ASPHALTopics | Spring 2014 | VOL 27 | NO 1

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

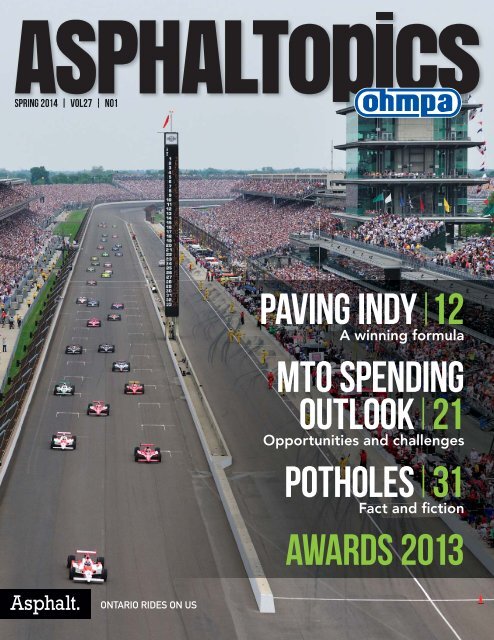

SPRING <strong>2014</strong> | <strong>VOL</strong><strong>27</strong> | <strong>NO</strong>1<br />

Paving Indy | 12<br />

A winning formula<br />

MTO Spending<br />

Outlook | 21<br />

Opportunities and challenges<br />

Potholes | 31<br />

Fact and fiction<br />

awards 2013

The official publication of the<br />

Ontario Hot Mix Producers Association,<br />

Asphaltopics<br />

is published three times a year.<br />

Ontario Hot Mix Producers Association<br />

365 Brunel Rd., Unit 4, Mississauga, ON, L4Z 1Z5<br />

Tel: 905.507.3707 | Fax: 905.507.3709<br />

Email: info@ohmpa.org | Website: www.ohmpa.org<br />

Publications Mail Agreement #40011181<br />

Advertising Sales<br />

Representative<br />

Editor<br />

Design &<br />

Editorial Layout<br />

Cover photo: IMS Photo by John Cote<br />

Patricia Abbas<br />

416.438.7609<br />

pabbas8@gmail.com<br />

Lara Henry<br />

416.638.8294<br />

larahenry@sympatico.ca<br />

pdplante.com inc.<br />

info@pdplante.com<br />

table of contents<br />

Presidential Points | 05<br />

Letters from the ED | 07<br />

Marcom Matters | 09<br />

Meet incoming OHMPA president<br />

Bentley Ehgoetz | 10<br />

New Indy road course a winning formula | 12<br />

Awards recognize<br />

outstanding achievement | 16<br />

MTO spending outlook brings<br />

opportunities and challenges | 21<br />

Warm mix comes of age | 26<br />

Potholes – fact and fiction | 31<br />

Quality control measures<br />

optimize RAP use in HMA | 32<br />

Environmental Essentials | 38<br />

Industry News | 40<br />

The Last Word | 42<br />

SPRING <strong>2014</strong> 3

30 Years

PRESIDENTIAL<br />

POINTS<br />

by Colin Burpee<br />

President, OHMPA<br />

Out with the old –<br />

in with the new<br />

According to the timeworn cliché, every dog has its day.<br />

As I stare down the rapidly approaching end of my tenure<br />

as the 35th president of the Ontario Hot Mix Producers<br />

Association, I can say that I’ve certainly had mine. And<br />

what a day it’s been!<br />

To say the past year has been a whirlwind would be a bit<br />

of an understatement. There’s been a lot of activity here<br />

at OHMPA over the last 12 months. Now as I reach the<br />

end of my presidential road, I can’t tell you how very<br />

proud I feel to have been part of such a professional<br />

and highly regarded organization during such a milestone<br />

point in its storied history.<br />

For 40 years, OHMPA has worked tirelessly as the voice<br />

of authority on behalf of the asphalt producing industry<br />

in Ontario. We’ve certainly come a long way since<br />

our humble roots in 1974 when a group of passionate<br />

industry leaders got together at an airport hotel to lay the<br />

organizational foundations of OHMPA. I doubt any of the<br />

men in the room that day could imagine that four decades<br />

later, their efforts would lead to an association with over<br />

120 members, five staff members and annual events that<br />

consistently attract hundreds and hundreds of people.<br />

I understand that our association has realized its success<br />

as a direct result of the valiant efforts of all those who<br />

came before me: the men in the room on that historic<br />

day in 1974, the 34 presidents who have previously sat<br />

in this position and, of course, the countless volunteers<br />

who selflessly gave their time and attention to OHMPA’s<br />

many committees and boards over the years. I also know<br />

that success will continue under the careful watch of<br />

those yet to come.<br />

Speaking of which, it’s a great honour and pleasure to hand<br />

the reins of our association over to the guy standing behind<br />

me in line — Bentley Ehgoetz of Lavis Construction. You’ll<br />

find a more fitting introduction to him on page 10 of this<br />

issue. Those already familiar with Bentley will know he’s a<br />

stand-up guy with a tremendous passion for our industry.<br />

Those who haven’t had the good fortune to meet him<br />

should make an effort to do so at an event this year.<br />

A freshly minted president isn’t the only new thing you’ll<br />

find around OHMPA these days. As I said, it’s been a busy<br />

year and there have been a lot of things unveiled lately.<br />

For starters, you might have noticed the new design of<br />

the magazine you’re now holding in your hands. A redesign<br />

of our association publication has been long overdue and<br />

the capable OHMPA staff somehow made it happen over<br />

the last couple of months. I think you’ll agree we’ve made<br />

a significant improvement to Asphaltopics that has upped<br />

the game on our stakeholder communications.<br />

Also new is our recently re-launched website<br />

(www.ohmpa.org) which has been designed with<br />

modern mobile technology in mind. If you haven’t<br />

checked it out yet, be sure to do so. There are a lot of<br />

new features including a digital library of Asphaltopics,<br />

volunteer spotlights and up-to-date industry news.<br />

Another canine cliché says you can’t teach an old dog<br />

new tricks. I feel good stepping down and giving<br />

someone else an opportunity to learn those tricks.<br />

This old dog is done!<br />

Colin Burpee is the president of OHMPA for 2013 and<br />

General Manager, Construction of Aecon Construction<br />

and Materials Ltd.<br />

SPRING <strong>2014</strong> 5

WE K<strong>NO</strong>W THE ROAD.<br />

WE’VE BEEN ON IT FOR 100 YEARS.<br />

At Aecon, our road to success has been a century long. We know about seamless<br />

road and bridge construction, the importance of exceptional raw materials and<br />

proven performance value of “just the right” asphalt hot mix.<br />

Superhighways and super structures require superior expertise.

