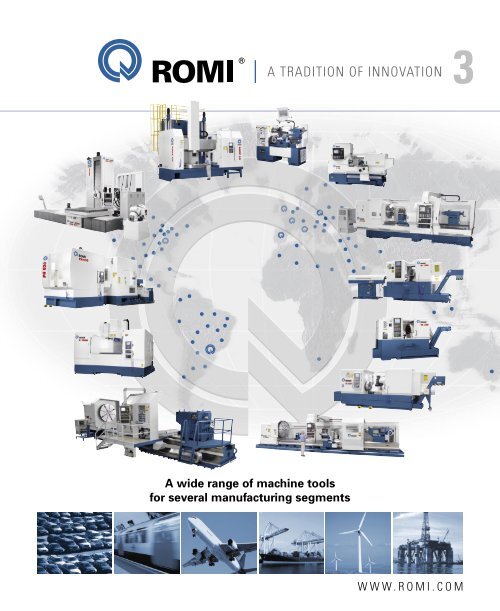

A TRADITION OF INNOVATION - Romi

A TRADITION OF INNOVATION - Romi

A TRADITION OF INNOVATION - Romi

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A wide range of machine tools<br />

for several manufacturing segments<br />

A <strong>TRADITION</strong> <strong>OF</strong> <strong>INNOVATION</strong><br />

W W W . R O M I . C O M<br />

3

ROMI GL SERIES<br />

TURNING CENTERS<br />

Bar feeder (optional)<br />

NEW!<br />

ROMI GL 170G<br />

TURNING CENTER FOR MACHINING<br />

PARTS FROM BARS<br />

EXAMPLES <strong>OF</strong> MACHINED PARTS<br />

Main motor: 15 hp / 11 kW ASA A2-5”<br />

Headstock - 6.000 rpm<br />

2 ILLUSTRATIVE IMAGE / EQUIPPED WITH OPTIONAL<br />

ROMI GL 240 / 240M ROMI GL 280 / 280M<br />

DESIGNED TO OPERATE IN ENVIRONMENTS<br />

<strong>OF</strong> MEDIUM AND HIGH PRODUCTION, WITH<br />

GREAT EFFICIENCY AND PRODUCTIVITY<br />

Rapid traverse (X axis): 36 m/min<br />

Rapid traverse (Z axis): 30 m/min<br />

GANG TOOLS SYSTEM,<br />

<strong>OF</strong>FERING FLEXIBILITY<br />

FOR MULTIPLE APPLICATIONS<br />

AND REDUCED MACHINING<br />

CYCLE TIME.<br />

HIGH VERSATILITY AND<br />

RELIABILITY CNC<br />

Fanuc 0i - TD CNC<br />

• 10,4” LCD<br />

color monitor<br />

• Serial port<br />

RS 232<br />

• PCMCIA card drive<br />

to send and store<br />

data

High speeds,<br />

turning precision,<br />

high thermal<br />

and geometric<br />

stability.<br />

NEW!<br />

ROMI GL 350 / GL 350M<br />

ACCURACY, SPEED AND RIGIDITY FOR<br />

TURNING PARTS DIAMETER UP TO<br />

400 mm AND LENGTH UP TO 1.000 mm<br />

HIGH PRECISION HEADSTOCK<br />

ROMI T SERIES<br />

ENGINE LATHES FOR TOOLROOM,<br />

PRODUCTION, MAINTENANCE<br />

AND TRAINING<br />

NEW!<br />

THE ROMI ENGINE<br />

LATHES EVOLUTION<br />

• ROMI T 240<br />

• ROMI T 350<br />

• ROMI T 500<br />

MECHANICAL AND ELECTRICAL PROJECT ACCORDING TO THE SAFETY STANDARD NR-12<br />

WWW.ROMI.COM<br />

Main motor: 25 hp / 18,5 kW Rapid traverse (X and Z axis): 30 m/min<br />

Designed to support<br />

tough machining<br />

applications.<br />

With fast and accurate<br />

indexing. M type turret<br />

for drilling, milling and<br />

tapping operation in one<br />

single clamping<br />

Tool turret for static and driven<br />

tools - for ROMI GL 240M,<br />

GL 280M, and GL 350M<br />

ASA A2-6” Headstock - 4.500 rpm<br />

ASA A2-8” Headstock - 3.500 rpm<br />

TOOL TURRET<br />

ROMI ES 40 SERIES<br />

ENGINE LATHES<br />

LINEAR GUIDES ON X AND Z AXIS<br />

Rapid traverse up to 36 m/min.<br />

• ROMI ES 40<br />

• ROMI ES 40A<br />

• ROMI ES 40B<br />

3

ROMI C SERIES<br />

CNC LATHES<br />

GREAT VERSATILITY FOR MACHINING DIFFERENT TYPES<br />

<strong>OF</strong> PARTS, <strong>OF</strong>FERING HIGH EFFICIENCY AND PRODUCTIVITY<br />

