National Hardwood Magazine - May 2021

In the May issue of National Hardwood Magazine, learn more about Crafted Elements, Mason's Mill & Lumber Co, sawmill safety and much more.

In the May issue of National Hardwood Magazine, learn more about Crafted Elements, Mason's Mill & Lumber Co, sawmill safety and much more.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SCAN ME<br />

TO LEARN MORE ABOUT<br />

OUR PRODUCTS!<br />

1-888-363-2628 | sales@uccoatings.com<br />

www.uccoatings.com<br />

Buffalo | Portland | Seattle

The The Granite Valley Difference<br />

The Granite Valley Difference<br />

Our Sawmills<br />

Our sawmills in<br />

Wisconsin prepare<br />

raw timber for delivery<br />

to our finishing mills.<br />

Quality<br />

Processing<br />

We “rough grade” our kiln-dried<br />

woods to ensure the best appearance.<br />

Quality assurance on every load.<br />

Custom<br />

Work<br />

To help you streamline your<br />

production process, we<br />

can supply custom-cut<br />

pre-production blanks<br />

to your specs.<br />

Ready<br />

Inventory<br />

Our average on-hand<br />

kiln-dried supply is<br />

10 million board feet.<br />

Get the wood you need,<br />

with quick turnaround.<br />

We do.<br />

Call it unconditional, all-encompassing, you name it.<br />

As a software developer committed solely to the lumber and<br />

building materials industry, DMSi has every corner of your<br />

operation covered. From inventory and sales to production<br />

and procurement, we make sure no corners are cut<br />

and no detail is left out. And that’s a promise we’ll hold true.<br />

Granite Valley Forest Products keeps growing as a single-source supplier to<br />

better serve you. We sell rough, S2S, straight-line ripping, and offer<br />

NHLA grades and customer-proprietary grading based on NHLA guidelines.<br />

Our Sawmills<br />

Our Sawmills<br />

Our sawmills in<br />

Our Wisconsin<br />

Sawmills<br />

in prepare<br />

Our sawmills in<br />

Our raw Our timber sawmills for in in delivery<br />

Wisconsin prepare<br />

raw to Wisconsin our for<br />

finishing<br />

Offices prepare mills.<br />

in Wisconsin, Indiana<br />

raw timber for delivery<br />

to our<br />

raw raw timber timber for to our finishing mills. & for Colorado<br />

delivery<br />

to to our our finishing mills. mills. Quality<br />

sales@granitevalley.com Quality<br />

Processing<br />

Quality<br />

Custom products are available to your exact specs for width, length and color.<br />

Visit our website to learn more or email us at sales@granitevalley.com.<br />

To help you streamline your<br />

granitevalley.com We “rough Work<br />

Processing<br />

grade” our kiln-dried<br />

production process, we<br />

To help you woods to ensure the best appearance. To help To can To help help you supply you you streamline custom-cut streamline your<br />

your<br />

We We “rough we<br />

We Quality We “rough “rough grade” assurance grade” grade” our our kiln-dried<br />

our our on every kiln-dried load. production pre-production production process, process, blanks we we we<br />

Alder | Aromatic woods Cedar can woods woods to | to Black ensure to to &<br />

ensure ensure the White the best best<br />

the the Ash<br />

best appearance.<br />

best | Aspen appearance. | Basswood can can to supply can your supply specs.<br />

custom-cut<br />

Beech | White & Quality Yellow Quality Quality assurance Birch assurance | Bitternut on on every every<br />

on on | every Butternut every load. load.<br />

load. load. | Cherry<br />

pre-production blanks<br />

blanks<br />

Grey & Red Elm | Hard Maple | Hickory | Red Oak | White Oak to to your to your to your your specs.<br />

specs.<br />

Norway<br />

Granite<br />

Pine<br />

Valley<br />

| White<br />

Forest<br />

Pine<br />

Products<br />

| Poplar<br />

keeps<br />

| Red &<br />

growing<br />

Silver Soft<br />

as a<br />

Maple<br />

single-source<br />

| Walnut<br />

supplier to<br />

Granite White better<br />

Granite Granite Valley Valley<br />

Cedar serve<br />

Valley Forest Valley | Rift you.<br />

Forest Forest<br />

&<br />

Products We Quartered sell<br />

Products Products<br />

rough,<br />

keeps Red<br />

keeps keeps<br />

S2S, &<br />

growing White straight-line growing<br />

Oak<br />

as as a as a single-source as a a<br />

ripping, single-source<br />

and<br />

supplier offer<br />

supplier to<br />

to to to<br />

NHLA<br />

better better better serve better<br />

grades serve serve you. serve you. you. We We you.<br />

and<br />

sell We sell We<br />

customer-proprietary<br />

rough, sell sell rough, rough, S2S, S2S, S2S, straight-line S2S, straight-line<br />

grading based<br />

ripping, ripping, ripping,<br />

on NHLA<br />

and and and and offer<br />

offer offer offer<br />

guidelines.<br />

Custom<br />

NHLA NHLA NHLA grades<br />

NHLA grades grades grades<br />

products<br />

and and customer-proprietary and and<br />

are customer-proprietary<br />

available to your exact<br />

grading grading grading<br />

specs<br />

based based based<br />

for width,<br />

on on NHLA on on NHLA NHLA<br />

length<br />

guidelines.<br />

guidelines.<br />

and color.<br />

Visit<br />

Custom Custom Custom Custom<br />

our<br />

products products products<br />

website to<br />

are are available are are<br />

learn<br />

available available<br />

more or<br />

to to your your to to<br />

email<br />

your your<br />

exact exact exact exact<br />

us at<br />

specs specs specs specs<br />

sales@granitevalley.com.<br />

for for width, for width, for width, width,<br />

length length length<br />

and and and and<br />

color.<br />

color.<br />

color.<br />

Visit Visit our Visit our Visit<br />

website website our<br />

Offices our website website<br />

to to learn learn to<br />

in to learn learn<br />

more more Wisconsin,<br />

more more email email or or email email<br />

us us at us at Indiana us<br />

sales@granitevalley.com.<br />

at at sales@granitevalley.com.<br />

& Offices Colorado<br />

in in in Wisconsin, Indiana<br />

Offices in Wisconsin, Indiana<br />

& Colorado<br />

& sales@granitevalley.com<br />

& Colorado<br />

sales@granitevalley.com<br />

sales@granitevalley.com<br />

granitevalley.com<br />

granitevalley.com<br />

Alder | Aromatic Cedar | Black & White Ash | Aspen | Basswood<br />

granitevalley.com<br />

Beech | White & Yellow Birch | Bitternut | Butternut | Cherry<br />

Alder Grey Alder | Aromatic & | Aromatic Red Elm Cedar | Cedar Hard | Black Maple | Black & | Hickory & White<br />

White Ash | Ash Red | | Aspen Oak Aspen | | White | Basswood<br />

Basswood Oak<br />

Alder<br />

Alder<br />

| Aromatic<br />

| Aromatic Cedar | Black & White Ash Aspen | Basswood<br />

Beech Norway Beech | | White Pine White Cedar & | White & | Yellow Black<br />

Yellow Pine Birch & Birch | White Poplar | Bitternut Ash | Bitternut | Red | Aspen | Butternut & | Butternut Silver | Basswood Soft | Cherry<br />

Beech | White & Yellow Birch | Bitternut | Butternut | Cherry | Cherry Maple | Walnut<br />

Beech | Grey<br />

Grey White Grey & & Red<br />

& Red Cedar & Red Yellow Elm Elm<br />

Elm | Rift Birch | Hard | Hard<br />

| Hard & Quartered | Maple Bitternut | | Butternut | Cherry<br />

Maple<br />

Maple | Hickory<br />

| Hickory Red Hickory & | White | Red<br />

Red Oak<br />

Oak Oak Oak | White Oak<br />

| White<br />

| White Oak<br />

Oak<br />

Grey & Norway<br />

Norway<br />

Red Norway Elm Pine Pine<br />

Pine<br />

| Hard | White | White<br />

| White<br />

Maple Pine Pine<br />

Pine<br />

| | Poplar<br />

|<br />

Hickory | Poplar<br />

Poplar | |<br />

|<br />

Red | Red Silver<br />

&<br />

Oak & Silver<br />

Silver<br />

| White Soft Soft<br />

Soft Maple<br />

Maple<br />

Oak Maple | Walnut<br />

| Walnut<br />

| Walnut<br />

Norway White<br />

White Pine Cedar | Cedar White |<br />

| Rift Pine Rift &<br />

& Quartered | Poplar Quartered | Red Red<br />

Red & & Silver White<br />

White Oak Soft OakMaple | Walnut<br />

White White<br />

Cedar Cedar<br />

| Rift | Rift<br />

& &<br />

Quartered Quartered<br />

Red Red<br />

& &<br />

White White<br />

Oak<br />

Oak<br />

Custom<br />

Work Custom<br />

Work<br />

Work<br />

Ready<br />

Inventory<br />

Ready<br />

Inventory<br />

Our average on-hand<br />

kiln-dried supply is<br />

Our 10 Our average million average board on-hand<br />

on-hand feet.<br />

kiln-dried Get is<br />

kiln-dried the supply wood supply you is<br />

isneed,<br />

10 10 10 with 10 million million quick board board turnaround. feet.<br />

feet.<br />

Get Get the Get the the wood wood you you need,<br />

with with quick quick turnaround.<br />

Visit DMSi.com

UCC_34095_<strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> Cover_v2.indd 1<br />