LETTERS<br />

FROM THE ED<br />

by Doug Duke<br />

Executive Director, OHMPA<br />

Let’s get this party started!<br />

Welcome to the new look Asphaltopics!<br />

As part of the celebration of OHMPA’s 40th anniversary,<br />

we wanted to give our publication a fresh new look.<br />

To be frank, we’re considering it a work in progress and<br />

we’re going to continue to refine the design through<br />

the remainder of the year. However, I’m sure you’ll<br />

agree we’ve done a lot of things well out of the gate<br />

starting on the cover with a bold new masthead.<br />

We methodically chose a font with an<br />

appearance and feel more appropriate<br />

for our industry. Like asphalt, it’s strong,<br />

it’s black and it will do the job for many<br />

years to come. I assure you, the life-cycle<br />

cost analysis on it would be excellent!<br />

Turning to the internal contents of the<br />

magazine, we’ve chosen a pleasant editorial<br />

copy font that’s easy on the eyes and makes<br />

reading a breeze. Meanwhile, headlines are crisp<br />

and clean and overall, everything has been tidied up<br />

and compartmentalized in a way that will make more<br />

and more sense with each issue we publish.<br />

It’s been a tremendous team effort to bolster Asphaltopics<br />

and we truly hope you like what you’re seeing. Ours is an<br />

association magazine to be very proud of and our only<br />

goal is to make it better. On that note, we’re open to any<br />

feedback and new ideas and we welcome you to get<br />

in touch if you have any comments or concerns at all.<br />

We’re here to listen.<br />

In the summer 2013 issue, I not-so-subtly hinted we would<br />

be stepping things up this year in recognition of 40 years<br />

of OHMPA. The re-branded magazine you now hold in<br />

your hands is only a small piece of that effort. Our events<br />

this year will also be upgraded starting immediately with<br />

our AGM and Conference taking place at the Trillium<br />

Westin at Blue Mountain in lovely Collingwood.<br />

Watch for a more diverse and interesting line-up<br />

of speakers, a unique video series honouring<br />

OHMPA’s ‘founding fathers’ and a few<br />

other surprises sure to make the event a<br />

memorable experience. Further down the<br />

road, we’ve got a few new tricks up our<br />

sleeves for our <strong>Spring</strong> Operations Seminar<br />

taking place on April 16th and our Road Tour<br />

which is kicking off this year on April 24th in<br />

the City of Guelph and will also visit Kingston<br />

and Sudbury before returning to the GTA.<br />

The anniversary celebrations will continue later this year<br />

as we take our always popular summer golf tournament<br />

to a scenic 36-hole Club Link facility in August. We’ll cap<br />

the year off in true style with our Fall Asphalt Seminar<br />

down in Niagara Falls.<br />

Be sure to keep your eyes open for all the details as they<br />

become available. OHMPA’s 40th anniversary celebration<br />

is just beginning and you’re not going to want to miss<br />

a thing!<br />

SPRING <strong>2014</strong> 7

8 OHMPA | ASPHALTOPICS

MARCOM<br />

MATTERS<br />

by Abigail Wright Pereira<br />

Marketing and Communications Director, OHMPA<br />

www.OHMPA.org – 2.0 *<br />

In 1998, OHMPA made its debut on the World Wide Web.<br />

Back then, businesses were just entering the “wild west”<br />

of the internet and making their presence known with<br />

a website that was sometimes little more than a landing<br />

page with general information. I guess you could say<br />

that those initial websites were barely at the 1.0 stage.<br />

Back then, people still relied on the Yellow Pages to get<br />

business information, and having a business cell phone<br />

meant that you were pretty high up on the corporate<br />

ladder. We’ve come a long way since then.<br />

www.ohmpa.org, there is no mistaking that we represent<br />

excellence in asphalt paving, offer top-notch technical<br />

and educational services and materials, and are heavily<br />

involved in promoting the best of the best through our<br />

awards program.<br />

Fast forward 16 years. From the first brainstorming<br />

session with staff and Marketing Committee Chairs<br />

Mike McLean and Donn Bernal, to the moment our web<br />

design company, Biz-zone, flipped the switch and we<br />

went live January 1, the website was about one year<br />

in the making. Just like the crafting of fine wine,<br />

good things come to those who wait.<br />

The new website was created on a responsive design<br />

platform, meaning that visitors to the site can easily view<br />

content regardless of the device they are using, whether<br />

it is a smart phone or notepad. We now have direct links<br />

to OHMPA’s social media channels, a newsfeed, and an<br />

ability to directly share pages via e-mail or social media.<br />

Additionally, the digital version of Asphaltopics is now<br />

easily accessible and prominently featured. This new<br />

platform will enable our website to easily keep up with<br />

the times as technology changes.<br />

Most important, the new website is the new face of<br />

OHMPA. As we boost our marketing and advocacy<br />

efforts, we want people to come to our website and easily<br />

understand who we are and what we do. When you visit<br />

*Web 2.0 — A second generation in the development of the World Wide Web, conceived<br />

as a combination of concepts, trends and technologies that focus on user collaboration,<br />