NEW!<br />

CNC LATHE<br />

ROMI C 680<br />

SUITABLE FOR MANY<br />

APPLICATIONS WITH<br />

SEVERAL CHUCKS<br />

AND TOOL HOLDER<br />

CONFIGURATIONS<br />

ROMI C 420 ROMI C 510<br />

Siemens 802D sl-PLUS CNC<br />

ROMI C 420, C 510 and C 620<br />

HIGH PERFORMANCE AND RELIABILITY<br />

WITH EXCELLENT FEATURES <strong>OF</strong><br />

PROGRAMMING AND OPERATION<br />

Main motor: 40 hp / 30 kW<br />

4 ILLUSTRATIVE IMAGE / EQUIPPED WITH OPTIONAL<br />

Siemens 802D sl-PRO CNC Distance between centers: 2 or 3 meters<br />

RMMP - ROMI MANUAL<br />

MACHINING PACKAGE<br />

(OPTIONAL)<br />

ASA A2-8” or ASA A2-11”<br />

high torque headstock<br />

THIS APPLICATION ALLOWS THE<br />

USER TO OPERATE THE MACHINE IN<br />

BOTH MANUAL AND AUTO MODE.<br />

THERE ARE THREE LEVELS <strong>OF</strong><br />

OPERATION ACCORDING TO THE<br />

OPERATOR SKILL:<br />

Swing over bed: Ø 680 mm<br />

ROMI C 620<br />

• MANUAL MODE<br />

• CYCLES MODE<br />

• TEACH IN MODE Conversational screen samples Example of conversational screens

ROMI C 830<br />

ROMI C 1000<br />

Siemens 802D sl-PRO CNC<br />

ROMI C 680, C 830, C 1000 and C 1000 BB<br />

Ethernet interface<br />

Power supply: 220 V<br />

USB interface<br />

RS-232 Serial interface<br />

Drive for compact flash card<br />

Pendant with handwheel, emergency<br />

button and JOG for axes.<br />

It is equipped with safety buttons, that<br />

prevent the handle to be turned accidentaly.<br />

WWW.ROMI.COM<br />

REAR CHUCK<br />

(OPTIONAL)<br />

Accessory to support<br />

long shafts and tubes<br />

Ø 375 MM (14,7 INCHES)<br />

THROUGH HOLE HEADSTOCK<br />

(ROMI C 1000 BIG BORE)<br />

The ASA A2-20” spindle version<br />

offers Ø 375 mm through hole, favoring<br />

the machining of large parts and large<br />

diameter pipes.<br />

5

ROMI C SERIES<br />

HEAVY DUTY CNC LATHES<br />

ROMI C 850H<br />

ROMI TECHNOLOGY:<br />

RELIABILITY AND<br />

PRODUCTIVITY FOR<br />

MANUFACTURING<br />

AND REPAIR <strong>OF</strong><br />

HEAVY DUTY PARTS.<br />

EXTREMELY ROBUST MACHINES FOR HEAVY MACHINING<br />

PROCESSES PROVIDING HIGH EFFICIENCY AND PRODUCTIVITY<br />

NEW!<br />

ROMI C 850H / C 1100H / C 1290H<br />

Main motor: 72 hp / 54 kW<br />

Headstocks:<br />

ASA A2-15” - Ø 260 mm through hole or<br />

ASA A2-20” - Ø 375 mm through hole<br />

Swing over bed up to 1.330 mm ( C 1100H)<br />

Siemens Sinumerik 840D sl CNC<br />

SUITABLE FOR MACHINING LARGE PARTS IN THE INDUSTRIES<br />

<strong>OF</strong> STEEL & SUGAR MILLS, ENERGY, OIL & GAS AND OTHERS<br />

ACCESSORIES: INCREASE PRODUCTIVITY AND EFFICIENCY IN MACHINING OPERATIONS<br />

Deep hole drilling support with transverse 3rd guide (optional) Electric turret for driven tools with Y axis (optional) C axis (optional)<br />