SCAN ME<br />

TO LEARN MORE ABOUT<br />

OUR PRODUCTS!<br />

3/22/21 2:48 PM<br />

Contents<br />

<strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong> MAY <strong>2021</strong> Volume 95 No. 4<br />

Features & Industry Events<br />

1-888-363-2628 | sales@uccoatings.com<br />

www.uccoatings.com<br />

Buffalo | Portland | Seattle<br />

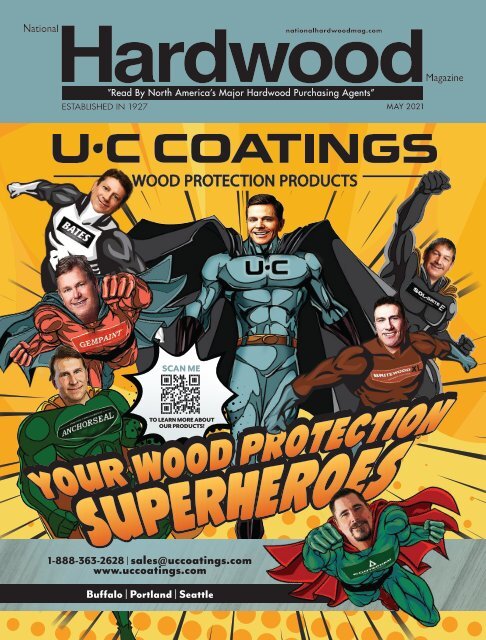

About The Cover<br />

“U-C Coatings is a leading manufacturer and<br />

supplier of premium wood protection products.<br />

For 50 years, our products have been used in<br />

a variety of industries, including hardwood and<br />

softwood logging and lumber production, wood<br />

products manufacturing, woodworking and<br />

wood decking markets. Our products are used<br />

worldwide to protect, conserve and enhance forest<br />

resources. Our goal is to help our customers<br />

achieve more with less waste and provide the<br />

highest level of protection for their products.<br />

The company offers Anchorseal® end sealers and edge sealers for<br />

lumber and other wood products, as well as Gempaint® for lumber branding.<br />

We continue to expand the Contechem® product line with Britewood<br />

for mold and sapstain control in softwood and hardwood applications.<br />

The Contechem® Sol-Brite product line provides excellent iron stain removal<br />

and brightening. Seal-Once® is a line of eco-friendly, waterbased<br />

sealers for wood and concrete that provides excellent water repellant performance<br />

and protection from the elements. The Eco Chemical® line of<br />

water-based wood stains and other coatings products is used by the pressure<br />

treating and fencing industries, as well as other prefinished wood<br />

manufacturing firms. The Bates line of glue releases help prevent glue<br />

buildup and make cleanup easier wherever adhesives are used while DPS<br />

protects finished parts from checking and delaminating while in storage.<br />

The company has operations in Buffalo, Portland, and Seattle. Contact<br />

us for any of your wood protection and finishing needs.”<br />

uccoatings.com<br />

20<br />

22<br />

Crafted Elements: Highly<br />

Skilled Workers Seek to Have<br />

a Positive Impact on Others<br />

Mason's Mill & Lumber Co.:<br />

Flexibility Enables Success<br />

24 HMA NatCon Welcomes<br />

Participants<br />

28 ALC Learns Low Interest Rates<br />

Continue To Drive Consumer<br />

Demand<br />

Departments<br />

6 Calendar<br />

8 U.S.A. Trends<br />

10 Canadian Trends<br />

12 News Developments<br />

14 HMA Update<br />

2 MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE<br />

30<br />

32<br />

34<br />

16 AHEC Report<br />

17 NWFA Review<br />

18 WCMA Insights<br />

19 NHLA News<br />

52 Who’s Who<br />

In-Person Plans Proceed for<br />

Well-Known Sawmilling EXPO in<br />

August<br />

Sawmill Safety: Addressing the Issues<br />

to Protect Your Business<br />

SCMA Convenes for Annual Meeting<br />

20<br />

56 Trade Talk<br />

62 Classified Profit<br />

Opportunities<br />

64 Advertisers Index<br />

Founded in 1927 by: O.L. Miller – 1894-1963<br />

Publisher: Paul J. Miller – 1963-2010<br />

• Forest Products Export Directory • Imported Wood Purchasing Guide<br />

• Import/Export Wood Purchasing News • <strong>Hardwood</strong> Purchasing Handbook<br />

• Green Books’s <strong>Hardwood</strong> Marketing Directory<br />

• Green Books’s Softwood Marketing Directory<br />

• The Softwood Forest Products Buyer<br />

Paul J. Miller Jr. – President<br />

Terry Miller – Vice President<br />

Zach Miller – Sales<br />

Sue Putnam – Editor<br />

Matthew Fite – Staff Writer<br />

Rachael Stokes – Graphic Artist<br />

Pamela McFarland – Graphic Artist<br />

Tammy Daugherty – Production Manager<br />

Jennifer Trentman – Green Book Market Sales<br />

Lisa Carpenter – Circulation Manager<br />

Lexi Hardin – Subscription & List Services<br />

ADVERTISING OFFICES:<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134<br />

901-372-8280 FAX: 901-373-6180<br />

Reach us via the Internet at: www.nationalhardwoodmag.com<br />

E-mail addresses:<br />

ADVERTISING: tammy@millerwoodtradepub.com<br />

EDITORIAL: editor@millerwoodtradepub.com<br />

SUBSCRIPTIONS: circ@millerwoodtradepub.com<br />

EDITORIAL CORRESPONDENTS:<br />

Chicago, Los Angeles, High Point, Grand Rapids, Portland, Toronto<br />

Controlled circulation postage paid at Memphis, TN<br />

(USPS #917-760)<br />

The NATIONAL HARDWOOD MAGAZINE (ISSN 0194-0910) is published<br />

monthly, except for two issues in December, for $55.00 per year and<br />

$65.00 (U.S. dollars) per year for Canada by <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Inc.,<br />

5175 Elmore Rd., Suite 23, Memphis, TN 38134. Periodicals Postage paid at<br />

Memphis, TN, and at additional mailing offices.<br />

POSTMASTER: Send address changes to <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>,<br />

P.O. Box 34908, Memphis, TN 38184.<br />

Publications mail agreement No. 40739074.<br />

Return undeliverable Canadian addresses to:<br />

P.O. Box 503, RPO W. Beaver Cre., Rich-Hill, ON L4B 4R6.<br />

The publisher reserves the right to accept or reject editorial<br />

content and Ads at the staff’s discretion.<br />

MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 3

Targeting Buyers<br />

Around the Globe!<br />

80% Renewal Rate in the 45th<br />

Forest Products Export Directory<br />

“...the Most Comprehensive Buyer’s<br />

Guide for the International Buyer...”<br />

Forest Products Export Directory<br />

Call now to reserve your<br />

space in the 46th Edition!<br />

Published in Fall <strong>2021</strong><br />

800-844-1280<br />

Full Page Rate: $2,800 Half Page Rate: $2,350<br />

Color Additional<br />

forestproductsexport.com<br />

exd@millerwoodtradepub.com<br />

Abenaki Timber Corporation<br />

Allegheny Veneer Co., Inc.<br />

Allegheny Wood Products, Inc.<br />

Ally Global Logistics LLC<br />

American Lumber Co.<br />

Anderson-Tully Lumber Co.<br />

Baillie Lumber Co.<br />

Beasley Forest Products, Inc./<br />

Thompson <strong>Hardwood</strong>s, Inc.<br />

Cardin Forest Products, LLC<br />

Clark Lumber Co., Inc.<br />

Cole <strong>Hardwood</strong>, Inc.<br />

Crown <strong>Hardwood</strong> Co., Inc.<br />

Cummings Lumber Co., Inc.<br />

Deer Park Lumber International<br />

Devereaux Sawmill, Inc.<br />

East Ohio Lumber Co.<br />

MO PAC Lumber Company<br />

NELMA (Northeastern Lumber<br />

Manufacturers Assoc.)<br />

Northern Appalachian Log<br />

& Forestry Co.<br />

Northwest <strong>Hardwood</strong>s, Inc.<br />

Nyle Systems LLC<br />

Parton Lumber Co., Inc.<br />

Penn-Sylvan International, Inc.<br />

Prime Lumber Company<br />

Primewood<br />

Ralph Taylor Lumber Co., Inc.<br />

Ram Forest Products, Inc.<br />

Ron Jones <strong>Hardwood</strong> Sales, Inc.<br />

Rossi Group<br />

SFPA (Softwood Forest Products<br />

Assoc.)<br />

Simon Lussier Ltd.<br />

Snowbelt <strong>Hardwood</strong>s, Inc.<br />

Softwood Export Council<br />

Somerset Wood Products, Inc.<br />

TMX Shipping Company, Inc.<br />

Taner Timber Co., Inc.<br />

Tuscarora <strong>Hardwood</strong>s, Inc.<br />

Two Rivers Timber Company, Inc.<br />

USA Woods International, Inc.<br />

Vexco, Inc.<br />

Wagner Lumber Company<br />

Wheeland Lumber Co., Inc.<br />

4 MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 5<br />

HHP, Inc.<br />

Harold White Lumber Co.<br />

Hanafee Bros. Sawmill Co., Inc.<br />

Hermitage <strong>Hardwood</strong> Lumber<br />

Sales, Inc.<br />

J.D. Irving Limited<br />

John & George International LLC<br />

King City / Northway Forwarding Ltd.<br />

Legacy Wood Products LLC<br />

Matson Lumber Company<br />

McClain Forest Products LLC<br />

Midwest <strong>Hardwood</strong> Corp.