sharing of user generated content and social networking.<br />

This initial launch is just the beginning. There will be<br />

several new features to look forward to in the coming<br />

year. By the end of <strong>2014</strong>, the website will feature an<br />

Association and Industry history page, which will include<br />

a gallery of photos, some dating back to the 1920s! We<br />

are also planning to launch a dynamic, animated Story<br />

of Asphalt page, sure to capture audiences in all sectors.<br />

Lastly, to bolster our efforts to bring young talent into<br />

the industry, we will have a new page which will allow<br />

members to view resumes of students interested in<br />

beginning their careers in the asphalt industry.<br />

<strong>2014</strong> started off on a high note with this website and<br />

there’s a lot more to look forward to. Stay tuned and<br />

feel free to reach out to me, abbi@ohmpa.org, with<br />

any questions or comments about the website.<br />

SPRING <strong>2014</strong> 9

Meet incoming<br />

OHMPA president<br />

Bentley Ehgoetz<br />

by Abigail Wright Pereira<br />

A current OHMPA board member with almost 30 years experience<br />

in the construction industry, Bentley is well positioned to lead the<br />

organization as it prepares to celebrate its 40th anniversary.<br />

We sat down with Bentley to talk about his background in the industry,<br />

his involvement with OHMPA, and his priorities for the year.<br />

Q: HOW DID YOU GET STARTED IN<br />

THE CONSTRUCTION BUSINESS?<br />

A: As a kid growing up in Perth County I was involved<br />

with my father’s construction business, Anson Ehgoetz<br />

Excavating Limited, which mainly dealt in aggregates<br />

and dragline operations. I was driving a dump truck<br />

at age 16 even before I had my car license. The<br />

construction business was in my blood and close<br />

to my heart.<br />

Q: GIVEN YOUR FAMILY’S BUSINESS, DID YOU GO<br />

STRAIGHT INTO CONSTRUCTION AFTER COLLEGE?<br />

A: Yes. After graduating from Fanshawe College in 1986<br />

with a degree in Civil Engineering Technology, I was<br />

hired as a construction foreman with the County<br />

of Perth, replacing a gentleman who retired after<br />

50 years. I had some big shoes to fill.<br />

Q: WHILE WORKING FOR THE COUNTY OF PERTH,<br />

HOW DID YOU GET IN<strong>VOL</strong>VED WITH ASPHALT?<br />

A: The county was heavily involved in constructing and<br />

rebuilding its roads using its own people; however,<br />

the paving was contracted out. At the time, the county<br />

didn’t do much testing, but with the help of a former<br />

MTO employee and from neighbouring Huron County,<br />

I set up Perth County’s first asphalt testing lab. Over<br />

the next few years I took numerous MTO and<br />

John Emery courses on hot mix asphalt and road<br />

reconstruction. In 1993, I was awarded the Scott McKay<br />

Memorial Award presented by MTO and the<br />

Municipal Engineers Association, and in 1996 the<br />

County Engineer retired and I was promoted to<br />

Director of Public Works.<br />

Q: WHEN AND HOW DID YOU MAKE THE SWITCH<br />

FROM WORKING FOR THE COUNTY TO BEING<br />

THE DIRECTOR OF OPERATIONS FOR LAVIS?<br />

A: I was talking with Gord Lavis one day about one<br />

of his employees who was moving on. He asked<br />

if I was interested in the position. Lavis was heavily<br />

involved with hot mix and cold-in-place recycling,<br />

which had always interested me. After thinking<br />

about it, I called up Gord and told him I was interested.<br />

I could tell that he was wondering if I knew what it<br />

took to be in the construction business after being<br />

a bureaucrat for 23 years. I assured him that growing<br />

up in the business I knew what it took. I went in the<br />

next day to sign the paper work. I’ve been with Lavis<br />

Contracting Co. Limited ever since January 2009.<br />

Q: WHEN DID YOU FIRST GET IN<strong>VOL</strong>VED<br />

WITH OHMPA?<br />

A: In 2009, OHMPA was looking for a board member<br />

to represent a family-owned business and Gord put<br />

my name forward. I had gone to several seminars<br />

10 OHMPA | ASPHALTOPICS

and golf tournaments in the past, but<br />

other than that I knew nothing about<br />

OHMPA. I joined the OHMPA board<br />

just one month after starting with Lavis<br />

and I felt I was in way over my head—<br />

it was a big learning curve. Gord had<br />

been been president of OHMPA in 1996<br />

and knew how the experience of being<br />

a part of OHMPA was invaluable. It was<br />

the best thing he ever did to move my<br />

career forward. The members were welcoming<br />

and were willing to help bring me up to speed. I still<br />

remember to this day, during my first year at OHMPA,<br />

Joe Bunting of Miller Paving coming up to me and<br />

saying, “Here’s my number. Don’t be afraid to call with<br />

any questions or issues anytime you may need help.”<br />

Q: SINCE JOINING OHMPA IN 2009, IN YOUR<br />

OPINION, WHAT HAVE BEEN OHMPA’S MOST<br />

SIGNIFICANT ACHIEVEMENTS?<br />

A: OHMPA strengthened its relationship with the Ontario<br />

Good Roads Association and its municipal members.<br />

This is really important to our members as the<br />

municipalities represent a large portion of the work.<br />

Bentley Ehgoetz<br />

Director of Operations, Lavis Contracting Co. Ltd.<br />

Director since: 2009<br />

Committee(s): OHMPA Executive Committee<br />

OHMPA/OGRA Municipal Liaison<br />

Committee<br />

OHMPA has also begun to promote the industry. Since<br />

hiring staff to help us in this endeavour, we have been<br />

more proactive instead of reactive in promoting the<br />

asphalt industry.<br />

Q: WHAT ARE SOME OF YOUR GOALS<br />

FOR YOUR YEAR AS PRESIDENT?<br />

A: It will be important to follow through on priorities<br />

identified in our strategic plan which include<br />

governance and advocacy. More important, however,<br />

will be to continue to build relationships with MTO<br />

and municipalities and provide our members the<br />

education they need to continue on producing<br />

a superior product.<br />

SPRING <strong>2014</strong> 11

New Indy road course<br />

a winning formula<br />

by Lisa Fattori<br />

IMS photo(s) by Chris Owens.<br />

Racing enthusiasts can look forward to a newly<br />

paved and modified road course at the world<br />

famous Indianapolis Motor Speedway (IMS) this<br />

season. The upgraded 2.439 mile infield circuit will host<br />

the inaugural IndyCar Indianapolis Grand Prix May 8th<br />

to 10th, as well as MotoGP’s Red Bull Indianapolis GP in<br />

August. The improvements not only ensure the safety of<br />

the course, they make the race more thrilling for drivers and<br />

spectators alike.<br />

“The original course was constructed in 1999, and some<br />

severe cracking had taken place,” says Kevin Forbes,<br />

IMS Director of Engineering. “Unlike highways that have<br />

a constant kneading action, raceways don’t have the<br />

steady traffic and will crack as a result. The geometry<br />

of the course also needed to be changed. Some of the<br />

corners were changed to make the race more competitive<br />

for drivers and therefore more entertaining for spectators.”<br />

Construction of the road course began in September 2013<br />

and was completed in just two months. The scope of work<br />

included milling the existing pavement, with the removal<br />

of five inches of asphalt, and the installation of five inches<br />

of new pavement. Corners one and two of the road course<br />

were completely changed to offer a slight elevation of<br />

approximately three feet. The corners were excavated<br />

down 14 inches and received a seven inch base of crushed<br />

stone, followed by seven inches of new asphalt. The<br />

sections were then married to the existing portions<br />

of the road course that remained in place.<br />

“At first we were going to remove the pavement all at<br />

once, but the base would be damaged from trucks and<br />

machinery,” Forbes says. “Instead, we re-paved the course<br />

in sections, leaving just enough asphalt to work from.”<br />

The elevation changes make for a more varied course and,<br />

although three feet may not seem significant, the change<br />

will enhance competition. “The speedway was built on<br />

Indiana farmland, which is completely flat,” Forbes says.<br />

“The interior road course is already surrounded by a lot<br />

of infrastructure, so it is difficult to find opportunities<br />

where we can create a hump or hill. Three feet is pretty<br />

significant and will make the road course more interesting<br />

and fun for race car drivers.”<br />

Turn 12 of the road course intersects with the warm-up<br />

area of the oval track, which is also the fourth turn of the<br />

MotoGP circuit. To make the geometry of the road course<br />

even more interesting, it is designed to accommodate<br />

IndyCar Series races moving in a clockwise direction,<br />

as well as MotoGP races that run counter clockwise.<br />

The 100 square feet shared space is an engineering feat,<br />

successfully accommodating four paths that cross in the<br />

same location. All pathways have different geometry, both<br />

horizontal and vertical, with certain banking required for<br />

each. The design had 900 data points and demanded<br />

unconventional paving practices to get the desired finish.<br />

“Screed operators tend to think just of drainage, but<br />

this section required the screed to go in four different ››<br />

12 OHMPA | ASPHALTOPICS

ONTARIO’S JAMES HINCHCLIFFE SET<br />

TO RACE ON NEW INDY ROAD COURSE<br />

INDY TRACK<br />

FAST FACTS<br />

· In 1909, the original oval track was paved<br />

using 3.2 million ten-pound bricks and<br />

mortar over a two-inch layer of sand.<br />

The track was nicknamed “The Brickyard”<br />

and, today, three feet of the original bricks<br />

remain at the start/finish line.<br />

· The Indy road course is the only track in<br />

North America that offers both clockwise<br />

and counter-clockwise options in racing.<br />

Clockwise races have five left turns and<br />

nine right turns.<br />

· The total paving area of the Indy road<br />

course is 16.2 acres, which is equivalent<br />

to nearly 16 football fields. The repaving<br />

project required 20,000 tons of asphalt.<br />

Oakville native, James Hinchcliffe, will be<br />

driving for the Andretti Autosport team in<br />

the IndyCar Indianapolis Grand Prix in May.<br />

The three-time winner for the 2013 IndyCar<br />

Series racing season got the racing bug<br />

when he was just nine years old, spending<br />

his weekends go-karting at Goodwood<br />

Kartways, just north of Toronto. At 17, he<br />

made the transition from karting to race car<br />

driving when he was selected to compete<br />

in the North American Formula BMW<br />

scholarship program in Spain—an important<br />

stepping stone that won him recognition<br />

and new opportunities.<br />

As racing’s rising star, Hinchcliffe is a fan favourite who signed on with IndyCar<br />

almost three years ago. “In 2011, I got the opportunity to make my IndyCar<br />

debut after many years of trying to get there,” Hinchcliffe says. “Then, in 2012,<br />

I started in the front row for the Indy 500. These were real career highlights.”<br />

In 2012, Hinchcliffe replaced Andretti team member, Danica Patrick, driving<br />

the brilliant green GoDaddy car. The car was renumbered #<strong>27</strong>, which is<br />

the same number that was used by Canadian drivers Gilles Villeneuve and<br />

Jacques Villeneuve. For the <strong>2014</strong> season, United Fiber & Data has replaced<br />

GoDaddy as Hinchcliffe’s sponsor and fans can look forward to another<br />

exciting racing season with Hinchcliffe sporting the blue and white colours<br />

of the high-tech company.<br />

While Hinchcliffe has driven both the oval and the road course at the<br />

Indianapolis Motor Speedway, he looks forward to trying out the new road<br />

course in the upcoming Grand Prix. “The oval is challenging, but a road<br />

course brings its own set of challenges,” he says. “When you have different<br />

