You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

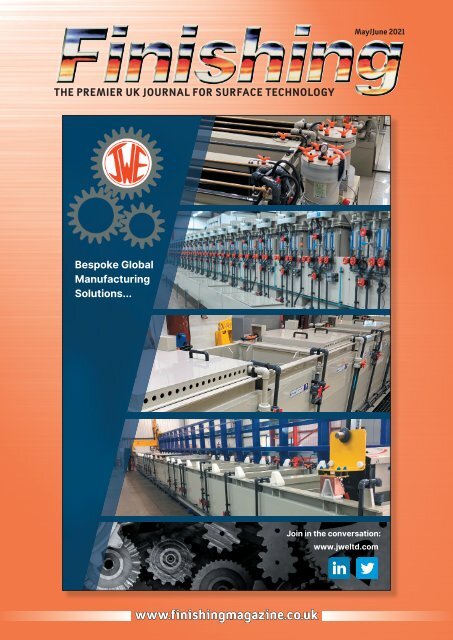

<strong>May</strong>/<strong>June</strong> <strong>2021</strong><br />

THE PREMIER UK JOURNAL FOR SURFACE TECHNOLOGY<br />

Bespoke Global<br />

Manufacturing<br />

Solutions...<br />

Join in the conversation:<br />

www.jweltd.com<br />

www.finishingmagazine.co.uk

THE<br />

POWER<br />

OF<br />

MEMBERSHIP<br />

THE SEA HAS ALL THE ATTRIBUTES YOU NEED<br />

Save money<br />

Save time<br />

Keep a step ahead with industry updates<br />

Enhance your reputation<br />

Gain political clout and expertise<br />

SURFACE<br />

ENGINEERING<br />

AWARDS<br />

FRIDAY 8 th OCTOBER <strong>2021</strong><br />

PARK REGIS BIRMINGHAM<br />

Visit www.sea.org.uk/<strong>2021</strong>-awards for<br />

sponsorship opportunities; if you wish<br />

to enter; or should you just wish to<br />

attend and support your industry.<br />

SEA SUPPORTS UK<br />

SEA members are working hard in the<br />

manufacturing supply chain, supporting<br />

programmes to improve the working lives<br />

of those on the frontline in the NHS as<br />

well as the comfort and survival of those<br />

suffering from Coronavirus in hospitals across<br />

the world. This includes parts produced for<br />

the UK Ventilator Challenge and 3D printing<br />

straps for masks, amongst many other things.<br />

Throughout these difficult times our members<br />

have undertook various activities to ensure that<br />

they are able to continue supporting industries<br />

that are reliant on the work they do. As an<br />

organisation we are proud to say that our<br />

members have continued to underpin<br />

manufacturing in the face of adversity.<br />

Visit the members’ directory today to find a supplier or get help with your surface treatment requirements:<br />

https://www.sea.org.uk/member-directory/<br />

For further details of how the<br />

Surface Engineering Association<br />

can support you, please contact<br />

Michaella Mais on 0121 237 1123<br />

or email michaella.mais@sea.org.uk<br />

Surface Engineering Association<br />

Federation House<br />

10 Vyse Street Birmingham<br />

West Midlands B18 6LT<br />

+44 (0)121 237 1123<br />

info@sea.org.uk<br />

www.sea.org.uk<br />

A

www.finishingmagazine.co.uk CONTENTS 3<br />

Editor<br />

John Hatcher<br />

Tel: 01923 437618<br />

E.mail: j.hatcher@turretgroup.com<br />

Display Advertising<br />

Stewart Freshwater<br />

Tel: 01923 437615<br />

E.mail: s.freshwater@turretgroup.com<br />

Classified Advertising<br />

Stewart Freshwater<br />

Tel: 01923 437615<br />

E.mail: s.freshwater@turretgroup.com<br />

Production Manager<br />

Carol Baird<br />

Tel: 01923 437619<br />

E.mail: c.baird@turretgroup.com<br />

Managing Director<br />

Ian Garmeson<br />

Circulation<br />

Tel: 0141 370 3883<br />

circulation@dimensionsmail.co.uk<br />

Published by<br />

Turret Group Ltd<br />

Cardinal Point<br />

Park Road<br />

Rickmansworth,<br />

WD3 1RE<br />

Tel: +44 (0) 1923 432705<br />

Fax: +44 (0) 1923 432770<br />

Web: www.turretgroup.com<br />

Annual Subscription Rates<br />

United Kingdom: £144.00<br />

Overseas: £168.00 (Airmail)<br />

Printed by Stephens & George<br />

<strong>May</strong>/<strong>June</strong> <strong>2021</strong> – Volume 45 Number 3 – ISSN no. 0264 2506<br />

In this issue...<br />

We now seem to be on the final countdown to ‘back to normal’ and as I write this we<br />

are now able to meet indoors and activities like eating and drinking out are back on the<br />

agenda. I guess the question is, will things ever be normal again?<br />

Work has changed, retail is different, even manufacturing has changed and we still<br />

don’t really know the true implications of the UK leaving the EU. We are in for an<br />

interesting near-future.<br />

In the news this issue Axalta has won some prestigious awards and the BCF has had<br />

positive results from its membership survey. We have a look at aluminium in the issue,<br />

plus features on powder coating and colour choice.<br />

Hopefully we can have a positive <strong>2021</strong> (Barclays is predicting a<br />

economic big bounce back) and an even better 2022.<br />

News<br />

Newsdesk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Features<br />

Eastern investment . . . . . . . . . . . . . . . . . . . . . . . . . . .10<br />

Powder perfection . . . . . . . . . . . . . . . . . . . . . . . . . . . .12<br />

Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14<br />

Lowering the burn . . . . . . . . . . . . . . . . . . . . . . . . . . .16<br />

All members of the SEA<br />

automatically receive <strong>Finishing</strong> Magazine<br />

Clean cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18<br />

Precision on show . . . . . . . . . . . . . . . . . . . . . . . . . . .22<br />

Investing in the future . . . . . . . . . . . . . . . . . . . . . . . .24<br />

Colour code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26<br />

Quick treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32<br />

© Copyright Turret Group Ltd <strong>2021</strong><br />

All Rights Reserved<br />

All rights reserved. No part of this publication<br />

may be produced in any material form (including<br />

photocopying it or storing it in any medium by<br />

electronic means and whether or not transiently<br />

or incidentally to some other use of this<br />

publication) without the written permission of<br />

the copyright owner except in accordance with<br />

the provisions of the Copyright, Designs and<br />

Patents Act 1988. Applications for the copyright<br />

owner's written permission to reproduce any<br />

part of this publication should be addressed to<br />

the info@turretgroup.com<br />

Regulars<br />

Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

Workshop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42<br />

Classified listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43<br />

<strong>Finishing</strong> (formerly <strong>Finishing</strong> Industries) was established in 1947 and incorporates Metal<br />

<strong>Finishing</strong> journal, Electroplating & Metal <strong>Finishing</strong>, The Plant Journal, Surface Coatings, and<br />

Industrial <strong>Finishing</strong> & Surface Coatings. <strong>Finishing</strong> is a member of the Metal <strong>Finishing</strong><br />

Association, a sustaining member of the Institute of Metal <strong>Finishing</strong> and the UK representative<br />

of the Groupement International des Revues de Traitements de Surfaces.<br />

<strong>Finishing</strong> – <strong>May</strong>/<strong>June</strong> <strong>2021</strong>

