Food & Ingredients June 2023

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

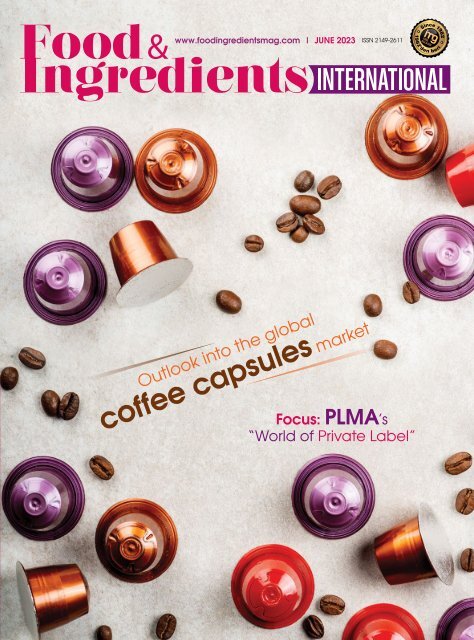

www.foodingredientsmag.com | JUNE <strong>2023</strong> ISSN 2149-2611<br />

Outlook into the global<br />

coffee capsules market<br />

Focus: PLMA’s<br />

“World of Private Label”

THIS<br />

MONTH<br />

HIGHLIGHTS<br />

8<br />

Arabatzis SA “kneads”<br />

innovation and<br />

sustainability<br />

10<br />

TopGum launches high<br />

caffeine cappuccino<br />

gummies<br />

12<br />

Bach Snacks innovates<br />

the world of snacks<br />

14<br />

interpack pleased the<br />

global processing and<br />

packaging industry<br />

22<br />

Liquid gold:<br />

echnological solutions<br />

for drying and<br />

protecting actives<br />

28<br />

Anuga and EIT <strong>Food</strong> enter<br />

a strategic partnership<br />

46<br />

The meat industry will return<br />

to the spotlight in Milan in<br />

2024 with MEAT-TECH and<br />

the new thematic exhibition<br />

PRO-TECH<br />

The next issue<br />

will be distributed<br />

from our stand at

Ayça SARIOGLU<br />

Coordinator<br />

ayca.sarioglu@img.com.tr<br />

Respectfully<br />

yours!<br />

The recent statistics and reports indicate<br />

that the food and beverage industry<br />

has seen their profit margins decrease<br />

considerably. However, due to the falling<br />

cost of commodities, these margins<br />

should increase in the coming years. <strong>Food</strong><br />

and beverage items are an inevitable<br />

part of life and they will always be. There<br />

are some other factors to generate higher<br />

profits out of this giant industry.<br />

The consumers are more conscious of<br />

all values in the food and beverage<br />

items including being organic, natural,<br />

confidence in raw materials and<br />

manufacturing lines, handling and<br />

packaging, etc. Corporate and brand<br />

reputations are expected to become<br />

increasingly important, as consumers are<br />

trying to stretch their dollar further and<br />

competition is increasing. With the increase<br />

in competition, the only way companies<br />

can separate themselves from others is<br />

by brand recognition. Consumers are<br />

now very concerned with the reputation<br />

of a company, or their brand image,<br />

with respect to the safety and quality<br />

of product. Increased innovation in the<br />

industry will lead to newer, healthier<br />

products and lower production costs, both<br />

of which should increase profit margins.<br />

Fairs and exhibitions are very important<br />

links of the whole chain to launch and<br />

introduce products and technologies. This<br />

time we will be at PLMA – Private Label<br />

Exhibition to be held in Amsterdam and<br />

Inter <strong>Food</strong> in Baku to see all novelties to be<br />

displayed in these two important meeting<br />

points of the industry. I wish lucrative<br />

business for all exhibitors and visitors.<br />

Publisher<br />

Hüseyin Ferruh IŞIK<br />

on behalf of<br />

ISTMAG<br />

Magazin Gazetecilik Yayıncılık<br />

İç ve Dış Tic. Ltd. Şti.<br />

Managing Editor (Responsible)<br />

Mehmet SOZTUTAN<br />

mehmet.soztutan@img.com.tr<br />

Advisory Editor<br />

Ali ERDEM<br />

info@img.com.tr<br />

International<br />

Sales Coordinator<br />

Ayca SARIOGLU<br />

ayca.sarioglu@img.com.tr<br />

+90 212 454 22 33<br />

Technical Manager<br />

Tayfun AYDIN<br />

tayfun.aydin@img.com.tr<br />

Advisory Graphics & Design<br />

Hakan SOZTUTAN<br />

hakan.soztutan@img.com.tr<br />

Digital Assets Manager<br />

Emre YENER<br />

emre.yener@img.com.tr<br />

Subscription<br />

sales@img.com.tr<br />

HEAD OFFICE<br />

İSTMAG MAGAZİN GAZETECİLİK YAYINCILIK<br />

İÇ VE DIŞ TİC. LTD. ŞTİ.<br />

İHLAS MEDIA CENTER<br />

Merkez Mahallesi 29 Ekim Caddesi No: 11<br />

Medya Blok Kat: 1 P.K. 34197<br />

Yenibosna - Bahçelievler / İSTANBUL / TÜRKİYE<br />

Tel: +90 212 454 22 22 Fax: +90 212 454 22 93<br />

LIAISON OFFICE<br />

Buttim Plaza A Blok Kat: 4 No: 1038<br />

Bursa / TÜRKİYE<br />

Tel: +90 224 211 44 50-51 Fax: +90 224 211 44 81<br />

PRINTED BY | İH LAS GAZETECİLİK A.Ş.<br />

İHLAS MEDIA CENTER Merkez Mahallesi<br />

29 Ekim Caddesi No: 11 A/41<br />

Yenibosna - Bahçelievler / İSTANBUL / TÜRKİYE<br />

Tel: +90 212 454 30 00<br />

www.foodingredientsmag.com<br />

sales@img.com.tr<br />

foodturkeymagazine<br />

foodturkeymag<br />

foodingredientsturkeymag<br />

<strong>Food</strong> <strong>Ingredients</strong> International<br />

<strong>Food</strong> & <strong>Ingredients</strong> International

Outlook into the global<br />

coffee capsules market<br />

Research has shown that coffee protects the<br />

liver, lowers the risk of type 2 diabetes, and<br />

prevents several cancers. Additionally, the<br />

rise in the trend of coffee drinking outside<br />

the home suggests an increase in recent<br />

years. Consequently, it is anticipated that<br />

rising coffee consumption will fuel the global<br />

coffee capsules market.<br />

Coffee capsules are small, single-use pods<br />

filled with pre-measured amounts of ground<br />

coffee that are designed to be used with a<br />

specific type of coffee machine. They typically<br />

come in a range of different flavors and<br />

strengths and are used to make individual<br />

servings of coffee quickly and easily.<br />

To use a coffee capsule, you simply insert<br />

it into the designated slot on your coffee<br />

machine and then press a button to start the<br />

brewing process. The machine punctures the<br />

capsule and hot water is then forced through<br />

the coffee grounds, extracting the flavor and<br />

aroma to create a fresh cup of coffee.<br />

Coffee capsules have become increasingly<br />

popular in recent years due to their<br />

convenience and ease of use, and they are<br />

now available from a wide range of different<br />

coffee brands and manufacturers. However,<br />

it is worth noting that the single-use nature of<br />

coffee capsules can create a lot of waste,<br />

so many people are now exploring more<br />

sustainable alternatives such as reusable coffee<br />

pods or traditional coffee brewing methods.<br />

The coffee capsules market faces a stiff<br />

challenge from the availability of alternative<br />

products including but not limited to tea,<br />

fruit juices, vegetable juices, health drinks,<br />

kombucha, chocolate drinks, milkshakes, lattes<br />

made with beets, matcha, chicory, and kefir<br />

are some among others.<br />

Countries such as China, Turkey, Ireland, the<br />

UK, India, and Iran, are heavy consumers<br />

of tea and milk products, proving to deter<br />

coffee drinking. Furthermore, these countries<br />

are also some of the largest producers of<br />

