conference on Biobased Packaging<br />

28 - 29 May 2019 - Düsseldorf, Germany<br />

Biobased packaging<br />

» can be recyclable and/or compostable<br />

» fits into the circular economy of the future<br />

» is made from renewable resources or waste streams<br />

» can offer environmental benefits in the end-of-life phase<br />

» can offer innovative features and beneficial barrier properties<br />

» can help to reduce the depletion of finite fossil resources and CO 2<br />

emissions<br />

That‘s why bioplastics MAGAZINE (in cooperation with Green Serendipity) is now<br />

organizing the third edition of<br />

bio PAC<br />

The 2 day-conference will be held on the<br />

28 th and 29 th of May 2019 in Düssseldorf, Germany<br />

Confirmed speakers include:<br />

BASF (Martin Bussmann), Ecoplaza (Steven Iijzerman),<br />

FKuR (Patrick Zimmermann), Novamont (Albertro Castellanza),<br />

Green Serendipity (Caroli Buitenhuis), Bio4pack (Patrick Gerritsen),<br />

Braskem (Marco Jansen), nova-Institute (Michael Carus),<br />

European Bioplastics, narocon (Harald Kaeb)<br />

Call for Papers is still open: Please send your proposal to mt@bioplasticsmagazine.com<br />

supported by<br />

Coorganized by<br />

Gold Sponsor<br />

1 st Media Partner<br />

Media Partner<br />

#bio-pac<br />

www.bio-pac.info

Films/Flexibles/Bags<br />

That’s not my bag –<br />

or is it?<br />

Certified compostable film applications with multiple benefits<br />

and different mechanical and thermal properties. The main<br />

application areas are films for organic waste bags, fruit<br />

and vegetable bags and dual-use bags (first for shopping,<br />

then for organic waste), multilayer packaging materials,<br />

and agricultural films. The certified compostable, partly<br />

biobased plastics are in no way inferior to conventional<br />

materials: they are just as effective and resistant, can be<br />

processed with conventional machinery, and are ideal for<br />

developing innovative solutions.<br />

ecovio F is suitable for producing compostable multilayer films<br />

with good barrier properties for packaging applications like coffee<br />

capsule pouches.<br />

Lightweight, tear-resistant and waterproof – thanks to<br />

their exceptional properties, plastic bags and films<br />

make our lives easier. But when it comes to biowaste<br />

collection, they can contribute to the formation of microplastic<br />

when disposed of together with organic waste. The<br />

EU commission estimates that the recycling rates for thin<br />

plastic bags will not rise above 10 % by 2020. For all applications<br />

that cannot be recycled mechnically, BASF offers the<br />

certified compostable plastic ecovio ® . It can be used to produce<br />

compostable blown films, thermoformable flat films<br />

or multilayer films, for applications as diverse as shopping<br />

bags, food packaging and agricultural films.<br />

Plastic bags and films help to keep food fresh, are a<br />

convenient way of carrying our shopping, and ensure<br />

that waste is disposed of hygienically. But when it comes<br />

to disposal, they cannot always be easily separated into<br />

their individual components for mechanical recycling.<br />

In addition, society is increasingly looking for alternative<br />

product solutions which are environmentally sustainable<br />

but are still just as convenient.<br />

With ecovio, which is made from the compostable and<br />

biodegradable BASF plastic ecoflex ® and polylactic acid<br />

(PLA), BASF developed in 20<strong>06</strong> a biodegradable plastic<br />

which is certified to EN13432 for industrial composting.<br />

Since then a broad range of different ecovio grades has been<br />

introduced into the market, with varying biobased contents<br />

Kitchen and food waste can be hygienically collected in<br />

organic waste bags made from ecovio F, then turned into<br />

compost in industrial composting facilities along with the<br />

bag. Thanks to its good resistance to moisture, liquid does<br />

not leak through, so there is no need to wash out the compost<br />

bin. Because of the material’s excellent tensile strength and<br />