4 NEWS www.finishingmagazine.co.uk<br />

Axalta wins big at the Edison Awards<br />

Axalta has won three bronze<br />

Edison Awards in the categories<br />

of Innovative Services,<br />

Sustainability and Engineering<br />

and Materials Science. Named<br />

after Thomas Edison, the Edison<br />

Awards have recognised and<br />

honoured some of the most<br />

innovative new products,<br />

services, and business leaders in<br />

the world since 1987.<br />

"We are proud to be an<br />

Edison Award recipient for the<br />

third consecutive year. Axalta’s<br />

focus on continuous innovation<br />

of our coating solutions is the<br />

key to our company’s success.<br />

Receiving three Edison Awards<br />

for innovations in three different<br />

categories is further validation of<br />

Axalta’s commitment to<br />

developing new technology to<br />

serve our customers,"<br />

commented Robert Roop,<br />

Axalta's chief technology officer.<br />

In the Innovative Services<br />

category, Axalta's LiDAR Gonio-<br />

Retroreflectometer System<br />

(ALGRS) won a bronze <strong>2021</strong><br />

Edison Award. This patented<br />

optical system measures the<br />

LiDAR reflectivity of vehicle<br />

coatings for advanced driverassistance<br />

systems (ADAS) or<br />

autonomous vehicles. ALGRS<br />

allows Axalta's chemists and<br />

designers to create LiDARcompatible<br />

coatings without<br />

compromising appearance or<br />

colour.<br />

ADAS, like emergency braking<br />

and collision avoidance, depends<br />

heavily on LiDAR technology to<br />

improve vehicle safety and<br />

advance autonomous vehicles.<br />

The novel coatings analysis<br />

provided by ALGRS enables new<br />

colour development and<br />

formulations that assure the<br />

LiDAR detectability of painted<br />

coatings over the wide range of<br />

traffic conditions that exist in the<br />

autonomous environment.<br />

Roop said, “ALGRS represents<br />

a major advancement in the<br />

technologies that are required to<br />

attain high levels of vehicle<br />

autonomy in a safe and<br />

responsible manner.”<br />

In the Sustainability category,<br />

Axalta’s Spies Hecker Permahyd<br />

5650 sealer, which is not<br />

commercially available in Europe,<br />

the Middle East and Africa, won<br />

a bronze <strong>2021</strong> Edison Award.<br />

The sealer provides collision<br />

repair shops in North America<br />

with a sustainable premium<br />

waterborne application system<br />

with lower solvent emissions.<br />

Axalta’s Spies Hecker Permahyd<br />

5650 sealer applies in a single<br />

coat giving refinishers the ability<br />

to improve productivity with a<br />

sustainable solution.<br />

“The combination of improved<br />

productivity and higher<br />

performance continues to drive<br />

technology roadmaps for the<br />

collision industry,” said Roop.<br />

“The Spies Hecker 5650<br />

application system not only helps<br />

our customers grow their<br />

businesses, it is also<br />

environmentally friendly and<br />

protects the communities in<br />

which we live and work.”<br />

Axalta’s Universal Titan Primer<br />

and Enamel Coating also won a<br />

bronze <strong>2021</strong> Edison Award in<br />

the Engineering and Materials<br />

Sciences category. This coating is<br />

designed for the kitchen cabinet<br />

market offering processing<br />

efficiency and superior<br />

appearance. Only one coat of<br />

primer and enamel are needed<br />

compared to the standard four<br />

coats. Universal Titan is also<br />

optimised to eliminate the need<br />

for two separate products for<br />

horizontal and vertical<br />

applications saving cost and<br />

simplifying the manufacturing<br />

process.<br />

New additives website<br />

BASF has launched a new website for ‘Performance and Formulation<br />

Additives’. The new website (http://www.basf.com/additives) offers<br />

multiple value-adding features. Its design provides faster and easier<br />

access to new additives, fulfilling increasing market needs for<br />

performance and sustainability as well as stricter regulatory<br />

requirements. The BASF ‘Performance & Formulation Additives’<br />

portfolio enables the conversion from solvent to water-based<br />

formulations, helps to reduce the CO2 footprint and contributes to a<br />

higher efficiency and reduction in complexity for our customers.<br />

BASF additive customers from various industries, such as paints and<br />

coatings, construction, printing and packaging, adhesives and<br />

composites can now easily access a series of new additive webseminars<br />

and podcasts through the website.<br />

The web-based tool ‘Lab Assistant’ has also been upgraded. This<br />

tool helps formulators to quickly explore BASF additive and<br />

formulation recommendations, compare products, access product<br />

safety data, order samples and contact our experts.<br />

“The new BASF Additive website combines our strong focus on<br />

innovation and digitalization and our commitment to serve our<br />

customers in the best possible way,” said Dr. Claus Dallner, vice<br />

president, global business management for performance & formulation<br />

additives, BASF.<br />

Digital support<br />

AMETEK Surface Vision has<br />

reinforced its telephone support<br />

service with digital tools to<br />

provide best-in-class 24/7<br />

emergency technical assistance,<br />

globally.<br />

Called Global 24/7, this<br />

support system utilizes state-ofthe-art<br />

remote access, virtual<br />

collaboration, and<br />

telecommunications tools to<br />

dynamically resource technical<br />

support from a pool of experts<br />

located across the globe. This<br />

ensures timely and universal<br />

support for AMETEK Surface<br />

Vision’s global installation base<br />

of thousands of systems and<br />

customers.<br />

The typical customers of<br />

AMETEK Surface Vision are<br />

industrial plants that<br />

manufacture metals, paper,<br />

plastics, and nonwoven<br />

materials, running around the<br />

clock with a staff operating on a<br />

shift system.<br />

They rely on their automated<br />

surface inspection systems. If,<br />

for some reason, that system<br />

does not function correctly, they<br />

may have to stop production.<br />

Global 24/7 is designed to<br />

address this issue by taking full<br />

advantage of the company’s<br />

global support network.<br />

Bringing in team members<br />

from all regions allows the<br />

service to be staffed 24/7 by<br />

technical experts and offers<br />

customers continuous support<br />

wherever located in the world.<br />

<strong>Finishing</strong> – <strong>May</strong>/<strong>June</strong> <strong>2021</strong>

PosiTector ® Inspection<br />

Unrivaled probe interchangeability<br />

for all of your inspection needs.<br />

Coating Thickness Probes<br />

n Ferrous n Non-Ferrous n Combination n Ultrasonic<br />

Surface Profile Probes<br />

n Depth Micrometer n Replica Tape Reader<br />

Environmental Conditions Probes<br />

n Integral n Cabled Magnetic Probe n Anemometer Probe<br />

n 1/2” NPT n Infrared<br />

Hardness Probes<br />

n Shore n Barcol<br />

Salt Contamination Probe<br />

n Bresle Method<br />

Ultrasonic Wall Thickness Probes<br />

n Corrosion n Multiple Echo Thru-Paint n Precision<br />

n Low Frequency n Xtreme<br />

NEW<br />

Design and Features<br />

Design and Features<br />

NEW<br />

Customized Inspection Kits...<br />

Build your own kit from a selection of gauge<br />

bodies and probes to suit your needs.<br />

Coating<br />

Thickness<br />

Surface<br />

Profile<br />

Environmental<br />

Conditions<br />

Hardness<br />

Salt<br />

Contamination<br />

Ultrasonic<br />

Wall Thickness<br />

Backwards Compatibility! The redesigned PosiTector gauge body accepts ALL coating thickness<br />

(6000/200), environmental (DPM), surface profile (SPG/RTR), salt contamination (SST), hardness<br />

(SHD/BHI), and ultrasonic wall thickness (UTG) probes manufactured since 2012.<br />