6 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

coffee alternatives, which severely hampers<br />

the consumption of coffee and in turn harms<br />

the coffee capsules market.<br />

The diversification of flavors in the coffee<br />

capsule market has played a significant role<br />

in propelling the Coffee Capsules Market<br />

Opportunities. By offering a wide range of<br />

flavors and strengths, coffee capsule brands<br />

are able to appeal to a broader range of<br />

consumers with different taste preferences.<br />

For example, some brands offer capsules with<br />

flavors such as caramel, hazelnut, vanilla, and<br />

chocolate, while others offer capsules with<br />

different strengths, such as mild, medium, and<br />

bold. This allows consumers to choose a flavor<br />

and strength that suits their individual taste,<br />

rather than being limited to a few options.<br />

In addition, the availability of a wide range<br />

of flavors helps to increase consumer<br />

engagement and loyalty. Consumers are<br />

more likely to purchase coffee capsules from<br />

a brand that offers a variety of flavors, as<br />

they can experiment with different flavors<br />

and find their favorites, which is fostering<br />

Coffee Capsules Market Trends. This can<br />

lead to increased brand loyalty and repeat<br />

purchases, which is beneficial for coffee<br />

capsule manufacturers.<br />

Moreover, diversification of flavors helps coffee<br />

capsule brands to differentiate themselves<br />

from competitors and stand out in a crowded<br />

Coffee Capsules Industry. By offering unique<br />

and innovative flavors, brands can attract new<br />

customers and create a strong brand identity.<br />

Overall, the diversification of flavors in the<br />

coffee capsule market has been a key driver<br />

of Coffee Capsules Market Growth, helping to<br />

increase consumer engagement, loyalty, and<br />

brand differentiation.<br />

• Cafes and restaurants use single-serving coffee<br />

options for their convenience as it reduces<br />

manual work and works as a way to reduce<br />

the need of employing professional baristas.<br />

Leading trends influencing the market<br />

• Coffee pods and capsules face strong<br />

competition from demand for other coffee<br />

options like instant coffee and RTD coffee.<br />

• Many new vendors have started<br />

introducing technologically innovative<br />

products to meet the constantly changing<br />

demand for coffee beans and capsules.<br />

• For instance, the Swiss coffee brand coffee<br />

introduced a single-serving coffee pod ball<br />

with a seaweed-based casing instead of an<br />

aluminum or plastic capsule in 2022.<br />

• In August 2022, Tim Hortons released four<br />

variations of capsules for its users to try out different<br />

flavors like decaf, bright, bold, and classic.<br />

Major challenges hindering the market growth<br />

• One of the major challenges for the market<br />

is the high price of coffee pods and capsules<br />

compared to traditional coffee products.<br />

• Consumers in developing economies like<br />

Asia, Eastern Europe, and Latin America prefer<br />

traditional coffee over coffee pods and<br />

capsules for its cheaper price range.<br />

• Consumers in highly populated nations like<br />

China, India, Indonesia, and Nigeria among<br />

others still prefer traditional coffee due to their<br />

efficiency and because they produce more<br />

cups of coffee than pods and capsules.<br />

• Hence, it becomes imperative that the<br />

players in the market scale down<br />

the prices of coffee pods and<br />

coffee capsules attract<br />

consumers from<br />

developing nations.<br />

Key factor driving market growth<br />

• The rapid urbanization and increasing<br />

availability of organized outlets for the<br />

convenience of the growing working<br />

population in many developing economies has<br />

increased the demand for convenient-to-use<br />

products has been increasing exponentially.<br />

JUNE <strong>2023</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

7

Arabatzis SA<br />

“kneads”<br />

innovation and<br />

sustainability<br />

From Greece to the world…<br />

The frozen dough industry<br />

M.Arabatzis SA-Hellenic Dough<br />

maintains an important sales<br />

network in 45 countries<br />

Michail Arabatzis SA - Hellenic Dough<br />

is one of the largest frozen dough<br />

industries in Europe and its products<br />

preserve and pass on the nutritional<br />

value of Greek cuisine to the next<br />

generation. The company chooses<br />

only the purest and finest ingredients<br />

and offers excellent products that<br />

stand out for their quality and<br />

delicious taste. Its portfolio has over<br />

700 branded and private labels<br />

products and invests to strategic<br />

cooperation with significant retailers.<br />

Michail Arabatzis SA - Hellenic Dough<br />

is aiming for global expansion through<br />

new international partnerships, while<br />

strengthening its presence in existing<br />

ones. It maintains an important<br />

sales network in 45 countries, with<br />

some main markets in Europe, USA,<br />

Canada, and Saudi Arabia. In 2022,<br />

Hellenic Dough penetrated the<br />

market of Israel and India, while this<br />

year, a significant cooperation is<br />

going to be fulfilled in Europe.<br />

The main pillars of Michail Arabatzis<br />

SA - Hellenic Dough are innovation and<br />

sustainable development. In addition, it<br />

invests systematically and continuously<br />

in infrastructures, technological<br />

modernization, as well as human<br />

resources. Arabatzis Michael SA -<br />

Hellenic Dough never stops innovating.<br />

It always develops new tasty flavors<br />

from excellent raw materials of high<br />

nutritional value that align with modern<br />

nutritional trends. Recently, it launched<br />

a new vegan product line, comprising<br />

delicious, crispy rolls filled with cheese<br />

or vegetable minced meat, as well as a<br />

twist filled with sweet pumpkin.<br />

The new SKUs are a vegan extension<br />

to its existing range, which comprises<br />

the beloved Bougatsa Thessaloniki with<br />

aromatic vanilla cream, or delicious<br />

hazelnut cream, the nutritious Sesame<br />

Koulouri Thessaloniki, also available<br />

in a whole grain version, twists with<br />

aromatic potato, traditional country pie<br />

with spinach, and the tasty mushroom<br />

pie. The new vegan products cater to<br />

everyone and are especially suitable for<br />

those who opt a vegetarian diet, either<br />

temporarily or on a permanent basis.<br />

8 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

Visit us<br />

at the PLMA<br />

