Wood In Architecture Issue 2, 2018

First published in 2017, Wood in Architecture (WIA) is a bi-annual trade magazine devoted to the international timber construction sector. The newest addition to the Panels & Furniture Group of wood magazines, WIA features in-depth insights to the latest industry news, incredible projects and leading trade events. WIA is an advocate for timber as a material of choice for today’s built environment, and is the perfect source of inspiration for architects, builders, engineers and interior designers across the globe.

First published in 2017, Wood in Architecture (WIA) is a bi-annual trade magazine devoted to the international timber construction sector. The newest addition to the Panels & Furniture Group of wood magazines, WIA features in-depth insights to the latest industry news, incredible projects and leading trade events. WIA is an advocate for timber as a material of choice for today’s built environment, and is the perfect source of inspiration for architects, builders, engineers and interior designers across the globe.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BIFA WOOD<br />

VIETNAM <strong>2018</strong><br />

Date: 24-27 October <strong>2018</strong><br />

Venue: Binh Duong Convention<br />

& Exhibition Centre (open ground)<br />

Duong Hung Vuong,<br />

Phu Hoa ward, Thu Dau Mot city,<br />

Binh Duong province, Vietnam<br />

WOOD & WOODWORKING<br />

MACHINERY FAIR<br />

ORGANISERS:<br />

BINH DUONG FURNITURE ASSOCIATION<br />

SUPPORTING MEDIA:<br />

ENDORSED BY:<br />

Binh Dinh Forest Products<br />

Association<br />

Dong Nai Handicraft and <strong>Wood</strong><br />

<strong>In</strong>dustry Association<br />

Vietnam Timber and Forest Product<br />

Association<br />

Jointly organised by<br />

BINH DUONG FURNITURE ASSOCIATION (BIFA)<br />

PANELS & FURNITURE Group<br />

Enquiries For <strong>In</strong>ternational Exhibitors<br />

Pablo Publishing Pte Ltd<br />

3 Ang Mo Kio Street 62 #01-23 Link@AMK<br />

Singapore 569139<br />

Tel: (65) 6266 5512<br />

Email: williampang@pabloasia.com<br />

info@pabloasia.com<br />

OFFICIAL COMPRESSOR:<br />

Taiwan Furniture Manufacturers’<br />

<br />

www.bifawoodvietnam.com

34<br />

14<br />

46<br />

CONTENTS<br />

04<br />

Editor’s Note: Building up<br />

BIG PICTURE<br />

14<br />

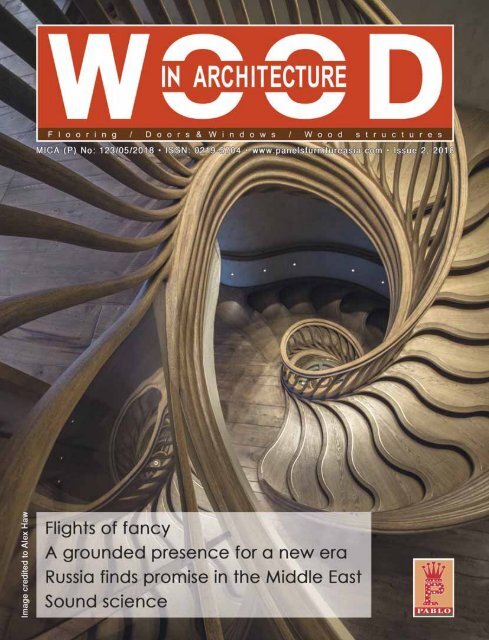

Flights of fancy<br />

ENGINEERED WOOD<br />

24<br />

A grounded presence for a new era<br />

28<br />

A somewhat convoluted collaboration<br />

52<br />

IN PERSON<br />

30<br />

Francis Yan: A tribute<br />

34<br />

Russia finds promise in the Middle East<br />

FIT-OUTS<br />

38<br />

TMT Oak offers new opportunities<br />

2 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

24<br />

56<br />

MATERIALS & TECHNOLOGY<br />

40<br />

<strong>In</strong>terview with Phil Fenwick on Red Oak<br />

42<br />

Living on water<br />

46<br />

Sound science<br />

52<br />

Much ado about saunas<br />

FLOORING<br />

56<br />

Opening a new world<br />

59 SHOW PREVIEWS<br />

63 SHOW REVIEWS<br />

68 CALENDAR OF EVENTS AND<br />

ADVERTISER’S INDEX<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

3

EDITOR’ S<br />

N O T E<br />

Singapore MICA (P) No. 123/05/<strong>2018</strong><br />

panelsfurnitureasia.com<br />

Sarah | Assistant Editor<br />

BUILDING UP<br />

Editor | Pang Yanrong<br />

yanrong@pabloasia.com<br />

Assistant Editor | Sarah Si<br />

sarahsi@pabloasia.com<br />

Assistant Editor | Szeto Hiu Yan<br />

hiuyan@pabloasia.com<br />

Deputy Executive Editor (Chinese Edition)<br />

Wendy Wei | pabloshanghai@163.net<br />

With this second biannual issue of <strong>Wood</strong> in <strong>Architecture</strong>, <strong>2018</strong> feels like it has<br />

flown past quickly – almost too quickly. It’s almost hard to believe we are coming<br />

to the third quarter of the year.<br />

As we look forward, we also look back to the moment how to build stairs, moving irrevocably<br />

upward and onward with stairs of stone, stairs of steel, stairs of wood (p. 14). Similarly,<br />

with knowledge and wood technology built up over the years, architect Kengo Kuma finally<br />

pushed through the controversies surrounding the Tokyo Olympic Stadium with Japanese<br />

cedar and cross-laminated timber (p. 24).<br />

Meanwhile, Russia seeks to expand on its trading ties to the Middle East, and made its<br />

presence felt at the Dubai <strong>Wood</strong>show earlier this year (p. 18), and oak inspires awe in us,<br />

forcing us to appreciate it in its warmth and glory (p. 38 & p. 40).<br />

<strong>Wood</strong> also continues to add to its portfolio, so to speak, providing the high life in Dubai (p.<br />

42) and showing just why it is nigh indispensable for healthy living (p. 52), culture (p. 46),<br />

and even education and (if need be) contemplation (p. 28) – or simply just flooring (p. 56).<br />

Graphic Designer | Edwin De Souza<br />

edwin@pabloasia.com<br />

Admin & Circulation Manager | Shu Ai Ling<br />

circulation@pabloasia.com<br />

General Manager,<br />

Pablo Beijing & Shanghai | Ellen Gao<br />

pablobeijing@163.com<br />

Associate Publisher | Pamela Buckley<br />

pamela@pabloasia.com<br />

Publisher | William Pang<br />

williampang@pabloasia.com<br />

<strong>Wood</strong> in <strong>Architecture</strong> is a member of<br />

But even as we continue on, reaching for ever greater heights, we stop and remember those<br />

who helped us along the way, whether as a mentor or valued colleague, such as Mr Francis<br />

Yan, a gifted architect from Revery <strong>Architecture</strong> who was based in Hong Kong (p. 30). He<br />

had been behind projects such as Arena Stage in Washington D.C., U.S.<br />

And in this era of great growth and change, we look at what is ahead, what we are building<br />

up to, and never forget where we came from, or the wood that we originally built with.<br />

PABLO PUBLISHING PTE LTD<br />

Pablo Publishing Pte Ltd<br />

3 Ang Mo Kio ■ Street 62 ■ #01-23 ■ Link@AMK<br />

Singapore 569139 ■ Tel: (65) 6266 5512<br />

E-mail : info@pabloasia.com<br />

Website : www.panelsfurnitureasia.com<br />

Company Registration No: 200001473N<br />

CONNECT WITH US:<br />

@panelsfurnitureasia<br />

All rights reserved. Views of writers do not necessarily reflect the views of the<br />

Publisher. No part of this publication may be reproduced in any form or by any<br />

means, without prior permission in writing from the Publisher and copyright<br />

owner. Whilst every care is taken to ensure accuracy of the information in<br />

this publication, the Publisher accepts no liability for damages caused by<br />

misinterpretation of information, expressed or implied, within the pages of<br />

the magazine. All advertisements are accepted on the understanding that the<br />