hence load-carrying capacity ecovio F can also be employed<br />

to make shopping bags. They are strong enough to be<br />

reused several times before finally being used as organic<br />

waste bags. Bags and pouches made from ecovio can be<br />

both welded and printed, so they can be clearly labeled as<br />

compostable, for example.<br />

Fruit and vegetable bags made of ecovio are more than<br />

simple carrier bags, too. The blown films can be extruded in<br />

the range from 10 to 12µm. They can be reused as organic<br />

waste bags and thus improve the collection and recovery of<br />

organic food waste. The bags possess high tear and wear<br />

Fruit and vegetable bags made of ecovio possess high tear and<br />

wear stability, are approved for food contact and reduce food<br />

losses due to their good breathability.<br />

14 bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13

Films/Flexibles/Bags<br />

By:<br />

Martin Bussmann, Jörg Auffermann, Dirk Stärke<br />

BASF SE<br />

Ludwigshafen, Germany<br />

Conventional mulch films made of polyethylene (PE) have to<br />

be collected from the fields and recycled after harvesting.<br />

Because of earth and plant remnants sticking to the films<br />

recycling is more difficult or even impossible. Mulch films<br />

made of ecovio M2351 are completely and biologically<br />

degraded by microorganisms like bacteria and fungi that<br />

exist naturally in the soil. Farmers can simply plow the<br />

ecovio mulch films back into the ground along with the<br />

plant debris. This saves time and money.<br />

ecovio M2351 is a ready-to-use compound that can<br />

be processed into soil-biodegradable mulch films on<br />

conventional PE film extrusion lines without the need for<br />

any additional slip or anti-block agents. Because of the<br />

material’s excellent mechanical properties, down-gauging<br />

up to 12, 10 and 8 μm thickness is possible.<br />

Bags made from ecovio can be both welded and printed, so they<br />

can be clearly labeled as compostable, for example.<br />

After more than ten years’ product development, versatile<br />

film applications for different industry sectors can be made<br />

of certified compostable plastics like ecovio. They benefit<br />

from the optimum balance of easy processing, tailormade<br />

material properties and the promotion of a circular<br />

economy.<br />

www.ecovio.basf.com<br />

stability, are approved for food contact and reduce food losses<br />

due to the good breathability of the material. The ecovio bags<br />

also comply with the recent standards in France and Italy for<br />

compostable fruit and vegetable bags made of renewable<br />

resources. In France, for example, single-use plastic bags<br />

that are thinner than 50 µm have to consist of at least 40 %<br />

of renewable resources and be home-compostable. Thus<br />

bags made of ecovio support a safer, cleaner and easier<br />

food waste collection, closing the loop of the food value<br />

chain.<br />

ecovio F is also suitable for producing compostable<br />

multilayer films with good barrier properties for packaging<br />

applications. The bioplastic, which is approved for direct and<br />

indirect food contact, is used as the sealing layer. The other<br />

film layers are also made from compostable materials such<br />

as cellophane. In order to ensure that the entire packaging<br />

can be disposed of together with the food waste and given<br />

to industrial composting, a holistic approach is possible:<br />

so, for example, closures and vent valves can also be<br />

produced from ecovio. Recycling food waste in this way is<br />

more resource-friendly than incinerating it or sending it to<br />

landfill.<br />

Films are not only employed for bags and packaging,<br />

they also have applications in agriculture and horticulture.<br />

Here, mulch films are used to increase the yield, speed<br />

up harvesting as well as to save water and herbicides.<br />

Mulch films made of ecovio M2351 are completey and biologically<br />

degraded by microorganisms like bacteria and fungi that exist<br />