Amstell<br />

Hall: 7<br />

Stand: J27

TopGum<br />

launches<br />

high caffeine<br />

cappuccino<br />

gummies<br />

The coffee-flavored<br />

gummy line is created<br />

with new proprietary<br />

microencapsulation<br />

technology.<br />

The gummy delivery system has been<br />

capturing the nutraceutical market, with<br />

research showing that the gummy is fast<br />

becoming Americans’ favorite way to take<br />

supplements. According to Innova Market<br />

Insights, gummy supplement launches grew<br />

by 54% in the five-year period from 2017-2022<br />

globally. This marks it as one of the fastestgrowing<br />

supplement segments.<br />

For its new coffee line, TopGum offers a choice<br />

of three popular, out-of-the-box flavors:<br />

espresso, cappuccino, and mocha. TopGum’s<br />

global customer base, which includes major<br />

food and supplement companies, can<br />

customize the Gummiccino matrix by adjusting<br />

dosage, flavor, color, shape, and size.<br />

In addition to providing the full coffee sensory<br />

experience, TopGum’s gummies deliver a true<br />

functional dose of caffeine: Each serving of two<br />

coffee gummies contains 40 mg of caffeine,<br />

which is equivalent to a standard espresso shot.<br />

TEL AVIV – Gummy supplement manufacturer<br />

TopGum, Ltd. launches Gummiccino, its<br />

new line of high-dosage delicious caffeine<br />

gummies. The product marks the first use of<br />

TopGum’s new proprietary microencapsulation<br />

technology designed to enhance flavor and<br />

boost absorption. The functional gummies are<br />

infused with an extract of robusta coffee beans<br />

(Coffea robusta) that perfectly captures the<br />

genuine aroma, flavor, and color of coffee.<br />

“Until now, coffee-flavored caffeine gummies<br />

have had a limited market presence due to<br />

tendencies to develop a bitter flavor,” explains<br />

Amichai Bar-Nir, CEO of TopGum. “Thanks to<br />

our novel TopCapsTM technology, busy coffee<br />

lovers can finally experience the rich flavor of<br />

coffee in gummy form, with zero bitterness.”<br />

“The product line represents the culmination<br />

of a lengthy and complex development<br />

process,” says Eli Edri, TopGum’s COO and VP<br />

of strategic partnerships. “Over the last couple<br />

of years, we worked on the development<br />

of a state-of-the-art microencapsulation<br />

technology—called TopCaps—that is uniquely<br />

tailored for gummies. This innovative technology<br />

allows consumers to savor the flavor and<br />

aroma of coffee-on-the-go, while energizing<br />

themselves with a single chewy treat.”<br />

10 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

This makes it an appealing and convenient<br />

alternative for the 74% of Americans who drink<br />

coffee daily. 1 It also appeals to consumers who<br />

simply need a quick energy boost.<br />

According to the International Coffee<br />

Organization, 2 between <strong>June</strong> 2020 and<br />

<strong>June</strong> 2021, Europeans consumed 242 million<br />

kilograms of coffee. Including the UK (21.8<br />

million kgs) and Switzerland (9.3 million kgs)<br />

into that figure, a staggering total of 273<br />

million kgs of coffee were consumed.<br />

“The new line represents a breakthrough in the<br />

caffeine gummy space,” adds Edri, “Our TopCaps<br />

microencapsulation system allows the body to<br />

effectively absorb the caffeine by coating the<br />

caffeine particles with a natural substance that<br />

breaks down in the stomach, not the mouth.<br />

TopCaps technology will allow additional<br />

functionalities, which will be presented next year.<br />

The company plans to leverage its TopCaps<br />

technology to formulate more innovative<br />

gummy-based products that cater to specific<br />

consumer needs. These projects will be led<br />

by the recently appointed head of R&D,<br />

Evgenia Lozinsky, who previously served as the<br />

CEO of PharmItBe. TopGum is establishing a<br />

specialized microencapsulation plant in Israel<br />

to bring its cutting-edge technology to the<br />

global market on a large scale.<br />

The new line joins TopGum’s catalog of<br />

nutraceutical-enriched gummies that are<br />

being commercialized on a private-label<br />

basis. The company also offers custom<br />

formulations to brands formulating gummies<br />

with their own ingredients. Using TopGum’s<br />

service, brands can take advantage of the<br />

growing gummy market faster than if they had<br />

to reinvent the technology on their own.<br />

1<br />

https://www.driveresearch.com/market-research-company-blog/coffee-survey/<br />

2<br />

The 10 European Countries That Drink the Most Coffee - N26<br />

JUNE <strong>2023</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

11

Bach Snacks innovates<br />

the world of snacks<br />

The industry’s ultimate pellet partner offers a wide range<br />

of pellets to answer every needs of snack manufacturers.<br />

Bach Snacks produces pellet snacks in all possible sizes and types.<br />

Since 1999, Bach Snacks has been one<br />

of the leaders in the production of semifinished<br />

dry pellet, with an extensive<br />

assortment of high-quality products made<br />

from potatoes, corn, and Cereals.<br />

Today, Bach Snacks is positioned<br />

as a major supplier of snack pellets,<br />

covering the Middle East, North Africa,<br />

Europe and Asia. Currently, the company’s<br />

production capacity exceeds 2000 Metric<br />

tons with more than 30 shapes,<br />

across more than 25 countries.<br />

Bach Snacks differentiates itself in the market by<br />

the close partnership it creates with customers,<br />

in order to provide the best services with the<br />

highest quality of products.<br />

With a diversified portfolio of pellets, Bach<br />

Snacks continually enhances its production<br />

lines, through the integration of the latest<br />

technologies and innovative techniques. By<br />

utilizing high-quality raw materials, developing<br />

various textures, flavors and shapes, Bach Snacks<br />

empowers leading brands, manufacturers and<br />

retailers to innovate in the world of snacks.<br />

To know more information about<br />

the company and range of product<br />

categories, please check the website<br />

www.bachsnacks.com<br />

or contact Bach Snacks Team on:<br />

BACH SNACKS SAL<br />

Kfarchima Industrial Zone<br />

LEBANON<br />

Tel : +961 5 431 555 | +961 5 431720<br />

Fax : +961 (5) 431721<br />

e-mail : bachsnacks@bachsnacks.com<br />

12 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

interpack pleased the global<br />

processing and packaging industry<br />

For those in the product packaging and processing business there was only one<br />

