l Buderus Plastic Mould Steel 2738 ISO-BM - Buderus Edelstahl GmbH

l Buderus Plastic Mould Steel 2738 ISO-BM - Buderus Edelstahl GmbH

l Buderus Plastic Mould Steel 2738 ISO-BM - Buderus Edelstahl GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

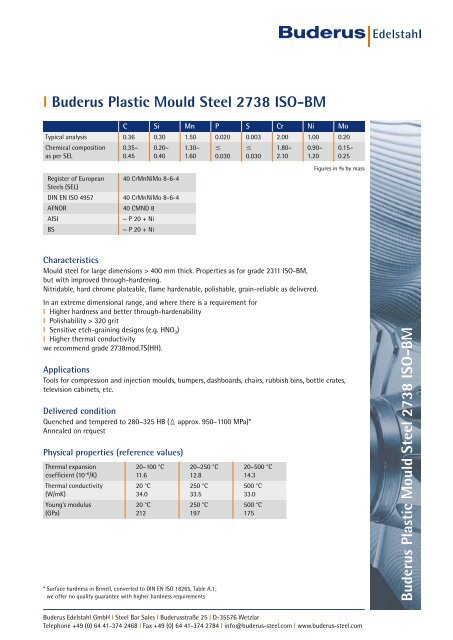

l <strong>Buderus</strong> <strong>Plastic</strong> <strong>Mould</strong> <strong>Steel</strong> <strong>2738</strong> <strong>ISO</strong>-<strong>BM</strong><br />

C Si Mn P S Cr Ni Mo<br />

Typical analysis 0.36 0.30 1.50 0.020 0.003 2.00 1.00 0.20<br />

Chemical composition 0.35– 0.20– 1.30– � � 1.80– 0.90– 0.15–<br />

as per SEL<br />

0.45 0.40 1.60 0.030 0.030 2.10 1.20 0.25<br />

Register of European<br />

<strong>Steel</strong>s (SEL)<br />

40 CrMnNiMo 8-6-4<br />

DIN EN <strong>ISO</strong> 4957 40 CrMnNiMo 8-6-4<br />

AFNOR 40 CMND 8<br />

AISI ~ P 20 + Ni<br />

BS ~ P 20 + Ni<br />

Characteristics<br />

<strong>Mould</strong> steel for large dimensions > 400 mm thick. Properties as for grade 2311 <strong>ISO</strong>-<strong>BM</strong>,<br />

but with improved through-hardening.<br />

Nitridable, hard chrome plateable, fl ame hardenable, polishable, grain-reliable as delivered.<br />

In an extreme dimensional range, and where there is a requirement for<br />

l Higher hardness and better through-hardenability<br />

l Polishability > 320 grit<br />

l Sensitive etch-graining designs (e.g. HNO3) l Higher thermal conductivity<br />

we recommend grade <strong>2738</strong>mod.TS(HH).<br />

Figures in % by mass<br />

Applications<br />

Tools for compression and injection moulds, bumpers, dashboards, chairs, rubbish bins, bottle crates,<br />

television cabinets, etc.<br />

Delivered condition<br />

Quenched and tempered to 280–325 HB (� approx. 950–1100 MPa)*<br />

Annealed on request<br />

Physical properties (reference values)<br />

Thermal expansion<br />

coeffi cient (10 –6 /K)<br />

Thermal conductivity<br />

(W/mK)<br />

Young’s modulus<br />

(GPa)<br />

20–100 °C<br />

11.6<br />

20 °C<br />

34.0<br />

20 °C<br />

212<br />

20–250 °C<br />

12.8<br />

250 °C<br />

33.5<br />

250 °C<br />

197<br />

* Surface hardness in Brinell, converted to DIN EN <strong>ISO</strong> 18265, Table A.1;<br />

we offer no quality guarantee with higher hardness requirements<br />

20–500 °C<br />

14.3<br />

500 °C<br />

33.0<br />

500 °C<br />

175<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> <strong>GmbH</strong> l <strong>Steel</strong> Bar Sales l <strong>Buderus</strong>straße 25 l D-35576 Wetzlar<br />