corners and brake zones, it really makes the driver think and makes us<br />

work harder. The new changes to the road course will make the race more<br />

interesting. As drivers, we don’t want a lead-follow race, and neither do<br />

the fans.”<br />

SPRING <strong>2014</strong> 13

Russell Redi-Mix Concrete,<br />

Manitoba and Saskatchewan<br />

14 OHMPA | ASPHALTOPICS

CONTINUED FROM PAGE 12<br />

directions,” Forbes says. “You would think the<br />

area would be all bumpy, but it isn’t. No matter<br />

how you turn, and in what direction, the road<br />

course is smooth.”<br />

The hot mix asphalt (HMA) used for the new course<br />

offers both flexibility and durability, for pavement<br />

that isn’t too soft in summer or too brittle in winter.<br />

A reclaimed asphalt pavement (RAP) content mix<br />

was used in the base and intermediate layers of the<br />

new sections, and in the underlying course of the<br />

rehabilitated area. A pure virgin mix was installed<br />

for the top layer of the entire road course due to<br />

the extremely high friction requirements.<br />

The surface layer includes steel slag<br />

and slag sand, which is an excellent<br />

aggregate because it doesn’t absorb<br />

the asphalt. “We’ve used steel slag and<br />

slag sand before; it’s what we placed on<br />

the oval in 2004,” Forbes says. “It’s been<br />

ten years and we still don’t have a single<br />

crack in that surface.”<br />

Speed is an important factor in<br />

determining the ideal profile of a<br />

race course surface. With highways,<br />

designers and operators look at the<br />

ridability of the surface. A race car,<br />

however, can travel <strong>27</strong>5 feet each<br />

second, making it much more sensitive<br />

to any variations in the pavement.<br />

For this reason, tolerance standards<br />

are very strict, and any areas that need<br />

extra grinding require a finer diamond<br />

head for a much smoother finish.<br />

“When cars are travelling at 187 mph,<br />

speed becomes a consideration,” Forbes<br />

says. “If something goes wrong, it may<br />

not be fatal, but it could be a seasonending<br />

or career-ending accident. It’s<br />

all about the smoothness of the track.<br />

If riders or drivers lose confidence, they<br />

may think that there are other issues with<br />

the pavement and they’ll slow down.<br />

If the surface is rough enough, drivers<br />

could lose control, but it also affects their<br />

confidence and the quality of race that<br />

they give to spectators.”<br />

Lisa Fattori is a freelance writer,<br />

specializing in the construction industry.<br />

QUALITY CONTROL INSPECTION AND TESTING<br />

AGGREGATE SELECTION AND EVALUATION<br />

ASPHALTIC CONCRETE MIX DESIGN<br />

PAVEMENT DESIGN ENGINEERING<br />

GEOTECHNICAL SERVICES<br />

GEOENVIRONMENTAL SERVICES<br />

19 Churchill Drive<br />

Barrie, Ontario L4N 8Z5<br />

(705) 734-3900<br />

Branch Offices<br />

45 Burford Road<br />

Hamilton, Ontario L8E 3C6<br />

(905) 561-2231<br />

16 Franklin Street South<br />

Kitchener, Ontario N2C 1R4<br />

(519) 893-7500<br />

SPRING <strong>2014</strong> 15

y Steve Pecar<br />

Trillium Awards<br />

While other industries are just beginning to introduce<br />

eco certifications and gold standards, the hot mix<br />

asphalt industry has been ahead of the curve, already<br />

meeting the strictest of guidelines. When a plant earns<br />

a Trillium Award they are recognized as being the best<br />

of the best.<br />

Since 2002, 55 plants have earned the Trillium Award<br />

and 35 have been recertified. Trillium Award status<br />

is granted for a three year period at which time the<br />

plant must apply again for recertification.<br />

The nine<br />

Trillium Award<br />

winning plants<br />

are:<br />

Every applicant for the award must comply with<br />

over 100 specific standards and supply supporting<br />

documentation that includes photographs and a short<br />

video. The applicants then go through a rigorous<br />

assessment process in seven categories:<br />

· Appearance<br />

· Operations<br />

· Environmental<br />

· Safety<br />

· Permitting and Compliance<br />

· Community Relations<br />

· Industry Participation<br />

16 OHMPA | ASPHALTOPICS

Accepting the Trillium Award on behalf of their<br />

companies are (from left to right): Jon Stadig,<br />

Glenn Ferguson, Justin Baxter, Ben Dopson,<br />

Amma Wakefield, Murray Ritchie, Karlo Jorgensen,<br />

Jeremy Dunn, George Brown, Glenn Martin.<br />

AECON CONSTRUCTION<br />

& MATERIALS LTD.<br />

Brampton Asphalt Plant<br />

Orangeville Asphalt Plant<br />

Goderich Asphalt Plant<br />

G. TACKABERRY & SONS<br />

CONSTRUCTION CO. LTD.<br />

Tackaberry Asphalt Plant<br />

MILLER GROUP<br />

Lavis Contracting Co. Limited –<br />

Holmesville Plant<br />

Mill-Am Asphalt Plant<br />

The Murray Group – Murphy Plant<br />

The Murray Group –<br />

Bowman Pit, Elora Plant<br />

Smith Construction –<br />

Turcotte Pit Asphalt Plant<br />

Ben Dopson, Propertry/Environmental Coordinator<br />

for Tackaberry, says the Trillium Award means a lot<br />

to his company and indicates hard work is paying<br />

off. “G. Tackaberry & Sons Construction Co. Ltd. is<br />

honoured to have been awarded with OHMPA’s 2013<br />

Trillium Award,” says Dopson in an official statement.<br />

“The implementation of the latest industry technology<br />

at Tackaberry’s new Gencor batch plant has improved<br />

efficiency and aided in maintaining a strong relationship<br />

with the local community.”<br />

Speaking of behalf of the Miller Group, Vice President<br />

Ryan Essex says the Trillium Award sets a high standard<br />

for the industry and is something his group is proud to<br />

receive. “It’s a goal to reach the Trillium status. We see<br />

it as the premier level you can reach because it is voted<br />

upon by your industry peers,” says Essex. “In our group,<br />

each of our managers strives to hit that status. The fact<br />

that we have a number of them is important to the<br />

company.”<br />

Essex adds that the recertifications are just as important<br />

because it shows continued good work. Miller received<br />

four Recertification Trillium Awards effective through<br />

to 2016. They are:<br />

· Miller Group: E.C. King — Sydenham Plant<br />

· Miller Group — New Liskeard Asphalt Plant<br />

· Miller Group — Port Colborne Asphalt Plant<br />

· Miller Group — Whitby Asphalt Plant<br />

Steve Pecar is a Mississauga-based writer,<br />

editor and designer.<br />

SPRING <strong>2014</strong> 17

AWARDS<br />

From left to right: John Blake (Immediate ORBA Past President),<br />

Tom O’Callaghan (Fowler), Deputy Minister of Transportation Carol Layton,<br />

Gilles Truchon (Fowler), Tim Fawcett (Fowler), John McBride (Fowler).<br />

Colin Burpee (left) and Lyle Moran<br />

Paver of the Year Award<br />

The Ontario Road Builders Association (ORBA)<br />

recently announced the Paver of the Year Award<br />

which is presented annually by the Ontario Ministry<br />

of Transportation. The award recognizes excellence<br />

in hot mix paving on a project completed in the<br />

award year. Projects are judged on criteria such<br />

as smoothness, night paving, competition,<br />

workmanship and mix quality, among others.<br />

For 2013, the honour goes to Fowler Construction<br />

Company Ltd. for its project on Highway 60 in<br />

Algonquin Park. Other finalists in this category were<br />

Aecon Materials, Miller Group, and Pioneer Construction.<br />

Tim Fawcett, Divisional Manager of Fowler Construction,<br />

reacted with great pride upon hearing the news which<br />

he had received just a short time before speaking to<br />

Asphaltopics. “This is great; we were really pleased<br />

to hear this,” Fowler said. “Highway 60 was a great<br />

project for us and a lot of people deserve the credit<br />

for a job that was well done.”<br />

Dr. Norman McLeod Award<br />

For 2013, OHMPA presented the Dr. Norman McLeod<br />

Award for Innovation in Road Building. The purpose<br />

of this award is to celebrate and recognize the pursuit<br />

of innovation in the hot mix asphalt industry.<br />

The winner of the award, Lyle Moran, Asphalt Team Leader<br />

for Imperial Oil Sarnia Research Centre, was honoured for<br />

his more than three decades of dedication to the industry<br />

which, through his commitment to the science of asphalt<br />

research, led to industry breakthroughs as recognized<br />

by 12 patents. Recently retired, Moran spent most of his<br />

career in asphalt research and development and technical<br />

marketing services.<br />

It’s an understatement to say that asphalt has played<br />

a significant part of Moran’s life and he has grown to<br />

appreciate so many aspects of it. “The beauty of asphalt<br />

research is that you are involved with the whole gamut,<br />

from the crude coming out of the ground, to the customer<br />

in the field,” he recently commented. “So we are studying<br />

both product and process development.”<br />

Moran’s impact on the asphalt industry in North America<br />

has been significant and will be long lasting.<br />

18 OHMPA | ASPHALTOPICS

RECOGNIZE OUTSTANDING<br />

ACHIEVEMENT<br />

Mark Cosby (left) and Colin Burpee Colin Burpee with Dr. Susan Tighe Colin Burpee with Sandy Brown (right)<br />