HARDWOOD CALENDAR<br />

INDUSTRIES<br />

INDUSTRIES<br />

CONTROLS<br />

CONTROLS<br />

Glen Thompson and Tommy Stiles, A.W. Stiles Contractors Inc., Matt Taylor, U-C Coatings LLC, Buffalo, NY; Damon Graf, DR Graf<br />

McMinnville, SURFACES, TN Mandalay Bay Convention Center, Las Vegas, Lumber NV. www.intlsurfaceevent.com. Co., Lexington, KY; and Tom Johel, June U-C 16-18. Coatings LLC<br />

whose topic was Growing the Global Pie.<br />

At this year’s IHLA Convention, multiple networking opportunities<br />

were offered, and the association’s board of directors<br />

held a business session. The 2017 board president<br />

for IHLA is Shaun Cook, of C.C. Cook & Son Lumber Co., of<br />

Reelsville, IN. Tom Oilar of Cole <strong>Hardwood</strong>, located in Logansport,<br />

IN, is the 2017 1st vice president and Brett Franklin,<br />

of Tri-State Timber LLC of Bloomington, IN is the IHLA<br />

<strong>May</strong><br />

Expo Richmond, Richmond Raceway Complex, Richmond, VA. www.exporichmond.com. <strong>May</strong> 21-22.<br />

June<br />

2nd vice president.<br />

Additionally, in conjunction with the IHLA meeting, the<br />

Fellowship of Christian Lumbermen held a brief meeting.<br />

IHLA is a non-profit trade organization comprised of sawmills,<br />

wholesale brokers, equipment vendors, secondary<br />

manufacturers, loggers and landowners, among others in<br />

the industry.<br />

Learn more at www.ihla.org. n<br />

July<br />

<strong>National</strong> Wood Flooring Association, EXPO, Orlando, FL. www.nwfaexpo.org. July 7-9.<br />

AWFS Fair, Las Vegas Convention Center, Las Vegas, NV. www.awfsfair.org. July 20-23. n<br />

CLEEREMAN LUMBER COMPANY 1930’s CLEEREMAN INDUSTRIES 1955 CLEEREMAN CONTROLS 2019<br />

CLEEREMAN LUMBER COMPANY 1930’s CLEEREMAN INDUSTRIES 1955 CLEEREMAN CONTROLS 2019<br />

CLEEREMAN<br />

CLEEREMAN<br />

TODAY<br />

TODAY<br />

For optimal efficiency. . .<br />

For optimal efficiency. . .<br />

knows what a sawmill needs:<br />

knows what a sawmill needs:<br />

Now, TWO ENTITIES TO SERVE YOU BETTER!<br />

Now, TWO ENTITIES TO SERVE YOU BETTER!<br />

Additional photos on next page<br />

NORTHERN & APPALACHIAN HARDWOOD<br />

NORTHERN & APPALACHIAN HARDWOODS<br />

[ WWW.SIMONLUSSIER.COM ]<br />

[ WWW.SIMONLUSSIER.COM]<br />

MATHIEU LUSSIER - Export Sales Manager m2lussier@simonlussier.com<br />

450.435.6591 - 16 BOUL. DE LA SEIGNEURIE EST, BLAINVILLE, QC CANADA J7C 3V5<br />

6 MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE APRIL 2017 n NATIONAL HARDWOOD MAGAZINE 51<br />

[ WWW.SIMONLUSSIER.COM ]<br />

NORTHERN & APPALACHIAN HARDWOOD<br />

CLEEREMAN The most trusted name in carriages<br />

CLEEREMAN The most trusted name in carriages<br />

n Over 1175 Carriages sold<br />

n Lowest Over 1175 cost Carriages of ownership sold<br />

n All Lowest parts cost in stock of ownership and reasonably priced<br />

n In-house All parts engineering stock and reasonably departmentpriced<br />

n Everything In-house engineering from single department piece equipment to<br />

n Everything turn-key mills from single piece equipment to<br />

turn-key mills<br />

STEFAN DRACOBLY<br />

President Of<br />

STEFAN Controls DRACOBLY<br />

President Of<br />

Controls<br />

PAUL CLEEREMAN<br />

VP Cleereman<br />

Industries PAUL CLEEREMAN & Controls<br />

VP Cleereman Sales<br />

Industries & Controls<br />

Sales<br />

DAN TOOKE<br />

Senior Optimization<br />

& Controls DAN TOOKE Engineer<br />

Senior Optimization<br />

& Controls Engineer<br />

CLEEREMAN the newest name in sawmill controls and optimization<br />

CLEEREMAN the newest name in sawmill controls and optimization<br />

n Simple easy to use touch n 3D data used for<br />

n Simple screen with easy additional to use touch n 3D opening data used the log for and<br />

tactile screen buttons with additional estimating opening the the log back and of<br />

n Remote tactile buttons access for<br />

log estimating profile the back of<br />

n Remote troubleshooting access for n Realistic log profile views of the log<br />

n No troubleshooting<br />

custom electrical<br />

n Sure Realistic Grip views Joystick of the log<br />

n No hardware, custom all electrical parts are n Sure handles Grip Joystick<br />

off-the-shelf hardware, all components<br />

parts are n Operational handles statistics and<br />

n Industry off-the-shelf Standard components n Operational reports statistics and<br />

n Industry JoeScan X6 Standard heads<br />

reports<br />

JoeScan X6 heads<br />

Cleereman Industries<br />

and Cleereman Industries Controls<br />

and Cleereman 715-674-2700 Controls<br />

www.cleereman.com<br />

715-674-2700<br />

www.cleereman.com<br />

info@cleereman.com<br />

info@cleereman.com

U.S.A. TRENDS<br />

Supplier news about<br />

sales, labor, prices, trends,<br />

expansions and inventories<br />

LAKE STATES<br />

NORTHEAST<br />

SOUTHEAST<br />

WEST COAST<br />

Sales of <strong>Hardwood</strong> lumber in the Lake States are<br />

strong, even “crazy”-strong, according to one source.<br />

A Michigan lumber provider said his market is “extremely<br />

busy. Since the turn of the year, it’s probably<br />

crazier than I’ve ever seen it.<br />

“The market was good six months ago,” he stated.<br />

“It’s better than it was then.”<br />

Products he sells are Hard and Soft Maple, Red and<br />

White Oak, Hickory, Walnut and Cherry. “They’re all<br />

pretty hot,” he pointed out. “Hard Maple’s probably the<br />

craziest. All the other ones are good.”<br />

Half of his customers are end users and the other<br />

half are distribution yards. “They all say they’re busy,<br />

The <strong>Hardwood</strong> lumber markets in the Northeast are<br />

strong, but, as has been the case for some time, product<br />

is hard to find.<br />

For example, a lumber provider in Pennsylvania said,<br />

“There’s not enough lumber of any kind in the system in<br />

our area. It’s just a shortage situation.” Nevertheless, he<br />

assessed the market is far better than several months<br />

ago. He stated that demand is high.<br />

This lumberman handles Cherry, Hard and Soft<br />

Maple, Ash, Red and White Oak and Yellow Poplar. “I<br />

would say that if we had more of any specie, it would<br />

very quickly sell out,” he noted. “There’s nothing that<br />

people aren’t asking us for, and there’s nothing we’re<br />

Sales of <strong>Hardwood</strong> lumber in the Southeast are strong,<br />

with prices at a high level – but one lumber provider is<br />

feeling some pushback from his customers against those<br />

prices.<br />

A Mississippi lumberman stated, “The market has<br />

been crazy, as other people have certainly said. Prices<br />

have been going up, but recently, I’m seeing a trend that<br />

folks are kind of pushing back on prices a little bit. The<br />

market may be readjusting a little bit since it took off like<br />

it did. We’re starting to see some changes along those<br />

lines. I think people, pretty much across the board, are<br />

starting to push back on higher prices, from what we see.<br />

“Our sales are better than several months ago,” he<br />

The <strong>Hardwood</strong> markets on the West Coast are encouraging<br />

– but not without problems.<br />

In California, a source said the market is “pretty strong.<br />

We can’t get enough wood; shipping is a problem; and<br />

prices are going up, but the demand is still there.” The<br />

market dynamics are similar to several months ago, he<br />

remarked.<br />

He sells about 80 different species of lumber. Poplar,<br />

White Oak and Walnut are his best sellers. Thicknesses<br />

range from 4/4 to 16/4 and grades are mostly uppers,<br />

Select and Better and No. 1 FAS.<br />

His customers are mostly end users: cabinet shops,<br />

furniture makers and trim manufacturers. “Residential<br />

Please turn to page 41<br />

Please turn to page 43<br />

Please turn to page 44 Please turn to page 45<br />

Kiln SticKS<br />

GW INDUSTRIES<br />

Importer and Distributor of Tropical <strong>Hardwood</strong> Kiln Sticks<br />

Greenwood Imports LLC<br />

Select No. 1 grade kiln sticks<br />

http://gwi.us.com/tropical-kiln-sticks<br />

<br />

• Industry Leading Kiln Controls<br />

www.nyle.com - kilnsales@nyle.com - (800) 777-6953<br />

• Installation Services & Turn-Key Packages<br />

Flat Profile<br />

Fluted Profile<br />

Leading the Industry as stocking distributors of imported hardwood kiln sticks with a<br />