Advertiser is authorised to publish the contents of the advertisements, and in<br />

this respect, the Advertiser shall indemnify the Publisher against all claims<br />

or suits for libel, violation of right of privacy and copyright infringements.<br />

<strong>Wood</strong> in <strong>Architecture</strong> MENA is a controlled-circulation magazine with two<br />

issues a year. It is mailed free-of-charge to readers who meet a set of criteria.<br />

Paid subscription is available to those who do not fit our terms of control.<br />

Please refer to subscription form provided in the publication for more details.<br />

Printed by Times Printers Pte Ltd<br />

4 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

NEWS<br />

STYLISH AND FORWARD<br />

GREENPANEL, INDIA’S largest<br />

manufacturer of wood panels, is now<br />

offering pre-laminated medium-density<br />

fibreboards as well as Club Grade highdensity<br />

fibreboards.<br />

Medium-density fibreboards and highdensity<br />

fibreboards, much like crosslaminated<br />

timber, are engineered wood<br />

products created by crushing hardwood<br />

or softwood and binding it before<br />

applying high temperatures and pressure<br />

to form panels.<br />

Though consisting of separate fibres,<br />

MDF and HDF are typically denser than<br />

plywood, stronger than particleboards,<br />

and can also be used as a building<br />

material.<br />

GreenPanel’s MDF products, coming in<br />

a wide range of stylish and decorative<br />

designs, offer plain solid colours, wood<br />

grains, and even textured finishes<br />

laminated with melamine impregnated<br />

base papers under heat and pressure to<br />

give a super smooth decorative finish. <strong>In</strong><br />

fact, they come in 48 shades and designs,<br />

and textures such as suede and matt are<br />

also available.<br />

Resistant to stains and scratches, the<br />

pre-laminated MDF provides maximum<br />

convenience and saves time with its easy<br />

installation and maintenance. Moreover,<br />

the pre-laminated MDF is impervious to<br />

moisture and climatic changes, and is<br />

thus also highly suitable for applications<br />

where dimensional stability is a vital<br />

factor.<br />

A first choice for applications in areas<br />

prone to moisture such as kitchens and<br />

bathrooms, GreenPanel’s Club Grade<br />

HDF is water resistant, perfect for humid<br />

places, and manufactured in cuttingedge<br />

plants using German technology.<br />

6 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

NEWS<br />

The choice of raw materials coupled<br />

with quality checks at every stage of<br />

manufacturing has resulted in boards<br />

that are heavy-duty, extremely strong<br />

and compact, as well as more easily<br />

profiled, carved, moulded and routed than<br />

plywood, making it a perfect substitute.<br />

Where plywood is vulnerable to<br />

woodworm, GreenPanel’s Club Grade HDF<br />

is anti-fungal, termite and borer resistant,<br />

and denser than plywood. Moreover, the<br />

Grade HDF is extremely cost-effective and<br />

comes at half the price of plywood. | WIA<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

7

NEWS<br />

WINNERS OF THE ARCHITIZER ANNUAL<br />

A+AWARDS ANNOUNCED<br />

CityLife Shopping District by Zaha Hadid Architects.<br />

Image credited to Zaha Hadid Architects<br />

ARCHITIZER, the world’s leading online<br />

resource for architecture and building<br />

products, has announced the winners of<br />

the 6 th Annual Architizer A+Awards.<br />

The A+Awards honour the best<br />

architecture, spaces, and products from<br />

across the globe, and this year’s winners<br />

include CityLife Shopping District by<br />

Zaha Hadid Architects, in Milan, Italy,<br />

and Chicago’s Apple Flagship Store by<br />

Foster + Partners; and Confluence Park by<br />

Lake|Flato, in San Antonio, Texas, United<br />

States (U.S.) among many others.<br />

The Gardens by Marge Arkitekter AB.<br />

Image credited to Marge Arkitekter AB<br />

This year, the A+Awards received over<br />

5,000 entries from over 100 countries. A<br />

jury-selected winner and a popular choice<br />

winner were awarded in each of the 98<br />

categories, with popular choice winners<br />

determined by more than 400,000 public<br />

votes cast from around the world.<br />

With projects from the Netherlands,<br />

Mexico, the U.S., China and Denmark, these<br />

Honourees demonstrated extraordinary<br />

contributions to the profession across the<br />

globe, highlighting projects that champion<br />

architecture’s potential to positively<br />

impact everyday life.<br />

<strong>In</strong> addition to the Jury and Popular Choice<br />

winners, Special Honouree Awards for<br />

achievement were awarded to five key<br />

influencers, including MVRDV for Firm of<br />

the Year and the Waterside Buddhist Shrine<br />

by ARCHSTUDIO for Project of the year.<br />

“The Award is an incredible honour. Every<br />

project we undertake excites us, either<br />

because it allows us to rethink standard<br />

typologies or because it offers new modes<br />

of engagement with communities. To<br />

be recognised for work that you deeply<br />

<strong>In</strong>visible Studio - Trailer by Jim Stephenson<br />

Architectural Photography + Films.<br />

Image credited to Jim Stephenson Architectural<br />

Photography + Films<br />

8 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

NEWS<br />

The Stable, designed by Studio Farris Architects.<br />

Image credited to Studio Farris Architects<br />

believe in is incredibly rewarding,” said<br />

2017 Honouree, Sir David Adjaye.<br />

The Conversation Plinth, the first hardwood cross-laminated timber structure built in the U.S.<br />

Image credited to IKD<br />

Back for its fourth edition, Phaidon’s<br />

annual compendium ARCHITIZER: The<br />

World’s Greatest <strong>Architecture</strong> will feature<br />

<strong>2018</strong> winners from the Typology and Plus<br />

Categories. This stunning hardbound<br />

book will be released in early 2019 and<br />

is the definitive guide to the year’s best<br />

buildings and spaces. | WIA<br />

Embodied Computation<br />

Lab, an interdisciplinary<br />

research facility.<br />

Image credited to The<br />

Living<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

9

NEWS<br />

SINGAPOREAN STUDENTS AT KTH ROYAL<br />

INSTITUTE OF TECHNOLOGY IDENTIFY NEW<br />

APPLICATIONS FOR SWEDISH PINE<br />

IN collaboration with industry<br />

organisation Swedish <strong>Wood</strong>, 27 students<br />

on the Entrepreneurship and <strong>In</strong>novation<br />

Management programme at KTH, most of<br />

them Singaporean, were asked to develop<br />

applications for Swedish pine. Creative<br />

solutions to social problems and strong<br />

ties to both nature and health can be seen<br />

in what the students produced.<br />

Tasked with identifying and developing<br />

new products in Swedish pine for the<br />

interior and lifestyle sector, they worked<br />

in teams of three or four, and were given<br />

around three months to complete the<br />

project.<br />

“The students demonstrated great interest<br />

in, and curiosity, about pine, which was<br />

a new material to most of them. They<br />

were particularly interested in the fact<br />

that Swedish pine is a renewable and<br />

natural material that contributes to a<br />

more sustainable lifestyle. It’s clear that<br />

environmental issues are important to<br />

this generation,” said Charlotte Dedye<br />

Apelgren, Director of <strong>In</strong>terior & Design at<br />

Swedish <strong>Wood</strong>.<br />

“Building the course around a concrete<br />

challenge from Swedish industry really<br />

engaged both the students and Swedish<br />

<strong>Wood</strong>, and that translated into very<br />

exciting end results,” Professor Björn<br />

Berggren of KTH explained.<br />

Swedish <strong>Wood</strong> has seen the students’<br />

presentations, which range from smart<br />

office solutions and musical instruments to<br />

window glass made from wood fibre. | WIA<br />

<strong>Wood</strong>3 by Pine Nordic, a group which presented a smart interior solution for offices in China.<br />