Milling head with Y axis (optional)<br />

6 ILLUSTRATIVE IMAGE / EQUIPPED WITH OPTIONAL

U type steady rest with set<br />

of cartridges with rollers for<br />

diameter adjustment<br />

Siemens Sinumerik<br />

840D sl CNC<br />

ROMI C 2200H / C 2600H<br />

Ø 575 mm (22,64 inches)<br />

through hole headstock<br />

(ROMI C 1600HBig Bore)<br />

WWW.ROMI.COM<br />

ROMI C 1300H / C 1600H<br />

ROMI C 1800H / C 2100H<br />

SINUMERIK 828D<br />

Compat, strong, simple... simply perfect!<br />

The SINUMERIK 828D is a panel-based CNC, tailor-made for<br />

use in milling and turning machines. The product combines CNC,<br />

PLC, operating and axis control functions for six CNC measuring<br />

circuits into one compact unit, which is designed to fit any<br />

operator panel housing in both its horizontal and vertical version.<br />

Despite its compact dimensions, the SINUMERIK 828D is a real<br />

powerhouse. Equipped with premium CNC functions such as<br />

the ability to execute kinematic transformations or powerful tool<br />

management makes it perfect for the jobshop.<br />

Compact, strong, simple…simply perfect!<br />

0800 7 73 73 73<br />

www.siemens.com.br/sinumerik<br />

7

ROMI VT SERIES<br />

VERTICAL CNC LATHES<br />

ROMI VT 2500<br />

ROMI VT 1400 ROMI VT 2000<br />

8 ILLUSTRATIVE IMAGE / EQUIPPED WITH OPTIONAL<br />

CAPACITY FOR TURNING<br />

DIAMETERS UP TO 6.000 mm<br />

WITH WEIGHT UP TO 60.000 kg<br />

FLEXIBILITY <strong>OF</strong> MACHINING PROCESSES FOR A<br />

WIDE RANGE <strong>OF</strong> LARGE CHUCK APPLICATIONS<br />

• ROMI VT 1400<br />

• ROMI VT 2000<br />

• ROMI VT 2500<br />

• ROMI VT 3000<br />

• ROMI VT 5000<br />

• ROMI VT 6000<br />

Siemens Sinumerik<br />

840D sl CNC<br />

MACHINING RESOURCES<br />

FOR TURNING, DRILLING,<br />

MILLING AND TAPPING OPERATIONS<br />

C axis and driven tool<br />

EXAMPLES <strong>OF</strong> MACHINED PARTS<br />

4-station square automatic<br />

turret electrically driven for<br />

8 tools<br />

Vertical RAM system with<br />

12-tools magazine capacity

ROMI G 550 / G 550M<br />

TURNING CENTER<br />

ROMI G 550M<br />

ROMI G 550<br />

NEW!<br />

M TYPE TURRET FOR FIXED AND DRIVEN TOOLS:<br />

VERSATILITY FOR TURNING, MILLING, DRILLING,<br />

AND THREAD OPERATIONS, IN ONE SINGLE CLAMPING.<br />

12-STATION TOOL TURRET<br />

Boring bar support<br />

(optional)<br />

HEADSTOCK:<br />

• ASA A2 - 8” - Ø 104 mm through hole<br />

• ASA A2 - 11” - Ø 142 mm through hole<br />

• ASA A2 - 15” - Ø 182 mm through hole<br />

WWW.ROMI.COM<br />

ROBUST STRUCTURE WITH<br />

HIGH POWER AND TORQUE.<br />

IT <strong>OF</strong>FERS PRECISION AND<br />

HIGH PRODUCTIVITY IN<br />

MACHINING PROCESSES.<br />

Fanuc Oi - TD CNC<br />

• Turning Center (T) applications<br />

Up to 8 controlled axis (2 paths)<br />

• Milling Center (M) applications<br />

Up to 5 controlled axis<br />

• High speed, high precision and high quality<br />

machining with “AI Contour Control” and<br />

“NANO interpolation” functions<br />

CNC Series 0i-D<br />

• FANUC PICTURE resource for easy customizing<br />

of the operation screens<br />

080077FANUC<br />

www.fanucfa.com<br />

ROMI G SERIES<br />

TURNING CENTERS<br />