DFT DFT Instruments UK UK LTD LTD<br />

16A 16A Long Long Drive, Meadway, Berkhamsted, Herts HP4 HP4 2PN 2PN<br />

t: t: 01442 879494 f: f: 01442 879595<br />

www.dftinstruments.co.uk e: e: sales@dftinstruments.co.uk<br />

Proud supplier of of DeFelsko Inspection Instruments

6 NEWS www.finishingmagazine.co.uk<br />

The BCF says that a survey showed that its members were pleased<br />

with what the organisation offered<br />

New partnership launched<br />

Tantec UK has announced the formation of an exciting new<br />

partnership with The Dynamize Marketing Group. The two companies,<br />

who are both based in Redditch, have agreed a 12-month contract<br />

that will see The Dynamize Marketing Group operate as Tantec UK’s<br />

digital marketing and management partner. The aim is to consolidate<br />

and grow the engineering firm’s reputation as a leading provider of<br />

corona and plasma surface treatment systems in the UK and Ireland.<br />

As part of the agreement, experts from both organisations will work<br />

closely to coordinate the firm’s marketing strategy and campaigns. This<br />

will involve members of The Dynamize Marketing Group’s team<br />

working onsite to deliver end-to-end marketing services. Amongst a<br />

number of exciting projects planned includes an e-commerce solution<br />

so that customers can easily purchase Dyne Pens and Inks. These are<br />

off-the-shelf surface energy measurement kits that can also test a<br />

surface’s adherence to adhesives, inks and coatings.<br />

Rebecca Baker, director at The Dynamize Marketing Group,<br />

commented; “We are delighted to be working with the team at Tantec<br />

UK. This is a fantastic opportunity for us to work with a leading UK<br />

engineering firm who are producing some of the most cutting edge<br />

solutions for multiple sectors across the UK and Ireland. We have big<br />

plans for the business and look forward to adding substantial value.”<br />

Announcing the collaboration, Chris Howey at Tantec UK said,<br />

“Tantec UK has a strong and loyal customer list, ranging from small<br />

manufacturers to blue chip companies. We have a global reputation<br />

and work hard to visit clients face-to-face. Customer visits have<br />

obviously changed dramatically since Covid, so our online presence<br />

and offering must meet the same quality we normally offer. We’re<br />

excited to see Dynamize demonstrate their skills and improve our<br />

website traffic so we can really get the message of how good this<br />

equipment is out to new customers!”<br />

New at the helm<br />

New chief executive, Tim Doggett, took the reins of the Chemical<br />

Business Association on 1 <strong>May</strong> <strong>2021</strong> following the retirement of the<br />

previous CEO, Peter Newport.<br />

Tim Doggett has a thirty-year career in logistics and distribution and<br />

has held a number of senior positions in national and international<br />

companies. He was latterly managing director of Clugston Distribution<br />

Services Limited, a road tanker and logistics company with annual<br />

sales of £17 million. The company has a fleet of more than 100 HGVs<br />

operating throughout the UK and Europe, annual sales of £17 million,<br />

and 150 employees.<br />

Tim joined the Association on 9 September 2020 and served as<br />

chief executive designate during the handover period.<br />

The Chemical Business Association’s chair, Kate Mingay, said, “I am<br />

delighted to formally welcome Tim and look forward to us working<br />

together.”<br />

The British Coatings Federation’s (BCF) recent member survey<br />

showed record satisfaction scores for BCF services, with an average<br />

rating of 8.2 out of 10 across 12 categories. The highest satisfaction<br />

rating related to BCF support in helping members prepare for Brexit,<br />

followed by member communications, response during the Covid<br />

crisis and staff service. Overall, 94% of respondents said BCF was<br />

meeting their needs, with only 5% saying their needs were only<br />

partially being met. After a year of major challenges in the sector,<br />

2020 saw a significant rise in member engagement, with much of<br />

this focused on Covid-19 and Brexit. Almost 300 people took part in<br />

the survey, a threefold increase on last year, and the overall<br />

satisfaction score was above 90% for the 5th consecutive survey.<br />

The BCF’s most valued services according to members, are<br />

communications, lobbying and technical advice. Technical seminars,<br />

webinars & workshops were also highly rated, alongside BCF’s work<br />

in raising the profile of the sector.<br />

BCF CEO Tom Bowtell said, “I’m delighted at the continued high<br />

levels of satisfaction and support for the BCF from our membership.<br />

It’s clear from members feedback that sustainability should be a key<br />

area of our future focus. Members are also very concerned about<br />

the future UK chemical regulations such as UK REACH, and see this<br />

as a major opportunity for BCF to support the industry.”<br />

The biggest threats to the BCF, as reported by BCF members,<br />

include less opportunity for the industry to grow as a result of the<br />

economic downturn post Covid, as well as the raw material supply<br />

situation being faced by the industry. Regulatory divergence from the<br />

EU also scored highly as a threat, and helping support members as<br />

they come to grips with the new trading environment with the EU<br />

will continue to be a major focus of activity for the Federation.<br />

Dustcontrol is safety certified<br />

Dustcontrol AB has been officially certified according to ISO 45001 on<br />

Occupational Health and Safety, further highlighting its commitment to<br />

provide a reduced ecological impact and safer working environment.<br />

According to the International Labour Organisation, more than<br />

7,600 people die from work-related accidents or diseases every single<br />

day, underlining the importance of implementing health and safety<br />

regulations that systematically collaborate, plan, support, examine and<br />

improve working environments.<br />

With this greater onus on reducing workplace risks and improving<br />

employer safety, ISO 45001 ensures that the wellbeing of staff is<br />

preserved at the forefront of an organisation’s ethos.<br />

As well as being certified according to ISO 45001, Dustcontrol is<br />

also certified with ISO 9001 on Quality Management Systems and<br />

ISO 14001 on Environmental Management Systems, demonstrating<br />

the company’s commitment to deliver high-quality products with a<br />

reduced environmental impact and in a safer working environment.<br />

James Miller, director of subsidiary Dustcontrol UK, said: “We’re<br />

proud that our factory has been certified under ISO regulations on the<br />

continued improvement of the working environment. At Dustcontrol,<br />

we are never satisfied with just selling products. We aspire to<br />

manufacture and customise high-quality portable dust extractors and<br />

industrial extraction systems with very high levels of filtration, in the<br />

most environmentally friendly and sustainable way possible.”<br />

<strong>Finishing</strong> – <strong>May</strong>/<strong>June</strong> <strong>2021</strong>

EXCELLENCE<br />

FOR WOOD COATING.<br />

Liquid & powder coating of wood<br />

• Perfect surfaces<br />

• Individual configuration<br />

• High efficiency & reliability<br />

Contact<br />

Wagner Spraytech (UK) Ltd<br />

a Member of WAGNER GROUP<br />

Telephone: 01327 368410<br />

enquiries@wagner-group.com<br />

wagner-group.com<br />

Contact<br />

Wagner Spraytech (UK) Ltd<br />

a Member of WAGNER GROUP<br />

Telephone: 01327 368410<br />

enquiries@wagner-group.com

8 NEWS www.finishingmagazine.co.uk<br />

Qualicoat looks at manufacturing with coated products<br />

Sustainability white paper<br />

Interpon has published a white paper detailing trends in sustainability<br />

and their impact on the construction and architectural sectors, and in<br />

particular how current and future developments in powder coatings are<br />

helping customers and the wider world meet challenging<br />

environmental targets.<br />

The white paper – Building a Sustainable Future – explores the<br />

macro issues of sustainability in the light of the UN’s Sustainable<br />

Development Goals (SDGs) and in the context of increasing<br />

urbanization and the importance of green space to our future health<br />

and wellbeing.<br />

It also focuses on the specific role that powder coatings play in<br />

meeting sustainability targets, obtaining green building certifications<br />

and their advantages in production and performance throughout their<br />

lifetime. Recent developments in application, curing and product<br />

innovation – especially in relation to a powder coating’s durability and<br />

finish – are further reducing the energy consumed, the waste<br />

generated, and the natural resources required, enabling architects to<br />

realise their imagination.<br />

Co-author, Bob Dirks, global segment manager architectural of<br />

AkzoNobel Powder Coatings, says the white paper contributes to the<br />

discussion around architectural sustainability: “With the demand for<br />

green buildings inexorably rising, so too is the role and significance of<br />

powder coatings. Their durability increases the lifetime not only of the<br />

materials they coat, but also of the entire building, and their ability to<br />

mimic other substrates including stone means less use of precious<br />

natural resources.<br />

“With a host of other benefits, including lower curing temperatures<br />

that help reduce energy consumption, our new white paper illustrates<br />

the vast contributions powder coatings can make to our sustainable<br />

future.”<br />

Daniela Vlad, business director of AkzoNobel Powder Coatings, sees<br />

transformative potential in these benefits: “Reducing building emissions<br />

both during creation and use can significantly improve a building’s<br />

sustainability credentials, and architects now have the tools to create<br />

buildings that will stand the test of time thanks to our innovative<br />

powder coatings that are unlocking new worlds of possibilities.”<br />

Award winner<br />

The Surface Treatment global business unit of BASF’s Coatings<br />

division, operating under the Chemetall brand, has been<br />

acknowledged by Novelis with the European Supplier Award 2020. It<br />

recognizes Chemetall for continuously pursuing excellence in quality<br />

as well as its expertise, reliability and professional services. The award,<br />