Image credited to Swedish <strong>Wood</strong><br />

RUSSIAN PLYWOOD USED FOR THE CONSTRUCTION<br />

OF GAS TANKERS FOR THE FIRST TIME<br />

VEZA Company, the world leader<br />

in birch plywood production, has<br />

completed shipments of products for<br />

the construction of a gas super tanker<br />

in Hudong-Zhonghua shipyard in China.<br />

Russian plywood was used for the<br />

manufacturing of gas carriers for the<br />

first time.<br />

The shipments were carried out as a part<br />

of Yamal LNG Project, and there are plans<br />

to construct one more tanker with the use<br />

of SVEZA’s products within that project.<br />

A specialised product, SVEZA Gas NO96,<br />

was provided for the construction of<br />

the carrier. Plywood acted as the main<br />

structural element of the LNG tankers,<br />

taking most of the load from the movement<br />

of liquefied gas during transportation.<br />

Characterised by low thermal conductivity<br />

and, as a consequence, the ability to<br />

withstand extreme temperatures from<br />

+80 ° C to -163 ° C, SVEZA Gas NO96<br />

is made of 100 per cent birch veneer in<br />

accordance with the BB/BB criteria.<br />

Produced on SVEZA’s production<br />

site in Saint Petersburg, SVEZA Ust-<br />

Izhora Combine passed the necessary<br />

certification of Gaztransport & Technigaz<br />

(GTT) that implies strict requirements not<br />

only towards product performance, but<br />

also towards technological processes,<br />

diversification of production and quality<br />

of raw materials.<br />

It was the first time Hudong-Zhonghua<br />

shipyard manufactured a vessel for Yamal<br />

LNG Project. | WIA<br />

10 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

NEWS<br />

MORE CHINESE WOOD PRODUCTS ADDED<br />

TO TRUMP’S FUTURE MASSIVE TARIFF LIST<br />

AS the trade war between the United<br />

States and China heats up, U.S. President<br />

Donald Trump has listed more than<br />

US$200 billion worth of Chinese<br />

exports to the U.S. that may be<br />

subjected to new tariffs come end of<br />

August.<br />

Figures from China’s Customs Department<br />

shows the value of wood products trade<br />

between China and the U.S. fell 16 per<br />

cent in March <strong>2018</strong>. China’s imports fell<br />

by five per cent, though first quarter data<br />

showed a nine per cent rise in Chinese<br />

exports of wood products. China's imports<br />

rose six per cent to US$2.28 billion in the<br />

first quarter of <strong>2018</strong>, while its exports<br />

to the U.S. rose 10 per cent to US$3.98<br />

billion. | WIA<br />

The list is massive and includes industrial<br />

goods and chemicals, consumer<br />

products, and wood products, and if<br />

it comes into effect, tariffs would be<br />

imposed on just under 50 per cent of<br />

all Chinese imports, according to the<br />

<strong>Wood</strong>working Network.<br />

<strong>Wood</strong> products that will face duties<br />

include oak, beech, maple, ash, cherry,<br />

mouldings, particleboards, and even<br />

various types of plywood.<br />

The proposed tariffs would be on top<br />

of 25 per cent tariffs that the Trump<br />

administration has already implemented<br />

on US$50 billion of Chinese goods:<br />

US$34 billion of which took effect on July<br />

6. China had vowed to retaliate.<br />

Because China imported just US$130<br />

billion worth of products from the U.S.<br />

last year, it is an unequal fight to fire back<br />

with matching tariffs.<br />

U.S. companies in China have already<br />

reported spikes in delayed product<br />

approvals, worker visas, and licensing<br />

applications. Cases of Chinese officers<br />

ordering seemingly random products<br />

have resulted in quarantines for certain<br />

products, and a surge in random border<br />

inspections was also reported.<br />

The <strong>In</strong>ternational Tropical Timber<br />

Organisation has also reported that<br />

trade of wood products between China<br />

and the U.S. are declining.<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

11

NEWS<br />

STRONG EXHIBITOR LINE-UP FOR LIGNA 2019<br />

THE next LIGNA may be staged only<br />

from 27 to 31 May next year, but its<br />

organisers, Deutsche Messe and the<br />

German <strong>Wood</strong>working Machinery<br />

Manufacturers’ Association (VDMA<br />

Holzbearbeitungsmaschinen), have<br />

announced that exhibitor registrations<br />

are coming in at a very pleasing pace.<br />

While opening day is still more than half<br />

a year away, exhibition space at the<br />

world’s leading trade fair for machinery,<br />

plant and tools for the woodworking and<br />

timber processing industry is already<br />

more than 80 per cent booked. To put<br />

that in perspective, LIGNA 2017 featured<br />

1,520 exhibitors and occupied 130,000<br />

square meters (1,400,000sqft) of display<br />

space.<br />

“I'm pleased to say we’re getting lots<br />

of first-time exhibitors, not to mention<br />

plenty of repeat exhibitors, many of whom<br />

are staging bigger displays this time<br />

around. What’s more, the outstanding<br />

response exhibitors are showing for the<br />

event serves as confirmation that we<br />

made the right move in 2017, at which<br />

time when we completely revamped the<br />

site, the layout of display categories<br />

and thus the locations of virtually every<br />

single exhibitor,” commented Christian<br />

Pfeiffer, Deutsche Messe’s Global Director<br />

LIGNA& <strong>Wood</strong>working Events.<br />

“Next year, the majority of the exhibitors<br />

will be retaining the locations they had<br />

in 2017 following the big change. The<br />

Surface Technology display launched in<br />

2017 will be home to a number of firsttime<br />

exhibitors in 2019. Companies from<br />

around the world are so eager to exhibit<br />

at LIGNA because they know it is the very<br />

best option when it comes to showcasing<br />

new products, presenting full-fledged<br />

plant and machinery in action, as well<br />

as for networking and comparing notes<br />

with industry peers.”<br />

LIGNA, the leading trade fair for machinery, plant and tools for the woodworking.<br />

Image credited to Deutsche Messe AG<br />

One of the regular LIGNA features automation and digitisation in combining<br />

is the <strong>Wood</strong> <strong>In</strong>dustry Summit. Just the customer-centricity of product<br />

looking at the summit's three focus individualisation with the economies of<br />

themes – “<strong>In</strong>tegrated <strong>Wood</strong>working – scale of large-series production. As well<br />

Customised Solutions”, “Smart Surface as enabling cost-effective batch-size-one<br />

Technologies” and “Access to Resources production, these smart woodworking<br />

and Technology” – it is clear that the and timber processing technologies are<br />

upcoming show will be strong on hightech<br />

highlights and innovations. From efficiency.<br />

yielding gains in energy and resource<br />

various angles, each of the show’s display<br />

categories will explore digitisation as the There is a great deal of interest in these<br />

engine and driving force of innovation in technologies at the moment, with the<br />

the wood industry.<br />

business climate looking very positive<br />

and the German <strong>Wood</strong>working Machinery<br />

“Timber processing and woodworking Manufacturers’ Association reporting<br />

are no longer just about standalone healthy order books for <strong>2018</strong>. The<br />

machines. <strong>In</strong>stead, what we have now United States and China – the two most<br />

are digitally integrated processes and important export markets for high-tech<br />

systems built around machines. LIGNA woodworking machinery – are forecasted<br />

2019 will thus traverse a wealth of reallife<br />

applications, with a strong focus digitisation, the main drivers of this<br />

to grow 8 per cent this year. Apart from<br />

on machine demonstrations and the boom for wood-industry technology<br />

innovative power of digitisation and suppliers are the worldwide megatrends<br />

automation,” Pfeiffer added.<br />

of sustainable building and urbanisation.<br />

<strong>In</strong> terms of attendance, the organisers are<br />

Highly integrated, interconnected predicting a strong turnout, particularly<br />

industrial processes pose a number from Germany, Poland and China –<br />

of new challenges. These, too, will be countries which in 2017 ranked among<br />