“place to be” from 4 to 10 May: interpack in Düsseldorf. Under the heading<br />

“Welcome Home” the trade fair welcomed visitors from all over the world.<br />

The joy of finally coming together as an industry was great.<br />

It delivered what it promised and exceeded<br />

exhibitors’ expectations: the world’s largest<br />

and most relevant packaging trade fair<br />

set standards yet again from 4 to 10 May,<br />

connected the industry on a global level and<br />

acted as both a marketplace and content<br />

hub. Visitors from 155 countries, many with<br />

firm intentions to buy, came to interpack <strong>2023</strong>.<br />

2,807 exhibitors showcased the power and<br />

creativity of the packaging industry with their<br />

technologies and solutions. What was easy<br />

to see were the numerous impulses, ideas<br />

and concrete business deals which will be<br />

implemented over the coming years.<br />

At the end of the trade fair Bernd Jablonowski,<br />

Executive Director at Messe Düsseldorf,<br />

says: “With interpack we were able to finally<br />

hold one of the Messe Düsseldorf’s most<br />

important events again. It has reported back<br />

impressively and reinforced its position as the<br />

global platform for the exchange amongst<br />

all players in the packaging sector, related<br />

process industries and all user industries. Our<br />

targets were exceeded by far.”<br />

Altogether approx. 143,000 visitors travelled<br />

to interpack in Düsseldorf, two thirds of<br />

them coming from abroad. Alongside many<br />

14 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

European countries, the largest visitor nations<br />

were India, Japan and the USA. Around 75% of<br />

visitors came from middle or top management.<br />

“interpack at last!” was a phrase frequently<br />

heard in the halls – because after a six-year<br />

break the big community was finally able to<br />

meet again in person. And this was reflected<br />

in the joy on people’s faces. “interpack <strong>2023</strong><br />

will reverberate with us for a long time – both<br />

in business and personal terms,” says Director<br />

Thomas Dohse after seven trade fair days<br />

adding: “The mood in the halls was great and<br />

the inter-cultural exchange enriching for all<br />

sides. It was ‘simply unique’ again.”<br />

This was underscored by the positive feedback<br />

from visitors, 96% of whom stated they had<br />

achieved their trade fair objectives. Just as<br />

satisfied were the exhibitors whose expectations<br />

had been exceeded many times over. “We<br />

thank Messe Düsseldorf for the outstanding<br />

organisation. I’m confident that I’m speaking<br />

on behalf of all companies here. interpack <strong>2023</strong><br />

is simply a must for suppliers and users from all<br />

over the world to exchange experiences and<br />

do business,” says Markus Rustler, President of<br />

interpack <strong>2023</strong> at the conclusion of the event.<br />

Transformation as an opportunity<br />

Considering current market developments,<br />

the enormous challenges but also the even<br />

bigger opportunities, this interpack definitely<br />

proved one of the most important ones in its<br />

history. The need to automate, the will to act<br />

sustainably and changed consumption habits<br />

are all expressions of transformation.<br />

interpack’s strategic orientation towards the<br />

four Hot Topics: Circular Economy, Resource<br />

Management, Digital Technologies and<br />

Product Safety found concrete expression in<br />

JUNE <strong>2023</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

15

live streams. Some 200,000 viewers dialled in<br />

during the run-time of the trade fair alone.<br />

The Spotlight Talks & Trends Forum proved a<br />

visitor magnet and focused on seven themes on<br />

seven days including amongst others, logistics,<br />

circular economy and e-Commerce. The<br />

programme was presented jointly by interpack,<br />

the dfv Conference Group and PackReport.<br />

numerous innovations. The trade fair, which<br />

has traditionally been a key cornerstone in the<br />

innovation cycle of the packaging industry<br />

and related process industries, also more than<br />

lived up to this claim this year.<br />

Sustainable packaging technologies<br />

All facets of sustainability were top themes<br />

at interpack. Exhibitors presented highend<br />

technologies and holistic concepts<br />

that consider efficiency and sustainability<br />

along their entire production line. “Many<br />

companies in the consumer goods industry<br />

have set their own sustainability targets,” says<br />

Richard Clemens, Managing Director of the<br />

<strong>Food</strong> Processing and Packaging Machinery<br />

Association within VDMA at interpack.<br />

“Over the past few years, packaging<br />

machinery manufacturers have succeeded<br />

in implementing sustainable packaging<br />

concepts by means of corresponding<br />

technical adaptations and newly developed<br />

machinery solutions. interpack is the showcase<br />

for innovations and, at the same time, the<br />

point of departure for developing further<br />

towards a sustainable circular economy,” says<br />

Clemens summing up.<br />

New and fresh impulses<br />

Also attracting plenty of attention were the<br />

other Specials such as the interpack Startup<br />

Zone, the joint stand Co-Packing, several<br />

award ceremonies spotlighting exciting<br />

packaging innovations, the ‘SAVE FOOD<br />

Highlight-Route’ with new approaches to<br />

fighting global food loss and waste and the<br />

promotion of women at ‘Women in Packaging’.<br />

The special buzz at this premiere came by<br />

way of the approximately 200 women from<br />

the international sector, who exchanged and<br />

established new networks during interpack.<br />

components – which was held as a concurrent<br />

event with 80 exhibitors in a separate hall –<br />

also went down well with visitors. The upstream<br />

industries supplying components and software<br />

to packaging technology and process<br />

engineering play a prominent role in the<br />

digitalisation of manufacturing processes.<br />

The next interpack will be held<br />

in Düsseldorf from 7 to 13 May 2026.<br />

The many solutions celebrating a world premiere<br />

at interpack also included a host of packaging<br />

materials and supplies in all their diversity. In<br />

excess of 1,000 exhibitors were showcased in this<br />

segment alone, making for a new record.<br />

Forward-looking content<br />

interpack is not only a business but also a content<br />

platform for the sector, both live and digitally. A<br />

total of 50 talks were hosted at the Tightly Packed<br />

TV studio care of interpack and ‘packaging<br />

journal’, thereby generating additional visibility<br />

and reach of the top themes and trends through<br />

16 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

Exhibitor Testimonials<br />

“The mood at interpack <strong>2023</strong> was excellent<br />

and we are happy to be part of this event<br />

again. It felt like in previous years and we<br />

are very satisfied with the quality of visitors.<br />

We were able to welcome numerous<br />

international delegations as well as all key<br />

business partners to our stand and thrill new<br />

potential customers.”<br />

Markus Rustler, Managing Partner at<br />

Theegarten-Pactec GmbH & Co. KG<br />

“Great mood, packed stands, good and<br />

plenty of business – this is how interpack <strong>2023</strong><br />

can be summarised. Our member companies<br />

are very satisfied. On the weekend – as<br />

expected – many customers came from<br />

overseas. The quality of visitors was very high<br />

– some of the machines were purchased<br />

straight off the stand. After the six-year break<br />

people delighted all the more at seeing the<br />

interpack family finally coming together again<br />

in Düsseldorf. To us, interpack is, and always<br />

will be, the leading trade fair of the industry.”<br />

Richard Clemens, Managing Director of<br />

VDMA’s <strong>Food</strong> Machinery and Packaging<br />

Machinery Association<br />

interpack for IMA is historically a point of<br />

reference in the exhibition panorama. As<br />

a matter of fact, in this <strong>2023</strong> edition we<br />

attended with an almost 5000 m2 booth:<br />

the biggest ever. 46 machines, 12 new<br />

models and 22 machines IiOT connected,<br />

expressing IMA’s commitment towards<br />

innovation and digitalisation. Great<br />

emphasis on sustainability as one of the<br />

main pillars of the IMA System, presenting<br />

solutions to handle new eco-friendly<br />

materials on our equipment. We recorded<br />

excellent attendance and our customers<br />

were extremely pleased by our polyhedric<br />

portfolio characterised by innovation.<br />

Monica Cervellati, Corporate Communication<br />

and Exhibitions Director IMA<br />

“interpack <strong>2023</strong> has been a success for Metsä<br />

Board. In our Innovation Lab area we provided<br />

inspiration for the visitors around circular<br />

packaging solutions made with renewable<br />

and easily recyclable materials helping to<br />

reduce the use of plastic. This year’s discussions<br />

exceeded our expectations. The quality of<br />

visitors was surprisingly high coming from all over<br />

the world and fulfilled fully the expectations we<br />

had in exhibiting at this international fair.”<br />

Marjo Halonen, VP Communications<br />

Metsä Board<br />

“interpack is an important trade fair for us. In 2017<br />

we were still represented with a smaller stand,<br />

for <strong>2023</strong> we opted in favour of an enlargement.<br />

What we especially liked is the trade fair’s high<br />