which was presented for the first time, was handed over during a<br />

virtual ceremony. By establishing the European Supplier Awards,<br />

Novelis strives to honor and foster its partnerships with suppliers to<br />

underline its commitment to quality, sustainability and innovation as<br />

core values and drivers of business success.<br />

Members of QUALICOAT, from the pretreatment systems providers,<br />

the powder systems providers and applicators, all work very closely<br />

together under the <strong>2021</strong> edition of the QUALICOAT Standard to<br />

ensure that architectural powder coating meets the highest<br />

standards for todays use in architectural applications. In order for<br />

the finished aluminium profiles to be made into windows, doors,<br />

roof lights and curtain walls, the material that is shipped to the<br />

fabricator needs to be carefully cut and manufactured into products<br />

ready for site installation. Great care is needed to ensure that the<br />

final product maintains its high quality finish.<br />

Low-tack protection tape is required to be placed on the final<br />

visible faces of the profile to protect the powder coating through the<br />

manufacturing process and is then often left on the product when<br />

installed on site, which offers ongoing protection. The supply and<br />

application of tape can be completed at the powder coat applicators<br />

premises or fabricators premises, often with the systems supplier or<br />

installers branded tape.<br />

Cutting the profiles into their assembly lengths, with either mitred<br />

ends or square cut ends, depending on the product, needs to be<br />

completed to a high standard with precision machinery to ensure<br />

that the final joint becomes watertight once constructed. More<br />

importantly is that a clean sharp cut gives a clean edge to the<br />

coating with less chance of the powder finish itself becoming<br />

stressed. If on cutting there are signs of chips revealing the<br />

aluminium surface, this could be a sign of poor powder coating<br />

adhesion and something the fabricator should take up with their<br />

powder coating supplier. It is crucial that architectural aluminium<br />

profiles are subject to an extensive pretreatment process, both<br />

equipment and processes are tightly controlled in the QUALICOAT<br />

standard.<br />

Prior to joining profiles, the tape should be cut back slightly and<br />

removed to reveal the joint surface, this especially important where<br />

mitre joints are to be made. Aluminium mitred corners are held<br />

together with substantial aluminium extruded or cast cleats and<br />

sometimes with the addition of stainless steel chevrons. It is<br />

imperative that the system manufacturers parts are used together<br />

with the correct two part epoxy adhesive specified in their<br />

construction manual. Care is needed to ensure that mating faces of<br />

the aluminium profile are ‘buttered’ with the adhesive prior to final<br />

assembly and crimping of the joint.<br />

It is critical to clean the final joint as soon as possible, as any<br />

adhesive left on the coated surface can damage the powder coat<br />

finish, or set and become impossible to remove. Sadly all too often<br />

products can be seen where adhesive has been spread across the<br />

mitre, seemly cleaned off and then only becoming visible as a<br />

damaged finish once the protective tape has been removed on site.<br />

A joint which is not glued, or has not been mitred accurately, allows<br />

surface contaminants left by the weather to enter the joint and begin to<br />

oxidise the cut ends of the aluminium, this is further exacerbated by<br />

window cleaning. As most window systems are internally drained, the<br />

unsealed mitre also allows drainage from the system through the joint<br />

which often leads to staining of the surface finish.<br />

Finally, the product fitted on-site is then offered a clean down and<br />

any protection tape on the inside and outside of the windows can<br />

be removed. It needs to be stressed that removal of the protection<br />

tape should be undertaken as soon as site conditions permit to<br />

reduce the possibility of blanching.<br />

<strong>Finishing</strong> – <strong>May</strong>/<strong>June</strong> <strong>2021</strong>

The Choice for the Professional Powder Coater<br />

Gema UK<br />

01202 763942<br />

uk.sales@gema.eu.com

10 PROFILE<br />

Eastern investment<br />

With an absolute commitment to its<br />

customers in China and Asia, Victrex<br />

is determined to extend the<br />

impressive record of collaborative innovation<br />

achieved at its AITC (Asia Innovation &<br />

Technology Centre) in Shanghai, and the<br />

company is now investing US$1 million in a<br />

significant expansion of the Centre. This<br />

important financial injection will help<br />

accelerate innovation and enhance customers’<br />

ability to turn ideas into prototype parts for<br />

testing and evaluation, speeding time to<br />

market and vitally enhancing the design-tomass<br />

production workflow for advanced<br />

engineering design in China and Asia<br />

generally.<br />

Andrew Storm, general manager China,<br />

commented, “Investment to support our<br />

customers with PEEK expertise to accelerate<br />

their speed to market has always been key.<br />

Since the AITC opened in Shanghai in 2006,<br />

as a 2000-square-metre technical centre of<br />

excellence, the facility has undergone dynamic<br />

growth and development offering injection<br />

and compression moulding, thermoforming<br />

and analytical capabilities. With this current<br />

upgrade, we can now offer a 4-axis CNC<br />

machine for part prototyping, part and tool<br />

design advice and process validation, as well<br />

as supporting Additive Manufacturing<br />

capabilities, supporting innovation for process<br />

and material development for 3D printing.”<br />

This further commitment to the AITC will<br />

provide customers with facility for total<br />

solutions, from Material Selection to Part<br />

Prototyping, and beyond, with the capability<br />

for advice on part design and injection<br />

moulding tool design, as well as the capability<br />

for part FEA (finite element analysis) and<br />

additive manufacturing equipment. This will<br />

significantly reduce the lead time for<br />

prototype sampling while providing databased<br />

quality inspection before sampling and<br />

concept-proof decision-making prior to<br />

committing to large investments for the<br />

customers.<br />

The AITC has assisted in the development<br />

of solutions for the Automotive and Aerospace<br />

sectors - where the goal is to reduce<br />

emissions and weight while maintaining the<br />

equivalent strength of metals and offer<br />

enhanced performance. These benefits can<br />

lead to improved fuel efficiency and total<br />

system cost reduction for the end-user and is<br />

vital in a situation where China is driving the<br />

production of electric vehicles (EVs) and New-<br />

Energy Vehicles (NEVs), for which powertrain<br />

architecture and energy-efficiency is a crucial<br />

design factor.<br />

With a global shortage of silicon chips, then<br />

the hugely important field of semiconductor<br />

chip fabrication is also a key focus of the<br />

AITC, to offer solutions to help enable faster<br />

silicon chip manufacturer, more uptime of<br />

semi-con fabs, and enhance yield as the node<br />

size on chips reduces.<br />

Technology and capacity<br />

enhancement<br />

Absolutely central to the implementation of<br />

this latest operational upgrade is the addition<br />

of a 4-axis CNC machine, and part design<br />

and tool design capability, and Additive<br />

Manufacturing (AM) capabilities, with these<br />

hardware and software upgrades significantly<br />

enhancing the capabilities of the lab,<br />

particularly in terms of enabling component<br />

design freedom, prototyping, and CAD<br />

(computer aided design and engineering).<br />

AM is increasing in China, as both a means<br />

of efficient prototyping and as a new<br />

manufacturing technique. Xinhua recently<br />

reported that the country’s “major additive<br />

manufacturers reported a total operating<br />

revenue of 7.5 billion yuan (about 1.14 billion<br />

US dollars) in the first nine months of the<br />

year”. This figure was up 10.3% year-on-year,<br />

according to the Ministry of Industry and<br />

Information Technology.<br />

Added Storm, “Adding this impressive array<br />

of new hardware and software will drive a<br />

major capability expansion of the AITC<br />

Application Lab, allowing it to provide<br />

technical support for customers at a very early<br />

stage in the integrated processes that take<br />

innovative product concepts and move them<br />

into mass production. In this way,<br />

opportunities will be recognised and defined<br />

and then applied in a time-efficient and costeffective<br />

way, helping to accelerate time to<br />

market, which can be a significant advantage<br />

for customers.”<br />

<strong>Finishing</strong> - <strong>May</strong>/<strong>June</strong> <strong>2021</strong>