explored at LIGNA, because taking the show’s Top Five visiting nations.<br />

digitisation seriously and spotting its | WIA<br />

opportunities are vital to recognising and<br />

adopting new business models. The show<br />

will have a strong focus on the role of<br />

12 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

NEWS<br />

TIMBER SHORTAGE IS AFFECTING AUSTRALIAN BUILDERS<br />

AUSTRALIAN builders and timber<br />

suppliers looking to use local wood<br />

products are finding that supply has been<br />

running out recently, according to the<br />

Naracoorte Herald.<br />

Naracoorte-based builder Paul Russell<br />

said that a shortage of local timber in<br />

the region is believed to be a result of<br />

excessive exporting of logs from Portland.<br />

Now, builders and carpenters have to<br />

make do with imported laminated timber<br />

from Europe, and though the quality<br />

is the same, Russell still prefers if it<br />

is local.<br />

“We went down to get some from one of<br />

our suppliers and all we wanted was 30<br />

lengths of timber and we couldn’t get it,”<br />

Russell explained. “They just didn’t have<br />

the 30 lengths of timber and they are all<br />

back ordered.”<br />

An anonymous local supplier said the<br />

shortage is unusual with local mills<br />

exporting logs, and businesses having to<br />

import timber back into the country due<br />

to shortages in supply.<br />

Russell also questions whether supply<br />

is fairly allocated: “Logs are being taken<br />

straight out to Portland to be exported<br />

and it is terrible that we have the supply<br />

down here but my question is, is there<br />

a certain amount left or allocated for<br />

domestic use?”<br />

The source of the timber stock has also<br />

been reported to come from Western<br />

Australia, yet this supply is only around 5<br />

per cent of what is used.<br />

“The quality of timber is the same,” said<br />

Russell, “but we use local plumbers and<br />

local electricians, so we would like to use<br />

local timber as well.”<br />

There are also reports there is about to<br />

be a blanket nine per cent increase in the<br />

cost of timber, which, according to Russell,<br />

means prices of housing will also rise by<br />

almost 10 per cent. The cost of jobs will<br />

go up as well, and a large house will cost<br />

an extra AUD$2,000 to AUD$2,500 just for<br />

the framing and trusses. | WIA<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

13

BIG PICTURE<br />

FLIGHTS OF<br />

FANCY<br />

As old as mankind, stairs are integral to<br />

daily life. They can suggest journeys, link<br />

two levels together, and can be constructed<br />

in various ways, like a spiral shape or the<br />

more traditional straightforward steps.<br />

Found in today’s modern homes all the way<br />

to ancient temples, these steps carry us all<br />

somewhere. However, some architects have<br />

decided on wood to heighten enjoyment,<br />

making climbing stairs less of an arduous<br />

journey and more of a pleasurable one.<br />

14 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

BIG PICTURE<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

15

BIG PICTURE<br />

16 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

BIG PICTURE<br />

31 RUE<br />

CAMBON IN<br />

WOOD<br />

Drawing inspiration from Coco Chanel’s famous<br />

mirror staircase in her French home, ACME’s<br />

staircase is twisting and dynamic.<br />

ACME’s wooden staircase in its studio, located in London, is<br />

everything but straightforward and conventional. Almost the<br />

complete opposite, the stairs are instead wildly twisting, and<br />

was specifically designed to give people a lively, convivial place<br />

to stop, interact, and engage with others.<br />

But one incredibly unique aspect of the staircase is that its shape<br />

provides its own structural integrity, with no reliance on either<br />

the top or bottom of the stairs. <strong>In</strong>stead, it is a freestanding, selfsupporting<br />

structure built of layers of cross-laminated timber<br />

and fixed with screws.<br />

The project, more than showing wood’s capability, also shows<br />

that a simple, single material can be used to produce a space<br />

that is practical, yet still beguiling and exquisite.<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

17

BIG PICTURE<br />

SPROUTING<br />

UP LIKE A<br />

STALK<br />

<strong>In</strong> Mayfair, London, laminated oak<br />

gives the impression of growing out<br />

of the ground to take centre stage.<br />

Dramatic and unfurling, the main staircase at the HIDE restaurant<br />

in 85 Piccadilly, London, is reminiscent of a tamed tree curling<br />

upwards. Built around a plywood core and structural steel with<br />

laminated veneer lumber and timber treads, the scalloped steps<br />

on the coiling structure seems to emerge like leaves from a stalk<br />

to form the shape. Steel plates embedded into the wood offer the<br />

stairs additional support.<br />

Each intricately designed step slowly and gradually transforms<br />

from one shape to another, from a slightly concave step that<br />

gradually morphs into a protruding curve, welcoming visitors and<br />

encouraging them onward.<br />

Organic and capable of making a statement, the main handrail,<br />

made out of solid timber and multiple fibres, rises gracefully from<br />

the floor in a series of vertical S-curved structures that end at the<br />

lift wall at the top of the stairs.<br />

18 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

BIG PICTURE<br />

OPENING<br />

POSSIBILITIES<br />

WITH PLYWOOD<br />

When designers were not able to build outwards<br />

due to set walls, they simply built inwards,<br />

creating planes and pockets.<br />

Designed by Atmos Studio and built out of Latvian birch plywood,<br />

American black walnut and even oak staved kitchen worktops,<br />

RoominaRoom was declared the <strong>Wood</strong> Awards’ Small Project<br />

Winner in 2013. Judges for the 2013 <strong>Wood</strong> Award described it<br />

as “the extraordinary translation of a huge idea into a functional<br />

product…deliciously mad and completely refreshing.”<br />

Timber ribs hold up the structure. and plywood sheets carved<br />

by CNC show off their unique grain patterns while still remaining<br />

compact and efficient.<br />

The stairs, timber floorstrips lipped with oak, grow from a corner<br />

of the room, flowing and fluid, with a filigree handrail that loops<br />

and traces the journey upward with carved contoured topography.<br />

It is easy to compare RoominaRoom to Gaudi and Art Nouveau,<br />

but it is still pragmatic and functional.<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

19

BIG PICTURE<br />

20 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

BIG PICTURE<br />

COMPLEX<br />

AND<br />

RADICAL<br />

Unique and fluid, the Organic Staircase in Amot<br />

Atrium Tower is as richly detailed and dynamic<br />

as the city it calls home.<br />

<strong>In</strong> the entrance hall of the Amot Atrium Tower in Tel Aviv, Israel,<br />

is an extraordinary sculptural staircase made out of American<br />

tulipwood. Designed by Oded Halaf and built by master craftsman<br />

Tomer Gelfand, the staircase is based on a radical idea to<br />

construct a tornado-like structure free of all visible support,<br />

highlighting the mix of knowledge, experience and immense<br />

creativity that went into this seemingly impossible project.<br />

<strong>In</strong>tricate and complex, stiff and stable where it looks to be fluid<br />

and flexible, the stairs begin at the reception desk and rise into<br />

an expressive tornado.<br />

“The entire structure includes the spiralling stairs and a tornadolike<br />

element, which seems to emerge from the reflecting walls of<br />

the entrance lobby. The stairs and the tornado elements merge<br />

at the top of the first floor, and the round top acts as a viewing<br />

balcony to the impressive hall below,” said Gelfand.<br />

The final result is a paradox of contemporary creation: What<br />

appears to be a flexible, artistic, hand-drawn work of art is<br />

really a completely unmoveable product of algorithmic data<br />

processing and utter computerisation – all held together by<br />

masterful craftsmanship.<br />

“Navigating it isn’t meant to be as simple as taking a functional<br />

set of stairs to get from one level of a building to the next, it’s<br />

an experience in itself, taking in the whole structure from a new<br />

angle with every step,” Gelfand concluded.<br />

But more than just a work of art, the stairs is also an example<br />

of how high-tech design and traditional woodworking can come<br />

together for modern usage.<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

21

BIG PICTURE<br />

WAVY AND<br />

WOODSY,<br />

SCULPTURAL<br />

AND PRACTICAL<br />

As much a sculpture as a staircase, these<br />

stairs fulfil its dual functions magnificently.<br />

Designed and created by Arquitctura en Movimiento Workshop, a<br />

studio based in Mexico, the stunning Wavy <strong>Wood</strong> Staircase serves<br />

to link two levels of an apartment together.<br />

Doubling as a big sculpture in the middle of the room, the<br />

u-shaped staircase is built of engineered walnut to contrast with<br />

the other materials used. And as the staircase rises, the steps<br />

slowly become narrower, and the connecting sections, less steep.<br />

With the exception of the first three steps – which rest<br />

independently on the ground like benches – the staircase is secured<br />

to either the wall or the ground, the fourth step onwards flowing<br />

in a graceful slope into a higher step. The top part of the structure<br />

also has additional support in the form of vertical steel cables that<br />

alternate as a balustrade as well.<br />

22 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

BIG PICTURE<br />

PERVASIVE,<br />

PENETRATING,<br />

SOARING AND<br />

STUNNING<br />

Designed by Ora Ito and located in Paris, France,<br />

the biomorphic staircase is a whirlwind in a<br />

place of mindful serenity.<br />

Soaring high and penetrating four floors of LVMH’s media<br />

division, the staircase is exactly what designer Ora Ito wanted<br />

it to be: Undoubtedly the centrepiece of the building.<br />

A stunning visual surprise for visitors, the parametric sculpture<br />

with a biomorphic structure, not unlike a tornado in the middle<br />

of a serene, minimalistic environment. According to the designer,<br />

“this huge half-whale and half-chimera snatches you, swallows<br />

you up, and spits you out at the right floor.”<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