reputation for consistent grade, reliable shipments and stable cost for over 35-years.<br />

Dennis Krueger<br />

866-771-5040<br />

greenwoodimportsllc@gmail.com<br />

Jackie Paolo<br />

866-504-9095<br />

jackie@gwi.us.com<br />

8 MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 9

CANADIAN TRENDS<br />

News from suppliers about prices, trends,sales and inventories<br />

ONTARIO<br />

As the first day of spring arrived, renewed optimism<br />

was felt by some lumber contacts as warmer weather<br />

was upon us. Of course, there was the usual slowdown<br />

caused by spring thaw for loggers to contend with. Also,<br />

the rollout of the COVID-19 vaccines have started across<br />

many provinces, although at a slower pace than planned,<br />

but is seen as a positive. Meanwhile, a third wave of the<br />

Covid virus is also cause for concern, as it could mean<br />

another lockdown as case numbers continue to rise.<br />

Businesses are following safety and distancing protocols<br />

to avoid shutting down their operations.<br />

Sales contacts commented that most grade lumber<br />

markets are performing well. Demand from cabinetmakers,<br />

flooring and furniture manufacturers, moulding and<br />

QUEBEC<br />

Lumber contacts reported that demand for most species<br />

was up as recently as March. With a positive housing<br />

market continuing at a strong pace, those in the<br />

<strong>Hardwood</strong> sector are more optimistic for <strong>2021</strong> and moving<br />

into spring. With COVID-19 vaccinations increasing,<br />

there is renewed optimism that the pandemic will hopefully<br />

end as more and more inoculations are completed.<br />

With the onset of spring, sawmills are keen to avoid potential<br />

stain during this time.<br />

Sources reported that Ash sales are good both on<br />

domestic and international markets. Sawmills are having<br />

no difficulty moving developing production. Hickory<br />

demand has improved to flooring and finished goods<br />

manufacturers. It was noted that the furniture, cabinet<br />

Please turn to page 48 Please turn to page 49<br />

WE CARE<br />

ABOUT YOUR<br />

SUCCESS<br />

BY OFFERING YOU OUR<br />

EXPERTISE IN HARDWOOD<br />

LOG & LUMBER HANDLING<br />

Contact us today for competitive rates and - Unparalleled service since 1977!<br />