SERFILCO INTERNATIONAL<br />

Global Products, Local Service & Advice You Can Rely On<br />

SerDuctor Airless Agitation for Improved Process<br />

Control & Emissions Compliance<br />

SerDuctor Airless Agitation<br />

systems provide controllable,<br />

turbulent movement where you<br />

need it most whilst driving down<br />

chemical emissions to help meet<br />

legislative targets<br />

• Reduce airborne emissions by ≥90%.<br />

• Save tank heating costs up to 25%.<br />

• Save metal as a result of more uniform brightness<br />

and thickness distribution.<br />

• Improves Throw deposit thickness in blind,<br />

through holes and recesses.<br />

• Permits use of increased current density,<br />

especially compared to air or cathode rod<br />

agitation, for faster plating rate.<br />

• Reduces carbonates in alkaline processes.<br />

• Reduces or eliminates gas-pitting.<br />

• Provides constant agitation because SERDUCTOR<br />

systems don’t clog.<br />

For more information on our complete range of equipment & our competitive service<br />

rates, or to talk to an engineer about your application contact Serfilco International:<br />

+44 (0) 161 775 1910 global@serfilco.com www.serfilco.co.uk

12 POWDER COATING<br />

Powder perfection<br />

When Tom Kenney was seeking a<br />

powder coater to support his new<br />

business venture, Kencar, he turned to<br />

Birmingham-based, Vertik-Al. Having come<br />

across the long-established powder coating<br />

specialist in a previous career, Tom was keen<br />

to understand what Vertik-Al could offer a<br />

new entrant into the fabrication and façade<br />

industry.<br />

“It was Vertik-Al’s dedication to quality that<br />

first sparked my interest. A former employer<br />

would out-source to them when a job<br />

required a guarantee. In my opinion, this<br />

made Vertik-Al a good fit for Kencar,<br />

underpinning our commitment to deliver<br />

high-quality bespoke architectural metal<br />

work,” says Tom Kenney, managing director<br />

of Kencar.<br />

Vertik-Al offers 25-year supplier backed<br />

guarantees on a range of colours and is the<br />

only applicator in the UK and Ireland to hold<br />

the GSB International quality seal for<br />

Approved Coated Aluminium. It is also one<br />

of a handful of applicators to boast<br />

membership of the product certification<br />

scheme, Qualicoat.<br />

Architectural Metalwork<br />

Established in 2016 and employing 25<br />

people from the local area, Kencar has grown<br />

rapidly in recent times and is quickly gaining<br />

a reputation for being a trusted supplier of<br />

metal work to the architectural façade<br />

industry.<br />

“We specialise in insulated panels, using<br />

one of the largest pressure bonding machines<br />

in the country. We can also fabricate various<br />

rainscreen and interlocking panels.” Fascia<br />

and soffit systems, copings, cappings, cills,<br />

brackets and flashings make up the remainder<br />

of the company’s product offering.<br />

Quality & Speed<br />

“Vertik-Al is renowned for its fastturnaround,<br />

our close proximity – we’re just<br />

20 minutes away - means we can maximise<br />

this. If we need a job doing quickly, we know<br />

it can be on the powder coating line within<br />

hours.<br />

“The team keep us updated on where jobs<br />

are in the production process allowing us to<br />

coordinate the most efficient drop-off and<br />

collection times.”<br />

Kencar has directly benefitted from Vertik-<br />

Al’s recent investment in new powder coating<br />

equipment, including two new horizontal<br />

plants and an upgraded booth alongside new<br />

automatic powder guns on line two. This<br />

investment has significantly reduced the time<br />

taken for colour changes, boosting the speed<br />

and efficiency of the entire powder coating<br />

process.<br />

“The new equipment is delivering incredible<br />

results; the quality of the application and finish<br />

is outstanding, across matt, gloss and textured<br />

coatings.”<br />

Heavy Metallic<br />

Glass has been a dominant feature in the<br />

façade industry for many decades but<br />

changes in architectural trends have led<br />

designers and architects to seek alternative<br />

materials and finishes; something that Kencar<br />

has experienced first-hand.<br />

“Architectural façade designers are<br />

exploring statement exteriors and detailing<br />

using metallics or standard colours like pewter<br />

and white in a metallic finish.<br />

“Designers also appreciate that bronze<br />

metallic powder coating is a successful<br />

alternative to the finish achieved by anodising;<br />

it replicates the look without the need for<br />

anodisation.”<br />

Successful Partnership<br />

“We have an incredibly good relationship<br />

with Vertik-Al. Their reliable service and<br />

support, particularly during the pandemic, is<br />

invaluable and directly impacts our ability to<br />

deliver high-quality metal work on-time and<br />

in-full.<br />

“Their supplier-backed guarantees,<br />

accreditations and certification are an<br />

important factor in the specification process<br />

and help us to stand apart from the<br />

competition.”<br />

<strong>Finishing</strong> - <strong>May</strong>/<strong>June</strong> <strong>2021</strong>

Stop the GRIND<br />

with Atotech<br />

UniPrep ® AC – the smart solution<br />

for removing scale from weld and<br />

laser cuts without grinding<br />

The UniPrep ® AC series is a proven and<br />

sustainable, near neutral pH alternative<br />

to mechanical and strong acid descaling<br />

methods that provides a safe working<br />

environment while improving paint<br />

adhesion to welds and laser cuts.<br />

• Enhanced paint performance<br />

• Improves safety<br />

• Saves time and money<br />

• Near neutral pH<br />

• Spray or immersion processes<br />

Free of APEs, P, F, B<br />

and hydrochloric<br />

and nitric acid<br />

Superior paint quality<br />

for multi-metal<br />

applications<br />

Atotech Group<br />

+44 (0)121 606 7777<br />

Read more on page 42<br />

sales.uk@atotech.com<br />

atotech.com

14 POWDER COATING<br />

Remote control<br />

Anew twin-screw powder coating<br />

extruder at Asian Paints, India’s market<br />

leading paints company was<br />

commissioned and started-up remotely by<br />

Baker Perkins engineers based at<br />

Peterborough in the UK.<br />

Baker Perkins has for some years logged in<br />

online to customers’ machines throughout the<br />

world to provide software updates and faultfinding<br />

advice.<br />

When international travel was impossible<br />

during the Covid lockdown, that ability was<br />

extended to commissioning. Sarang Powar,<br />

senior manager engineering at Asian Paints<br />

says, “Baker Perkins is a solution oriented<br />

expert in extruders: Asian Paints PPG has<br />

been a longstanding customer of Baker<br />

Perkins. They have been an invaluable<br />

resource especially during the pandemic,<br />

when the MPX50 extruder was remotely<br />

commissioned seamlessly.”<br />

A video link allowed step-by-step guidance<br />

from a Baker Perkins’ engineer in the UK to<br />

the customer’s engineer on-site. Remote<br />

support is achieved through an Ewon Flexy<br />

gateway and Wi-Fi VPN connection fitted in<br />

the extruder control panel and providing<br />

remote access to the PLC.<br />

The module was fitted in the UK, complete<br />

with an India-compatible SIM card, to enable<br />

the Baker Perkins commissioning engineer on<br />

site to be supported remotely by colleagues in<br />

the UK. When Covid struck, it was agreed<br />

that Baker Perkins UK would support a local<br />

engineer to carry out the commissioning.<br />

Mechanical and commissioning checklists<br />

supplied by Baker Perkins and followed by an<br />

Asian Paints engineer, ensured the machine<br />

was ready for production. Baker Perkins then<br />

viewed the extruder remotely via the Ewon,<br />

and navigated the HMI screens to offer<br />

training on operation and functionality.<br />

Asian Paints then went into production: the<br />

remote process did not extend the expected<br />

length of commissioning.<br />

Most Baker Perkins unit machines can now<br />

be remotely commissioned; operator training<br />

may also be carried out online.<br />

Commissioning, start-up and training costs<br />

and time can all be significantly reduced as<br />

engineers do not have to leave Baker Perkins’<br />

office in the UK. The company is intending to<br />

widen the service to production systems.<br />

Asian Paints Limited is an Indian<br />

multinational paint company headquartered in<br />

Mumbai, Maharashtra. The company<br />

manufactures and distributes paints and<br />

coatings for a variety of surfaces and<br />

applications, primarily for home decoration.<br />

Asian Paints is India's largest and Asia's third<br />

largest paints corporation. It is double the size<br />

of any other paint company in India<br />

The company has come a long way since its<br />

small beginnings in 1942. It was set up as a<br />

partnership firm by four friends who were<br />

willing to take on the world's biggest, most<br />

famous paint companies operating in India at<br />

that time. Over the course of 25 years, Asian<br />

Paints became a corporate force and India's<br />

leading paints company. Driven by its strong<br />

consumer focus and innovative spirit, the<br />

company has been the market leader in paints<br />

since 1967 and includes wall coverings and<br />

waterproof coatings as well as design and<br />

decorating services in its portfolio.<br />

<strong>Finishing</strong> - <strong>May</strong>/<strong>June</strong> <strong>2021</strong>