Bleeds Black Award<br />

The year 2013 marked the inaugural presentation<br />

of OHMPA’s Bleeds Black Award. Recipients are<br />

those individuals chosen for their commitment<br />

and passion to the continual improvement of<br />

asphalt, one that makes it the pavement<br />

of choice in Ontario.<br />

The name of the award stems from a comment<br />

made by Tim Fawcett of Fowler Construction<br />

Company Ltd. who once said that a colleague’s<br />

passion and commitment to asphalt is so great<br />

that when cut, he “bleeds black.”<br />

There were three inaugural recipients of this award:<br />

· MARK COSBY, Foreman, Vineland Asphalt<br />

Plant, Walker Aggregates<br />

· Dr. SUSAN TIGHE, Professor and Canada<br />

Research Chair, Norman W. McLeod Professor<br />

in Sustainable Pavement Engineering,<br />

Director of CPATT, University of Waterloo<br />

· SANDY BROWN, Technical Director, OHMPA,<br />

and Canadian Regional Engineer for the<br />

Asphalt Institute.<br />

Mark Cosby has been working in the asphalt pavement<br />

industry for more than 25 years. His vast experience and<br />

knowledge of asphalt make him an extraordinary operating<br />

foreman. He is continually looking for improvements in asphalt<br />

production to make the process more efficient, environmentally<br />

friendly, and cost effective, all while maintaining high quality.<br />

Cosby has also shown a great talent for training new employees<br />

and his expertise is being passed along to those whose talents<br />

he has greatly helped to foster.<br />

Dr. Susan Tighe says she was thoroughly shocked when her<br />

name was called during the award presentations. “It caught<br />

me off guard, but I am very honoured,” says Dr. Tighe. She<br />

says she enjoys interacting with those in the industry and takes<br />

great pride knowing that many of her students have gone on<br />

to be leaders in the industry. Dr. Tighe says she tries to mentor<br />

students and attract good people to the field. She believes<br />

this is necessary as the industry needs to recruit qualified<br />

people into the industry, ones who can follow in the<br />

footsteps of current leaders.<br />

Sandy Brown, too, was also caught off guard by the honour,<br />

but appreciates the recognition. “This is the type of industry<br />

where you learn a lot and I like to learn,” Brown says. “It’s very<br />

nice to get an award for doing something that you love and<br />

be honoured by those people who you really respect.”<br />

SPRING <strong>2014</strong> 19

WE DARE TO BE DIFFERENT,<br />

SO YOU CAN BE YOUR BEST.<br />

For More Info<br />

rdtc.co/mcacF<br />

We could tell you about the new innovative features on the Roadtec<br />

Shuttle Buggy MTV like 38% more auger surface area or how all<br />

of the conveyor floors are made of chromium carbide plate. We<br />

could talk about our stronger chains with newer sprockets. But the<br />

thing that really separates us from the others is how we backed it<br />

up with the industry leading EDGE extended warranty; A 3 year,<br />

3,000 hour unlimited warranty that isn’t prorated. Roadtec will<br />

reimburse you for your labor and covers everything but wear parts.<br />

That’s how we DARE TO BE DIFFERENT.<br />

Standard Warranty:<br />

1 YEAR OR 1,000 HOURS<br />

EDGE Extended Warranty:<br />

3 YEARS OR 3,000 HOURS<br />

EDGE Engine Warranty:<br />

5 YEARS OR 6,000 HOURS

MTO spending outlook brings<br />

opportunities and challenges<br />

by Lisa Fattori<br />

Canada’s aging infrastructure has prompted the need<br />

for more effort on bridge rehabilitation and replacement<br />

right across the country. In Ontario, the Ministry of<br />

Transportation (MTO) has been in dialogue with industry<br />

stakeholders to prepare contractors for the upcoming<br />

opportunities and challenges that will present themselves<br />

in road construction in the next five years. A shifting<br />

dynamic within road construction will require ingenuity,<br />

diversification and new partnerships, particularly among<br />

paving companies whose core business has been in the<br />

construction and rehabilitation of provincial highways.<br />

An MTO presentation at the Ontario Road Builders<br />

Association (ORBA) Convention in February, <strong>2014</strong>,<br />

provided a budget update and outlined the geographic<br />

distribution of projects and tender profiles for 2013/14.<br />

The current construction budget is down slightly to<br />

$2.2 billion, from $2.4 billion the year before, with<br />

31 per cent of the budget slated for the central region.<br />

Minor highway projects awarded have dropped from<br />

315 valued at $138 million in 2012/13 to 253 in 2013/14,<br />

at a value of $98 million.<br />

In <strong>2014</strong>, MTO has planned for 82 bridge rehabilitation<br />

projects, with a forecasted 142 projects for 2015. In<br />

subsequent years, to 2018, anticipated bridge rehabilitation<br />

projects fluctuate from 115 to 125 per year. These figures<br />

do not represent bridges that are included in pavement<br />

rehabilitation projects or expansion projects. Nor do they<br />

include structural culverts greater than three metres.<br />

While there is clearly a greater emphasis on bridge work<br />

in coming years, increases in this sector don’t necessarily<br />

mean significant decreases in the amount of paving work<br />

that will be available. “Over the last several years, we’ve<br />

seen an upward trend in spending,” says Shael Gwartz,<br />

Director, Investment Strategies Branch, MTO. “The<br />

increase in the rehabilitation of bridges began about four<br />

years ago, but we’re going to see a significant increase<br />

in the next five years. This work will not be at the expense<br />

of paving projects. I don’t foresee a significant change<br />

in pavement work in the future, based on what the<br />

budget is today.”<br />

Alterations to tender packages and the combination<br />

of bridge and road projects may skew project profiles,<br />

making it difficult to categorize contracts and make<br />

comparisons between paving jobs and bridgework.<br />

“Last year, we put out 300 to 400 contracts, but I don’t<br />

know, off hand, how much of that is just for paving,”<br />

Gwartz says. “We have a mixture of the two. The contracts<br />

we plan on tendering today may change due to many<br />

factors, and then the upcoming budget can always<br />

change our plan. It’s a bit of a moving target.”<br />

Pairing road paving jobs with bridgework means that local<br />

traffic is disturbed only once, and combination projects<br />

are more efficient in delivering shorter construction times<br />

and pooled resources. Road construction, however, has<br />

historically been divided into specialized groups that<br />

include bridge building and road building companies. ››<br />

SPRING <strong>2014</strong> 21

Only Astec has the patented Double Barrel Green ® System.

In the Middle<br />

of Nowhere,<br />

Or in the Middle of Everything.<br />

Astec can configure a plant to fit your site, whether<br />

that site is in the middle of nowhere or in the middle<br />

of a major metropolitan area.<br />

And every Astec plant, no matter where it is located,<br />

is also backed by the Astec Service and Parts<br />

departments available 24/7 anywhere.<br />

Astec is the right choice.<br />

On the big island of Hawaii.

CONTINUED FROM PAGE 21<br />

Even if bridge paving jobs are sub-contracted out<br />

to road paving companies, the projects are relatively<br />

small, requiring less than 1,000 tonnes of paving, compared<br />

to between 15,000 and 30,000 tonnes of paving for<br />

the average road job. The higher cost of new bridge<br />

construction and rehabilitation compared to roadwork<br />

also has paving contractors concerned that the current<br />

level of investment in road infrastructure can’t be<br />

maintained. Greater competition for fewer jobs could<br />

drive down prices, which would reduce the profitability<br />

of awarded contracts.<br />

“Contractors don’t scale up and down at the flip of a<br />

switch,” says Regan Cox, President of Cox Construction<br />

Limited in Guelph. “We invested to make sure that there<br />

was capacity and some of us have 50 per cent or more<br />

of our work going exclusively to the ministry. We’re<br />

cognizant of the fact that a lot of our bridges are reaching<br />

their 50- and 60-year life spans, but we also have more<br />

registered cars in the province than 50 years ago. Also,<br />

this winter is wreaking havoc on our roads, but our current<br />

funding isn’t going to be able to keep up the asset.”<br />

The province’s investment in municipal transit<br />

developments, coupled with awarding contracts<br />

to off-shore companies, further dilutes the funding<br />

available for shave and pave type projects. The City of<br />

Ottawa’s light rail transit (LRT) system, Waterloo Region’s<br />

rapid transit project and the extension of the TTC subway<br />

line to York University and Vaughan have all received<br />

funding, and the Metrolinx initiative, including The Big<br />

Move project, continues to be a priority for the province.<br />

LRT expansions, however, require the expertise of bridge<br />

builders, which may create a shortfall in the workforce<br />

needed for bridge rehabilitation projects.<br />

“Approximately $500 million of the MTO’s budget this<br />

year went to Alternative Financing and Procurement<br />

(AFP) projects, and eventually those payments can<br />

eat into the whole infrastructure budget,” says Geoff<br />

Wilkinson, Executive Director at ORBA. “We have a lot<br />

of LRT projects planned and on the go, which is also a<br />

consideration, because it puts a strain on the capacity<br />

of bridge construction companies when coupled with<br />

this increase demand for bridge rehabilitation. MTO<br />

is aware of this capacity issue and, hopefully, will take<br />

this into account in designing their plans.”<br />

The MTO has tried to shift tendering to the fall and<br />

winter so that contractors can spread out their work<br />

over the construction season, and not have to scramble<br />

to complete projects in the fall. While the year’s early<br />

tenders, from January to March, are on par with last<br />

year’s figures, this spring’s provincial budget will help<br />

contractors plan for the rest of <strong>2014</strong> and beyond.<br />

Partnerships between paving and bridge contractors,<br />

the diversification of core business, and the dissemination<br />

of larger projects into collaborations among smaller<br />

contractors, will help paving operators to weather<br />

a manageable level of budget constraint in the next<br />

few years.<br />

“MTO’s capital budget has grown from $750 million<br />

to $2.2 billion in 10 years, which is unheard of in other<br />

jurisdictions south of the border,” Gwartz says. “We’ve<br />

been able to convey to the province of Ontario the<br />

importance of our bridges and roads to the economy<br />

and we’re striving to reach our performance targets<br />

by tendering all types of projects.”<br />

24 OHMPA | ASPHALTOPICS

WE’RE PAVING THE WAY FOR<br />

THE BEST ROADS IN CANADA.<br />

Quality road construction - efficient, on schedule and at a profit – Nortrax and BOMAG will get you there. We offer<br />

decades of paving, milling and compaction experience and support. Our Cedarapids pavers, CMI reclaimers, and<br />

BOMAG mills and rollers are rock solid machines that will simply exceed your expectations. Partnering with us is<br />

a sure thing for your bottom line. Contact your Nortrax dealer or a BOMAG application specialist today for more<br />

information – you’ll be glad you did!