Telephone +49 (0) 64 41-374 2468 l Fax +49 (0) 64 41-374 2784 l info@buderus-steel.com l www.buderus-steel.com<br />

<strong>Buderus</strong> <strong>Plastic</strong> <strong>Mould</strong> <strong>Steel</strong> <strong>2738</strong> <strong>ISO</strong>-<strong>BM</strong>

l <strong>2738</strong> <strong>ISO</strong>-<strong>BM</strong><br />

Heat treatment<br />

Stress relieving Temperature: Approx. 600 °C in the annealed state<br />

Approx. 550 °C in the quenched and tempered state<br />

Duration: 1 hour per 50 mm wall thickness<br />

Cooling: Furnace<br />

Soft annealing Temperature: 720 °C<br />

Duration: 1 hour per 25 mm wall thickness<br />

Cooling: Furnace<br />

Hardening Temperature: 880 °C<br />

Duration: 1 minute per mm wall thickness<br />

Quenching hardness Max. 54 HRC in oil, hot bath or vacuum<br />

Tempering Temperature: See tempering curve<br />

Duration: 1 hour per 25 mm wall thickness<br />

Cooling: Air<br />

Working hardness 280–325 HB<br />

Tempering curve<br />

Hardness in HRC<br />

60<br />

58<br />

56<br />

54<br />

52<br />

50<br />

48<br />

46<br />

44<br />

42<br />

40<br />

38<br />

36<br />

34<br />

32<br />

30<br />

28<br />

26<br />

0 100 200 300 400 500 600 700 800<br />

Tempering temperature in °C<br />

TTT curve (continuous)<br />

Temperature in °C<br />

1200<br />

1100<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

M s<br />

M f<br />

Average values on samples dia. 25 x 50 mm long<br />

hardened at 880 °C in oil<br />

HB converted from HRC<br />

707 707 707 705 710 650 657 657 642 642 608 514 420 311<br />

HB<br />

(461)<br />

436<br />

413<br />

392<br />

373<br />

354<br />

337<br />

319<br />

303<br />

286<br />

0 1 10 10 2 10 3 10 4 10 5 10 6<br />

Seconds<br />

Austenitising temperature: 880 °C<br />

Ac 3<br />

Ac 1<br />

1<br />

Minutes<br />

10<br />

Time<br />

100 1000 10 000<br />

F<br />

B<br />

P<br />

Through-hardenability (schematic)<br />

Core hardness in HRC<br />

35<br />

34<br />

33<br />

32<br />

31<br />

30<br />

29<br />

28<br />

27<br />

THRUHARD SUPREME® HighHard<br />

Surface hardness = 35 HRC<br />

THRUHARD SUPREME®<br />

Surface hardness = 31 HRC<br />

<strong>2738</strong><br />

Surface hardness = 31 HRC<br />

26<br />

2311<br />

Surface hardness = 31 HRC<br />

25<br />

200 400 600 800 1000 1200 1400<br />

Diameter in mm<br />

Legal notice. <strong>Buderus</strong> <strong>Edelstahl</strong> <strong>GmbH</strong> has taken every possible care in compiling this information; the data is nevertheless subject to intervening changes. <strong>Buderus</strong> <strong>Edelstahl</strong> <strong>GmbH</strong> disclaims all liability and any warranty as regards the accuracy, currency,<br />

correctness and completeness of the information provided. The information provided is merely descriptive and indicative in nature, and binding only when expressly agreed as undertakings in a contract made with <strong>Buderus</strong> <strong>Edelstahl</strong> <strong>GmbH</strong>. <strong>Buderus</strong> <strong>Edelstahl</strong><br />

<strong>GmbH</strong> moreover reserves the right to make changes at any time without prior notice. <strong>Buderus</strong> <strong>Edelstahl</strong> <strong>GmbH</strong> disclaims all liability for loss or damage of any kind, including consequential loss, arising in connection with use of the information provided.<br />

This publication supersedes all previous ones. © <strong>Buderus</strong> <strong>Edelstahl</strong> <strong>GmbH</strong>, Wetzlar, 07/2010