naturally in the soil.<br />

bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13 15

IN THE CIRCULAR ECONOMY,<br />

NOTHING IS WASTED,<br />

EVERYTHING IS TRANSFORMED.<br />

We are moved by improving people’s lives through<br />

sustainable solutions in chemicals and plastics.<br />

HERE IS WHAT BRASKEM<br />

IS COMMITTED TO DOING TOGETHER:<br />

That is why the transition to a Circular Economy—<br />

where everything can be used and reused in a<br />

continuous cycle—moves us to action. And it<br />

starts with education on how we produce and how<br />

Optimize<br />

the design of plastic<br />

products with our<br />

clients and partners<br />

for more efficient<br />

recycling and reuse.<br />

Continue<br />

investing in the<br />

development of<br />

renewable-based<br />

plastic products.<br />

we consume in society.<br />

We know that plastic is essential for our quality<br />

of life, from providing agricultural productivity to<br />

ensuring food safety and hospital hygiene. We also<br />

Develop and<br />

support new<br />

technologies<br />

and methodologies<br />

for recycling.<br />

Promote<br />

conscious<br />

consumption<br />

and recycling<br />

programs.<br />

know that plastic should be used sustainably—<br />

either reused, recycled or reclaimed.<br />

Braskem believes in the strength of this movement<br />

and invites everyone to join us. Each one of us has<br />

a role to play.<br />

Get to know our positioning in full<br />

braskem.com/circulareconomy<br />

Expand<br />

the studies<br />

on Life Cycle<br />

Assessment and<br />

environmental<br />

and climate<br />

impacts<br />

of plastic.<br />

Support<br />

private,<br />

governmental<br />

and academic<br />

partnershipsaimed<br />

at understanding,<br />

preventing<br />

and solving<br />

the problem<br />

of marine<br />

waste.<br />

Support<br />

the measurement<br />

and reporting<br />

of recycling<br />

rates on plastic<br />

packages.<br />

Encourage<br />

comprehensive<br />

science-based<br />

policies to understand<br />

the origins of and to<br />

prevent marine<br />

waste, and to improve<br />

the management of<br />

solid waste overall,<br />

particularly<br />

of plastic.<br />

PASSION FOR TRANSFORMING<br />

16 bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13

©<br />

©<br />

-Institut.eu | <strong>2018</strong><br />

-Institut.eu | 2017<br />

Full study available at www.bio-based.eu/reports<br />

Full study available at www.bio-based.eu/reports<br />

©<br />

-Institut.eu | 2017<br />

Full study available at www.bio-based.eu/markets<br />

Bio- and CO 2 -based Polymers & Building Blocks<br />

The best market reports available<br />

Data for<br />

2017<br />

Bio-based Building Blocks<br />

and Polymers – Global Capacities<br />

and Trends 2017-2022<br />

Bio-based polymers:<br />

Evolution of worldwide production capacities from 2011 to 2022<br />

Million Tonnes<br />

6<br />

5<br />

4<br />

3<br />

Dedicated<br />

Drop-in<br />

Smart Drop-in<br />

without<br />

bio-based PUR<br />

2<br />

1<br />

2011<br />

2012 2013 2014 2015 2016 2017 <strong>2018</strong> 2019 2020 2021 2022<br />

18-05-22<br />

Authors: Raj Chinthapalli, Michael Carus, Wolfgang Baltus,<br />

Doris de Guzman, Harald Käb, Achim Raschka, Jan Ravenstijn,<br />

<strong>2018</strong><br />

This and other reports on the bio-based economy are available at<br />

www.bio-based.eu/reports<br />

Commercialisation updates on<br />

bio-based building blocks<br />

Standards and labels for<br />

bio-based products<br />

Bio-based polymers, a revolutionary change<br />

Comprehensive trend report on PHA, PLA, PUR/TPU, PA<br />

and polymers based on FDCA and SA: Latest developments,<br />

producers, drivers and lessons learnt<br />

million t/a<br />

Selected bio-based building blocks: Evolution of worldwide<br />

production capacities from 2011 to 2021<br />

3,5<br />

actual data<br />

forecast<br />

3<br />

2,5<br />

Bio-based polymers, a<br />

revolutionary change<br />

2<br />

1,5<br />

Jan Ravenstijn 2017<br />

1<br />

0,5<br />