Warm mix<br />

comes of age<br />

by Steve Pecar<br />

The success of a 56,000 tonne<br />

warm mix project in Algonquin<br />

Park could be the turning point<br />

in ushering in the technology<br />

on a broader basis throughout<br />

Ontario.<br />

The project, a 24-km stretch along Highway 60, was<br />

completed in the fall of 2013 and has already earned<br />

Fowler Construction accolades throughout the paving<br />

world. However, it is the scope of the project, one of the<br />

largest by warm mix asphalt (WMA) standards in Ontario,<br />

which has industry observers taking notice. With a project<br />

of this size producing solid results, all stakeholders are<br />

looking at the prospect of increased use of warm mix<br />

on future road paving sites.<br />

Tim Fawcett, Divisional Manager of Fowler Construction<br />

Company Ltd., believes the use of WMA has progressed<br />

to the point where all levels of governments should be<br />

pleased and that the next steps to broader use can be<br />

taken. He points out that when the Ontario Ministry of<br />

Transportation (MTO) first started calling for warm mix<br />

jobs, they were just small test sections, no larger than<br />

3,000 tonnes. “They wanted to see proof that it worked,<br />

what the fuel savings and environmental impact were,<br />

and all for good reason,” he says.<br />

Now, with the projects getting larger and with answers<br />

to many of these questions, Fawcett says it shows WMA<br />

works. The MTO has taken out some former requirements<br />

and recognizes it as a proven technology that is used<br />

throughout the world. “It’s been acknowledged that<br />

we can produce these new technologies and do so<br />

successfully,” Fawcett says. “We know that we can<br />

produce at the top of our game and give the MTO<br />

what they are looking for with no issues.”<br />

Getting the MTO’s blessing on WMA is important<br />

say many from within the industry. While lower tier<br />

jurisdictions set their own mandates and have their<br />

own jobs to contract out, most look to Queen’s Park<br />

for its expertise and direction. Seyed Tabib, Senior<br />

26 OHMPA | ASPHALTOPICS

Tabib says that after several years of building up the<br />

trials, the side-by-side comparison of warm to hot mix<br />

has been very good, if not better, in some areas, which<br />

is pushing its growth. Tabib adds that since WMA projects<br />

commenced in 2008, about 500,000 tonnes have been<br />

used on provincial highways. However, for <strong>2014</strong> alone,<br />

almost that entire amount — 400,000 tonnes — has<br />

been proposed for projects.<br />

Bituminous Engineer, Bituminous Section, MTO, says<br />

warm mix is a good initiative that is proving to be a winwin<br />

scenario for both the province and asphalt cement<br />

industry. “It saves fuel, produces lower emissions, and<br />

provides a safer work environment,” says Tabib, adding<br />

that public perception of construction sites is changing.<br />

Tabib also points out that <strong>2014</strong> is likely the last year<br />

the MTO will mandate warm mix on selected contracts.<br />

The province changed their specification in 2012 to allow<br />

contractors to use warm mix technology on any hot mix<br />

project. “MTO specification is permissive,” he says.<br />

“If the contractors want to use 100 per cent warm<br />

mix, it is allowed.”<br />

Virgil Gazzolla of Gazzolla Paving Ltd. believes the<br />

time is now for WMA and agrees that the testing and<br />

monitoring periods have shown that it is a technology ››<br />

SPRING <strong>2014</strong> <strong>27</strong>

Albarrie’s Door Seals & Dryer/Drum Seals<br />

have been designed to stop air leaks,<br />

create system efficiency and save you money!<br />

Albarrie’s Door Seal<br />

C (500 F)<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Compliance, Productivity and Investment Protection<br />

Albarrie’s Drum/Dryer Seal<br />

C (932 F)<br />

<br />

<br />

<br />

<br />

<br />

<br />

Toll Free: 1.855.737.3906<br />

www.albarriefiltration.com

CONTINUED FROM PAGE <strong>27</strong><br />

that is continually proven successful.<br />

“Why wait?” asks Gazzolla. “It works.<br />

It’s safe. It’s a better technology. We<br />

should be moving ahead with this.”<br />

Mike McLean of McAsphalt Industries<br />

Limited believes the Highway 60<br />

project is a good indicator of things<br />

to come and points to awards won by<br />

Fowler Construction for the paving<br />

job. McLean says warm mix is a<br />

process revolutionizing the paving<br />

business. He is quick to point out,<br />

though, that hot mix is still very much<br />

in the picture and that both processes<br />

should continue to thrive.<br />

McLean says the hurdle that has to<br />

be jumped for warm mix is the cost.<br />

He says the higher costs involved can<br />

make it prohibitive for some firms and<br />

if they are allowed to choose, they<br />

may go with the less expensive hot<br />

mix methods. McLean adds that the<br />

industry has been working with both<br />

local and provincial governments to<br />

put warm mix in their specifications to<br />

level the playing field. Lanark County,<br />

for instance, has made a commitment<br />

to warm mix even though it may have<br />

to leave room for the higher price<br />

from contractors to do so. “But they<br />

are happy with the results they are<br />

getting and are willing to pay a little<br />

more,” says McLean. ››<br />

There are various technologies that are used in producing<br />

WMA and the process is ever-evolving. As such, the techniques<br />

used on projects throughout Ontario can vary on a company-bycompany<br />

and even a job-by-job basis based on needs and the<br />

technology the contractor is familiar with or has chosen to use.<br />

That being said, there are four general technologies used in warm<br />

mix today and several components of each additive:<br />

1. Organic additives – Sasobit, SonneWarmix, Asphaltan-B,<br />

and Licomont BS-100.<br />

2. Chemical additives – Evotherm, Resiset WMX, Cecabase RT<br />

3. Water-bearing additives – Aspha-min, Advera WMA<br />

4. Water-based processes – Double Barrel Green (Astec),<br />

Green Machine (Gencor), LEA (McConnaughay), WAM Foam<br />

For their large project on Highway 60 in Algonquin Park last year,<br />

Fowler Construction used PG 58-34 asphalt cement with Evotherm 3G<br />

warm mix additive, and an anti-stripping additive. There was also 15<br />

per cent reclaimed asphalt pavement used in the mix.<br />

Tim Fawcett of Fowler Construction believes the technology used was<br />

made to order for such a large project and the positive results can be seen<br />

in the finished work. “Everyone involved was satisfied,” he says. “The crew<br />

found it very easy to work with — there were no problems whatsoever.”<br />

Fawcett says he was pleased with the compaction results and that it<br />

worked well in colder weather, specifically during October temperatures.<br />

There were no complaints of fumes or odours. Further, he says, the warm<br />

mix held up to transportation necessities with loads travelling 53 km from<br />

the Huntsville asphalt plant to Algonquin.<br />

With 13 million tonnes of asphalt used across Ontario for all purposes last<br />