23

ENGINEERED WOOD<br />

A GROUNDED PRESENCE FOR<br />

A NEW ERA<br />

CATCHING UP WITH THE TOKYO OLYMPIC STADIUM 2020<br />

Despite a rocky start marred with numerous controversies, in a dramatic turn of events, the<br />

construction of the Tokyo Olympic Stadium 2020 is has finally pushed through with full steam<br />

ahead with a final understated design – a restrained three-level arena stadium featuring the<br />

innovative use of wood.<br />

The stadium’s architect – globally acclaimed Kengo Kuma – is himself an advocate of using<br />

natural materials, especially Japanese cedar, mixed with architectural designs that relate<br />

harmoniously to its surrounding.<br />

The new Japan Olympic Stadium is currently 40 per cent completed

ENGINEERED WOOD<br />

He might have produced an<br />

ostensibly simple design that<br />

rejects flashy forms, but like<br />

his other visually deceptive works,<br />

it is a return to values of traditional<br />

Japanese architecture for Kengo Kuma,<br />

packing a thoughtful punch with a more<br />

humane, grounded approach to stadium<br />

architecture.<br />

The construction of the stadium was<br />

delayed for more than a year as the<br />

late British-Iraqi architect Zaha Hadid’s<br />

earlier chosen design was abandoned.<br />

<strong>In</strong> fact, construction only began in<br />

December 2016 after Kengo Kuma’s<br />

stadium design emerged as the winner of<br />

a hastily arranged second competition. <strong>In</strong><br />

the most recent update in July from the<br />

Japan Times, Takeo Takahashi, general<br />

manager of the stadium project, told<br />

reporters attending their first media tour<br />

of the stadium that “roughly four-tenths”<br />

of the construction has been completed,<br />

and going “as planned”.<br />

Since construction started, as reported<br />

by StadiumDB.com, all excavation work<br />

had been finished in May last year;<br />

construction of the primary concrete and<br />

steel structure commenced in September;<br />

installation of the roof and the initial<br />

furnishing works on the stadium's vast<br />

floor space started in February this year;<br />

and in April, the first exterior works and<br />

the pedestrian decks – a key aesthetic<br />

feature, was underway.<br />

MOST CHALLENGING PHASE<br />

Perhaps the most challenging phase will<br />

be the construction of its roof, made up<br />

mainly of steel for strength and lumber<br />

to suppress deformation in case of an<br />

earthquake or strong wind.<br />

The stadium will have a partial roof<br />

which will open in the centre, with an<br />

overhang of approximately 60 metres<br />

circling the venue. The roof’s frame will<br />

be a hybrid structure integrating steel<br />

and lumber from cedar and larch from all<br />

47 prefectures of Japan.<br />

Pressure injection processing will be<br />

added to increase the durability of the<br />

laminated lumber as well as as antiseptic<br />

and anti-termite measure.<br />

The total weight of the metal and<br />

wooden frame is expected to exceed<br />

19,000 tonnes including the weight of<br />

all equipment in place. The structure is<br />

thus divided into 108 segments, each 15<br />

metres wide and 60 metres long. Every<br />

segment could weigh as much as 180<br />

tonnes including equipment and only 14<br />

segments can be assembled at one time<br />

due to lack of space.<br />

The stadium is expected to open in early<br />

2020, following two months of inspections<br />

and handover proceedings, so that it will<br />

be ready for the Olympic Games opening<br />

ceremony in July.<br />

MODEST DESIGN, EXPENSIVE<br />

STADIUM<br />

The new stadium with its seating capacity<br />

of 68,000 is being built with an estimated<br />

cost of ¥153 billion (US$1.27 billion),<br />

half of which will be paid by the central<br />

government. It is to become the most<br />

expensive stadium in Japan's history and<br />

one of the costliest worldwide.<br />

Zaha Hadid’s futuristic creation was<br />

scrapped as cost estimates ballooned<br />

to ¥252 billion (US$2.1 billion) and<br />

faced disapproval from both Japanese<br />

architects and the public over its massive<br />

size at 78,100 square metres and height<br />

of 75 metres, which they felt would<br />

neither blend in with nor respect its<br />

environment, among other criticism.<br />

Kuma’s design, at 72,400 square metres<br />

and 47.4 metres high, is more restrained.<br />

It is an open-air stadium with a huge<br />

oculus above the track, a latticed wood<br />

and steel canopy shelters with sitting<br />

stands underneath. Terraces with eaves<br />

on each level will feature plants and trees,<br />

structured in such a way that it minimises<br />

costs for heating and cooling while also<br />

allowing the building to blend in with the<br />

surrounding parkland.<br />

Moreover, the stadium has adopted high<br />

durability specifications and finishing<br />

materials so that the main structure will<br />

require no major repair for 100 years.<br />

USING WOOD TO BUILD<br />

One characteristic that stands out in<br />

Kuma’s design is the extensive use of<br />

wooden materials, leveraging on wood’s<br />

warm texture and quiet charm to create<br />

a very Japanese stadium.<br />

<strong>In</strong> an interview with Nippon.com, Kuma<br />

explained that wooden construction is<br />

now a major trend on the international<br />

building scene, and though Japanese<br />

people were badly traumatised by the<br />

Great Kantō Earthquake of 1923 when<br />

fire consumed the wood-built capital of<br />

Tokyo, leading to a clear preference of<br />

concrete, major technological strides<br />

in the past two decades placed wooden<br />

materials on par with concrete in terms<br />

of fire resistance.<br />

The alleged higher cost of using wood<br />

may not necessarily hold true as well. The<br />

stadium heavily features both Japanese<br />

cedar and larch, domestically grown<br />

and readily available, keeping prices<br />

low. Moreover, transporting domestic<br />

wood generates a much lower carbon<br />

footprint.<br />

Kuma also stated his desire to include<br />

wood from regions hit by the 2011<br />

earthquake and tsunami – as well as from<br />

almost every Japanese prefecture – to<br />

display them in a way that makes visitors<br />

understand where they come from.<br />

Additionally, Japanese cross-laminated<br />

timber (CLT) will be used for lockers<br />

in the athletes’ dressing rooms,<br />

outdoor information boards and other<br />

independent boards.<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

25

ENGINEERED WOOD<br />

The roof’s frame will be a hybrid structure integrating steel and<br />

lumber from cedar and larch from all 47 prefectures of Japan<br />

“<br />

Rejecting the<br />

need for architecture<br />

to be constantly at<br />

the leading edge of<br />

technology, wasting<br />

taxpayers' money<br />

and destroying<br />

the surrounding<br />

environment, he hopes<br />

the stadium comes to<br />

represent a "kinder"<br />

architecture.<br />

”<br />

EVOKING THE SENSES<br />

An architect with a great focus on evoking<br />

the senses through detail rather than<br />

form, Kuma designed the stadium as<br />

a sensuous experience that kicks off<br />

once visitors approach the building, with<br />

Japanese wood playing a key role.<br />

Describing his fondness of wood in an<br />

interview with NHK, he said: “When you’re<br />

close to wood…you can smell it. It smells<br />

great. As people approach the stadium,<br />

they will experience a sensation they’ve<br />

never felt before going to a stadium, or<br />

any large-scale public facility.”<br />

Envisioning its visual impact, Kuma<br />

conjured up an imaginary visual tour in<br />

his own words – as people step inside,<br />

they can feel the wood architecture,<br />

their gazes resting on the centre of the<br />

stadium, taking in the track and athletics<br />

field, the fresh grass and right above that<br />

will be wood.<br />

“Athletes will feel like they are really out in<br />

nature. You will have all these top athletes<br />

gathering from around the world, but it<br />

will feel like they are competing out on<br />

the open ground.”<br />

A KINDER ARCHITECTURE<br />

With modern technology providing<br />

robust solutions to the maintenance,<br />

flexibility and flammability of many natural<br />

materials, Kuma believes architects need<br />

to re-embrace the use of wood, stone and<br />

rice paper, and think beyond concrete.<br />

It is his belief that people want a softer,<br />

warmer, and more humane architecture.<br />

Creating sustainable architecture for<br />

future generations is therefore of the<br />

utmost importance. Or perhaps many<br />