Picture: Gehr Kunststoffwerk<br />

2011<br />

2012<br />

2013<br />

2014<br />

2015 2016 2017 <strong>2018</strong> 2019 2020<br />

2021<br />

L-LA<br />

Succinic<br />

acid<br />

Epichlorohydrin<br />

1,4-BDO<br />

MEG<br />

2,5-FDCA<br />

Ethylene<br />

D-LA<br />

Sebacic<br />

1,3-PDO<br />

acid<br />

11-Aminoundecanoic acid<br />

MPG<br />

DDDA<br />

Lactide<br />

Adipic<br />

acid<br />

E-mail: j.ravenstijn@kpnmail.nl<br />

Mobile: +31.6.2247.8593<br />

Author: Doris de Guzman, Tecnon OrbiChem, United Kingdom<br />

July 2017<br />

This and other reports on the bio-based economy are available at<br />

www.bio-based.eu/reports<br />

Authors: Lara Dammer, Michael Carus and Dr. Asta Partanen<br />

nova-Institut GmbH, Germany<br />

May 2017<br />

This and other reports on the bio-based economy are available at<br />

www.bio-based.eu/reports<br />

Author: Jan Ravenstijn, Jan Ravenstijn Consulting, the Netherlands<br />

April 2017<br />

This and other reports on the bio-based economy are available at<br />

www.bio-based.eu/reports<br />

Policies impacting bio-based<br />

plastics market development<br />

and plastic bags legislation in Europe<br />

Asian markets for bio-based chemical<br />

building blocks and polymers<br />

Market study on the consumption<br />

of biodegradable and compostable<br />

plastic products in Europe<br />

2015 and 2020<br />

Share of Asian production capacity on global production by polymer in 2016<br />

100%<br />

A comprehensive market research report including<br />

consumption figures by polymer and application types<br />

as well as by geography, plus analyses of key players,<br />

relevant policies and legislation and a special feature on<br />

biodegradation and composting standards and labels<br />

80%<br />

60%<br />

Bestsellers<br />

40%<br />

20%<br />

0%<br />

PBS(X)<br />

APC –<br />

cyclic<br />

PA<br />

PET<br />

PTT<br />

PBAT<br />

Starch<br />

Blends<br />

PHA<br />

PLA<br />

PE<br />

Disposable<br />

tableware<br />

Biowaste<br />

bags<br />

Carrier<br />

bags<br />

Rigid<br />

packaging<br />

Flexible<br />

packaging<br />

Authors: Dirk Carrez, Clever Consult, Belgium<br />

Jim Philp, OECD, France<br />

Dr. Harald Kaeb, narocon Innovation Consulting, Germany<br />

Lara Dammer & Michael Carus, nova-Institute, Germany<br />

March 2017<br />

This and other reports on the bio-based economy are available at<br />

www.bio-based.eu/reports<br />

Author: Wolfgang Baltus, Wobalt Expedition Consultancy, Thailand<br />

This and other reports on the bio-based economy are available at<br />

www.bio-based.eu/reports<br />

Authors: Harald Kaeb (narocon, lead), Florence Aeschelmann,<br />

Lara Dammer, Michael Carus (nova-Institute)<br />

April 2016<br />

The full market study (more than 300 slides, 3,500€) is available at<br />

bio-based.eu/top-downloads.<br />

www.bio-based.eu/reports<br />

bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13 17

From Science & Research<br />

PLA in the post-consumerrecycling<br />

stream<br />

The constant increase in global production capacities<br />

of biobased plastics [1] results in a variety of products<br />

made of biobased plastics that reach the established<br />

disposal streams as post-consumer wastes after being<br />

used. In Germany, one of these disposal streams is the collection<br />

and disposal of lightweight packaging waste by the<br />

yellow bin or the yellow bag system. KNOTEN WEIMAR and<br />

TU Chemnitz have investigated the behaviour of biobased<br />

plastic products in the sorting of lightweight packaging<br />

wastes at operating plants and pointed out possible options<br />

for material recycling. The research project was carried<br />

out on behalf of the German Federal Ministry of Food and<br />

Agriculture (BMEL) and funded by the project management<br />

organization Fachagentur für nachwachsende Rohstoffe<br />

(FNR) [2].<br />

The scheme in Fig. 1 gives an overview of the various<br />

disposal routes and the recycling and disposing processes<br />

of various packaging waste as well as the recyclable<br />

