FORGED: Making a Knife with Traditional Blacksmith Skills

This book will teach you to hand build a knife using the traditional method of blacksmiths of old — FORGING. Traditional forging of a knife blade is a process which uses the ancient techniques of moving hot steel with hammer and anvil alone into a knife-form that is ready for filing, heat treating and sharpening with no or very minimal electric grinding. This book also teaches traditional fit-and-finish skills using only hand tools. It explains an ancient riveted full-tang handle construction system that surpasses modern methods. In the author's words; "In my early blacksmithing years, I was lucky to get to know some old smiths who wrangled hot iron every day just to make a living. They unselfishly taught me traditional blacksmithing skills and knife forging methods. Every time I use those skills and methods, I honor their friendships, and by teaching you, the reader, we keep alive the memory of those old-time iron pounders." Hardcover, 132 pages, 150 photos and illustrations, $29.95.

This book will teach you to hand build a knife using the traditional method of blacksmiths of old — FORGING.

Traditional forging of a knife blade is a process which uses the ancient techniques of moving hot steel with hammer and anvil alone into a knife-form that is ready for filing, heat treating and sharpening with no or very minimal electric grinding.

This book also teaches traditional fit-and-finish skills using only hand tools. It explains an ancient riveted full-tang handle construction system that surpasses modern methods.

In the author's words; "In my early blacksmithing years, I was lucky to get to know some old smiths who wrangled hot iron every day just to make a living. They unselfishly taught me traditional blacksmithing skills and knife forging methods. Every time I use those skills and methods, I honor their friendships, and by teaching you, the reader, we keep alive the memory of those old-time iron pounders."

Hardcover, 132 pages, 150 photos and illustrations, $29.95.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

You will connect eye-hand coordination <strong>with</strong> speed and force. Practice both<br />

indexing and coverage for a lath strip or two. After completing a lath strip<br />

divided <strong>with</strong> 1-inch dots do the same exercises <strong>with</strong> ½-inch dots. Then do the<br />

same thing <strong>with</strong> 1/4-inch dots. Sections of lath can be held <strong>with</strong> the vice grips and/or<br />

the knife tongs. When you finally hit actual hot steel this muscle memory exercise<br />

will pay big dividends.<br />

Forging the <strong>Knife</strong> Handle<br />

We begin forging <strong>with</strong> the handle because forging the blade first would require<br />

you to grip the thin finished blade <strong>with</strong> tongs or vice grips and then forge the<br />

handle. A blade-first sequence would surely result in the blade being misshaped<br />

or otherwise damaged by the gripping pressure of the tongs or vise grips while<br />

you forge the handle.<br />

Remember that the knife billet is 1/8-inch thick, 1-inch wide and eight-inches long,<br />

<strong>with</strong> a notch at the mid-way point of four inches (for info on the notch see previous<br />

section: Bar Stock Used for the Frontier <strong>Knife</strong>).<br />

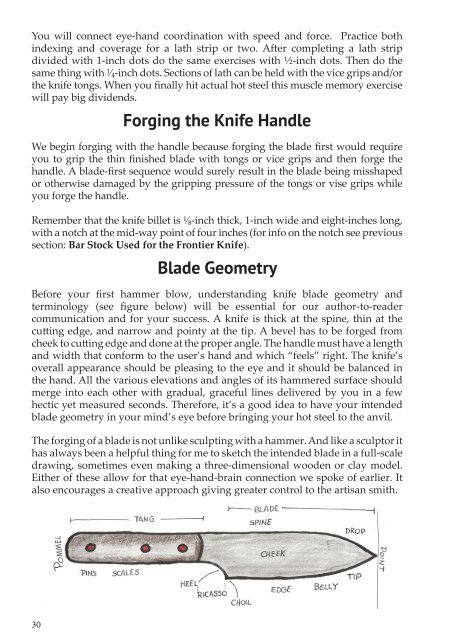

Blade Geometry<br />

Before your first hammer blow, understanding knife blade geometry and<br />

terminology (see figure below) will be essential for our author-to-reader<br />

communication and for your success. A knife is thick at the spine, thin at the<br />

cutting edge, and narrow and pointy at the tip. A bevel has to be forged from<br />

cheek to cutting edge and done at the proper angle. The handle must have a length<br />

and width that conform to the user’s hand and which “feels” right. The knife’s<br />

overall appearance should be pleasing to the eye and it should be balanced in<br />

the hand. All the various elevations and angles of its hammered surface should<br />

merge into each other <strong>with</strong> gradual, graceful lines delivered by you in a few<br />

hectic yet measured seconds. Therefore, it’s a good idea to have your intended<br />

blade geometry in your mind’s eye before bringing your hot steel to the anvil.<br />

The forging of a blade is not unlike sculpting <strong>with</strong> a hammer. And like a sculptor it<br />

has always been a helpful thing for me to sketch the intended blade in a full-scale<br />

drawing, sometimes even making a three-dimensional wooden or clay model.<br />

Either of these allow for that eye-hand-brain connection we spoke of earlier. It<br />

also encourages a creative approach giving greater control to the artisan smith.<br />

30