EASY OPERATION.<br />

DOUBLE PRODUCTIVITY.<br />

SuperCenter EVO<br />

Powder preparation & supply center<br />

• Ideal for frequent & fast color changes<br />

• High degree of automation for optimum efficiency<br />

• Double-designed fresh powder station for increased productivity<br />

wagner-group.com<br />

Contact<br />

Wagner Spraytech (UK) Ltd<br />

a Member of WAGNER GROUP<br />

Telephone: 01327 368410<br />

enquiries@wagner-group.com

16 CASE STUDY<br />

Lowering the burn<br />

The latest process gas burner technology<br />

from Lanemark Combustion Engineering<br />

Ltd. is now helping one of the country’s<br />

leading manufacturers of construction<br />

equipment to benefit from optimised energy<br />

usage and minimised emissions.<br />

Warwickshire-based Thwaites Ltd., who<br />

provide a wide range of dumper truck designs<br />

particularly to the construction industry, have<br />

replaced two well-proven existing Lanemark<br />

FD5EP-3 burner installations with the<br />

company’s latest force-draught gas and air<br />

FD5GAP-3 models. The result is a<br />

combination of excellent heat control and an<br />

anticipated, significant saving in gas usage.<br />

“The two new burners have been fixed to<br />

two separate drying ovens, both of which<br />

receive products via an overhead conveyor –<br />

one for an epoxy primer preheat facility and<br />

the other for a polyurethane top coat drying<br />

installation,” says Jeff Foster, Lanemark’s sales<br />

director who says up to 60 different<br />

components for 1 - 10 tonne machines are<br />

handled each day.<br />

“In both cases the burners, which here<br />

operate with a Propane gas source, fire<br />

through the wall of the oven into a<br />

combustion chamber with a recirculating fan<br />

then distributing the heat evenly around the<br />

oven chamber,” he adds.<br />

The replacement of the two existing<br />

Lanemark burners – both hi/lo units which<br />

have delivered reliable performance since<br />

1998 – have allowed Thwaites to gain from<br />

the latest designs and technology.<br />

Lanemark’s FDGA burners utilise the latest<br />

‘air pressure lead’ mono-bloc gas valve<br />

technology which is central to ensuring safe<br />

and efficient gas/air ratios are always<br />

maintained even under variable plant<br />

operating conditions. These offer significant<br />

benefits compared with alternative fixed<br />

gas/air valve linkage control arrangements<br />

while the absence of mechanical linkages<br />

between the gas and combustion air control<br />

valve and dampers means the need for<br />

adjustment or the risk of sticking are avoided.<br />

“We have ensured that the mounting<br />

flanges have remained unchanged over the<br />

period so the removal of the old and the<br />

connection of the new burners proved to be a<br />

very straightforward exercise,” adds Jeff Foster.<br />

He points out that the work was completed in<br />

just two days during a shutdown maintenance<br />

period.<br />

Thwaites’ Paintshop Supervisor highlights<br />

the importance of the new installations –<br />

“Temperature control and stability are vital<br />

for the paint adherence process to be<br />

optimised and this is fulfilled by the Lanemark<br />

burners,” he says. “Typically, we set the oven<br />

temperature to 90°C but the burners can<br />

operate at up to 110°C – a useful factor<br />

during winter months when ambient<br />

temperature can, of course, be somewhat<br />

lower.”<br />

Thwaites decision to install the two new<br />

Lanemark burners was partly based on the<br />

company’s long term association with the<br />

burner manufacturer. Apart from the burners<br />

that were replaced meeting operational<br />

requirements for more than 20 years,<br />

Thwaites had also, more recently, benefited<br />

from a further FDGA unit installed on a new<br />

stand-alone oven. “The performance here<br />

meant we had no hesitation in opting for the<br />

two additional Lanemark burners for the paint<br />

drying facility,” adds the Paintshop Supervisor.<br />

With the ongoing support of the Lanemark<br />

BurnerCare service package – which offers a<br />

range of benefits from installation,<br />

commissioning and service plans to spare<br />

parts supply and rapid engineer call-out, if<br />

needed – the new installations at Thwaites are<br />

set to deliver reliable, long term process<br />

heating efficiency for many years to come.<br />

Central to such an important element of the<br />

production process, this translates into<br />

significant, ongoing peace of mind for the<br />

dumper truck manufacturer.<br />

<strong>Finishing</strong> - <strong>May</strong>/<strong>June</strong> <strong>2021</strong>