material fractions produced. Products made of biobased<br />

plastics can also be integrated into this system.<br />

Sensor-based sorting with near-infrared (NIR) devices<br />

is a key element of modern sorting plants and enables the<br />

sorting of different types of plastics.<br />

Drop-in solutions such as biobased PET and PE, are<br />

sorted out together with conventional equivalents.<br />

However, biobased novel plastics (e.g. PLA, PLA blends or<br />

starch based materials) can also be detected and sorted out<br />

due to their characteristic NIR spectra.<br />

It can be concluded that the sorting of e.g. PLA blends as<br />

representatives of biobased novel plastics as single fraction<br />

is technologically viable. Impurities of the sorted fractions<br />

can thus be kept to a minimum.<br />

In preparation for a practical field test in a conventional<br />

sorting plant, the NIR spectra of several different PLA<br />

blends (plastic yoghurt cups, sheets but also dishes, cups<br />

and bottles) were scanned in the existing NIR devices.<br />

In order to determine the current initial quantity, a sorting<br />

test was first run for lightweight packaging sorting with<br />

approx. 25 tonnes of lightweight packaging input material.<br />

The result showed that the current quantity of products<br />

made from PLA/PLA blends and starch blends in all of the<br />

analysed material streams is predominantly below 1.1 ‰.<br />

A further sorting test (three subtests) investigated the<br />

detectability and sortability or material output of PLA<br />

products/wastes at an operating plant in more detail.<br />

The goal was to determine where PLA materials remain<br />

under unchanged sorting conditions (without positive<br />

sorting of PLA or without activating the PLA spectrum on<br />

the NIR devices) and to test the detectability and sortability<br />

of PLA materials from the post-consumer stream. Cups,<br />

forks and dessert cups were used as PLA input material.<br />

Subsequent to material mixing (Fig. 2) the material was<br />

fed into the sorting process.<br />

Three sorting tests were carried out (see above), the<br />

Fig. 1<br />

Disposal paths and recycling, reutilization and disposal processes of separate packaging wastes<br />

Taking back systems for packaging waste<br />

Deposit systems<br />

PET -Bottles<br />

Light weight packaging via dual systems (yellow bin/bag)<br />

e.g. cups, bowls, bottles, films etc.<br />

Sorting -/Pre-treatment plants (Disposal company), Sorting dry<br />

Process steps a.o. crushing, sieving, metal separation, sensor-based sorting (NIR), air separation, manual control<br />

Products: relevant enriched reusable materials<br />

(incl. impurities caused by sorting performance, material-compounds / -mixtures, residues and pollutants)*<br />

PET PS PE / PP Films MP RDF** Residues<br />

Final recipient plant, Conditioning wet-dry-<br />

Process steps (per material): a.o metal separation,<br />

sensor-based sorting (NIR), crushing, washing,<br />

sink-float separation (separation by density), drying, if any extruding<br />

Sinking<br />

fraction<br />

(ρ > 1)<br />

e.g. PET<br />

Swimming<br />

fraction<br />

Sinking<br />

fraction<br />

e.g. PE / PP<br />

Swimming<br />

fraction<br />

(ρ < 1)<br />

Final recipient plant,<br />

Conditioning dry<br />

Process steps (per material):<br />

a.o. metal separation, crushing,<br />

sieving, air separation, sorting,<br />

if any agglomeration<br />

e.g. Mixed plastics (MKS)<br />

Thermal<br />

treatment<br />

(MVA )<br />

PET<br />

a.o. residues<br />

a.o. residues<br />

PE / PP<br />

z.B. PO<br />

Recyclates,<br />

e.g. PET, PO, PS<br />

(material recycling)<br />

Reductant, gases<br />

and oils<br />

(raw material recycling<br />

e.g. steel plant)<br />

Fuel<br />

(energetic<br />

utilisation e.g.<br />

cement and CHP<br />

station)<br />

Energy<br />

(disposal,<br />

if possible<br />

energetic<br />

utilisation***)<br />

*Specification for individual recyclable material available; **classification as final recipient plant for RDF-production; ***MVA if possible energetic utilisation<br />

