Pressure Wash News Summer

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

When I Find Myself in<br />

Times of Trouble<br />

Troubleshooting pressure washer<br />

pump problems -- a checklist.<br />

BY JOE ANISH<br />

By following a few simple maintenance procedures,<br />

you can prolong the life of your pressure<br />

pump as well as cut down on untimely<br />

breakdowns.<br />

As a seasoned pressure washer repair veteran,<br />

car wash operator, and a Cat Pump distributor<br />

for more than 35 years, Vilco Supply<br />

Company has serviced and solved thousands<br />

of pressure pump problems over<br />

the past three decades.<br />

Vilco Suppy has seen multiple<br />

pressure washer problems that could have been<br />

prevented, by simply servicing the pump on a<br />

routine schedule and identifying potential problems<br />

while servicing.<br />

One of the most common mistakes, is not<br />

changing the pump oil as often as needed. Vilco<br />

Supply recommends changing pump oil every<br />

200-250 hours of operation. If you do not have an<br />

hourly service time counter on your equipment,<br />

simply use a log entry schedule to keep up with the<br />

operating hours on a daily or weekly basis.<br />

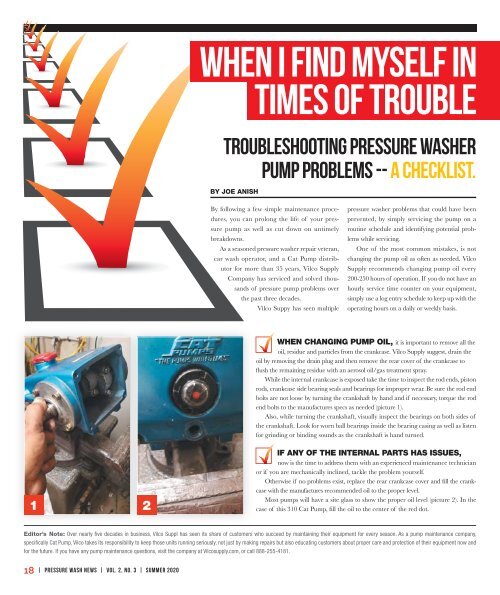

WHEN CHANGING PUMP OIL, it is important to remove all the<br />

oil, residue and particles from the crankcase. Vilco Supply suggest, drain the<br />

oil by removing the drain plug and then remove the rear cover of the crankcase to<br />

flush the remaining residue with an aerosol oil/gas treatment spray.<br />

While the internal crankcase is exposed take the time to inspect the rod ends, piston<br />

rods, crankcase side bearing seals and bearings for improper wear. Be sure the rod end<br />

bolts are not loose by turning the crankshaft by hand and if necessary, torque the rod<br />

end bolts to the manufactures specs as needed (picture 1).<br />

Also, while turning the crankshaft, visually inspect the bearings on both sides of<br />

the crankshaft. Look for worn ball bearings inside the bearing casing as well as listen<br />

for grinding or binding sounds as the crankshaft is hand turned.<br />

1 2<br />

IF ANY OF THE INTERNAL PARTS HAS ISSUES,<br />

now is the time to address them with an experienced maintenance technician<br />

or if you are mechanically inclined, tackle the problem yourself.<br />

Otherwise if no problems exist, replace the rear crankcase cover and fill the crankcase<br />

with the manufactures recommended oil to the proper level.<br />

Most pumps will have a site glass to show the proper oil level (picture 2). In the<br />

case of this 310 Cat Pump, fill the oil to the center of the red dot.<br />

Editor’s Note: Over nearly five decades in business, Vilco Suppl has seen its share of customers who succeed by maintaining their equipment for every season. As a pump maintenance company,<br />

specifically Cat Pump, Vilco takes its responsibility to keep those units running seriously, not just by making repairs but also educating customers about proper care and protection of their equipment now and<br />

for the future. If you have any pump maintenance questions, visit the company at Vilcosupply.com, or call 888-255-4181.<br />

18 | PRESSURE WASH NEWS | VOL. 2, NO. 3 | SUMMER 2020