DEVELOPERS AND MANUFACTURERS OF SPECIALIST<br />

ELECTROPHORETIC COATINGS<br />

The Hawking name has been associated with the development and<br />

marketing of specialist electrophoretic<br />

coating systems since 1985.<br />

Hawking Electrotechnology Ltd is at the forefront of technological<br />

advancements in this field and supplies its products<br />

through a distribution network that extends<br />

into some 35 countries worldwide and growing.<br />

• UV/LED Radiation cure coatings<br />

• Friction control applications<br />

• Super durable Architectural finishes<br />

• Anti-bacterial / Anti-viral systems<br />

• Outstanding colours and effects<br />

• Unrivalled matting technology<br />

‘If it conducts electricity we can<br />

coat it, protect it, enhance it’<br />

Hawking Electrotechnology Ltd<br />

T: +44 (0) 1384 483019<br />

sales@hawking.co.uk<br />

www.hawking.co.uk

18 CASE STUDY<br />

Clean cut<br />

There is no compromise for component<br />

cleanliness when it comes to the<br />

demands and expectations of global<br />

OEMs involved in the automotive and<br />

aerospace sectors, as precision engineering<br />

specialist Grainger and Worrall Machining Ltd<br />

fully appreciated when they bought their first<br />

MecWash Maxi in 2016<br />

With blue-chip OEM customers throughout<br />

the world, the company turned to MecWash<br />

Systems of Tewkesbury, Gloucestershire, UK<br />

when it came to investing in a component<br />

washing system capable of not only meeting,<br />

but exceeding the stringent standards of the<br />

automotive sector.<br />

So a few years later when the company was<br />

awarded the contract to machine V8 blocks<br />

and bedplates for a niche high-end OEM<br />

operating at the pinnacle of the performance<br />

car market, they again turned to MecWash.<br />

As part of Grainger and Worrall’s £3 million<br />

investment to support the low volume<br />

production cell, MecWash Systems was to<br />

provide a second precision cleaning system<br />

which was versatile enough to clean both the<br />

block and the bedplate separately at various<br />

points during manufacture and in the<br />

assembled condition, whilst still achieving the<br />

highest cleanliness standards. The Maxi with<br />

its rear feed and dedicated jetting capability<br />

was the ideal choice.<br />

MecWash Systems collaborated with<br />

Grainger and Worrall to identify the key<br />

features of the components and three<br />

bespoke fixtures were manufactured which<br />

were capable of dedicated jetting via the<br />

special rear feed, ensuring cleanliness of the<br />

oil ways, water jacket and blind machined<br />

holes.<br />

Because of the Maxi’s versatility, Grainger<br />

and Worrall subsequently contacted MecWash<br />

again when the precision machining specialist<br />

won a contract to machine the cylinder block<br />

for a new high-performance engine.<br />

MecWash were able to manufacture a new<br />

fixture which also fitted into the Maxi and<br />

utilised the dedicated jetting facility for the<br />

new block, whilst not impacting on the<br />

production of the V8 block and bedplate.<br />

Grainger and Worrall, based in Bridgnorth,<br />

Shropshire, is renowned globally for being at<br />

the forefront of sand casting technology and<br />

precision engineering development and<br />

innovation, particularly for prototype and low<br />

volume production of complex prismatic parts<br />

across many industry sectors as well as body<br />

structure, power storage enclosures and<br />

electric drive units for the next generation of<br />

transport. Grainger and Worrall count many<br />

major OEMs and Tier 1 suppliers among their<br />

customers.<br />

The company commissioned the MecWash<br />

Maxi aqueous washing system with an Aqua-<br />

Save because of its versatility for cleaning all<br />

types of precision machined components,<br />

from small parts to blocks and heads for V8,<br />

V10 and V12 engine prototypes.<br />

“Our customers expect a ‘production like’<br />

solution, which means that whatever we are<br />

producing for them has to be as close to a<br />

mass-produced part as possible. This ensures<br />

testing is representative of the final product<br />

and significantly reduces time in bringing it to<br />

market,” said Mark Davies, plant director at<br />

Grainger and Worrall Machining Ltd.<br />

“For that to happen we have to ensure<br />

there is no compromise when it comes to<br />

cleaning and degreasing any machined<br />

component. Even a microscopic contaminant<br />

can have a potentially devastating effect on<br />

testing and validation.<br />

“That is why we must ensure we offer our<br />

customers the same levels of cleanliness on<br />

the prototype components as in the<br />

mainstream production facilities.”<br />

He said the Maxi was a perfect solution as<br />

it is designed to clean complex and intricate<br />

machined parts, including the removal of<br />

many different types of contamination, like<br />

coolant and swarf.<br />

“Coupled with bespoke fixturing and<br />

jetting, the Maxi delivers unrivalled and<br />

repeatable cleanliness on even the most<br />

complex of components, harnessing the<br />

advantages of traditional agitation, jet wash<br />

and spray wash technologies,” he said.<br />

“It is capable of cleaning components to the<br />

most exacting standards, enabling us to<br />

measure them accurately against the ever<br />

increasing and more rigorous manufacturing<br />

tolerances demanded by OEMs.”<br />

The addition of the MecWash Aqua-Save<br />

technology to the Maxi provides additional<br />

benefits for Grainger and Worrall.<br />

<strong>Finishing</strong> - <strong>May</strong>/<strong>June</strong> <strong>2021</strong>