18 bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13

From Science & Research<br />

By:<br />

Jasmin Bauer,Carola Westphalen<br />

KNOTEN WEIMAR<br />

Internationale Transferstelle Umwelttechnologien GmbH<br />

Weimar, Germany<br />

Tobias Hartmann, Roman Rinberg,,Lothar Kroll<br />

Technische Universität Chemnitz<br />

Chemnitz, Germany<br />

material first underwent the automated sorting process<br />

and was then manually separated from the fractions.<br />

The following results were achieved:<br />

• Detecting and, in particular, separation of PLA materials<br />

as individual material fraction in a state-of-the-art plant<br />

is possible.<br />

• Sorting under normal conditions for lightweight<br />

packaging (PLA detection not active) approx. 9 % of the<br />

PLA input goes into the PVC fraction. Hence, PLA is<br />

classified as PVC if no PLA spectrum is active.<br />

• Small scale adaption was made by adjusting the plant<br />

technology by scanning the PLA spectra.<br />

• Positive sorting on PLA results in a sorting rate of 55%.<br />

• Positive sorting on PLA+PE/PP extracted 46% of PLA<br />

input.<br />

The generated test material (PLA fraction) was grinded,<br />

washed and the grist was purified to 90 % PLA with the help<br />

of Hamos GmbH (Penzberg, Germany) in the company’s<br />

own pilot plant. The purification took place in three stages:<br />

air separation, metal separation and plastic-plastic<br />

separation. The main contamination after the cleaning<br />

process was adhesive label residues from the yoghurt cup.<br />

As not enough input material was available for the final<br />

regranulation on an industrial plant, a test material (~ 0.8 t)<br />

Fig. 2 Input material (left), automated sorting process (right)<br />

was mixed analogous to the purified fraction. This grist<br />

was regranulated at Sysplast GmbH&Co. KG in Nürnberg,<br />

Germany on a Coperion ZSK 50MC with an Ettlingen rotary<br />

filter ERF (sieve width 250 µm) with throughputs of up to 400 kg<br />

per hour. The impurities were separated effectively and a<br />

green regranulate was obtained (see Fig. 3).<br />

The mechanical testing revealed the following losses<br />

with regard to the virgin material (Ingeo 2003D from<br />

NatureWorks):<br />

Young’s modulus -1 %<br />

tensile strength -24 %<br />

Charpy unnotched -31 %<br />

Charpy notched -17.4 %<br />

All the tests and results mentioned, as well as further<br />

experiments on the recycling of PLA, including a life cycle<br />

assessment, are detailed in the final report of the research<br />

alliance “Nachhaltige Verwertungsstrategien für Produkte<br />

und Abfälle aus biobasierten Kunststoffen” funded by<br />

BMEL in which eight partners from science and industry<br />

participated [3]. A quick overview of the most important<br />

results, as well as further links to the joint project and the<br />

partners, are summarised in the results paper “PLA in the<br />

waste stream” (download link see [4]).<br />

References:<br />

[1] European Bioplastics, nova-Institut (2017). www.biobased.eu/markets<br />

[2] https://www.fnr.de/index.php?id=11150&fkz=22019212<br />

[3] https://www.european-bioplastics.org/pla-in-the-waste-stream/<br />

[4] https://www.umsicht.fraunhofer.de/content/dam/umsicht/en/<br />

documents/press-releases/2017/pla-in-the-waste-stream.pdf<br />

www.bionet.net | www.leichtbau.tu-chemnitz.de<br />

Fig. 3: seperates impurities (left) and green PLA regranulate (right)<br />

bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13 19

Bioplastics from waste streams<br />

By:<br />

Vlaďka Matušková<br />

Project Manager<br />

NAFIGATE Corporation, a.s.<br />

Prague, Czech Republic<br />

Waste Cooking<br />

Oil as a Source<br />

for PHA<br />

Low quality waste cooking oil (WCO) has traditionally<br />

been regarded as a low-value waste product, unfit for<br />

further use. Not by Czech company NAFIGATE Corporation,<br />

however, whose Hydal Biotechnology uses 100 % waste in<br />

the form of waste cooking oil to produce fully biodegradable<br />

PHA biopolymer. The company uses oil also as a source of<br />

energy, making biopolymer significantly more affordable<br />

than bioplastics manufactured from the so-called firstgeneration<br />

feedstock, such as corn or sugar cane. Hence,<br />

the technology is Zero Waste with 50 % less energy<br />

consumption than conventional polyethylene (PE).<br />

Nafigate Corporation’s innovative and patented Hydal<br />

biotechnology has won global acclaim, earning, for example,<br />

the 2015 Frost and Sullivan Technology Innovation Award,<br />

Seal of Excellence, as well as being named one of the Top 10<br />

products in China. It is a technology for upcycling: it takes<br />

a waste product and transforms this into a completely<br />

different product – a biopolymer. The company’s strategy<br />

is based on a production system that is aimed at closing<br />

the loop, in line with the key principle of the concept of the<br />