Lloyd Lovett - llovett@kingcityusa.com<br />

Peter Lovett - plovett@kingcitynorthway.com<br />

10 MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 11

NEWS DEVELOPMENTS<br />

NEWS ABOUT NORTH AMERICAN INDUSTRIAL<br />

HARDWOOD CONSUMERS INCLUDING MERGERS,<br />

PLANT EXPANSIONS & ASSOCIATION ACTIVITIES<br />

WEST BROS FURNITURE INTRODUCES NEW<br />

LINEUP WITH U.S. HARDWOODS<br />

Available this month, West Bros Furniture, a case<br />

goods manufacturer located in Hanover, ON, is introducing<br />

a new lineup of writing desks. Walnut, White Oak and<br />

12 MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE<br />

Cherry are among the U.S. lumber species used in these<br />

products.<br />

West Bros’ design partner was Blake Tovin and together<br />

they are releasing the new desks, mostly 52-inch designs.<br />

In a statement, West Bros said these pieces aim<br />

to complement the manner in which<br />

people work from home.<br />

All the desks’ drawer construction<br />

is dovetail joinery in Maple, according<br />

to a company spokesperson.<br />

The new desk lineup includes:<br />

Camber, made of solid Cherry;<br />

Phase, manufactured with Black<br />

Walnut and White Oak; Serra, made<br />

of solid Walnut; Fulton, featuring<br />

White Oak solids and veneers; and<br />

The Fulton desk by West Bros Furniture<br />

features solid White Oak.<br />

Hayden, as well as Odeon, comprised<br />

of solid White Oak.<br />

West Bros has been producing<br />

high quality, sustainable solid wood<br />

in their Ontario plant for over two decades.<br />

The company remains family<br />

owned and operated.<br />

Learn more at www.westbrosfur<br />

niture.com.<br />

CITT RELEASES STATEMENT<br />

ON CHINA’S DECORATIVE<br />

PLYWOOD IMPORTS<br />

The Canadian International Trade<br />

Tribunal (CITT) recently issued a determination<br />

that decorative plywood<br />

imports from China have not injured<br />

and are not threatening to injure Canadian<br />

producers of the product.<br />

The Canadian <strong>Hardwood</strong> Plywood<br />

and Veneer Association (CHPVA), located in St. Lazare,<br />

QC, said in a statement that it was surprised and disappointed<br />

by this decision.<br />

In a parallel investigation the Canada Border Services<br />

Agency (CBSA) determined that large volumes of Chinese<br />

imports of decorative plywood<br />

were being dumped and subsidized<br />

at margins of up to 300 percent. The<br />

CITT was responsible for determining<br />

if the unfairly traded imports had<br />

caused injury to the Canadian industry<br />

or threatened to do so in the<br />

future.<br />

In recent years, several Canadian<br />

companies producing decorative<br />

plywood have gone out of business<br />

in the face of competition from<br />

dumped and subsidized Chinese<br />

imports. The complaint was filed<br />

to address the impact that unfairly<br />

traded Chinese imports have had<br />

on the Canadian market.<br />

At the time of this writing, the<br />

CHPVA found it difficult to understand<br />

how the Tribunal reached the<br />

conclusion it did in this case. Subsequently,<br />

CHPVA and coalition member<br />

companies filed an appeal of the<br />

CITT decision in the Federal Court<br />

of Appeal in Ottawa on March 19.<br />

The CHPVA is the national association<br />

representing the Canadian<br />

<strong>Hardwood</strong> plywood and veneer industry<br />

in all technical, regulatory,<br />

quality assurance, and product acceptance.<br />

Its members manufacture rotary,<br />

sliced, and jointed <strong>Hardwood</strong> veneer,<br />

as well as decorative panels<br />

used in manufacturing furniture,<br />

paneling, cabinetry, doors, shelving,<br />

and other similar products.<br />

Its associate members are businesses<br />

engaged in production,<br />

sales, and distribution of materials<br />

and machines for the industry, or<br />

that provide services such as brokerage,<br />

research, consultation, and transportation to the<br />

industry.<br />

For additional information: Patrick Laurin, executice<br />

vice president, at plaurin@chpva.ca.<br />

UPGRADE YOUR<br />

OPTIMIZATION EXPERIENCE<br />

BIG enough to support your operation; small enough to care.<br />

09 Members on<br />

the software team<br />

13 Members on<br />

the controls team<br />

24/7Support<br />

with experts<br />

in 3 time zones<br />

across the globe<br />

40+Optimization<br />

systems<br />

700+ Control<br />

Systems installed<br />

worldwide<br />

704.200.2350<br />

sales@automationelecusa.com<br />

automationelecusa.com<br />

Please turn to page 54<br />

MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 13

HMA UPDATE<br />

LOOKING AHEAD<br />

<strong>National</strong> Conference and Expo<br />

<strong>2021</strong> is now in the HMA event(s)<br />

‘completed’ column! And to the HMA<br />

members, association colleagues<br />

and industry suppliers who made<br />

their way to Austin to participate in<br />

this long awaited and much anticipated<br />

industry event, a heart-felt ‘thank<br />

you.’ Despite the legion of naysayers,<br />

you took that leap of Faith, joined us<br />

in Austin and helped jump-start <strong>2021</strong>.<br />

Wasn’t it wonderful to be out and about again, after such<br />

an extraordinarily confining 2020?<br />

If you were unable to be with us in Austin, you missed<br />

an awesome event. The Conference’s two evening receptions,<br />

Vendor Expo Café and the morning meal networking<br />

venues provided multiple opportunities for participants<br />

to mix and mingle, catch up on lost time, enjoy<br />

each other’s company, and of course, cruise the Vendor<br />

Expo for the latest and greatest being offered by our industry<br />

suppliers.<br />

The Thursday/Friday Business Sessions were a mix of<br />

in-person and virtual presentations built around our Conference<br />

theme, “Resilience.” Based on attendee comments<br />

thus far, the information provided was spot-on and<br />

even entertaining! (To all of our presenters, ‘thank you!’)<br />

I’m extremely pleased that participants found one Business<br />

Session, “The Real American <strong>Hardwood</strong> Coalition<br />

Update,” especially informative. As part of the presentation,<br />

the Initiative’s Marketing Plan was ‘rolled out.’ Funding<br />

milestones were identified. And soon, in accordance<br />

with 5O1(c)3 guidelines, the Coalition will be electing officers<br />

- comprised of the Executive Directors of associations<br />

that are participating in the Initiative. Really exciting.<br />

Additionally, up and running is RealAmericanHard<br />

wood.org, a website to communicate the Initiative’s prog-<br />

ress and accomplishments. I encourage<br />

all industry stakeholders to visit the<br />

site, especially if you have questions<br />

about how businesses and individuals<br />

can contribute to the effort. You’ll most<br />

likely find the answers there. And if not,<br />

reach out to info@realamericanhard<br />

wood.org.<br />

ONE FINAL CONFERENCE<br />

COMMENT<br />

I would be remiss if I did not thank HMA’s Ian Faight<br />

for traversing the exhibit floor, iPhone at the ready, and<br />

making FaceTime ‘Live’ a reality during the vendor Expo.<br />

Not only was it a fun activity for the industry suppliers<br />

who opted to participate, it provided them an additional<br />

opportunity to present their products and services. As I<br />

said, it was fun. Visit HMA’s Facebook page to see which<br />

vendors were not camera shy.<br />

WHAT’S NEXT?<br />

Plans are in the works for a Spring/Summer “Live”<br />

Regional Meeting – virtual style. Yes, the camera crew,<br />

drone and HMA staff will again take to the road to film<br />

several HMA member facilities. And once all of the<br />

‘bloopers’ have been edited out, the virtual tours, narrated<br />

“live,” will be available as online events to HMA<br />

members and <strong>2021</strong> <strong>National</strong> Conference exhibitors and<br />

sponsors. (Modern technology is indeed wonderful!)<br />

Stay tuned for more details.<br />

And looking ahead to 2022 - HMA’s <strong>National</strong> Conference<br />

and Expo is set for March 23-25, at the Sandestin<br />

Golf and Beach Resort, Miramar Beach, Florida. Plan on<br />

joining us, there! Springtime in Florida! n<br />

BY LINDA JOVANOVICH,<br />

EXECUTIVE VICE PRESIDENT,<br />

HARDWOOD MANUFACTURERS ASSOCIATION,<br />

PITTSBURGH, PA<br />

412-244-0440<br />

WWW.HMAMEMBERS.ORG<br />

14 MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE

AHEC REPORT<br />

NWFA REVIEW<br />

<strong>2021</strong> AHEC EVENTS UPDATE<br />

Real Wood. Real Life.<br />

As we finally start to get a clearer picture<br />

of a post-COVID world returning to normal,<br />

AHEC has updated our events calendar and<br />

are building towards a busy end of the year.<br />

In addition to our full schedule of design,<br />

marketing, educational, and networking<br />

events, AHEC has also planned in person<br />

events for the industry at the following<br />

shows in <strong>2021</strong>:<br />

FMC Shanghai, Shanghai, China<br />

(September 7-11)<br />

VietnamWood <strong>2021</strong>, Ho Chi Minh City,<br />

Vietnam (October 20-23)<br />

AHEC SE Asia Convention, Bangkok,<br />

Thailand (October 25)<br />

FIMMA Maderalia, Valencia, Spain (November 15-19)<br />

Cairo Woodshow, Cairo, Egypt (December 9-12)<br />

It’s difficult to forecast a global immunization timeline,<br />

but with the Biden administration announcing a plan for<br />

all adults to be eligible for the vaccine by April 10th, we<br />

feel increasingly optimistic that international travel will<br />

be able to resume quickly. The exact form of the AHEC<br />

space at these trade shows will be flexible for now, and<br />

it’s likely we will continue to build “Open Plan” pavilions<br />

to allow for an uncertain number of participants.<br />

Of course, participation is still subject to travel<br />

restrictions, and it’s likely that travelers will be required<br />

to show proof of vaccination before being allowed<br />

to travel internationally. Events in China in particular<br />

may be difficult to attend in <strong>2021</strong>, as China is currently<br />

requiring travelers to have taken the Chinese COVID-19<br />

vaccine, which is not even available in the United States.<br />

Nevertheless, large trade shows have already returned<br />

to China, with Interzum Guangzhou being held as<br />

usual in March. Americans were not able to attend, but<br />

many local Chinese representatives of U.S. <strong>Hardwood</strong><br />

companies attended the AHEC pavilion, and we will host<br />

a similar format at FMC Shanghai in September if travel<br />

restrictions are unchanged. Due to these<br />

restrictions, we have postponed both our<br />

participation in the SylvaWood trade show in<br />

Shanghai and the AHEC China convention<br />

in Chengdu, which were scheduled for June.<br />

VietnamWood <strong>2021</strong>, held every other<br />

year in Ho Chi Minh City, is the return<br />

of the largest trade show in the country.<br />

This is the cornerstone event in what has<br />

become the second largest export market<br />

for American <strong>Hardwood</strong> lumber. Right after<br />

VietnamWood, AHEC is planning to host our<br />

AHEC SE Asia Convention in Bangkok,<br />

Thailand on October 25th. All AHEC<br />

members who wish to attend this networking<br />

and educational event will be given a free tabletop booth<br />

with their company logo at the cocktail reception with our<br />

attending Asian buyers.<br />

FIMMA Maderalia in Valencia, Spain, rescheduled<br />

to November 15-19, will be an excellent opportunity for<br />

the U.S. <strong>Hardwood</strong> industry to connect with European<br />

buyers, and with Interzum Cologne moving to an onlineonly<br />

format, this will be the only pavilion of the year in<br />

Europe.<br />

It was unfortunately not possible to host a full U.S.<br />

<strong>Hardwood</strong> Pavilion at Dubai Woodshow in <strong>2021</strong>, but<br />

companies looking to make connections in the Middle<br />

East will still have an opportunity to do so at the Cairo<br />

Woodshow this December in Egypt.<br />

Above all, our goal at AHEC is to represent the<br />

American <strong>Hardwood</strong> industry and connect U.S.<br />

companies to new markets. By providing a low-cost way<br />

to exhibit at international trade shows we hope to make<br />

it easy for small, family-owned companies to make a big<br />

global impact.<br />

If you are interested in attending our SE Asia<br />

Convention or any of the trade shows listed here, please<br />

contact AHEC's International Program Manager, Tripp<br />

Pryor, tpryor@ahec.org. n<br />

Oscar Wilde once said that “imitation<br />

is the sincerest form of flattery that<br />

mediocrity can pay to greatness.” If<br />

that is the case, then the <strong>Hardwood</strong> industry<br />

is truly great, because it is often<br />

imitated. Wood-look products have<br />

saturated the market during the past<br />

few years, but with one big difference:<br />

fake wood products offer none of the<br />

attributes of real wood.<br />

The <strong>Hardwood</strong> industry recognizes that it must address<br />

this discrepancy, which is why the NWFA partnered with<br />

other <strong>Hardwood</strong> organizations – including the <strong>Hardwood</strong><br />

Federation, <strong>Hardwood</strong> Manufacturers Association, Appalachian<br />

<strong>Hardwood</strong> Manufacturers Inc., <strong>National</strong> <strong>Hardwood</strong><br />

