Plastic waste from cables - Borealis

Plastic waste from cables - Borealis

Plastic waste from cables - Borealis

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Plastic</strong> <strong>waste</strong><br />

<strong>from</strong> <strong>cables</strong><br />

Introduction<br />

As with all industrial activity, <strong>waste</strong> is generated during the<br />

manufacturing of <strong>cables</strong> and when <strong>cables</strong> are scrapped. For<br />

economical and environmental reasons recycling or recovery<br />

of the material components <strong>from</strong> this <strong>waste</strong> is essential. The<br />

need for effective recycling solutions is based on the increasing<br />

scarcity of natural resources and the need to reduce the<br />

environmental burden – including the generation of greenhouse<br />

gases.<br />

<strong>Borealis</strong> and Borouge are the world’s leading providers for<br />

innovative, value-creating plastics solutions for the wire and<br />

cable industry. Our philosophy is to provide innovative materials<br />

that allow for the problem free operation of <strong>cables</strong> over very long<br />

time spans. Long life, without the need to frequently scrap and<br />

replace <strong>cables</strong>, is an effective way to limit the environmental<br />

burden.<br />

Even so, we understand our responsibility to deal with issues<br />

related to cable <strong>waste</strong>, and have been, for many years, active in<br />

research with industry partners to further develop the recycling<br />

technology.<br />

Cable <strong>waste</strong><br />

Cable <strong>waste</strong> comes <strong>from</strong><br />

• cable production<br />

• end of the functional life of the <strong>cables</strong><br />

• scrapped <strong>cables</strong> when there is no need.<br />

The <strong>waste</strong> can comprise of a multitude of components such as<br />

metals, plastics, rubber, paper and glass fibres.<br />

Driving force for cable <strong>waste</strong> recycling<br />

The main driving force to recycle cable <strong>waste</strong> is to recover the<br />

valuable metals such as copper and aluminium.<br />

Recycling of plastic components is encouraged by authorities in<br />

Europe as disposal in landfills is not accepted. Disposal by other<br />

means are associated with costs and therefore the industry is<br />

encouraged to find new cost effective solutions for the handling<br />

of cable <strong>waste</strong>.<br />

Cable plastic <strong>waste</strong> management<br />

Waste that is generated during cable manufacturing is sorted<br />

at the source and either reprocessed or recycled for alternative<br />

applications. Waste <strong>from</strong> end of life and scrapped <strong>cables</strong> that are<br />

collected <strong>from</strong> different sources constitute a broad mix of cable<br />

types and material components. A pre-sorting of these <strong>cables</strong><br />

is made as a first step, then granulation and separation of the<br />

plastics <strong>from</strong> the metal occurs.<br />

Separation of the plastics is made by a sink / float technique<br />

where heavy plastics sink in water and lighter plastics float.<br />

A new technology that combines the sink / float techniques with<br />

a gravimetric separation allows for a further separation of metal<br />

<strong>from</strong> the light plastic making a total separation yield of 99–99.9 %<br />

metal. This means that the purity of the light plastics is high and<br />

attractive for energy recovery or recycling.

WC HO 501 GB 2012 02 BB<br />

Recycling of cable plastic <strong>waste</strong><br />

The main plastic components in cable <strong>waste</strong> <strong>from</strong> <strong>cables</strong> recycled today are PVC and<br />

polyethylene, either in crosslinked (XLPE) or thermoplastic (PE) form.<br />

The separation technique in use today enables effective separation of the two main types.<br />

The PVC fraction can be re-melted and processed to new products.<br />

As the separated components are less clean than virgin material, the recycled material is<br />

typically used in applications with lower quality requirements.<br />

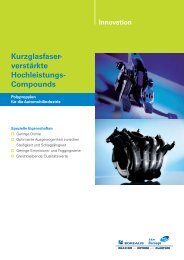

XLPE <strong>from</strong> cable <strong>waste</strong> can be recycled<br />

XLPE <strong>waste</strong> is crosslinked and it cannot be reprocessed as a 100% ingredient. However, it<br />

has been shown that a mix between virgin PE and up to 60 % XLPE <strong>waste</strong> gives a mixture<br />

that can be reprocessed. This results in a material with good mechanical properties that can<br />

be used, for example, in injection moulded articles. As the market for moulded products<br />

based on recycled polyolefins represents several thousand tonnes per year in Europe, this<br />

offers many opportunities. Recycle of <strong>waste</strong> <strong>from</strong> <strong>cables</strong> in certain cable applications is also a<br />

possibility such as cable jacketing (figure 1).<br />

Another option is to recover the energy of PE and XLPE. These materials originate <strong>from</strong><br />

hydrocarbons and carry an energy capacity similar to oil. As the new technique for cable<br />

<strong>waste</strong> separation produces a very clean light fraction, it can be used in such applications as<br />

complementary fuel in district heating plants or in cement kilns.<br />

Production <strong>waste</strong><br />

XLPE/LLDPE recycled<br />

compound<br />

Figure 1: Recycling of XLPE into <strong>cables</strong><br />

Granulated XLPE<br />

Extrusion cable jacked<br />

Grounded XLPE<br />

Cable with inner-jacket of<br />

recycled compound<br />

References<br />

• „Environmental considerations for<br />

end of life disposal of <strong>cables</strong>”<br />

B. Helmesjö, B. Hagström.<br />

Jicable 2003. B.4.2 p. 421– 426<br />

• „Electrical insulation systems<br />

and assessment methodologies<br />

for energy technology and clean<br />

environment”.<br />

R.N. Hampton. Nord-IS 2005.<br />

Invited paper<br />

• „Development of recycling<br />

technology of XLPE”.<br />

Sekiguch et.al. Jicable 2007.<br />

C.5.1 p 599 – 604.<br />

• „Recycling of XLPE insulations”.<br />

A. Boss, B. Hagström.<br />

NordIS 2009<br />

• „PlastSep- A new technology<br />

for sorting and recycling of<br />

cable polymers”.<br />

E. Rasmussen,<br />

A. Boss NordIS 2009