external forces such as the boom and bust<br />

of the Japanese economy as well as the<br />

earthquake and tsunami of 2011 have left<br />

their mark upon him. But Kuma’s brand<br />

of “defeat architecture” often speaks of

ENGINEERED WOOD<br />

humility towards nature, and he thinks of<br />

architecture as one big part of the cycle<br />

of nature and life. <strong>In</strong> the NHK interview,<br />

he pointed out that the Meiji Shrine was<br />

constructed from wood taken from forests,<br />

and after many decades or even centuries,<br />

the wood will decompose and return once<br />

more to the forest. The same cannot be<br />

said for concrete buildings.<br />

Taking the lead in a transformation which<br />

he believes is happening in architecture<br />

– rejecting the need for architecture<br />

to be constantly at the leading edge of<br />

technology, wasting taxpayers’ money and<br />

destroying the surrounding environment,<br />

he hopes the stadium comes to represent<br />

a “kinder” architecture. | WIA<br />

All images are credited to the Japan Sport<br />

Council<br />

268 WOODEN SEATS TO BE INSTALLED<br />

Less than one per cent, or 268 out of 60,579 of Tokyo's Olympic Stadium<br />

seats will be wooden, according to The Asahi Shimbun. Domestically grown<br />

lumber will be used for the armrests and backs. But these luxury seats will<br />

be set aside for the VVIPs and the remaining chairs will be plastic.<br />

Since 2016, the country's timber industry has been advocating for the<br />

installation of wooden seats for all spectators as a symbol of Japan's<br />

craftsmanship as well as to promote the forestry industry. However, wooden<br />

seats probably cost twice more than plastic seats.<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

27

ENGINEERED WOOD<br />

A SOMEWHAT<br />

CONVOLUTED<br />

COLLABORATION<br />

MultiPly, with its interconnected spaces that overlap and<br />

intertwine, represent more than a collaboration between<br />

Waugh Thistleton Architects, Arup, and the American<br />

Hardwood Export Council: It represents the re-evaluation<br />

of affordability and the use of wood in construction.<br />

View of the structure looking out of the<br />

Blavatnik Hall into Sackler Courtyard.<br />

Image credit: Forbes Massie<br />

28 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

ENGINEERED WOOD<br />

The result of a collaboration<br />

between Waugh Thistleton<br />

Architects, Arup and the American<br />

Hardwood Export Council (AHEC), MultiPly<br />

is a modular cross-laminated tulipwood<br />

pavilion, located at the V&A Museum’s<br />

Sackler Courtyard in London, United<br />

Kingdom. Comprised of a series of<br />

maze-like interconnected spaces that<br />

overlap and intertwine, the structure will<br />

encourage visitors to re-examine how to<br />

design and build.<br />

The flexible three-dimensional structure<br />

will be made out of 17 modules of<br />

American tulipwood cross-laminated<br />

timber with digitally fabricated joints.<br />

Owing to its modular structure, the pavilion<br />

can be taken apart and reassembled<br />

relatively easily.<br />

But on a deeper level, MultiPly faces the<br />

two biggest challenges we face today –<br />

housing and the effects of climate change,<br />

and presents the fusion of modular<br />

systems and sustainable construction<br />

materials as a solution.<br />

“The main ambition of this project is<br />

to publicly debate how environmental<br />

challenges can be addressed through<br />

innovative, affordable construction,”<br />

Andrew Waugh, co-founder of Waugh<br />

Thistleton Architects, said. “We are at<br />

a crisis point in terms of both housing<br />

and CO₂ emissions and we believe that<br />

building in a versatile, sustainable material<br />

such as tulipwood is an important way of<br />

addressing these issues.”<br />

TWO SIDES, SAME COIN<br />

<strong>In</strong> the day, the structure will offer promises<br />

of fun and play, labyrinths ushering<br />

visitors through stairs, corridors, over<br />

bridges, and open spaces in a merry<br />

dance, encouraging them to explore the<br />

potential of wood in architecture.<br />

The permeability of the space will also<br />

allow visitors to explore the concepts of<br />

space and light, drawing them in even<br />

as they peek through the façade and<br />

experience new and carefully considered<br />

views around them.<br />

But in the evenings, as day gives way<br />

to dusk, MultiPly turns in a quiet space,<br />

extending an invitation for peaceful<br />

contemplation and showing off the beauty<br />

of its natural material.<br />

At the bottom of it all, however, MultiPly<br />

explores a new, more sustainable way of<br />

building, and pioneers an innovative use<br />

of wood in architecture as it combines a<br />

modular design with a readily available<br />

carbon-negative material to demonstrate<br />

the aesthetic, structural and environmental<br />

properties of wood.<br />

MATERIALS<br />

Engineered wood, CLT can be used to build<br />

walls and floors, and even the structure<br />

of entire buildings. A layered construction<br />

with the wooden planks turned at right<br />

angles with each successive layer, the<br />

resulting panel boasts strength in both<br />

directions, similar to plywood. As it can<br />

be machined to incredibly high tolerances,<br />

CLT has been proven to be stronger<br />

than steel and concrete, making it ideal<br />

for prefabrication and rapid assembly,<br />

as it can lower construction time by an<br />

estimated 30 per cent.<br />

“Continuing our exploration of hardwood<br />

CLT on installations such as Endless Stair<br />

and The Smile, MultiPly provides a playful<br />

opportunity to experiment and innovate<br />

with this tactile and adaptable material,”<br />

concluded Carolina Bartram, project<br />

director of Arup.<br />

“CLT is usually made of softwood trees.<br />

Together with Arup, AHEC started a process<br />

of experimenting with CLT made from<br />

fast-grown North American tulipwood.<br />

The planks are imported from the United<br />

States, but the panels themselves will be<br />

manufactured in the United Kingdom’s own<br />

fledging CLT factory in Scotland,” Roderick<br />

Wiles, AHEC regional director, concluded.<br />

“Testing has shown that the tulipwood<br />

is considerably stronger than spruce; it<br />

also has a superior appearance. We are<br />

positive that MultiPly will prove to be<br />

another great learning experience for us<br />

and a unique story that will serve as an<br />

inspiration for anyone wanting to design<br />

with wood.” | WIA<br />

Scale model of the pavilion<br />

Sketch of the render from above<br />

Sketch of the render looking into the Sackler<br />

Courtyard from Exhibition Road<br />

Unless otherwise stated, all images are<br />

credited to Waugh Thistleton Architects<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

29

IN PERSON<br />

FRANCIS YAN:<br />

A TRIBUTE<br />

A major force, an undeniable talent.<br />

Francis Yan was more than a director<br />

of Revery <strong>Architecture</strong> – he was<br />

an inspiration, a mentor, a friend.<br />

A<br />

gifted and talented architect,<br />

especially in the area of design<br />

and construction administration,<br />

in Hong Kong, Francis Yan was a force<br />

to be reckoned with for some of Revery<br />

<strong>Architecture</strong>’s most impactful projects,<br />

including the University of Chicago<br />

Francis and Rose Yuen Campus and<br />

Xiqu Centre opera house, which is to<br />

be featured on Hong Kong’s new $100<br />

banknotes for 2019 to 2020.<br />

“I had the pleasure to work alongside<br />

and be mentored by Francis for over<br />

12 years, and we worked together on<br />

several projects when he was still working<br />

in our Vancouver office,” Amirali Javidan,<br />

associate director of Revery <strong>Architecture</strong>,<br />

said.<br />

“Many of our senior architects at Revery<br />

<strong>Architecture</strong> were very honoured and<br />

lucky to have learned so much from him,<br />

which we will take with us throughout<br />

our careers.”<br />

Though Yan passed away in May <strong>2018</strong>,<br />

during his life, he was recognised for<br />

his dedication, knowledge, tremendous<br />

patience and uncanny understanding of<br />

what it took to realise large-scale cultural<br />

and institutional projects. <strong>In</strong> addition,<br />

Yan played a key role in contract reviews,<br />

specifications, and quality control for<br />

30 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

IN PERSON<br />

Mr Francis Yan (left) and Arena Stage in Washington D.C., United States, designed by Venelin Kokalov and with which Yan was also involved<br />