Innovation in Thru-Process<br />

Automotive Paint Monitoring<br />

Safe ATEX Certified Temperature Profiling<br />

Intrinsically Safe<br />

• 20 measurement<br />

channels<br />

• Paint & Powder coating<br />

• Includes Phoenix Factor<br />

cure index calculation<br />

New Optic Video Profiling System<br />

During Production<br />

• Detect paint runs, drips<br />

and defects<br />

• Spot transport problems<br />

• Identify oven damage<br />

Phoenix Temperature Measurement<br />

T:01353223100 E:sales@phoenixtm.com www.phoenixtm.com

20 INSTALLATIONS<br />

Transport safety<br />

Millions of people rely on public transport infrastructure every day and<br />

it will be crucial to the opening of economies after COVID-19<br />

lockdowns around the world. Yet many viruses and bacteria, including<br />

the SARS-COV-2 virus, can survive for up to 3 days on some surfaces,<br />

meaning regularly touched areas in public spaces have the potential to<br />

be cross contamination hotspots.<br />

Now, AFFIX Labs’ durable semi-permanent surface coating Si-Quat,<br />

that is proven to kill 99.9% of bacteria and viruses, including SARS-<br />

COV-2, will be helping to make public transport safer as people<br />

around the world begin getting back onto buses and trains.<br />

Si-Quat helps to prevent cross contamination with a durable layer of<br />

polymerized active ingredient that binds to walls, handles, furniture,<br />

and other key touch points, staying in place for up to 12 months and<br />

killing 99.9% of viruses and bacteria that come into contact with the<br />

treated surface. The coating has been tested and certified to be<br />

effective against bacteria, viruses, and fungi, and has passed the<br />

rigorous EN45545-2 HL3 flammability norm for trains and REG118.3<br />

for busses.<br />

Kiel has been manufacturing high quality seating for public transport<br />

globally for more than 75 years and will now be offering Si-Quat to<br />

clients as a new solution to protect travellers on their transport<br />

networks. With Si-Quat already registered on several continents a quick<br />

roll out is truly achievable.<br />

“We are delighted to be working with AFFIX Labs to roll out Si-Quat<br />

in public transport systems around the world. It’s easy to apply, it works<br />

and we have had great support from the AFFIX-Labs team. We hope<br />

that our partnership can help to re-open countries and boost<br />

passengers trust in once again using public transport,” said Daniel<br />

Fräde, Kiel’s sales director bus division.<br />

Furnace finance<br />

ALP Aviation is increasing its production capacity and expanding<br />

process capability with the purchase of an additional Vector vacuum<br />

carburizing furnace from SECO/WARWICK.<br />

“Our 13-year relationship with ALP AVIATION continues to be of<br />

mutual benefit on all technical and managerial levels.<br />

SECO/WARWICK provides the technology, equipment and process<br />

knowledge which has enabled our client to grow their business. Our<br />

Group values working close to the customer. ‘Be close to the<br />

customer’ is our philosophy when building partnerships, and is central<br />

to our success as a company,” says Sławomir Wo niak, CEO,<br />

SECO/WARWICK Group.<br />

“We continue to work with SECO/WARWICK for a number of<br />

reasons, the most important for us is the comprehensive support we<br />

receive for our technical staff to facilitate the implementation of<br />

procedures according to our rigid requirements,” says Duygu Erten,<br />

director of Special Processes of ALP AVIATION.<br />

Paint plane process<br />

The aerospace company Turkish Aerospace is currently building one of<br />

the most high-tech production facilities ever seen in the aerospace<br />

industry. Sixteen robots from Dürr will coat more than 50 different<br />

components in two highly automated paint shops in the future. Dürr<br />

developed a new solution for this which, for the first time, enables both<br />

water-based and solvent-based 2C and 3C paints to be metered and<br />

mixed directly in the robot – economically and with high precision.<br />

Dürr received the order in September 2020.<br />

A lot of work in aircraft production is still done by hand, with up to<br />

95% of all components still being coated manually. Turkey’s stateowned<br />

aircraft manufacturer Turkish Aerospace Industries (“Turkish<br />

Aerospace”) is set to change this with its new highly automated paint<br />

shops. In the two new paint shops, Turkish Aerospace will manufacture<br />

large numbers of components for Airbus and Boeing.<br />

Highest requirements for coating<br />

Freezing cold temperatures of negative 76ºF at high altitudes,<br />

roasting hot temperatures of 140ºF when landing in a desert: the<br />

coatings used in the aviation industry have to meet high functional and<br />

safety requirements because of the temperatures and weather<br />

conditions they are exposed to. There is also the aesthetic<br />

consideration, given the important contribution made by the color<br />

scheme to an aircraft’s brand recognition. The range of main colors,<br />

hardeners, and thinners stipulated by Turkish Aerospace is very<br />

extensive, and requires a complicated color supply system. To meet<br />

these challenges, Dürr took its tried-and-tested system for water- based<br />

and solvent-based 2C paints out of its standard automotive painting<br />

setting and enhanced it. The system at Turkish Aerospace meters and<br />

mixes all three of the necessary components so that the incompatible<br />

water-based and solvent-based paints can be processed directly in the<br />

robot without coming into contact with each other. This is the first time<br />

that such a complicated metering and mixing technology has been<br />

mounted so close to the atomizers. This minimizes paint and solvent<br />

losses when changing color and also saves time.<br />

The EcoGun spray guns used are extremely precise and, with their<br />

excellent area performance, perfect for painting large components like<br />

fuselage sections or wing components up to 10 meters in length. This<br />

is faster than manual coating processes, and produces a higher-quality<br />

result and less overspray. Recirculated air can be used in the fully<br />

automated paint booths, saving the energy that would otherwise be<br />

needed to condition the fresh air.<br />

The sixteen EcoRP E133 painting robots will be installed in two new<br />

buildings on Turkish Aerospace’s site in Ankara, and programmed<br />

using DXQ3D.onsite. The Dürr software is the universal toolbox that<br />

enables operators to configure the process parameters and robot paths<br />

of the application robots. Specific consumption data for paints, solvents,<br />

energy, and air will also be meticulously recorded so that Turkish<br />

Aerospace can match them to the individual components in the future.<br />

This data will make it possible to optimize manufacturing processes.<br />

The data acquisition is also important in meeting the high safety<br />

standards in the aviation industry. DXQ3D.onsite offers scope for future<br />

expansion, opening the door for additional modules like the<br />

DXQequipment.maintenance tool.<br />

The general contractor for the construction of the two paint shops<br />

is the Turkish plant manufacturer VIG Makina. The company has<br />

around 400 employees, is specialized in surface treatment & painting<br />

systems as well as manufacturing of aluminum production<br />

machineries and has an excellent reputation across all industries.<br />

“We’re very proud to realize this pilot project for the aviation industry<br />

with VIG Makina. With our painting robots, application technology<br />

and color supply system, we are significantly advancing automation in<br />

the aviation industry,” says Sabine Mewis, key account manager<br />

aviation industry at Dürr.<br />

<strong>Finishing</strong> – <strong>May</strong>/<strong>June</strong> <strong>2021</strong>

PYROLYSIS &<br />

BURN OFF OVENS<br />

UK’S LEADING MANUFACTURER<br />

Our Pyrolysis ovens provide you with a quick and highly effective<br />

process for the removal of plastic, paints and resins<br />

Longworth’s pyrolysis & burn off ovens are second to none in design and build quality, built to last and have the latest<br />

in technological features. Our ovens provide a quick and highly effective process for the removal of plastics, paints<br />

and resins from jigs, filters, shelving, food trays, motors, automotive parts and a multitude of other components.<br />

Accreditations<br />

BS EN ISO 9001:2008<br />

Call Longworth today for a no obligation meeting on how we can help you and your business<br />

call<br />

01254 680501<br />

email<br />

enquiries@bmlongworth.com<br />

visit<br />

www.bmlongworth.com

22 DEBURRING EXPO<br />

Precision on show<br />

The business climate and the order<br />

situation are improving for industrial<br />

enterprises. Now is the time for<br />

companies to generate fresh impetus with<br />

new and further developed solutions.<br />

DeburringEXPO offers an ideal platform to<br />

this end in the fields of deburring technology<br />

and precision surface finishing, and will be<br />

held at the Karlsruhe Exhibition Centre from<br />

the 12th through the 14th of October, <strong>2021</strong>.<br />

With theme parks covering “Cleaning After<br />

Deburring”, “Automated Deburring with<br />

Industrial Robots” and “AM Parts <strong>Finishing</strong>”,<br />

highly topical issues will also be addressed at<br />

the 4th leading trade fair for deburring<br />

technology and precision surface finishing.<br />

The expert forum, which is in great demand<br />

as a source of knowledge, will also offer<br />

information concerning the latest trends and<br />

developments, as well as practical solutions.<br />

Demand is rising in many industry sectors<br />

such as machinery manufacturing, medical<br />

and pharmaceuticals technology, toolmaking,<br />

metrology, precision engineering, sensor and<br />

drive technology, as well as in the automotive<br />

industry. Amongst other factors, this trend is<br />

also being driven by export. As a result,<br />

investments that were put on hold last year<br />

are back on the agenda once again. Issues<br />

such as deburring, edge rounding and the<br />

production of precision surface finishes also<br />

play an important role in this regard. Stricter<br />

as well as changing requirements must also<br />

be met in some cases during the production<br />

and reconditioning of products in these work<br />

steps.<br />

As the only technology platform for<br />

deburring, rounding and the production of<br />

precision surface finishes, DeburringEXPO<br />

provides a complete overview of the current<br />

state of the art, developments and trends,<br />

processes and methods, as well as quality<br />

assurance and services. “DeburringEXPO is an<br />

important trade fair for 4MI GmbH, where we<br />

can present our solutions expertise in the field<br />

of flow grinding. And thus there’s no doubt<br />

that we’ll exhibit again – and we’re already<br />

looking forward to it now because we’ve<br />

found that although video conferencing is<br />

useful for discussing and clarifying numerous<br />

issues, it can’t replace face-to-face meetings at<br />

a trade fair, towhich visitors also bring parts<br />

and drawings,” adds Dr.-Ing. Detlef Bottke,<br />

CTO at 4MI GmbH. 4MI is one of the<br />

companies that have placed firm bookings for<br />

their booth locations at the 4th leading trade<br />

fair in Karlsruhe from the 12th through the<br />

14th of October, <strong>2021</strong>. The same goes for<br />

Rösler Oberflächentechnik GmbH, whose<br />

marketing manager Daniel Hund also<br />

considers trade fairs indispensable:<br />

“Participation at DeburringEXPO is a must<br />

for us as manufacturers of solutions for mass<br />

finishing and shot blasting technology, as well<br />

as post-processing of additively manufactured<br />

parts. We meet up with our customers at the<br />

trade fair in a targeted fashion and we’re<br />

looking forward to exchanging ideas again<br />

personally after months of exclusively virtual<br />

contact. Beyond this, participation at the trade<br />

fair provides us with an ideal opportunity for<br />

gaining a concentrated overview of what’s<br />

happening in the market, current and future<br />

focal points in various industry sectors and<br />

their latest developments.” Furthermore, the<br />

exhibitor list includes numerous other solution<br />

providers from various sectors for deburring,<br />

rounding and the production of precision<br />

surface finishes. “We’ve been experiencing a<br />

significant increase in demand for booth floor<br />

space since the end of February.<br />

Consequently, we’re quite confident that we’ll<br />

be able to hold DeburringEXPO in October<br />

<strong>2021</strong> on a scale comparable to the event in<br />

2019 – of course in compliance with relevant<br />

protective measures and with a hygiene<br />

concept that offers exhibitors and visitors<br />

greatest possible safety,” reports Hartmut<br />

Herdin, managing director of private trade fair<br />

promoters fairXperts GmbH & Co. KG.<br />

<strong>Finishing</strong> - <strong>May</strong>/<strong>June</strong> <strong>2021</strong>

THIS IS HANGON<br />

HangOn is a partner who helps customers to find smart solutions to increase<br />

the efficiency in their coating process and improve their profitability.<br />

We develop and produce in own factories. Our products are distributed from<br />

our warehouses into more than 40 countries.<br />

WEB www.hangon.co.uk EMAIL sales@hangon.co.uk TELEPHONE 01547 540 573<br />

HangOn Ltd. Leintwardine, Craven Arms, Shropshire, SY7 0NB

24 PROFILE<br />

Investing in the future<br />

The success enjoyed by Lanemark<br />

Combustion Engineering Ltd. since its<br />

formation in the early-1980’s can be<br />

attributed not only to its production and<br />

technical capabilities but also to its ongoing<br />

commitment to training and personnel<br />

development. Jeff Foster, Sales Director at the<br />

Nuneaton-based organisation, which<br />

manufactures process gas burner systems that<br />

are used in a range of industries – from metal<br />

pretreatment and brewing to the<br />

petrochemical sector – draws attention to the<br />

benefits of this approach –<br />

“Some 30% of our current workforce either<br />

has been, or still are apprentices,” he says,<br />

“and this reflects on our philosophy that<br />

remains strong to this day.”<br />

Lanemark operates a defined structure that<br />

enables apprentices and trainees to progress<br />

in the company in a way that meets both their<br />

own and the organisation’s needs. “In all<br />

cases, apprentices start their careers with us in<br />

the workshop environment and are then<br />

given the opportunity to progress into<br />

different disciplines,” adds Jeff Foster. He<br />

highlights technical manager Aidan Lewis,<br />

service manager Chris Wilson,<br />

machine/fabrication shop supervisor James<br />

Keene and service engineer Matthew Jee – all<br />

of whom have committed to the Lanemark<br />

approach and have benefited as a direct<br />

result.<br />

By its very nature, Lanemark operates in an<br />

extremely specialist sector of the<br />

manufacturing and processing industries. The<br />

company’s burner systems have always been<br />