Lumber Association, American <strong>Hardwood</strong> Export<br />

Council, Maple Flooring Manufacturers Association, Decorative<br />

<strong>Hardwood</strong> Association, and numerous state and<br />

regional groups – to create the Real American <strong>Hardwood</strong><br />

Coalition. The Coalition’s goal is to create a national consumer<br />

campaign promoting the benefits and attributes<br />

of real <strong>Hardwood</strong> products. This effort is well underway<br />

having already completed consumer research, branding<br />

strategy, and a website (realamericanhardwood.com).<br />

The next step is to develop a consumer-focused campaign<br />

that will launch in the coming months.<br />

For its own part, the <strong>National</strong> Wood Flooring Association<br />

faces a similar challenge. The wood flooring industry<br />

has experienced market loss to wood-look products. This<br />

primarily has been caused by other flooring product categories<br />

being promoted as water-proof. However, waterproof<br />

flooring is a false marketing concept. The flooring<br />

material itself may be waterproof, but the baseboards,<br />

mouldings, and seams are not. Because these generally<br />

are not sealed, water would travel through or past<br />

them. This presents two problem scenarios. First, the<br />

water will penetrate the seams or ends of the flooring<br />

material that are not sealed. Second, the water will travel<br />

to the subfloor material below the floor itself, which is<br />

not waterproof. As a result, the material can distort, mold<br />

can develop, and any damaged material will need to be<br />

replaced.<br />

The NWFA developed a “Real<br />

Wood. Real Life.” marketing campaign<br />

to promote the positive attributes of<br />

real wood floors: they contribute to a<br />

healthy indoor environment, they are<br />

durable, they are easy to maintain,<br />

they offer long-term value, and they<br />

are an environmentally responsible<br />

flooring choice.<br />

Campaign materials include a variety of elements that<br />

can be used in different ways, and for different purposes.<br />

LOGO<br />

The “Real Wood. Real Life.” logo provides a quick<br />

and easy way to identify products as being made from<br />

real wood. It can be used on product packing, websites,<br />

marketing materials, social media channels, trade show<br />

events, etc.<br />

DIGITAL ADS<br />

Digital ads can be used across all social media channels.<br />

Individual ads speak to a specific attribute of wood<br />

floors, including durability, sustainability, health, maintenance,<br />

and value.<br />

PRINT ADS<br />

Print ads can be used in magazines, newspapers, special<br />

advertising inserts, etc. These ads are high-resolution,<br />

print-ready, and, like the digital ads, they promote<br />

the benefits of real wood floors over other flooring options.<br />

FACT SHEETS<br />

Fact sheets can be used as home show handouts, direct<br />

mail inserts, showroom materials, and even faceto-face<br />

meetings. Each sheet details one aspect of the<br />

real wood story: ease of maintenance, how wood floors<br />

support environmental responsibility, how wood floors increase<br />

the value of a home, etc.<br />

Please turn to page 40<br />

BY MICHAEL SNOW,<br />

EXECUTIVE DIRECTOR,<br />

AMERICAN HARDWOOD EXPORT COUNCIL,<br />

STERLING, VA<br />

703-435-2900<br />

WWW.AHEC.ORG<br />

BY MICHAEL MARTIN,<br />

PRESIDENT & CEO,<br />

NATIONAL WOOD FLOORING ASSOCIATION,<br />

CHESTERFIELD, MO<br />

800-422-4556<br />

WWW.NWFA.ORG<br />

16 MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE<br />

MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 17

WCMA INSIGHTS<br />

NHLA NEWS<br />

WCMA Plans Live Event, Partners with Industry<br />

Colleagues, Expands Outreach Programs<br />

The WCMA Board of Directors created its<br />

strategic plan for the next two years recently,<br />

and included expanded educational and<br />

communication programs, as well as playing<br />

key roles in wood industry promotions.<br />

With a more active presence on social media<br />

platforms, and a recently launched blog,<br />

the WCMA is more accessible to its members,<br />

wood industry partners, and the public.<br />

We look forward to offering more news, added<br />

resources, and new insights as we move<br />

forward.<br />

Collaborating with fellow trade associations is a priority<br />

for <strong>2021</strong>. We continue to partner with the Wood Industry<br />

Resource Collaborative (WIRC) in developing strategies<br />

to promote wood industry careers. It is exciting to see the<br />

“You Wood” website launched recently, and the WCMA is<br />

proud to be a contributing member of this important initiative.<br />

WCMA is also supporting the Real American <strong>Hardwood</strong><br />

Coalition (RAHC), a voluntary, industry-wide domestic promotion<br />

initiative for American <strong>Hardwood</strong>s. In addition to offering<br />

financial support, I have had the pleasure to serve<br />

on the Executive Committee in developing plans and doing<br />

the work that helps reach our goals of increasing American<br />

<strong>Hardwood</strong> sales, improving industry stability, and raising<br />

awareness of the health and environmental benefits of Real<br />

American <strong>Hardwood</strong>. Our members know that reaching<br />

consumers in a meaningful way will have a positive impact<br />

on their bottom line!<br />

<strong>2021</strong> FALL CONFERENCE AND PLANT TOUR<br />

EVENT<br />

The WCMA is excited to be returning to a live event for<br />

the <strong>2021</strong> Fall Conference and Plant Tour Event. The event<br />

offers numerous networking opportunities and will give attendees<br />

an excellent opportunity to learn how industry professionals<br />

stay updated in areas such as woodworking machinery,<br />

equipment, tooling, supplies, software, and overall<br />

business solutions.<br />

The event will be open to WCMA member companies and<br />

Tech Partners. Non-members are encouraged to attend to<br />

see what the WCMA is all about. We are sure that after participating<br />

in these excellent networking opportunities, you<br />

will be excited to join.<br />

Conference details and registration will be announced<br />

soon, visit the WCMA website for more information. www.<br />

wcma.com<br />

<strong>2021</strong> VIRTUAL ROUND TABLE SERIES<br />

Having adapted to the use of virtual meeting<br />

platforms this past year, an initiative to<br />

expand WCMA’s education and member outreach<br />

programs has begun. Part of this expansion<br />

is the development of Virtual Round<br />

Table events. Discussion topics will include<br />

employee retention, recruitment and engagement,<br />

lean management, supply trends, and<br />

more.<br />

These monthly, one-hour sessions will be<br />

open to all WCMA members and other interested<br />

parties. Registration and information will be available<br />

on the WCMA website. www.wcma.com<br />

WCMA MEMBERSHIP – IF YOU ARE NOT A<br />

MEMBER, YOU ARE MISSING OUT!<br />

Below are several of the key benefits of being a member<br />

with the WCMA:<br />

•Networking/Information Exchange – One of the main<br />

reasons that members join and stay with the WCMA is<br />

because of the access that it provides to a wide range<br />

of industry experts. Your colleagues are often your best<br />

source for in-depth insight and ideas. WCMA gives you<br />

the opportunity to connect with industry professionals<br />

across the United States and into Canada.<br />

•Virtual and Live Events – The WCMA hosts events designed<br />

with our members in mind. As you can see by the<br />

outlines for <strong>2021</strong> above, these events offer members a<br />

great chance to improve your knowledge of your industry<br />

and to connect with your peers.<br />

•Exclusive use of Real American <strong>Hardwood</strong> Coalition<br />

branding and marketing resources.<br />

I would love an opportunity to discuss membership in<br />

more detail with you. Please email me directly at amy@<br />

wcma.com or call 651-332-6332. You can see more about<br />

membership and activities that the WCMA is working on at<br />

our website, www.wcma.com. n<br />

BY AMY K. SNELL, CAE,<br />

EXECUTIVE DIRECTOR,<br />

WOOD COMPONENT<br />

MANUFACTURERS ASSOC.,<br />

LINDSTROM, MN<br />

651-332-6332<br />

WWW.WCMA.COM<br />

INTRODUCING THE NHLA LEADERSHIP AWARD<br />

In April 2019, the NHLA Board of Managers<br />

approved the NHLA Women in Leadership<br />

Award to recognize women leaders in the<br />

<strong>Hardwood</strong> lumber industry. If you were at the<br />

2019 NHLA Convention, you will remember<br />

the moving moments when then President<br />

Darwin Murray presented a posthumous<br />

award to Mrs. Pat Crites of Allegheny Wood<br />

Products. Her husband John Crites and the<br />

entire family accepted the award in her honor.<br />

For me, it was one of the most important “feel good”<br />

moments of the conference.<br />

After a thorough review of the award concept, the<br />

NHLA Board recently voted to expand the award criteria<br />

to include both men and women leaders. NHLA Vice<br />

President Jon Syre will serve as the NHLA Leadership<br />

Award Selection Committee.<br />

The award will honor an industry leader who has supported<br />

NHLA and the <strong>Hardwood</strong> industry through the trials<br />

and tribulations that best characterizes the nature of<br />

the <strong>Hardwood</strong> industry. And after what we have all been<br />

through in the past several years, I for one believe it is<br />

time for a celebration of a man or woman who defines<br />

what leadership looks like for the entire <strong>Hardwood</strong> industry.<br />