many of Revery’s projects that were later<br />

constructed.<br />

REVERY ARCHITECTURE<br />

Established in 1982 by Canadian architect<br />

Bing Wing Thom, the award-winning firm,<br />

Revery <strong>Architecture</strong> (formerly Bing Thom<br />

Architects), is led by design principal<br />

Venelin Kokalov, technical principal<br />

Shinobu Homma, and a team of directors<br />

who bring additional experience in<br />

urban planning, engineering, sustainable<br />

buildings, construction, and much more<br />

with an emphasis on both design and<br />

building execution. Until his passing,<br />

Francis Yan held a prominent position at<br />

Revery as managing director of its Hong<br />

Kong office.<br />

Based in Vancouver, Canada, with an<br />

office in Hong Kong, directors and staff<br />

all share one fundamental belief:<br />

“We believe that great architecture<br />

has the transformative power to uplift<br />

– not only the physical, but also the<br />

economic and social conditions of a<br />

community,” Yan had said. “The firm’s<br />

belief in this power has become the<br />

grounding philosophy for the office,<br />

and has resulted in memorable<br />

architecture around the world that<br />

consistently taps into something beyond<br />

aesthetics.”<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

31

IN PERSON<br />

Xiqu Centre opera house, designed by Revery's design principal, Venelin Kokalov, is to be featured on Hong Kong's new $100 banknote<br />

Passionate about the positive social and<br />

economic value architectural excellence<br />

can bring to communities, allowing them<br />

to thrive, Revery <strong>Architecture</strong> more often<br />

than not integrates a wide range of uses<br />

into the buildings they design, crafting<br />

structures that are both vibrant and<br />

sustainable.<br />

LED TO SINGAPORE<br />

Throughout Revery’s history, the firm has<br />

stood out as a strong proponent for the<br />

use of wood and other natural materials<br />

in construction, regarding it as all but<br />

second nature.<br />

“When we were approached to participate<br />

in a design competition for the new<br />

Academic Building South at Nanyang<br />

Technological University in Hong<br />

Kong, which called for a building to<br />

be constructed with an Engineered<br />

<strong>Wood</strong> System, we agreed without<br />

hesitation,” Yan had recalled. “But it<br />

was working on the competition entry<br />

that introduced us to Singapore’s<br />

recent push for a renaissance in wood<br />

construction.”<br />

Soon after, Yan and his team of<br />

architects met up with Mr Ang Kian<br />

Siang, Group Director of the Building<br />

and Construction Authority (BCA)<br />

Environmental Sustainability Group to<br />

familiarise themselves with the driving<br />

forces behind the push.<br />

“The main driving force was to<br />

raise construction productivity and<br />

fundamentally change the design and<br />

construction processes where as much<br />

work may be done off-site in a controlled<br />

manufacturing environment as possible,”<br />

Yan continued.<br />

“But as this initiative is still relatively<br />

new to Singapore, the knowledge within<br />

the local industry is still in its infancy.<br />

We see opportunities to bring our<br />

knowhow to Singapore in a time where<br />

designers are leveraging on the strength,<br />

stability and design flexibility of mass<br />

timber products to push beyond wood’s<br />

perceived boundaries, achieving building<br />

heights and spans that would have once<br />

required concrete, steel, or masonry for<br />

structural support.”<br />

Presently, Revery <strong>Architecture</strong> has<br />

begun sharing information with the<br />

BCA, helping them better understand<br />

what the Canadian wood industry can<br />

bring to Singapore and started dialogue<br />

with various local stakeholders and<br />

manufacturers regarding partnership<br />

opportunities.<br />

Along with the more commonly known<br />

glue-laminated timber and crosslaminated<br />

timber, according to Yan, the<br />

Canadian wood industry can now offer a<br />

wider range of products, including naillaminated<br />

timber, structural composite<br />

lumber like laminated veneer lumber as<br />

well as laminated strand lumber.<br />

Most engineered wood products are<br />

produced from pre-seasoned wood in wellconditioned<br />

fabrication facilities. For a<br />

difference in climates, Canadian wood has<br />

been exported for use in other countries<br />

with varying climatic conditions, and the<br />

timber structures would be protected<br />

within the building envelope designed to<br />

shelter the materials from the elements.<br />

Moreover, for mass timber structures<br />

meant to be outside building envelopes,<br />

there are coating systems which were<br />

developed specially to protect them. On<br />

top of that, there is also the option of<br />

choosing a timber species more resistant<br />

to weather.<br />

“Transfer of wood technology from<br />

Canada to other countries is not new,”<br />

32 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

IN PERSON<br />

Yan had pointed out. “The Canadian <strong>Wood</strong> Council has had a<br />

successful history of helping China set up fabrication facilities in<br />

various cities, and we are working to bring the same technology<br />

transfer to Singapore.”<br />

A TRIBUTE<br />

Respected and loved at Revery, Yan had spent almost half of his<br />

40-year career with the company, having joined in 1999, and<br />

proving his brilliance in project management and construction<br />

administration. Having moved to Hong Kong more recently, Yan<br />

then enjoyed a further string of architectural successes.<br />

Significantly, Yan had managed to sow the seeds of bringing<br />

engineered wood into Singapore before his passing.<br />

well suited for use as interior structural elements.”<br />

As a passionate advocate of Revery’s approach to architecture,<br />

Yan was admired for his deep knowledge of design, management,<br />

and specifications. Articulate, professional, and a perfectionist, he<br />

was also disciplined and generous, his mentorship inspiring many<br />

young architects and enriching the lives of those around him.<br />

Remembered fondly as a gentleman, a gentle and helpful soul,<br />

and a well of kindness by his friends, colleagues and mentees, Yan<br />

never viewed architecture as a job, instead living and breathing<br />

the process, applying the same rules and creativity to the many<br />

goals he achieved in his life.<br />

“We met up with some local manufacturers and were excited to<br />

learn of their capability in producing glulam with hard wood,” he<br />

had enthused. “These products are well suited for use as external<br />

structural members and will work well in combination with the<br />

various mass wood products produced with soft woods that are<br />

Revery <strong>Architecture</strong> takes great pride in sharing its passion for<br />

unique, transformative architecture, and the entire team – in<br />

Vancouver and Hong Kong – remains steadfast in its commitment<br />

to upholding the exceptional service, attentiveness, and creative<br />

design excellence upon which the firm is founded.| WIA<br />

Surrey Central City, British<br />

Columbia, Canada, which<br />

uses plywood, also<br />

designed by Venelin Kokalov<br />

All images are credited to Nic Lehoux<br />

and Revery <strong>Architecture</strong><br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

33

IN PERSON<br />

RUSSIA FINDS<br />

PROMISE<br />

IN THE<br />

MIDDLE EAST<br />

For the first time, Russian timber companies were represented<br />

under a Russian pavilion at the Dubai <strong>Wood</strong>Show. Victor<br />

Evtukhov, State Secretary, Deputy Minister of Trade and<br />

<strong>In</strong>dustry of the Russian Federation, talks about the promise<br />

of the Middle East.<br />

34 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

IN PERSON<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

35

IN PERSON<br />

Russian wood products are in high demand in the Middle East<br />

Russian wood products are in high demand in the Middle<br />

East, a region that is experiencing expansion across<br />

industries such as energy, construction, infrastructure<br />

and telecommunications. It is considered a market of infinite<br />

potential, which is why Russian timber companies participated<br />

in the Dubai <strong>Wood</strong>Show in March to reach out to the market.<br />

Victor Evtukhov, State Secretary, Deputy Minister of Trade<br />

and <strong>In</strong>dustry of the Russian Federation, said the region is<br />