year, Sandy Brown, Technical Director of the Ontario Hot Mix Producers<br />

Association, says there is plenty of room to increase warm mix use. Brown<br />

says WMA benefits can be measured. Better workability and compaction,<br />

late season paving ability, reduced fuel usage, reduced plant emissions,<br />

the reduction of green house gases, increased use of reclaimed asphalt<br />

pavement and improved conditions for workers are all benefits to WMA use.<br />

SPRING <strong>2014</strong> 29

CONTINUED FROM PAGE 29<br />

With the price of the additives and the possibility of plant<br />

retrofits to accommodate the warm mix process, MTO<br />

admits there are higher costs involved with WMA, but for<br />

now will let contractors decide the extent of its use unless<br />

otherwise specified. Ultimately, the key for MTO is to<br />

ensure the best practices are in place to make sure roads<br />

are safe, environmentally friendly, soundly constructed,<br />

long lasting, and created without major disruptions to<br />

drivers — all at a price beneficial to taxpayers.<br />

“We have to look after everyone’s best interest,” says<br />

Pamela Marks, Head, Bituminous Section, MTO. Marks<br />

says the Ministry has to weigh all of the factors in<br />

determining the future of warm mix. And while positive<br />

results have been reported in all sectors, MTO is not<br />

going to force the use of the technology.<br />

“We are allowing it to be a tool in a contractor’s tool box,<br />

something they can use to help them in their process,”<br />

says Marks, adding that the technology is evolving and<br />

MTO has to look at all aspects that may benefit the<br />

infrastructure of the province.<br />

OHMPA’s<br />

40 th Anniversary<br />

Annual General Meeting<br />

Westin Trillium House<br />

Blue Mountain, Collingwood<br />

March 26 th<br />

Reception, President’s Dinner and Auction<br />

for Asphalt Research & Advocacy<br />

March <strong>27</strong> th – AGM<br />

To download the registration brochure for full details,<br />

go to OHMPA’s website www.ohmpa.org<br />

30 OHMPA | ASPHALTOPICS

TECHNICALLY<br />

SPEAKING<br />

by Sandy Brown<br />

OHMPA Technical Director<br />

Potholes – fact and fiction<br />

Thanks to the polar vortex, pothole season arrived a little<br />

early this year. As a result, this winter there has been a lot<br />

of talk in the media about potholes and whether there<br />

could be a cure for what ails the roadways.<br />

The reality is that there is no panacea for potholes.<br />

Potholes typically occur five to seven years after the<br />

road is paved and are the result of water that gets into<br />

the pavement. When the ground freezes, so does the water,<br />

causing expansion. Repeated freezing and thawing of the<br />

water in the pavement structure weakens the surfacing to<br />

the point where the weight of passing vehicles begins<br />

to break up the pavement matrix and a pothole is born.<br />

The key to pothole prevention is to build a durable<br />

road with good drainage, adequate pavement thickness,<br />

and tight longitudinal joints. You also need to properly<br />

maintain the road by sealing the cracks and the longitudinal<br />

joints. If water doesn’t get to the pavement in the<br />

first place, the pothole problem is resolved.<br />

There has also been a lot of talk about the quality of the<br />

asphalt cement in Ontario with references in the media to<br />

“garbage asphalt”. Nothing could be further from the truth.<br />

All asphalt cement used by Ontario municipalities meets<br />

OPSS.MUNI 1101 specifications and this specification is<br />

under constant development. MTO and industry formed<br />

a Binder Task Group in 2006 to look at improving the<br />

performance of asphalt cement used in Ontario. Initially<br />

the group looked at low temperature performance, but<br />

the scope has broadened to include other aspects.<br />

The municipal specification is revised regularly and the<br />

latest revision, issued in November of 2013, is based on<br />

work by the Task Group. The specification incorporates<br />

two new test procedures. The first limits the use of<br />

polyphosphoric acid (PPA) and the second limits the use<br />

Re-refined Heavy Vacuum Distillate Oil (RHVDO) residue.<br />

However, there is no municipal specification in Ontario<br />

for the use of polymers, and in particular elastomeric<br />

polymers, in asphalt cement. Polymer modification<br />

was introduced in North America in the 1970s, but it<br />

wasn’t until we started to specify asphalt cement using<br />

Superpave Performance Grading (PGAC) in the late<br />

1990s that polymer use became more prevalent. PGAC<br />

grading requires the asphalt cement to perform over<br />

a wider range of temperature reflecting different traffic<br />

and environmental conditions.<br />

There is no “new asphalt” as has been referenced in the<br />

media. Higher performance asphalt cements have been<br />

available in Ontario for municipal use since the adoption<br />

of the Superpave specification, but they are seldom asked<br />

for because there is an increase in cost. These materials<br />

are available and specified in OPSS.MUNI 1101 under<br />

what is called grade bumping. While typically only used<br />

on higher traffic roads, products such as PGAC 70-28 have<br />

been available for over 10 years and can be specified on<br />

any project.<br />

The MTO and Industry Binder Task Group have been<br />

studying new test procedures for asphalt cement for the<br />

last seven years. Two different test procedures have been<br />

reviewed: The Double Edge Notched Tension (DENT)<br />

test (using equipment originally introduced in 1910), and<br />

a newer procedure developed in the United States called ››<br />

CONTINUES ON PAGE 36<br />

SPRING <strong>2014</strong> 31

Crushing and fractionation of a bulk excavation RAP pile<br />

Quality control measures<br />

optimize RAP use in HMA<br />

by Lisa Fattori<br />

Reclaimed Asphalt Pavement (RAP) is a proven high<br />

quality product, yet many municipalities are still not<br />

allowing its use in the construction and rehabilitation<br />

of roads within their jurisdictions.<br />

While paving contractors are responsible for ensuring<br />

quality control in the management of RAP stockpiles,<br />

as well as the mix design of hot mix asphalt (HMA) with<br />

RAP, the onus of quality assurance rests with the owner<br />

of a project. Some municipalities that don’t have a quality<br />

assurance program in place or who don’t want to incur<br />

the cost of testing are rejecting RAP altogether. Others<br />

still see RAP as a recycled material that is inherently<br />

inferior. Increased awareness about the benefits of RAP<br />

and a higher level of confidence about its performance<br />

is needed to dispel biases and convince all municipalities<br />

to accept RAP in their pavements.<br />

“Ontario Provincial Standards (OPS) have the same<br />

technical requirements for provincial and municipal<br />

roads,” says Stephen Senior, Head, Soils and Aggregates<br />

Section, Materials Engineering and Research Office at the<br />

Ministry of Transportation (MTO). “The big difference is<br />

in administration. MTO performs tests to ensure quality<br />

assurance, but municipalities may not have the resources to<br />

test. They have to rely on the quality control of contractors.”<br />

RAP has been used in pavements since the 1970s, and<br />

by 1986, 45 per cent of MTO’s annual placement of hot<br />

mix contained RAP. In 2009, the Ministry updated its OPS<br />

recycling policy to allow up to 20 per cent RAP in surface<br />

course mixes and 40 per cent RAP in binder course<br />

mixes, up from 15 per cent and 30 per cent respectively.<br />

Recycled aggregates from the RAP have been previously<br />

tested and evaluated, and are considered to be high value<br />

materials ideal for provincial roads and King’s highways.<br />

Aggregates to be used for high performance surface<br />

layers, where there is a high friction demand, must<br />

come from designated sources. “We’d like to see these<br />

aggregates milled from the surface course going back<br />

into the new surface,” Senior says. “These aggregates<br />

32 OHMPA | ASPHALTOPICS

Four RAP bins<br />

In many cases,<br />

RAP is much more<br />

consistent than virgin<br />

aggregates coming<br />

from quarries.<br />

are coming from quarries in eastern and northern Ontario and have very good<br />

resistance to polishing. The 400 series highways have premium pavements with<br />

higher value aggregates that have excellent frictional properties. That makes<br />

them ideal for highways with heavy traffic and higher speeds.”<br />

Hot mix plants that accept RAP into their yards follow strict quality control<br />

practices to ensure that RAP supplies are free from contaminants. Operators<br />

know where the milled asphalt is coming from, be it a parking lot, municipal<br />

road or series 400 highway. Any questionable material is placed in a<br />

separate pile. At Capital Paving, for example, samples are taken daily during<br />

RAP production and are tested for asphalt cement content and aggregate<br />

gradation. RAP materials are fractionated or separated into dedicated piles of<br />

course and fine material. Fractionation further enhances the consistency of RAP.<br />

“I’ve been involved in processing RAP for 20 years and it’s always been very<br />

consistent,” says Mark Latyn, Quality Control Manager for Capital Paving Inc.<br />

“We take samples every day and test the grade of the material. Fractionating<br />

the RAP helps to minimize the segregation that often occurs in variable sized<br />

aggregate stockpiles.” ››<br />

SPRING <strong>2014</strong> 33

Exclusive Canadian Distributor<br />

Gyratory Compactor<br />

PQI 380 Asphalt Density Gauge<br />

Supplying<br />

Testing &<br />

Monitoring<br />

Instruments<br />

Since 1946<br />

Vancouver (604) 872-7894 Burlington (905) 333-5510 Montreal (514) 735-5267 www.hoskin.ca<br />