international attendance and the new hall<br />

concept. We will be back in 2026 again.”<br />

Andreas Grabotin, Zone Director DACH<br />

markem-imaje<br />

“Interpack <strong>2023</strong> was one of the most eagerly<br />

awaited events for our industry. It was a<br />

great opportunity to meet our customers<br />

and partners again and to start new<br />

projects and collaborations. We exhibited<br />

more than 50 machines with a focus on<br />

sustainability, digital innovation, laboratory<br />

solutions, sterile packaging, inspection and<br />

traceability. In particular, our visitors showed<br />

interest in eco-friendly solutions, in our<br />

innovative robot with parallel architecture<br />

and AI applications. I was impressed by<br />

the determination of visitors who visited us<br />

with specific requests. At the same time, we<br />

regret that due to the difficulties the world<br />

is facing in this moment, we couldn’t meet<br />

customers from some geographical areas.”<br />

Valentina Marchesini, Director of Human<br />

Resources and Head of Marketing &<br />

Communications at Marchesini Group S.p.A.<br />

“For Uhlmann Pac-Systeme, interpack was<br />

a great success. Our stand concept with its<br />

clear focus on sustainability was very well<br />

received by visitors. We also stimulated the<br />

interest of trade fair visitors who actually did<br />

not have us on their programme. Sustainability<br />

as a driver of innovation in products and<br />

services, both at Parenteralia and Oral Solid<br />

JUNE <strong>2023</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

17

Exhibitor Testimonials<br />

Dose - this is what our customers are looking<br />

for and this has also enabled us to develop<br />

new contacts. The live experience and the<br />

opportunity to just get in touch, that’s really a<br />

trademark of interpack, and we’re very happy<br />

that the fair could take place again.”<br />

Gabi Bauer, Head of Marketing &<br />

Communication Uhlmann Pac-Systeme<br />

“Process and packaging technology for a<br />

better life - that’s what visitors experienced at<br />

the Syntegon stand. This included numerous<br />

solutions with answers to market trends such as<br />

automation, digitalisation and sustainability.<br />

And the feedback from our customers showed<br />

that we have met their requirements. Whether<br />

new machines, entire lines or services, the<br />

interest was great. The first interpack with our<br />

Syntegon brand was a complete success for us”.<br />

Dr. Michael Grosse, Vorsitzender der<br />

Geschäftsführung Syntegon<br />

“The face-to-face conversations proved a<br />

tremendous added value for us. On all days<br />

we registered a high number of visits by<br />

customers and interested parties. Concrete<br />

business deals were already concluded<br />

during the trade fair days, and a multitude<br />

were initiated. At interpack we placed a lot of<br />

emphasis on flexible solutions for a wide variety<br />

of confectionery machinery for chocolate,<br />

marshmallows and jelly as well as on service and<br />

digitalisation to also always support customers<br />

beyond the initial equipment purchase.”<br />

Jessica Runkel, Managing Director Winkler und<br />

Dünnebier Süßwarenmaschinen<br />

“We are pleased that we can finally exhibit<br />

at interpack again after six years and meet<br />

with so many international customers after<br />

the pandemic period. Our principal theme<br />

at interpack is holistic line integration. As a<br />

total solutions provider we have extended<br />

our portfolio in various segments and are<br />

delighted that this has met with such strong<br />

interest among our many visitors.”<br />

Tobias Weber, CEO Weber<br />

Maschinenbau GmbH<br />

“Reusability has become a key criterion for<br />

packaging – be it of glass, paper or plastics.<br />

Starlinger’s circular solutions for Big Bags made<br />

of rPET and rPP went down especially well with<br />

our visitors at interpack. Our customer Packem<br />

from Brazil, a pioneer for Big Bags in recycled<br />

PET, was awarded the WorldStar Packaging<br />

Award for its Bag-to-Bag project. This was a<br />

special trade fair highlight for us!”<br />

Angelika Huemer, Managing Partner,<br />

Starlinger & Co Gesellschaft m.b.H.<br />

“We were absolutely delighted to be at<br />

interpack again at last after six years! To my<br />

mind, nothing replaces direct customer contact.<br />

We have brought along many new products to<br />

the trade fair, including various innovations with<br />

a focus on sustainability, process reliability and<br />

handling. Our stand at interpack was a perfect<br />

communication platform to enter into dialogue<br />

with customers and obtain direct feedback on<br />

our new products. Overall, the quality of visitors<br />

and also the volume were very good. We plan<br />

to be back in three years.”<br />

Axel Schäfer, Global Head of Marketing &<br />

Commercial Product Management, Schütz<br />

GmbH & Co. KGaA.<br />

“interpack is an important source of impetus<br />

for the transformation to more environmental<br />

protection and efficient production processes in<br />

the packaging industry. These are precisely the<br />

points we are targeting with our holistic solutions<br />

- whether with resource-saving packaging<br />

systems, comprehensive service offerings or<br />

forward-looking machine technologies. The<br />

strong interest shown in our solutions at interpack<br />

proves to us that we are on the right track.<br />

“Dr. Johannes T. Grobe, Geschäftsführer Sales<br />

und Service der KHS Gruppe<br />

“interpack <strong>2023</strong> was very successful for<br />

us - even in direct comparison to the last<br />

interpack, we recorded more visitors at our<br />

stand. We also rate the quality of the leads we<br />

captured as very positive.”<br />

Adrian Ritzhaupt, Group Director Commercial &<br />

Service, Mosca GmbH<br />

18 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

In food<br />

machinery,<br />

it is Lakidis...<br />

Founded in 1965 and headquartered in<br />

Greece, LAKIDIS SA company has a passion<br />

to offer the best and the most convenient<br />

machinery for the food manufacturers<br />

throughout its history of over a half century.<br />

Owing its success to this commitment, the<br />

company is constantly growing and building<br />

up a truly international brand. As a reliable<br />

producer of integrated solutions in the field<br />

of food machinery for over 57 years with a<br />

global network of around 30 agencies that<br />

distribute Lakidis <strong>Food</strong> Machinery and a great<br />

number of customers worldwide, Lakidis SA<br />

supports the processing of meat, poultry and<br />

fish products. The company also supports<br />

and provides solutions for industries such as<br />

petfood, snacks, puff pastry, sauce & dips,<br />

baby food, fruit and plant-based products.<br />

R&D development, production and<br />

assembling take place in private owned<br />

The Greek company’s sales<br />

team works with customers’<br />

team from beginning to<br />

the end to understand their<br />

needs, define a budget<br />

and develop balance<br />

between quality - production<br />

and costs and the R&D<br />

department develops the<br />

solutions most suitable for the<br />

customers’ demand. This way<br />

the customer gets what they<br />

really require and what is the<br />

most ideal for them.<br />

20 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

facilities, thus enabling compliance with<br />

the highest quality standards. Its vertical<br />

production unit ensures that it has full control<br />

over the production processes, accurate<br />

timing and maintain quality standards<br />

throughout all stages. The manufacturing<br />

of the company’s various codes starts with<br />

the selection of exclusive raw materials,<br />

runs through each stage with precision &<br />

consistency robot welding, CNC processing,<br />

glass blasting (surface treatment), and<br />

electric & electronic assembly. The<br />

production takes into account all known<br />

industry standards and goes far beyond<br />

that. Reliability, ease of use and compliance<br />

with the highest hygiene standards are the<br />

special features of the Lakidis products.<br />

Recommending the appropriate machine<br />

for each customer’s specific requirements<br />

is something Lakidis takes great value<br />

in. The company’s sales team works with<br />

customers’ team, from start to finish, to<br />

understand their needs, define a budget<br />

and develop balance between quality -<br />

production and costs. As a professional<br />

approach and respect to the customer, the<br />

Lakidis team is always close by and ready<br />

to help with meetings, video calls and<br />

technicians training when required. From the<br />

first spark of inspiration to implementing a<br />

solution, Lakidis is committed to excellence<br />

in everything they do. Because this is what<br />

they say: #welovewhatwedo.<br />

More information about the company<br />

and their products can be attained at:<br />

www.lakidis.gr, 14th Old National Rd.,<br />

Thessaloniki-Veria, Greece<br />

+30 2310 722772, +30 2310 722367,<br />

sales02@lakidis.gr.<br />

JUNE <strong>2023</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

21

Liquid gold: technological solutions<br />

for drying and protecting actives<br />

When choosing between<br />

spray drying and spray<br />

granulation, the end product<br />

properties will determine<br />

the preferred method.<br />

decades to process high-volume bulk products<br />

such as milk powder. Spray drying is also<br />