Circular Economy, which is to retain the value of a material<br />

as long as possible within the cycle.<br />

Moreover, the environmental aspects of this breakthrough<br />

technology have been analysed with the help of Life Cycle<br />

Assessment (LCA), the only tool to objectively assess the<br />

impacts of Hydal PHA manufacturing on the environment.<br />

Due to the Zero Waste production system and use of waste<br />

material, the LCA demonstrated a significant positive effect<br />

of the production of PHB polymers from Waste Cooking<br />

Oil using Hydal’s environmental biotechnology. Compared<br />

to polymers made from first generation feedstock and<br />

conventional polyethylene, Hydal PHA production does<br />

not result in the depletion of natural resources, has a<br />

smaller CO 2<br />

footprint and is not associated with ecotoxicity,<br />

freshwater toxicity, acidification, eutrophication and other<br />

negative environmental impacts.<br />

The final biopolymer can be used in various fields,<br />

including for bioplastics production. Another key area is<br />

the cosmetics industry, for which Hydal PHA provides ideal<br />

properties. Hydal PHA is offered in the form of a whole<br />

range of P3HB particles with a nano surface area of up to<br />

8 m 2 /g. According to the certified analysis, the purity of the<br />

final biopolymer – P3HB or PHBV – is higher than 99 %,<br />

with a high molecular weight. Recently, the company in<br />

cooperation with Nafigate Cosmetics launched a new<br />

product - Coconut shower peeling milk, in which microbeads<br />

have been replaced with Hydal P3HB. As a new cosmetics<br />

eco-design concept, it is being market under the name<br />

“Dedicated to You and Nature” to reflect its biodegradable<br />

and biocompatible properties.<br />

PHA can be also used in the medical sector, since P3HB<br />

particles of varying sizes are able to act as transport<br />

systems for active substances. P3HB is additionally<br />

approved for medical purposes by the FDA. Hydal PHA<br />

enables the production of microfibres with a nano surface<br />

area of 30-40 m 2 /g.<br />

Agriculture is another area, in which Hydal PHA may find<br />

application. Hydal PHA-based enhanced efficiency fertiliser<br />

represents controlled-release fertilizers, which gradually<br />

supply the nutrients to the soil. This controlled-release<br />

technology results in some 50 % less fertiliser being<br />

needed compared to conventional methods (fertilizers<br />

are coated with PHA). Furthermore, waste biomass from<br />

the production process offers another source for fertiliser<br />

manufacturing, while last but not least, phosphorus from<br />

the production process can be recycled.<br />

www.nafigate.com<br />

20 bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13

Bioplastics from waste streams<br />

Life Cycle Assessment on PHB production from Used Cooking Oil<br />

100<br />

80<br />

60<br />

40<br />

20<br />

-0<br />

-20<br />

-40<br />

-60<br />

-80<br />

-100<br />

Abiotic<br />

depletion<br />

Abiotic<br />

depletion<br />

(fossil fuels)<br />

Global<br />

warming<br />

(GWP 100a)<br />

Global<br />

warming<br />

(GWP 100a)<br />

Human<br />

toxicity<br />

Fresh water<br />

aquatic<br />

ecotox.<br />

Marine<br />

aquatic<br />

ecotoxicity<br />

Terrestrial<br />

ecotoxicity<br />

Photochemical<br />

oxidation<br />

Acidification<br />

Eutrophication<br />

PHB LDPE, granulate Polylactide, granulate<br />

Method: CML-IA baseline V3.05/EU25/Characterization<br />

bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13 21

Bioplastics from waste streams<br />

Is Algae a sustainable<br />

feedstock for bioplastics?<br />

As demand for bioplastics grows, the industry is starting<br />

to feel the challenge of finding sustainable biofeedstock.<br />

Algae appears to be a promising source<br />

[1]. Algae can be both grown commercially, or harvested<br />

from commercial and industrial processes, such as water<br />

treatment.<br />

Growing algae commercially for bioplastics<br />

applications<br />

Algae is already commercially grown for nutraceuticals<br />

(e.g. Omega 3 EPA/DHA), cosmetics, food and animal feed<br />

supplements, according to Barry Cohen, President of The<br />

National Algae Association (The Woodlands,Texas, USA).<br />

Cohen notes that algae is a microorganism that doubles<br />

in population every couple of days. Cohen estimates that<br />

an algae producer would need only 60 days to cultivate a<br />

particular strain for client review, testing, and certification.<br />

Another 60-90 days may be required to fulfill a large volume<br />

order suitable for bioplastics. Algae strains suitable for<br />

bioplastics have already been proven in the lab.<br />

Cohen notes that the biggest challenge to growing algae<br />

for bioplastics is finding a client who can fund 30-40% of the<br />