“very promising,” and that there are plans to expand existing<br />

partnerships and to conclude new ones.<br />

One of the strategies to advance in this market is to participate<br />

in international exhibitions such as the Dubai <strong>Wood</strong>Show.<br />

Victor Evtukhov,<br />

State Secretary, Deputy Minister of Trade and <strong>In</strong>dustry<br />

of the Russian Federation<br />

“It was quite rewarding for us since we managed to demonstrate<br />

our wood processing advantages and find new partners this<br />

region and elsewhere,” Evtukhov said.<br />

The United Russian stand received over 1,000 visitors from<br />

30 countries and all showed interest in wood-based products<br />

such as plywood, particleboard, OSB, MDF, glulam, LVL, wall<br />

panels, furniture boards and sawn timber. Over 150 negotiations<br />

were conducted, one of which is the agreement with Utralam<br />

to supply scaffold planks to Kuwait, a deal worth US$500,000.<br />

“The relatively close proximity between Russia and Middle East<br />

makes doing business with Russia a good choice for Middle<br />

Eastern companies that want to buy high quality wooden<br />

materials at a low price,” Evtukhov remarked. Furthermore, the<br />

low cost of domestic wood and high manufacturing standards<br />

give Russia an advantage, and is in high demand around the<br />

world, not just the Middle East.<br />

“Russian companies have experience in international<br />

partnership and the necessary flexibility to agree on mutually<br />

beneficial terms of cooperation,” Evtukhov added.<br />

INCREASED TRADE INTEREST<br />

<strong>In</strong> fact, Russia has been supplying wood-based products to<br />

Saudi Arabia, Lebanon and Oman for many years and trade<br />

interest is growing. Saudi Arabia, for instance, is interested<br />

to import more Russian wood products. It is also investing<br />

in Russia’s wood processing sector. Last year, the Business<br />

Partners Association for Cooperation with the Kingdom of Saudi<br />

Arabia (RUSA) signed an MOU which will see Russia supplying<br />

wooden products to partners in Saudi Arabia.<br />

36 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

IN PERSON<br />

Russia has increased its production<br />

capacity of OSB and LVL in the<br />

last few years<br />

is often associated with country homes,<br />

modern technology is showing us that<br />

multi-storey buildings are possible in<br />

wood as well,” Evtukhov said.<br />

Multiple agreements have also been<br />

reached with large wood companies<br />

in Russia: Demidovo Plywood Mill and<br />

Syktyvkar <strong>Wood</strong> <strong>In</strong>dustry Complex have<br />

clinched deals to export their products<br />

to Saudi Arabia.<br />

SVEZA company has also supplied birch<br />

plywood for construction projects in<br />

Abu-Dhabi, for the Park Hyatt hotel,<br />

Rosewood Abu Dhabi hotel, Al Bahar<br />

Tower office building and new airport<br />

terminal. Some of these products were on<br />

show in Dubai, including the SVEZA Laser,<br />

a slab form plywood that complies with<br />

industrial standards of manufacturers of<br />

flat cutting dice and other goods using<br />

laser cutting.<br />

INCREASING MARKET SHARE<br />

As Russia targets to increase its export<br />

share of value-added goods, the ministry<br />

is also studying global demand and<br />

manufacturing goods that will be in high<br />

demand in future. For example, Russia<br />

has increased its production capacity of<br />

OSB and LVL in the last few years.<br />

Another area of growth is wood<br />

construction. “While wood construction<br />

Already, construction of modern ecoblocks<br />

in Moscow and around have<br />

been developed. For instance, the<br />

<strong>Wood</strong> City residential block, a project<br />

in Moscow that covers the territories<br />

where old prefab concrete five-storey<br />

buildings are currently located. Some<br />

parts of these houses will be modernised<br />

using technologies for wooden building<br />

construction. <strong>In</strong> other words, the<br />

buildings will be a combination of stone<br />

and wood.<br />

Another project is the Sokol Town<br />

residential block in Moscow region,<br />

located near the natural forest. The<br />

priorities of the project are to make it<br />

affordable for the middle class as well as<br />

to have the block bled into the existing<br />

landscape. For the construction, the<br />

wood-framed panel technology will be<br />

used along with three types of finishing<br />

for the exterior: brick, metal and wooden.<br />

A school and a kindergarten are also<br />

planned to be constructed within the<br />

block. | WIA<br />

WOOD IN ARCHITECTURE • ISSUE 2 • <strong>2018</strong><br />

37

TMT OAK<br />

OFFERS NEW<br />

OPPORTUNITIES<br />

FIT-OUTS<br />

By Michael Buckley<br />

Thermally Modified Timber (TMT) is not new but TMT oak<br />

lumber is. Or at least it is new in Southeast Asia. The softwood<br />

industry and the rubber wood processors have been working<br />

with TMT for years to improve durability. But each has their<br />

own limitations of strength and stability and in some cases<br />

the process has been partially successful. Up until now the<br />

American hardwood industry has provided TMT material<br />

principally in ash and tulipwood to provide exterior solutions.<br />

Previously almost all applications for U.S. hardwood<br />

species have been restricted to interiors, but not anymore.<br />

American TMT white oak<br />

furniture and flooring<br />

38 ISSUE 2 • <strong>2018</strong> • WOOD IN ARCHITECTURE

FIT-OUTS<br />

Notable exterior projects promoted<br />

by AHEC in recent years have<br />

included “Room on a Hill” at<br />

Chisenhale School in East London where<br />

the outdoor play and learning structure<br />

designed by renowned London-based<br />

architect Asif Khan is made from TMT<br />

tulipwood slats in a galvanised metal<br />

frame and a TMT ash deck. The “Bostanli<br />

footbridge” and “Bostanli sunset lounge”<br />

project in Izmir Turkey, designed by<br />

Studio Evren Basbug architects are made<br />

of TMT ash boards in a series of wooden<br />

platforms that recline on a wooded<br />

hillside all the way down towards the sea.<br />

The recently opened Maggie’s Centre for<br />

cancer care, by architect Alex de Rijke in<br />

UK unveiled the first commercial use of<br />

TMT tulipwood cladding.<br />

“The opportunities for decking, flooring,<br />

cladding, exterior patio furniture and<br />

other outdoor uses are very exciting,”<br />

says AHEC Regional Director John Chan<br />

as the response to the pavilion was so<br />

positive. <strong>In</strong> the case of red oak which<br />

represents about 30 per cent of the<br />

American sustainable hardwood forest<br />

resource, any new market is significant<br />

in AHEC’s efforts to balance demand with<br />

what is growing in the forest.<br />

<strong>In</strong> this edition of the annual American<br />

hardwood supplement we have sought<br />

out the views of both oak sawmillers<br />

and TMT processors to provide a real<br />

understanding on the material and its<br />

pros and cons. But the photos should<br />

provide inspiration to those looking for<br />

a new angle on oak – one of the world’s<br />

most popular of all hardwoods. | WIA<br />

Reproduced with permission.<br />

However TMT red and white oak, recently<br />

launched in Asia, is opening up a new<br />

perspective in that it offers a hardwood<br />

that looks like walnut – at a fraction<br />

of the cost and in specifications that<br />

walnut buyers can only dream of.<br />

Furthermore the treated lumber is<br />

available direct from the USA or locally<br />

in the region. AHEC’s pavilion at the<br />

<strong>In</strong>ternational Furniture Fair Singapore<br />

demonstrated the point well.<br />

TMT American red oak furniture by Jarrod Lim<br />

TMT white oak<br />

after a fivemonth<br />

test in<br />

<strong>In</strong>donesian rain<br />

in Java

MATERIALS & TECHNOLOGY<br />

<strong>In</strong>terview with<br />

PHIL FENWICK<br />

ON RED OAK<br />

Phil Fenwick<br />

has been Baillie Lumber’s Director<br />

of Asia Sales for many years.<br />

Q: As a producer of red oak lumber<br />

what do you see as the main differences<br />

to white oak?<br />

A: The difference between red oak and<br />

white oak is that it comes down to texture<br />

and colour. The tubules of white oak are<br />

closed, whereas the red oak tubules are<br />

open – giving a little bit more of a rougher<br />

appearance of the grain. <strong>In</strong> general the<br />

other main difference is there are typically<br />

ranges of colour in red oak, such as tan or<br />

wheat all the way to a deep red. White oak<br />

tends to be mostly tan or almost brown in<br />

colour. Sometimes it is hard to distinguish<br />

white oak from red oak, especially if the<br />

red oak is more northern due to the very<br />

light colour and appearance.<br />

Q: How does red oak perform in flooring<br />

and furniture?<br />

A: Red oak performs extremely well in<br />