As you consider the man or woman you might nominate<br />

for this award, you may ask, what is a leader, what<br />

defines leadership? Leadership is a quality that is very<br />

difficult to quantify, because it is hard to put on paper.<br />

Leadership is influenced by perception, like the positive<br />

mark or legacy an individual leaves behind as they move<br />

forward through their lives and careers. Leaders are<br />

innovators and iconoclasts, rebels when they need to<br />

be, negotiators and debaters. They are individuals who<br />

learn as much as they educate, great leaders are great<br />

followers all at the same time. And the one common trait<br />

all <strong>Hardwood</strong> leaders have is an ongoing commitment to<br />

NHLA and our industry.<br />

It is time to celebrate their contributions with a nomination<br />

acknowledging their contributions.<br />

SO HOW DOES IT WORK?<br />

The NHLA Leadership Award will be presented on<br />

a bi-annual basis to recognize a male or female NHLA<br />

member for their significant and ongoing contributions<br />

and leadership to NHLA and its members. All NHLA<br />

members in good standing are qualified<br />

to win the award. The award may also be<br />

presented posthumously.<br />

A nominee must be a NHLA member for<br />

20 years or more prior to being nominated.<br />

He or she must demonstrate ongoing<br />

contributions and dedication to serving<br />

the industry, and consistent recognition<br />

of his/her role as a collaborative industry<br />

leader. He or she should be a proven<br />

innovator with a consistent track record of supporting<br />

NHLA and the <strong>Hardwood</strong> industry.<br />

Nominees must be actively engaged in the <strong>Hardwood</strong><br />

industry; exceptions may be made for retirees from the<br />

<strong>Hardwood</strong> industry and NHLA membership.<br />

TO NOMINATE<br />

To nominate an individual, you must present an outline<br />

of the honorees contributions and describe the positive<br />

impact of his or her actions to NHLA and the <strong>Hardwood</strong><br />

industry. You should provide references/support from a<br />

minimum of two NHLA members in good standing. Individuals<br />

nominating others may add information as they<br />

deem necessary.<br />

Once nominated, the President of the NHLA Board<br />

will appoint an Award selection committee that includes<br />

representatives from all segments of NHLA membership<br />

and chaired by the Board Vice President. The Committee<br />

will be made up of representatives from all member<br />

segments who are charged with the responsibility<br />

of reviewing nominees and submitting one finalist for<br />

the award. Individuals serving on the Selection Committee<br />

who are nominated for an award must recuse him<br />

or herself from Committee deliberations. In <strong>2021</strong>, the<br />

award will be presented at NHLA Annual Convention &<br />

Exhibit Showcase in West Palm Beach, Florida.<br />

For more information, or to ask questions, please<br />

email l.christie@nhla.com. n<br />

BY LORNA D. CHRISTIE,<br />

EXECUTIVE DIRECTOR,<br />

NATIONAL HARDWOOD<br />

LUMBER ASSOC.,<br />

MEMPHIS, TN<br />

901-377-1818<br />

WWW.NHLA.COM<br />

18 MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 19

Dundee, OH—You could cent moisture content). Most of their ness to work with any species is one<br />

be forgiven if you are not material purchases are in the form of our big advantages,” Dennison<br />

yet familiar with Crafted of laminated turning blanks that are said.<br />

Elements, located here. They are, S4S, and PET. Crafted Elements The company also works with a<br />

after all, relatively new to the industry.<br />

But the craftsmanship that goes cies, because the company takes craftspeople, such as architects, fur-<br />

works with a long list of wood spe-<br />

variety of customers, including fellow<br />

into their work reveals that, while the pride in its versatility. “Our willing-<br />

Please turn to page 36 <br />

company may be new, there is a lot<br />

of experience behind the name.<br />

“One of our core beliefs is that above all else, we<br />

“My career began in 1992 at the<br />

age of 16 at my father’s metalworking<br />

job shop as a custodian and gen-<br />

with and serve. Many of our employees take this<br />

should have a positive impact on those we work<br />

eral laborer,” craftsman and owner<br />

Todd Dennison recalled. “At the age<br />

to heart and strive to make this approach a part of<br />

of 17, I began to apprentice under their everyday lives.”<br />

some of the journeyman machinists<br />

at the company, including my father. – Todd Dennison, a craftsman for and the owner of Crafted Elements<br />

I spent the next several years not realizing<br />

that I was learning and practicing<br />

valuable machinist skills that I<br />

would later-on use to build my career<br />

in woodworking.”<br />

Dennison was later offered a floorlevel<br />

machine set-up/operator position<br />

in a custom woodworking shop,<br />

and worked his way up to the plant<br />

manager position over the next few<br />

years. By 2006, he and two partners<br />

had purchased the company.<br />

“We then purchased two stair component<br />

manufacturing companies in<br />

2007 and 2008 and combined the<br />

three companies in one location in<br />

Newcomerstown, OH,” he said. “In<br />

2009, I sold my ownership in those<br />

companies and worked with Brown<br />

Wood Inc. to open up a manufacturing<br />

facility for them. I managed that<br />

facility for nine years before ultimately<br />

purchasing the manufacturing facility<br />

from them and starting Crafted<br />

Wooden milk bottles with custom designs<br />

come from Crafted Elements.<br />

Elements. Our focus is on manufacturing<br />

high-end custom wood, metal,<br />

Crafted Elements<br />

and acrylic components for many industries.”<br />

Crafted Elements is a manufacturer<br />

of mouldings, carvings, large diameter<br />

turnings, decorative legs and<br />

bun feet. Annual lumber purchases<br />

total approximately 300,000 board<br />

Highly Skilled Workers Seek to Have<br />

feet of Hard and Soft Maple, Red<br />

and White Oak, Poplar and Cherry,<br />

a Positive Impact on Others<br />

Todd Dennison is a craftsman and the owner of Crafted Elements in Dundee, OH. Annual<br />

as well as Alder, Walnut, Birch and<br />

lumber purchases for Crafted Elements total approximately 300,000 board feet of Hard<br />

Beech (No. 1 and No. 2 Common, and Soft Maple, Red and White Oak, Poplar and Cherry, as well as Alder, Walnut, Birch<br />

By Scott Dalton<br />

and Beech.<br />

Select, 4/4 to 16/4, S4S, 6 to 8 per-<br />

20 MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 21

“We’ve grown steadily and<br />

continually,” he said. “I think<br />

a lot of that’s due again to<br />

our efforts to constantly try<br />

new things and embrace new<br />

products and new ideas versus<br />

just doing what we’ve always<br />

done.”<br />

– Eric Boer, Vice President,<br />

Mason’s Mill & Lumber Co.<br />

This residential project showcases the typical mouldings and millwork produced by Mason’s Mill & Lumber Co., located in Houston,<br />

TX.<br />

Mason’s Mill & Lumber Co.:<br />

Flexibility Enables Success<br />

By Daniel Connolly<br />

Houston, TX–Some years ago, Mason’s Mill & Lumber<br />

Co., located here, began holding lunch-andlearns<br />

and other continuing education programs<br />

for architects.<br />

The reason: architects and designers end up driving<br />

many building decisions and related sales of wood products,<br />

said the company’s Vice President, Eric Boer.<br />

“We learned that a long time ago,” he said. “By networking<br />

with the architects, they end up specifying your<br />

products or services. So we get that pull-through when<br />

a set of blueprints finally hits the job site, your products<br />

are on there.”<br />

Based at 9885 Tanner Road in Houston, Mason’s Mill<br />

& Lumber is part distribution yard, part manufacturer.<br />

The company distributes a wide range of lumber –<br />

mostly domestic <strong>Hardwood</strong>s, as well as <strong>Hardwood</strong> decking,<br />

plywood, antique and reclaimed woods, and specialty<br />

wood products.<br />

It also manufactures architectural millwork and has<br />

nearly 7,000 profiles in its knife library.<br />

First incorporated in 1990, the company now has 50<br />

employees at its 150,000-square-foot facility and celebrates<br />

its 31st year in <strong>2021</strong>. Boer says creativity and a<br />

diverse approach to product lines and services are what<br />

have helped the company succeed.<br />

“We’ve grown steadily and continually,” he said. “I think<br />

a lot of that’s due again to our efforts to constantly try<br />

new things and embrace new products and new ideas<br />

versus just doing what we’ve always done.”<br />

The company keeps an inventory of about 1.2 million<br />

board feet of product on hand at any time. The company<br />

purchases 2.5 million board feet annually of all domes-<br />

tic <strong>Hardwood</strong>s (Alder through Walnut), 4/4 through 16/4,<br />

and imports Mahogany, Spanish Cedar, Ipe, Cumaru<br />

and Garapa decking.<br />

Products offered include custom moulding, flooring,<br />

stair treads, decking and radius millwork.<br />

Mason’s Mill & Lumber Co. buys its domestic <strong>Hardwood</strong><br />

products directly from sawmills. The company<br />

brings in the products kiln-dried and does not operate<br />

its own kiln.<br />

It sells much of its product rough to contractors, cabinet<br />

shops, door manufacturers and similar companies.<br />

But it also manufactures wood products into items such<br />

as mouldings, interior and exterior cladding, custom<br />

flooring, stair treads and custom decking.<br />

Among the specialty products that Mason’s Mill & Lumber<br />

carries and promotes is Accoya brand wood, which is<br />

placed through a process called acetylation that makes it<br />

far more durable and stable. Mason’s Mill & Lumber also<br />

carries and promotes products by Thermory, a company<br />

that modifies wood through heat and steam to increase<br />

longevity.<br />

The company has also built a specialty business in reclaimed<br />

wood.<br />

“We buy that from several companies that specialize<br />

in dismantling and taking down old buildings: old barns,<br />

old warehouses, old grain silos, things like that,” Boer<br />

said. “They used Oak or longleaf pine or old Cypress,<br />

100, 150, 200 years ago to manufacture things. It’s obviously<br />

got a lot of character and a lot of history.”<br />

The salvage companies remove all the nails and bolts<br />

and prepare the antique wood for resale.<br />

“There’s been a huge demand in the last few years<br />

for reclaimed antique White Oak timbers, beams, and<br />

lumber, which we manufacture into flooring, or mouldings<br />

or millwork.”<br />

Among the key personnel at Mason’s Mill & Lumber are (from left): Sam Damiani,<br />