ideal for products with a low solids content as<br />

relatively high temperatures can be used. Due<br />

to the fact that a lot of water evaporates, the<br />

cooling effect and the short processing time<br />

help reduce heat-related damage. However,<br />

the fine particles generated can create dust<br />

problems, especially when enzymes or other<br />

proteins are involved. As they are often potent<br />

allergens and finely distributed as dust, further<br />

processing is therefore required.<br />

Gudrun Ding<br />

Head of Business Development<br />

Process Technology<br />

Glatt Ingenieurtechnik<br />

The optimal process for the conversion of liquid<br />

products into bulk materials depends on the<br />

desired properties of the final particles, and<br />

the specific application. Here, Glatt is wellplaced<br />

to advise on the pros and cons of each<br />

method thanks to its experience and expertise<br />

in designing fluid bed systems for individual<br />

needs and end products.<br />

The process of drying liquids allows the<br />

resulting product to be more easily managed<br />

and stored at ambient temperatures.<br />

Furthermore, not only is the end product more<br />

stable than liquid raw materials, but it also has<br />

significantly reduced weight and volume, thus<br />

reducing transportation and storage costs.<br />

To dry liquids quickly and effectively, spraying<br />

them into a hot air stream (spray drying) is a<br />

cost-effective method that has been used for<br />

Targeted solutions for numerous applications<br />

Fluidised bed spray granulation processes<br />

take the basic concept of spray drying to a<br />

whole new level, with targeted solutions for a<br />

range of material systems, applications and<br />

market sectors. Compared with spray drying,<br />

the fluidised bed process allows the desired<br />

product properties, including structure and<br />

size, to be adjusted in a targeted manner. This is<br />

made possible by combining two process steps:<br />

convective drying or solidification and particle<br />

formation, with particle sizes from 200 µm to 2<br />

mm easily achievable. By contrast, spray drying<br />

only produces particles of about 10 µm - 300 µm<br />

in diameter. The dispersed droplet dries during<br />

its descent from the spray tower, which means<br />

its size is limited by the height of the tower, so<br />

significant particle growth can only be achieved<br />

with an additional agglomeration step.<br />

Fig.1: Spray granulated particles with onion structure.<br />

Copyright: Glatt<br />

22 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

Fig.2: Continuous fluid bed process with grinding-screen circuit.<br />

Copyright: Glatt<br />

Droplet formation and film drying<br />

In contrast to spray drying, during which the<br />

liquid containing solids is atomised in an empty<br />

process chamber, in spray granulation it is<br />

dispersed into a bed of fluidised particles. The<br />

solvent - usually water or an organic substance<br />

- quickly evaporates, so that particle<br />

growth occurs by droplet formation and film<br />

drying (Fig.1). During this process, known as<br />

granulation drying or build-up granulation,<br />

new nuclei are continually generated.<br />

They can be produced in two ways: by<br />

abrasion and/or the fact that some atomised<br />

droplets miss the particles suspended in the<br />

fluidised bed and dry directly. Externally,<br />

granulation nuclei can be formed from fine<br />

particles or crushed granulates derived from<br />

the grinding-screen circuit. Here, oversize and<br />

undersize particles are separated, crushed by<br />

a pin mill and fed back into the process. Both<br />

the direct (spray drying) nucleation - the socalled<br />

overspray - and the indirect nucleation<br />

control the steady growth of the particles<br />

during the process, and form the basis for<br />

stable and continuous granulation. (Fig.2)<br />

Creation of custom particles<br />

Thanks to their multi-chamber design,<br />

continuously operated fluidised bed spray<br />

granulation systems (Fig.3) allow for the<br />

combination of several process steps.<br />

Theoretically, a rectangular fluid bed system<br />

can be built to any size, so that different<br />

product properties can be set in successive<br />

process chambers to create custom particles.<br />

In several projects, Glatt process engineers<br />

were able to decrease the particles size<br />

significantly and generate soluble, powdery<br />

particles from a solution of e.g. hydrolysed<br />

proteins by using a fluid bed with an<br />

initial spray-drying step. These were then<br />

agglomerated and reached a higher density<br />

due to collisions and ongoing wetting. Finally,<br />

these particles dissolved faster in water<br />

as they immerse more quickly than purely<br />

spray-dried products. Besides the solubility,<br />

this process reduces packaging volumes due<br />

to the higher bulk density, which generates<br />

savings in storage and transportation - a step<br />

further for sustainability. (Fig.4)<br />

Fig.3: A wide range of material systems,<br />

applications and industrial sectors can profit<br />

from fluidised bed spray granulation.<br />

Copyright: Glatt<br />

JUNE <strong>2023</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

23

Fig.4: Visibly different: REM-pictures of a fluidised<br />

bed spray granulation product (above) and<br />

the same product from a traditional spray tower.<br />

Fig.5: Cut granule with microencapsulated oil.<br />

Copyright: Glatt Copyright: Glatt Copyright: Glatt<br />

occur if the moisture suddenly escapes.<br />

Furthermore, depending on the drying speed<br />

and concentration of solids in the liquid, the<br />

particles might rupture, which makes them<br />

unsuitable for encapsulated actives. (Fig.5)<br />

Protecting active components<br />

Spray granulation also produces compact,<br />

round spheres with an onion-shaped structure<br />

by building up the product layer by layer. This<br />

enables flexible and complex product design as<br />

particles can be formed from different solid layers,<br />

with cores loaded and coated (Fig.6), giving<br />

nutraceutical manufacturers the opportunity<br />

to create functional products with added<br />

value. Furthermore, coating the previously spray<br />

granulated particles can be done with the same<br />

apparatus to protect the active component or<br />

mask unpleasant tastes and smells.<br />

Spray granulates differ from dried products in<br />

that particle size, shape and structure can be<br />

adjusted according to the desired application.<br />

Fluid bed spray granulation is recommended<br />

for sensitive nutraceuticals, for example, and<br />

for turning emulsions and oils into compact<br />

particles. As they have a smaller surface area<br />

compared with spray dried products, these<br />

nutraceuticals are better protected against<br />

oxidation and have a lower drying temperature.<br />

Glatt closely monitors every fluid bed project,<br />

from commission through to installation.<br />

Beyond the development of customised and<br />

functional product solutions, the company<br />

also offers project initiation, development and<br />

delivery to turnkey factories.<br />

Closed-circuit environment<br />

Multi-chamber fluidised bed systems can<br />

spray from above or below. Intermediate<br />

drying and cooling steps are also possible,<br />

and subsequent cooling can be done in the<br />

same unit. Fluidised bed spray granulation<br />

systems that handle organic solvents or<br />

oxidation-sensitive products can also be easily<br />

integrated into a closed-circuit environment.<br />

Copyright: Glatt<br />

A key difference between spray drying and<br />

fluidised bed spray granulation is particle size<br />

and morphology: in spray drying, particles dry<br />

from the outside in; while in fluidised-bed spray<br />

granulation, the particles dry from the inside out.<br />

The hot air stream in which the droplets dry<br />

creates a hard outer shell, which boosts the<br />

concentration of the dissolved component,<br />

yet the inner core of the particle remains<br />

liquid. As the temperature increases, this<br />

moisture evaporates and diffuses, causing<br />

hollow spheres. Indentations in the particles<br />

24 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong><br />

Fig.6: The onion-shaped structure is clearly visible<br />

in these amino acid granules.<br />

Meet Glatt in Istanbul:<br />

Visit Glatt at the <strong>Food</strong> & Nutritional<br />

<strong>Ingredients</strong> in Istanbul from May 31 to<br />

<strong>June</strong> 2, <strong>2023</strong>, hall10, booth D201. Don’t<br />

miss the lecture on “Spray Granulation vs.<br />

Spray Drying – Fluid Bed Technology as an<br />

Innovative Drying Process for Hydrolyzed<br />

Proteins?” on May 31, 16:45-17:15 local time<br />

by Dr. Jens Bergmann, Sales Manager<br />

Process Technology <strong>Food</strong>, Feed & Fine<br />

Chemicals, Glatt Ingenieurtechnik.

foodfeedfinechemicals.glatt.com<br />

Tailored enhancing of your ProducTs<br />

» Homogeneous and dust-free granules from powdery and liquid raw materials.<br />

» Drying and shaping in just one process step by fluidized bed and spouted bed technology.<br />

» Perfect determination of particle properties.<br />

» Maximum options for functionalization.<br />

» Protection of volatile and sensitive substances.<br />

» More performance, stability and safety for application, handling and storage.<br />

Glatt supports your product idea starting at the early stage of the product formulation and<br />

the process development to the scale up and the final production.<br />

Glatt. Integrated Process Solutions.