34 OHMPA | ASPHALTOPICS<br />

User friendly intuitive software<br />

Real-time display of data<br />

Accepts 300 mm high molds<br />

for AMPT specimens<br />

<br />

Graphical interface with<br />

touch screen<br />

Advanced GPS system<br />

Built in data logger

CONTINUED FROM PAGE 33<br />

Processed and fractionated RAP stockpiles<br />

RAP supplies remain in the region where reclaimed asphalt is milled, which<br />

furthers the predictability about the characteristics of the stockpile. “Because<br />

RAP comes from within a limited geographic area, we see the same materials<br />

from year to year,” says Fernando Magisano, Vice President of Technical<br />

Services for K.J. Beamish Construction Co. Ltd. “For four years running, we<br />

studied our stockpiles in Holt (York Region), Midland, Barrie and Orillia and<br />

found that the average grading was very consistent. In many cases, it’s much<br />

more consistent than virgin aggregates coming from quarries.”<br />

More sustainable road construction using RAP has enormous environmental<br />

benefits: it saves on dwindling aggregate supplies; recycles non-renewable<br />

petrochemical resources; diverts reclaimed asphalt from landfills; and<br />

contributes to provincial and municipal recycling initiatives. While many<br />

municipalities are accepting RAP in binder courses, some are still stipulating<br />

the use of all virgin material in surface layers. Usage varies from jurisdiction<br />

to jurisdiction, with some not allowing<br />

the use of any RAP in the surface or<br />

the binder. While the pending Bill 56,<br />

the Aggregate Recycling Promotion<br />

Act, would help make the usage of<br />

RAP more mainstream, municipalities<br />

need more information and assurances<br />

about RAP to make better informed<br />

decisions.<br />

“When it comes to using RAP, there<br />

is an inherent conservatism by some<br />

municipalities, but people need to<br />

be open-minded about looking at<br />

it,” says Dr. Susan Tighe, Director<br />

of Centre for Pavement and Transportation<br />

Technology at the University<br />

of Waterloo. “If you follow the specs<br />

and do the testing, then you end up<br />

with a very high quality mix. Most<br />

companies are using RAP; it provides<br />

cost savings and is much better for<br />

the environment.”<br />

SPRING <strong>2014</strong> 35

CONTINUED FROM PAGE 31<br />

the Percent Recovery portion of the Multiple Stress Creep<br />

Recovery (MSCR) procedure (using equipment introduced<br />

in the early 1990s). Based on research carried out both<br />

here in Ontario and in the United States, the newer<br />

MSCR Percent Recovery test is a much more reliable<br />

and accurate testing procedure.<br />

These tests help to determine if elastomeric polymers<br />

have been used in the formulation of modified asphalt<br />

cement. Both tests are being evaluated on 33 contracts<br />

in an industry/MTO partnership, testing asphalt cement<br />

<br />

<br />

<br />

<br />

<br />

√ Bulk Lubricant Dispensing<br />

√ Fluid Inventory Control & Management<br />

√ Workbench Tanks<br />

√ Oil & Grease Pumps<br />

√ Control Valves & Dispensing Meters<br />

√ Hose Reels<br />

grades ranging from PGAC 52-40 to PGAC 70-34<br />

all across Ontario. These test sections are full MTO<br />

reconstruction projects, not just trials. The field work<br />

for these projects started in 2010. Now that some of<br />

the contracts are three years old, field inspection of<br />

pavements will be starting. The objective is to look at<br />

the performance over seven to eight years of the initial<br />

pavement life. The monitoring of all the trial sections<br />

will be completed in about five years.<br />

While field performance hasn’t been evaluated yet,<br />

there have been some interesting<br />

conclusions from the laboratory<br />

testing carried out to date. The<br />

conclusion seems to be that it<br />

doesn’t matter which of the additional<br />

procedures (MSCR or DENT) you<br />

specify for acceptance — when you<br />

ask for one value, you also get the<br />

other. Given that finding, in 2012 MTO<br />

adopted a new specification that<br />

includes the MCSR Percent Recovery<br />

for all their projects.<br />

In the meantime, if municipalities<br />

wish to modify their specifications,<br />

any asphalt cement supplier in Ontario<br />

can and will supply material to local<br />

contractors that meets MTO’s Percent<br />

Recovery criteria under MSCR for<br />

modified grades (any grades other<br />

than PG 58-28 or PG 52-34 which<br />

are considered unmodified grades<br />

for lower service pavements). It may<br />

cost a bit more and the performance<br />

advantage hasn’t been fully<br />

determined yet, but the industry is<br />

ready and has been supplying material<br />

meeting that specification for three<br />

or four years.<br />

For Total Lube Solutions,<br />

<br />

Master Distributor for:<br />

Tel 1.800.668.5458 sales@flocomponents.com www.flocomponents.com<br />

Finally, one modifier that may be<br />

used in some grades of asphalt<br />

cement is derived from recycled<br />

and re-refined engine oil. Known as<br />

Re-refined Heavy Vacuum Distillate<br />

Oil residue (RHVDO), this product<br />

comes from a refinery where engine<br />

oil for your car is recycled. This not<br />

the sludge collected from the local<br />

garage, but rather a processed<br />

material that meets engineering<br />

and environmental guidelines.<br />

Using recycled and refined engine<br />

oil residue is a sound environmental<br />

practice instead of burning or<br />

36 OHMPA | ASPHALTOPICS

landfilling the material. The controlled use of RHVDO<br />

residue in asphalt cement not only improves the low<br />

temperature properties according to papers presented<br />

at the Canadian Technical Asphalt Association (CTAA) in<br />

the last two years, it also fits with MTO’s initiatives to have<br />

the greenest roads in North America. This material is not<br />

added indiscriminately as has been suggested. The use<br />

of this material is controlled by the test procedures<br />

adopted in the recent revision of OPSS.MUNI 1101.<br />

Industry and MTO both agree that there is a continual<br />

need for better performing roads and for improved tests<br />

to evaluate asphalt cement. That is what OHMPA and<br />

the industry are striving for by partnering with MTO and<br />

conducting trials. However, the asphalt cement plays<br />

a very small part in the development of potholes which<br />

seems to be the biggest cause for concern whenever<br />

we have one of these harsh winters.<br />

Book<br />

7<br />

Ontario<br />

Traffic<br />

Manual<br />

January <strong>2014</strong><br />

Temporary Conditions<br />

MTO releases<br />

updated Book 7<br />

The Ministry of Transportation<br />

(MTO) has released the final version<br />

of the newly updated Ontario<br />

Traffic Manual Book 7 – Temporary<br />

Conditions for <strong>2014</strong>.<br />

The new Book 7 was posted on<br />

MTO’s website at the end of<br />

January. Print copies will be<br />

available starting April 1st.<br />

Along with the release, MTO made<br />

available a Summary of Changes<br />

document to conduct a gap<br />

analysis between the old and<br />

new versions of Book 7.<br />

Sections 5 and 6 of the manual<br />

contain MTO specifications for<br />

devices and procedures which<br />

are contractually mandatory<br />

on MTO highways.<br />

For further details, please<br />

contact Nadia Todorova at ORBA<br />

(nadia@orba.org) or<br />

(905) 507-1107 ext. 225.<br />

AN AECON COMPANY<br />

YOUR ROAD TO SUCCESS IS PAVED<br />

WITH OUR IN<strong>NO</strong>VATIVE SOLUTIONS<br />

AME Materials Engineering knows the road.<br />

When it comes to pavement engineering<br />

and design solutions, we offer a full range of<br />

analysis, consulting and testing services to<br />

ensure cost-effective strategies for all your<br />

infrastructure expansion and maintenance<br />

needs. Whether the job calls for new<br />

construction, rehabilitation or pavement<br />

preservation, our proven expertise and focus<br />

on green energy technologies are here to<br />

support your success.<br />

AME…AS IN<strong>NO</strong>VATIVE AS THE ROAD IS LONG.<br />

CALEDON<br />

905 840 5914<br />

ame@amecorp.ca<br />

OTTAWA<br />

613 726 3039<br />

ame.ottawa@amecorp.com<br />

SPRING <strong>2014</strong> 37

ENVIRONMENTAL<br />

ESSENTIALS<br />

by Corey Kinart<br />

Ministry releases new<br />

noise guildeline NPC-300<br />

On October 21, 2013, the Ontario Ministry of the<br />