contract price upfront to fulfill a large volume order quickly.<br />

The industry is self-funded and even though producers can<br />

scale easily into commercial production, they have limited<br />

resources to bear large volume production expenditures<br />

alone. Partnerships within the greater supply chain will be<br />

required to get commercially-grown algae into large-scale<br />

bioplastics production.<br />

Harvesting algae from existing water treatment<br />

processes<br />

Algae thrives in our wastewater and other high-nutrient<br />

(i.e. polluted) environments. While its presence helps filter<br />

harmful nutrients out of the water, its overgrowth in nutrientrich<br />

conditions is also a menace [2] to freshwater supplies.<br />

There is a rising demand to contain algae overgrowth<br />

in waterways and reduce the water nutrient levels that<br />

support algae. This can be done while harvesting algae to<br />

generate feedstock for bioplastics and other applications.<br />

Two innovative start-ups are seizing this opportunity:<br />

Working with a wastewater treatment byproduct<br />

Kelvin Okamoto is the Founder and CEO of Gen3Bio<br />

(West Lafayette, Indiana, USA), an innovative company<br />

that converts algae into biofeedstock for resale using a<br />

proprietary blend of enzymes. Okamoto noted that Gen3Bio<br />

harvests the algae from treatment processes that filter<br />

problematic nutrients from wastewater.<br />

Gen3Bio has a mobile pilot facility that hooks into the<br />

nutrient removal systems at wastewater treatment plants,<br />

utilizing its own blends of algae to do the job. Gen3Bio then<br />

harvests the spent algae for processing and resale. The<br />

company plans to share a percentage of net revenue from<br />

the sale of the resulting algae biofeedstock with wastewater<br />

facilities.<br />

The main outputs of Gen3Bio’s operation include sugars,<br />

fats, and proteins from the spent algae. Gen3Bio ferments<br />

sugars extracted from the algae to produce succinic acid.<br />

Succinic acid (cf. bM 03/2013) has multiple uses; among<br />

them, it is a common ingredient in the production of<br />

polybutylene succinate (PBS) (cf. bM 05/2016 and [3, 4]).<br />

PBS is a biodegradable thermoplastic with properties<br />

similar to polypropylene. It is sometimes blended with PLA.<br />

It can be used for the production of both durables (e.g.<br />

fishnets, automotive composites) and non-durables (e.g.<br />

food packaging, disposable cups).<br />

Harvesting algae out of our water supply<br />

While Gen3Bio harvests spent algae from a wastewater<br />

treatment process, Omega Material Sciences filters<br />

problematic algae directly out of the water. Omega Material<br />

Sciences (Lakeland, Florida Area, USA) is an R&D lab that<br />

is working on a large-scale source of algae feedstock for<br />

bioplastics. Its founder, Keith Ervin, has developed a water<br />

treatment media to safely extract algae blooms from both<br />

freshwater and wastewater at high volumes.<br />

Ervin notes that traditional approaches to algae<br />

remediation cannot generate biofeedstock at meaningful<br />

scales because they kill off algae, leading the organism<br />

to emit toxins into the water upon their demise. Ervin’s<br />

method leads to chemical and mechanical separation<br />

of algae blooms from water, making it safe and effective<br />

in producing clean water and harvesting the algae at a<br />

commercial scale.<br />

Ervin has received significant attention from the water<br />

treatment community for his technology. Building the<br />

infrastructure to harvest his algae at scale to feed the<br />

demand for bioplastics will require collaboration and<br />

investment across industries, however. Ervin is looking for<br />

partners and stakeholders to make this happen.<br />

Algae-based materials may already be in your<br />

shoes<br />

Algae is already making an appearance in consumer<br />

products. Algix, a company located in Meridian, Mississippi,<br />

USA, has been producing a plastic composite out of algae<br />

for some years. The algae is combined with traditional<br />

plastics to create Algix’ Solaplast line of resins, which are<br />

approximately 45 % algae. Ryan Hunt, Co-Founder and CTO<br />

at Algix, stated that the algae acts as a biobased filler in<br />

the Solaplast resins, lowering the environmental footprint<br />

of the resulting composite.<br />

22 bioplastics MAGAZINE [<strong>06</strong>/18] Vol. 13

Bioplastics from waste streams<br />

By:<br />

Joanna Malaczynski<br />

Consultant<br />

DESi Potential<br />

Bend, Oregon, USA<br />

Algix’ daughter company, Bloom, converts the algae<br />

composite into an EVA foam that can be used in consumer<br />

goods. Bloom’s algae foam can already be found in some<br />

flip flops, running shoes, and even surfboard traction pads.<br />

The company is launching products with companies such as<br />

Adidas, Altra Running, BOGS, Clark’s, Toms, Vivobarefoot<br />