Juha Väre, CFO of Paulig<br />

International food and beverage<br />

company Paulig has announced<br />

a unique Climate Fund to<br />

accelerate climate emission<br />

reductions in its value chain. The<br />

fund, which is valued at EUR 2.7<br />

million in <strong>2023</strong>, will be allocated<br />

to projects targeting emission<br />

reductions in wheat and coffee<br />

value chains, logistics and<br />

Paulig’s own operations. Projects<br />

are chosen annually and are<br />

implemented together with<br />

Paulig’s partners and suppliers.<br />

In addition to the new fund,<br />

Paulig will continue other<br />

sustainability initiatives and work<br />

towards its ambitious targets.<br />

Paulig launches a unique<br />

Climate Fund to accelerate<br />

climate actions in the value chain<br />

“Our ambition is to be a sustainable frontrunner<br />

in the food and beverage industry, and our<br />

target is to reduce greenhouse gas emissions<br />

from our own operations by 80% and from our<br />

value chain by 50% by 2030. With this unique<br />

fund we will strengthen the impact and agility<br />

of our climate actions, enhance our innovation<br />

capabilities, and accelerate our progress<br />

towards our ambitious climate targets. The fund<br />

enables us to further drive actions that have<br />

the biggest value chain climate impact on the<br />

company level,” says Lea Rankinen, Director,<br />

Sustainability & Public Affairs at Paulig.<br />

Paulig has used a climate fee for emission ton<br />

to evaluate the needed budget for annual<br />

CO2 emission reductions. This budget forms<br />

the basis for the annual fund. For <strong>2023</strong>, the<br />

fund is valued at EUR 2.7 million.<br />

“We have used an internal carbon price of<br />

EUR 50 for CO2 ton and then evaluated the<br />

needed budget for our targeted climate<br />

impact reductions. This evaluated cost<br />

needed for targeted emission reductions<br />

is then included in our financial plan and<br />

annual budget. Applying the internal carbon<br />

price mechanism as part of our financial<br />

planning helps us understand how carbon<br />

emissions could affect our profit and loss<br />

statement and our investment choices,”<br />

explains Juha Väre, Paulig’s CFO.<br />

Focus on wheat and coffee value chains<br />

The fund is allocated to projects selected<br />

annually on the basis of Paulig’s strategic<br />

initiatives. The selection principles<br />

emphasise each project’s reduced climate<br />

impact potential, innovativeness, cost-<br />

26 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

efficiency and scalability potential. The<br />

fund is mainly allocated to projects related<br />

to wheat and coffee value chains and<br />

logistics. The rest of the projects are linked<br />

to emission reductions in Paulig’s own<br />

operations, such as the carbon neutrality<br />

of factories, as well as other collaborations.<br />

New project proposals and initiatives are<br />

reviewed annually.<br />

“Our criteria for selecting the projects<br />

are based on Paulig’s company strategy,<br />

sustainability approach and science-based<br />

climate targets. Tortillas and coffee have the<br />

biggest climate impact in our value chain.<br />

The focus is to help reduce emissions in raw<br />

materials farming and advance regenerative<br />

farming methods. Most of the projects are<br />

planned and implemented together with our<br />

suppliers and partners. Working together, we<br />

aim to discover new innovations and ways to<br />

improve our operations and collaboration,”<br />

Rankinen states.<br />

The climate impacts of the projects are<br />

measured using relevant carbon accounting<br />

standards and progress is followed up regularly.<br />

“We monitor the progress of the climate<br />

projects regularly against the targets and<br />

budget. Our goal is also to turn best practices<br />

into routines and adapt them as part of<br />

our operations. We will expand the use of<br />

new innovations, methods and technology<br />

discovered in the projects by scaling them<br />

within the value chain,” Rankinen continues.<br />

Paulig already has on-going climate projects<br />

that enhance more sustainable farming<br />

practices and cultivating methods regarding<br />

wheat production and coffee.<br />

Paulig will continue its work towards its<br />

ambitious sustainability targets. In addition to<br />

Climate action and circularity, the work focuses<br />

on Fair & Inclusive way of working and Health<br />

and well-being of people and the planet.<br />

JUNE <strong>2023</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

27

Anuga and EIT <strong>Food</strong><br />

enter a strategic partnership<br />

The leading global trade fair for food and<br />

beverages taps into the extensive know-how<br />

of Europe’s leading initiative for food innovations.<br />

28 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

EIT <strong>Food</strong>, the world’s largest and<br />

most dynamic initiative for food<br />

innovations is the new partner of<br />

Anuga. In line with the key theme<br />

of Anuga, “Sustainable Growth”,<br />

the aim of the long-term, strategic<br />

partnership is to promote the<br />

dialogue and the interdisciplinary<br />

cooperation to achieve a<br />

sustainable food system. Together<br />

the leading global trade fair for<br />

food and beverages and EIT <strong>Food</strong><br />

will create a platform for innovative<br />

ideas and new sustainable<br />

developments in the food industry.<br />

To this end, they are bringing the<br />

most important players from the<br />

industry and fields of politics and<br />

business together at Anuga in<br />

Cologne from 7 to 11 October <strong>2023</strong>.<br />

“We are delighted to have the experts<br />

of EIT <strong>Food</strong> and its network on board<br />

in the scope of this new, strategic<br />

partnership. New ways towards an<br />

improved, global food system will be<br />

highlighted in the course of different<br />

event formats and subsequently there<br />

will be an opportunity to engage in a<br />

direct exchange with an international<br />

trade audience and the trade<br />

media,” explained Bastian Mingers,<br />

Vice President <strong>Food</strong>.<br />

Dr. Andy Zynga, CEO of EIT <strong>Food</strong>,<br />

adds: “EIT <strong>Food</strong> is very pleased to<br />

work more closely with Anuga, in<br />

addition to the partnership with<br />

Anuga HORIZON. The goal of the food<br />

community is clear: only together will<br />

we build an innovative and resilient<br />

food system, which is integral in<br />

driving greater food security and a<br />

healthier planet. This requires new<br />

ideas, solutions and collaboration<br />

within the industry, for which Anuga<br />

offers a fantastic opportunity.”<br />

The key contents of the partnership<br />

are among others:<br />

• a professional exchange and<br />

knowledge transfer<br />

• the joint development of the<br />

conference and event programme<br />

of Anuga with panel discussions,<br />

workshops and speakers<br />

• joint press events in the run-up to<br />

and during Anuga<br />

JUNE <strong>2023</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

29

New investment action<br />

from Euro Gıda<br />

Euro Gıda, one of the leading food products manufacturers, is starting<br />

the construction of an additional warehouse facility in its factory in<br />

Kemalpasa, Izmir, to meet the increasing sales volume and production<br />

capacity. At the same time, it switches to the use of clean energy with<br />

the solar energy system installed on the roof of the factory.<br />

Euro Gıda, which has the strongest position in<br />

the sector in the category of pickles, roasted<br />

vegetables and gourmet sauces, produces<br />

private label products for the leading brands<br />

and retail markets of Turkey and Europe, while<br />

also reaching the whole world with the Melis<br />

brand. It exports 70% of its production, which is<br />

made with 55 thousand tons of raw vegetables<br />

per year it receives from contracted farmers<br />

with controlled agriculture.<br />

Established in 1995, Euro Gıda incorporated<br />

the Melis brand in 2007 and moved to its<br />

modern facilities with a closed area of 55,000<br />

m2 on a 75-decare land in Kemalpaşa, Izmir<br />

in 2013, which had been built with a large<br />

investment. In 2016, it further strengthened<br />

its position in the sector by acquiring Ran<br />

Tarımsal, which produces dried tomato and<br />

processed onion products. It has increased<br />

its capacity up to 120 million jars with<br />

machinery and line investments to meet the<br />

increasing business volume by gaining new<br />

customers and new markets every year. As of<br />

<strong>2023</strong>, it continues its investments with a new<br />

warehouse facility and Solar Energy System.<br />

30 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

The construction of the new warehouse<br />

facility, which will provide an additional<br />

storage area of 6150 m2 with a rack system<br />

with a capacity of 22 thousand pallets, which<br />

is planned to be completed in four months,<br />

started with the groundbreaking ceremony<br />

where Euro Gıda Chairman of the Board<br />

Haluk Önen, Advisory Board Members Renkin<br />

Akbulak, Pınar Ilgaz, Ahmet Süha Erol and<br />

General Manager Bahadır Açık pressed the<br />

button to pour the first foundation mortar.<br />

At the groundbreaking ceremony, it was also<br />

announced that the Solar Energy System was<br />

commissioned. Thanks to the 5,267 solar panels<br />

placed on the roof, it is planned that the<br />

electrical energy to be used in the production<br />

of pickles and canned vegetables, whose<br />

production season is summer, will be obtained<br />

from clean energy to a large extent.<br />

Speaking at the ceremony, Haluk Önen,<br />

Chairman of the Board of Directors, said,<br />

“As Euro Gıda, we are growing by adding<br />

new successes every year. We are proud<br />