sales manager, Eric Boer, vice president and Mason Spellings, general<br />

manager.<br />

Pictured is Enrique Flores, mill manager at Mason’s Mill & Lumber.<br />

Married couple Michael and Anne Spellings founded<br />

the company and continue to own it to the present day.<br />

Early on, they added two key people: sourcing and sales<br />

specialist John Sorenson, as well as Eric Boer, a secondgeneration<br />

lumberman from a timber importing family.<br />

Today Sam Damiani is the sales manager. Mason<br />

Spellings, the son of the founders, is general manager.<br />

The company’s work with antique wood led Mason<br />

Spellings and a machinist several years ago to build a<br />

wire-brushing machine.<br />

“So we’re taking new growth – <strong>Hardwood</strong> that’s been<br />

harvested recently – and pass it through this wire brushing<br />

machine to give it an antique-type texture,” Boer said.<br />

“We offered that service to architects, showed them how<br />

we manufacture it and get the look of antique woods for<br />

a fraction of the price. So we’ve opened some doors that<br />

way.”<br />

Major sections of its operation include warehousebased<br />

storage and two mills: a planing mill and a moulding<br />

mill.<br />

Please turn to page 39 <br />

22 MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 23

HMA NatCon Welcomes Participants<br />

Photos by Paul Miller Jr. and Terry Miller<br />

Austin, TX - Recently, 120 participants were on<br />

hand to visit exhibitor booths that presented<br />

products and services at the <strong>Hardwood</strong> Manufacturers<br />

Association’s (HMA) <strong>National</strong> Conference and<br />

Expo, which was held here at the Hyatt Regency.<br />

Themed “Resilience,” the HMA event also featured virtual<br />

speakers as well as live events and networking.<br />

Included among the speakers/presenters were the following:<br />

• Thomas Brush, consultant/coach and founder of<br />

Advancement Designs. His interactive workshop was<br />

entitled, “Being Clear on What is Real: An Overlooked<br />

Pathway to Resilience.”<br />

• ITR Economics Senior Forecaster Connor Lokar’s<br />

presentation was entitled “Moving Forward.” He<br />

analyzed the economic landscape, assessing business<br />

demand for <strong>2021</strong> and beyond.<br />

• Joshua and Jacob Pribanic, principals of LastLine<br />

Cyber Inc., addressed the cyber threat landscape in<br />

a presentation entitled, “The Scary Truth About Cybercrime.”<br />

• Michael Snow, executive director of the American<br />

<strong>Hardwood</strong> Export Council, presented a Global Markets<br />

Update and Judd Johnson, <strong>Hardwood</strong> Market<br />

Report Editor, discussed the domestic <strong>Hardwood</strong><br />

landscape.<br />

• <strong>Hardwood</strong> Federation Executive Director, Dana Lee<br />

Cole, updated HMA attendees about what is on the<br />

horizon in the nation’s capital.<br />

The HMA Board of Directors elected Troy Brown, Kretz<br />

Lumber Co. Inc., Antigo, WI, president of the HMA.<br />

Other HMA officers for <strong>2021</strong> are Vice President Tommy<br />

Petzoldt, East Perry Lumber Co., Frohna, MO; and<br />

Executive Vice President Linda Jovanovich, HMA, Pittsburgh,<br />

PA.<br />

HMA Board of Directors also elected members to the<br />

Executive Committee. In addition to the officers, they<br />

are: Geoff Henderson, Anderson-Tully Co., Vicksburg,<br />

MS; Hal Mitchell, Atlanta <strong>Hardwood</strong> Corp., Mableton,<br />

GA; Craig Miller, Battle Lumber Co. Inc., Wadley, GA;<br />

Wayne Law, New River <strong>Hardwood</strong>s, Mountain City, TN;<br />

and Tom Gerow, Wagner Millwork LLC, Owego, NY. Bob<br />

Miller, Frank Miller Lumber Co., Union City, IN, will serve<br />

on the Executive Committee as the immediate past president.<br />

During the Conference’s Business Meeting, HMA<br />

Burt Craig, Matson Lumber Co., Brookville, PA; Chuck Boaz, Corley<br />

Manufacturing Co., Chattanooga, TN; Lance Johnson, ISK<br />

Biocides Inc., Memphis, TN; Jim Burris, Corley Manufacturing<br />

Co., Chattanooga, TN; and Tom Inman, Appalachian <strong>Hardwood</strong><br />

Manufacturers Inc., High Point, NC<br />

members elected Directors: Hal Mitchell, Atlanta <strong>Hardwood</strong><br />

Corp., Mableton, GA; Richard Buchanan, Granite<br />

<strong>Hardwood</strong>s Inc., Granite Falls, NC; Bruce Dahn, HHP<br />

Inc., Henniker, NH; Kirby Kendrick, Kendrick Forest<br />

Products Inc., Edgewood, IA; and Bucky Pescaglia, MO<br />

PAC Lumber, Fayette, MO.<br />

Newly appointed to the HMA NextGen Leaders Council—formerly<br />

known as the HMA Millennial Council—are:<br />

Ian Faight and Linda Jovanovich, <strong>Hardwood</strong> Manufacturers Assoc./Southern<br />

Cypress Manufacturers Assoc., Pittsburgh, PA;<br />

and John Stevenson, Thompson <strong>Hardwood</strong>s Inc./Beasley Forest<br />

Products, Hazlehurst, GA<br />

Kaitlyn Wood, Gates Milling Inc., Gatesville, NC; Lindsey<br />

DiGangi, Pennsylvania Lumbermens Mutual Insurance<br />

Co., Philadelphia, PA; and Patrick Cullinan, Stella-Jones<br />

Corp., Pittsburgh, PA. Bob Miller, Frank Miller Lumber<br />

Co., Union City, IN, continues to serve as the Council<br />

Coordinator.<br />

Also, networking receptions were held. n<br />

Learn more about the <strong>Hardwood</strong> Manufacturers Association by<br />

visiting www.hmamembers.org.<br />

Dana Lee Cole, <strong>Hardwood</strong> Federation, Washington, DC; Scott<br />

Cummings, Cummings Lumber Co. Inc., Troy, PA; and Kaitlyn<br />

Wood, Mark Tuck and Kelsey Kennedy, Gates Milling Inc., Gatesville,<br />

NC<br />

Tommy Petzoldt, East Perry Lumber Co., Frohna, MO; Linda Jovanovich,<br />

<strong>Hardwood</strong> Manufacturers Association, Pittsburgh, PA;<br />

and Troy Brown, Kretz Lumber Co. Inc., Antigo, WI<br />

(Front, from left): Paul Miller Jr., <strong>National</strong> <strong>Hardwood</strong> <strong>Magazine</strong>, Memphis, TN; Trent Yoder, Yoder Lumber Co. Inc., Millersburg, OH;<br />

Scott Cummings, Cummings Lumber Co. Inc., Troy, PA; Peter McCarty, TS Manufacturing, Dover-Foxcroft, ME; Marv Bernhagen, Lewis<br />

Controls/Corley Manufacturing, Chattanooga, TN; (Back, from left): Brian Schilling, Pike Lumber Co. Inc., Akron, IN; Troy Brown, Kretz<br />

Lumber Co. Inc., Antigo, WI; Wayne Law, New River <strong>Hardwood</strong>s, Mountain City, TN; Tommy Petzoldt, East Perry Lumber Co., Frohna,<br />

MO; and Norm Steffy, Cummings Lumber Co. Inc.<br />

24 MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE<br />

Craig Miller, Battle Lumber Co. Inc., Wadley, GA; Skipper Beal,<br />

Beal Lumber Co. Inc., Little Mountain, SC; Tommy Battle, Battle<br />

Lumber Co. Inc.; and Randy Clark, Stella-Jones Corp., Alexandria,<br />

LA<br />

Brian Turlington, SII Dry Kilns, Lexington, NC; Parker Dukas and<br />

Eric Porter, Abenaki Timber Corp., Kingston, NH; and Bob Pope,<br />

SII Dry Kilns, Montpelier, VT<br />

Additional photos on next page<br />

MAY <strong>2021</strong> n NATIONAL HARDWOOD MAGAZINE 25

HMA NATCON PHOTOS Continued<br />

Barry Black, Taylor Machine Works Inc., Louisville, MS; Chris Taylor,<br />

Timber Automation LLC, Hot Springs, AR; and Robert Taylor<br />

and Hal Nowell, Taylor Machine Works Inc.<br />

Jim Higgins, SII Dry Kilns, Lexington, NC; Bob Pope, SII Dry<br />

Kilns, Montpelier, VT; and Brian Turlington, SII Dry Kilns, Lexington,<br />

NC<br />

Bill Behan, Gross and Janes Co., Kirkwood, MO; and Colin Campbell,<br />

Stacy Thompson and Randy Panko, Wood-Mizer LLC, Indianapolis,<br />

IN<br />

Josh Davis, Farm Credit Mid-America, Louisville, KY; Paul Miller<br />