The New Spruce Forge Manual of Locksmithing: A Blacksmith’s Guide to Simple Lock Mechanisms

The New Spruce Forge Manual of Locksmithing: a Blacksmith’s Guide to Simple Lock Mechanisms is a totally revised and expanded version of the original work from 1999. This new hardcover edition, at 304 pages and with more than 800 color photos and illustrations, is more than double the size of the original manual. It is divided into two distinct sections: Technical Information - This section is a reference manual in itself that covers the specific tools and techniques needed to build all the parts for each lock, as well as providing the information needed to understand the assembly instructions outlined in the second section. The Locks: Patterns & Instructions - This section provides the plans and detailed instructions for each of the 14 lock projects in this new edition. The clear assembly instructions describe when and how to use the technical information provided in section one. The authors have maintained their original trademark style that relies on well-illustrated step-by-step instructions that guide you through the whole lock-making process. They have also kept their low-tech approach that demonstrates how to go about creating good work using only a handful of simple tools. Making blacksmith locks is an age-old skill the authors of this manual are helping to preserve by passing on their knowledge to this book’s readers. The New Spruce Forge Manual of Locksmithing is also an excellent introduction to benchwork, which is a useful skill for any blacksmith to acquire. This manual will become a valuable, trusted and often referred to sourcebook in your blacksmithing library. Hardcover, 304 pages, more than 800 photos and illustrations.

The New Spruce Forge Manual of Locksmithing: a Blacksmith’s Guide to Simple Lock Mechanisms is a totally revised and expanded version of the original work from 1999. This new hardcover edition, at 304 pages and with more than 800 color photos and illustrations, is more than double the size of the original manual.

It is divided into two distinct sections:

Technical Information - This section is a reference manual in itself that covers the specific tools and techniques needed to build all the parts for each lock, as well as providing the information needed to understand the assembly instructions outlined in the second section.

The Locks: Patterns & Instructions - This section provides the plans and detailed instructions for each of the 14 lock projects in this new edition. The clear assembly instructions describe when and how to use the technical information provided in section one.

The authors have maintained their original trademark style that relies on well-illustrated step-by-step instructions that guide you through the whole lock-making process. They have also kept their low-tech approach that demonstrates how to go about creating good work using only a handful of simple tools.

Making blacksmith locks is an age-old skill the authors of this manual are helping to preserve by passing on their knowledge to this book’s readers. The New Spruce Forge Manual of Locksmithing is also an excellent introduction to benchwork, which is a useful skill for any blacksmith to acquire. This manual will become a valuable, trusted and often referred to sourcebook in your blacksmithing library.

Hardcover, 304 pages, more than 800 photos and illustrations.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

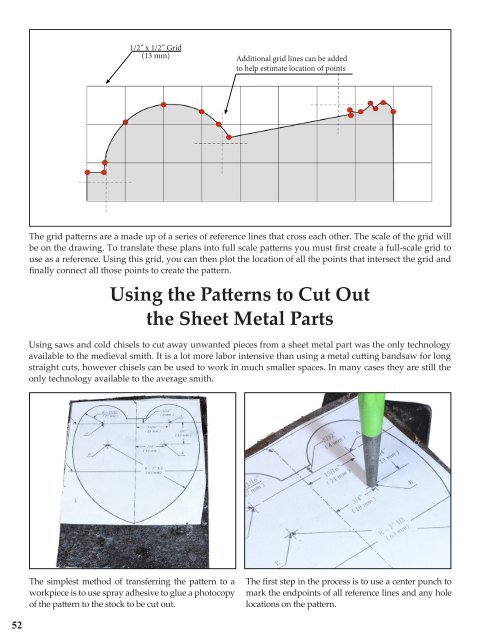

1/2” x 1/2” Grid<br />

(13 mm) Additional grid lines can be added<br />

<strong>to</strong> help estimate location <strong>of</strong> points<br />

<strong>The</strong> grid patterns are a made up <strong>of</strong> a series <strong>of</strong> reference lines that cross each other. <strong>The</strong> scale <strong>of</strong> the grid will<br />

be on the drawing. To translate these plans in<strong>to</strong> full scale patterns you must first create a full-scale grid <strong>to</strong><br />

use as a reference. Using this grid, you can then plot the location <strong>of</strong> all the points that intersect the grid and<br />

finally connect all those points <strong>to</strong> create the pattern.<br />

Using the Patterns <strong>to</strong> Cut Out<br />

the Sheet Metal Parts<br />

Using saws and cold chisels <strong>to</strong> cut away unwanted pieces from a sheet metal part was the only technology<br />

available <strong>to</strong> the medieval smith. It is a lot more labor intensive than using a metal cutting bandsaw for long<br />

straight cuts, however chisels can be used <strong>to</strong> work in much smaller spaces. In many cases they are still the<br />

only technology available <strong>to</strong> the average smith.<br />

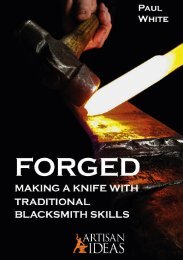

<strong>The</strong> simplest method <strong>of</strong> transferring the pattern <strong>to</strong> a<br />

workpiece is <strong>to</strong> use spray adhesive <strong>to</strong> glue a pho<strong>to</strong>copy<br />

<strong>of</strong> the pattern <strong>to</strong> the s<strong>to</strong>ck <strong>to</strong> be cut out.<br />

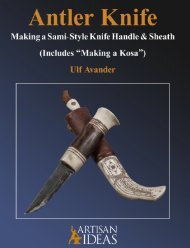

<strong>The</strong> first step in the process is <strong>to</strong> use a center punch <strong>to</strong><br />

mark the endpoints <strong>of</strong> all reference lines and any hole<br />

locations on the pattern.<br />

52