of contributing to the export of our country<br />

and the development of our region. The<br />

jar capacity, which was 50 million when<br />

our factory was put into operation in 2013,<br />

has increased to 120 million jars today. We<br />

continue our investments within the framework<br />

of our needs. Thanks to our warehouse<br />

facility, which we laid the foundations of<br />

together today, we will effectively use all our<br />

production lines at full capacity and provide<br />

better service to our customers.”<br />

Speaking on his part at the ceremony, Bahadır<br />

Açık, General Manager of Euro Gıda, said:<br />

“With our respect to the nature and future<br />

generations, we started the investment for<br />

the SPP, we completed the assembly and<br />

installation of the panels. In the new season,<br />

we will produce our products with the<br />

electricity we obtain from solar energy. Thanks<br />

to the SPP we have commissioned, we will<br />

prevent approximately 2,500 tons of carbon<br />

emissions per year. The Aegean region has<br />

rich resources in every respect, and the sun<br />

is one of them. As we turn the cucumbers<br />

and vegetables grown in the fields under the<br />

Aegean sun into healthy products, we will now<br />

derive our energy from the sun.”<br />

JUNE <strong>2023</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

31

New factory investment<br />

from Ulusoy Un<br />

in the earthquake zone<br />

Türkiye’s leading flour producer and exporter<br />

Ulusoy Un continues its investments.<br />

Ulusoy Un, which made a big impression<br />

with Söke, which it incorporated in 2022,<br />

bought a new flour factory in Hatay Antakya Organized<br />

Industrial Zone. Thus, while the number of factories<br />

with in Ulusoy Un increased to 5, the total production<br />

capacity increased from 3.925 tons/day<br />

to 4.200 tons/day. With the activation of the facility,<br />

it is aimed to contribute to the economic development<br />

and employment of the earthquake region.<br />

Ulusoy Un, which incorporated Söke in 2022<br />

and closed the year with a sales revenue<br />

of 20.4 billion TL, made a new factory<br />

investment in the earthquake zone. Ulusoy<br />

Un, registered in Hatay Province Belen<br />

District Şenbük Quarter, 113 Island, parcel<br />

3 in Hatay Antakya Organized Industrial<br />

Zone, on a 5,095 square meter land with<br />

a crushing capacity of 275 tons/day, with<br />

a total price of 14,350,000 Turkish Liras,<br />

registered in Block 113, parcel 4. The storage<br />

area on a land of 5,091 square meters was<br />

purchased with a total price of 5,000,000<br />

Turkish Liras. The facility, which has a closed<br />

32 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

and fully undamaged was determined. The<br />

facility is planned to be put into operation<br />

in the third quarter of <strong>2023</strong>, following the<br />

revision works to be carried out for capacity<br />

increase and technology renewal. With the<br />

commissioning of the facility, it is aimed<br />

to increase employment and contribute<br />

to economic development in the region<br />

affected by the earthquake disaster. Dr.<br />

Eren Günhan Ulusoy, Chairman of Ulusoy<br />

Un’s Board of Directors, said, “Ulusoy Un is a<br />

company that exports to 92 countries today<br />

and serves the food safety of not only Türkiye<br />

but also the world. Our company continues<br />

to grow with its new breakthroughs. With the<br />

purchase of shares of Söke Değirmencilik<br />

San ve Tic. A.Ş in 2022, a total of 2485 tons/<br />

day, 2085 tons/day in Samsun and 400 tons/<br />

day in Çorlu, 1440 tons/day capacity of<br />

Aydın and Ankara Factories belonging to this<br />

company has been increased. As a result of<br />

the addition, our total production capacity<br />

reached 3,925 tons/day. With the new<br />

purchase, our total production capacity will<br />

reach 4,200 tons/day, and we will continue<br />

to maintain our position as Türkiye’s largest<br />

flour producer by far. With this purchase,<br />

we aim to increase our export tonnage<br />

thanks to the cost advantage by using<br />

the ports in Mersin, Adana and Iskenderun<br />

regions for the supply of raw materials and<br />

the proximity to the southern neighbours<br />

of our country. With the production of the<br />

facility, our company will have access<br />

to the domestic market in the south and<br />

southeast of our country with more costeffective<br />

transportation. Thus, with our<br />

factories located in 5 different regions within<br />

our company, we will reach the active<br />

production capacity that will expand sales<br />

to all regions of Türkiye.”<br />

area of 6,880 square meters on a total area<br />

of 10,186 square meters, is currently inactive.<br />

A Quick Structural Health Monitoring (QSHM)<br />

report was obtained regarding whether<br />

it was damaged in the earthquake in<br />

Kahramanmaras, and all the buildings in<br />

the real estate in question were examined<br />

Consolidating its place in Türkiye’s largest<br />

companies surveys conducted for 2021, Ulusoy<br />

Un became the 323rd largest exporter in<br />

Turkey according to the TIM1000 list, the 71st<br />

company in the Fortune 500 list and the 86th<br />

largest company in Türkiye according to the<br />

Capital500 research. Ulusoy Un was also ranked<br />

28th in the “Top 500 Companies of Anatolia”<br />

research conducted by the Economist<br />

magazine. Ulusoy Un, one of the largest food<br />

companies in Türkiye, also has the innovation<br />

leader award of the food industry within the<br />

scope of the “Platinum Global 100 Index”.<br />

JUNE <strong>2023</strong> FOOD & INGREDIENTS INTERNATIONAL<br />

33

Nestlé inaugurates new research<br />

institute aimed at supporting<br />

sustainable food systems<br />

Nestlé has officially inaugurated the Institute<br />

of Agricultural Sciences to help advance<br />

sustainable food systems by delivering<br />

science-based solutions in agriculture.<br />

Speaking at the inauguration, Paul Bulcke,<br />

Nestlé Chairman, said: “We have nurtured<br />

direct relationships with generations of farmers<br />

around the world. To continue providing<br />

people with tasty, nutritious and affordable<br />

foods, we need to transition together to<br />

a more sustainable food system. The new<br />

institute will strengthen our expertise and<br />

use our global network to support farming<br />

communities and protect our planet.”<br />

With global food systems under pressure,<br />

there is an urgent need to accelerate new<br />

approaches that ensure a sustainable food<br />

supply for a growing world population while<br />

contributing to farmer livelihoods.<br />

At the new institute, Nestlé experts screen and<br />

develop solutions in key focus areas such as plant<br />

science, agricultural systems and dairy livestock.<br />

It builds on the company’s existing plant<br />

science expertise in coffee and cocoa. Over<br />

many years, Nestlé plant scientists have been<br />

contributing to Nestlé’s sustainable cocoa and<br />

coffee sourcing plans - the Nestlé Cocoa Plan<br />

and Nescafé Plan (pdf, 9Mb) - including the<br />

recent discovery of more disease and droughtresistant<br />

coffee varieties.<br />

Nestlé is now strengthening this expertise<br />

and expanding it to further crops, including<br />

pulses and grains. The institute is also working<br />

with farmers to trial regenerative agriculture<br />

practices to improve soil health and encourage<br />

biodiversity. In addition, experts explore novel<br />

approaches in dairy farming that have potential<br />

to reduce greenhouse gas emissions in the<br />

areas of cow feed and manure management.<br />

Jeroen Dijkman, Head of Nestlé Institute<br />

of Agricultural Sciences, said: “Our goal is<br />

to identify the most promising solutions to<br />

promote the production of nutritious raw<br />

materials while minimizing their environmental<br />

impact. We take a holistic approach and look<br />

at several factors including impact on yield,<br />

carbon footprint, food safety and cost, as well<br />

as the viability of scale-up.”<br />

As part of Nestlé’s global R&D network, the<br />

institute collaborates closely with external<br />

partners including farmers, universities,<br />

research organizations, startups and industry<br />

partners to assess and develop sciencebased<br />

solutions. The new institute reaffirms<br />

the company’s commitment to strengthening<br />

Switzerland’s unique innovation ecosystem.<br />

Speaking at the official opening, Valérie Dittli,<br />

State Councilor of the Swiss Canton of Vaud, said:<br />

“The new institute is strengthening the Canton<br />

of Vaud as a center of excellence for research<br />

and education in agriculture and nutrition. It also<br />

contributes to the efforts that are underway to<br />

support farmers in the face of climate change.<br />

Agriculture is at the core of quality nutrition<br />

and in the Canton of Vaud we can count on<br />

an innovative ecosystem that brings together<br />

partners including agricultural professionals,<br />

schools for higher education and private research<br />

centers such as the one from Nestlé.”<br />

In addition to its new facilities at Nestlé<br />

Research in Switzerland, the institute<br />

incorporates an existing plant science<br />

research unit in France, and farms based in<br />

Ecuador, Côte d’Ivoire and Thailand, as well as<br />

partnerships with research farms.<br />

34 FOOD & INGREDIENTS INTERNATIONAL JUNE <strong>2023</strong>

IFF launches ENOVERA 2000<br />

range to replace up to 50 percent<br />

vital gluten in whole wheat bread<br />

IFF announced the launch of ENOVERATM<br />

2000 range in Europe, the latest addition to<br />

its comprehensive range of market-leading<br />

solutions for the bakery industry. A nextgeneration<br />

enzyme dough strengthener,<br />

ENOVERATM 2000 range is designed<br />

for bakery manufacturers interested in<br />

vital gluten replacement, particularly in<br />

challenging applications such as whole<br />