The POWER of

The POWER of

The POWER of

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>The</strong><br />

Pultrusion Process<br />

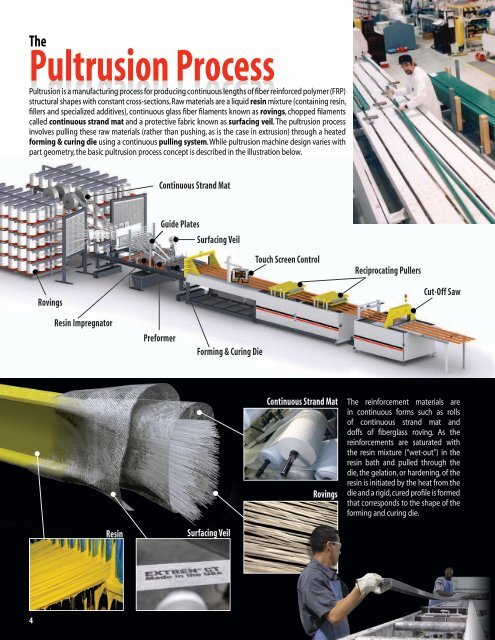

Pultrusion is a manufacturing process for producing continuous lengths <strong>of</strong> fiber reinforced polymer (FRP)<br />

structural shapes with constant cross-sections. Raw materials are a liquid resin mixture (containing resin,<br />

fillers and specialized additives), continuous glass fiber filaments known as rovings, chopped filaments<br />

Process<br />

called continuous strand mat and a protective fabric known as surfacing veil. <strong>The</strong> pultrusion process<br />

involves pulling these raw materials (rather than pushing, as is the case in extrusion) through a heated<br />

Pultrusion<br />

forming & curing die using a continuous pulling system. While pultrusion machine design varies with<br />

part geometry, the basic pultrusion process concept is described in the illustration below.<br />

4<br />

Rovings<br />

Resin Impregnator<br />

Resin<br />

Continuous Strand Mat<br />

Guide Plates<br />

Surfacing Veil<br />

Preformer<br />

Forming & Curing Die<br />

Surfacing Veil<br />

Touch Screen Control<br />

Continuous Strand Mat<br />

Rovings<br />

Reciprocating Pullers<br />

Cut-Off Saw<br />

<strong>The</strong> reinforcement materials are<br />

in continuous forms such as rolls<br />

<strong>of</strong> continuous strand mat and<br />

d<strong>of</strong>fs <strong>of</strong> fiberglass roving. As the<br />

reinforcements are saturated with<br />

the resin mixture (“wet-out”) in the<br />

resin bath and pulled through the<br />

die, the gelation, or hardening, <strong>of</strong> the<br />

resin is initiated by the heat from the<br />

die and a rigid, cured pr<strong>of</strong>ile is formed<br />

that corresponds to the shape <strong>of</strong> the<br />

forming and curing die.