ROMI G 30<br />

ROMI G 30M<br />

Fanuc 21i - TB CNC<br />

EXCELLENT POWER AND TORQUE,<br />

FAST DISPLACEMENT AND HIGH<br />

MACHINING PRECISION<br />

• 100 Mbps (standard) Ethernet<br />

communication - Connection between the<br />

CNC and PC to transfer<br />

data and monitoring the machine status<br />

• PLC memory up to 32Kb (0i package A)<br />

- Logic Program Status Monitoring directly<br />

on the CNC screen<br />

9

ROMI D SERIES<br />

VERTICAL MACHINING CENTERS<br />

ROMI D 1500 structure<br />

HIGH TECHNOLOGY<br />

CONTROLS:<br />

EXCELLENT<br />

PERFORMANCE<br />

AND RELIABILITY<br />

NEW!<br />

ROMI D 1500<br />

Broad framework,<br />

extremely robust,<br />

designed to high loads,<br />

absorb cutting forces<br />

and vibrations under the<br />

most adverse machining<br />

conditions<br />

10 ILLUSTRATIVE IMAGE / EQUIPPED WITH OPTIONAL<br />

Fanuc Oi - MC<br />

CNC<br />

ROMI D 600, D 800 ,<br />

D 1000 and<br />

D 1250 standard<br />

IDEAL FOR HIGH PRODUCTION,<br />

TOOLROOMS, SIMPLE AND COMPLEX<br />

PART GEOMETRY<br />

Spindle cartridge with<br />

ISO 40 or 50 spindle.<br />

Allows high speed, ensuring<br />

performance even under most<br />

heavy cutting conditions<br />

Siemens<br />

Sinumerik 828D CNC<br />

ROMI D 600,<br />

D 800AP, D 1000AP,<br />

D 1250AP and D 1500<br />

ROMI D 600<br />

ROMI D 800<br />

ROMI D 1000<br />

ROMI D 1250

MOVING COLUMN VERTICAL<br />

MACHINING CENTER<br />

ROMI DCM 3000<br />

FLEXIBILITY FOR MACHINING LONG AND HEAVY PARTS<br />

DEMANDING HIGH GEOMETRIC ACCURACY<br />

Main Motor: 30 hp / 22 kW<br />

Rapid traverse:<br />

X and Y axis: 30 m/min<br />

Z axis: 24 m/min<br />

Travels:<br />

X: 3.000 mm<br />

Y: 800 mm<br />

Z: 600 mm<br />

Table surface: 3.200 x 840 mm<br />

Max. admissible weigth: 2.500 kg/m 2<br />

WWW.ROMI.COM<br />

Siemens Sinumerik 828D CNC<br />

Spindle: ISO 40 - 10.000 rpm<br />

HIGH PERFORMANCE BORING MILL<br />

ROMI LAZZATI HBM 130T<br />

Double Arm Automatic tool<br />

changer, with 60 tools capacity<br />

NC rotary table: 1.500 X 2.000 mm<br />

Max. admissible weigth: 12.000 kg<br />

ROMI PH SERIES<br />

HORIZONTAL MACHINING CENTER<br />

ROMI PH 630<br />

Siemens Sinumerik 828D CNC<br />

IDEAL FOR PRODUCTION <strong>OF</strong><br />

AUTOMOTIVE INDUSTRY<br />

COMPONENTS, AGRICULTURAL<br />

MACHINERY, PUMPS, GEARBOXES<br />

AND GENERAL EQUIPMENT<br />

• Spindle: ISO 50<br />

• Speed range: 6.000 or 10.000 rpm<br />

• Power: 48 hp / 36 kW<br />

• Pallet: 630 x 630 mm<br />

• Rapid traverse: 50 m/min<br />

• Tool magazine: 60 or 120 tools<br />

ROMI PH 400<br />

TECHNOLOGY, RELIABILITY AND PRODUCTIVITY<br />

FOR LARGE PARTS MACHINING<br />

Headstock<br />

• Ø 130 mm quill dia.<br />

• ISO 50<br />

• 3.000 rpm<br />

• 79 hp / 58 kW<br />

Siemens Sinumerik<br />

840D CNC<br />

Peripheral protection<br />

with safety system<br />

11

ROMI MACHINE TOOLS<br />

ENGINE LATHES<br />

ROMI T SERIES<br />

ENGINE LATHES<br />

ROMI ES 40 SERIES<br />

CNC LATHES<br />

ROMI C SERIES<br />

HEAVY DUTY<br />

CNC LATHES<br />

ROMI C SERIES<br />

VERTICAL<br />

CNC LATHES<br />

ROMI VT SERIES<br />

ILLUSTRATIVE IMAGE / EQUIPPED WITH OPTIONAL<br />

PRODUCTIVITY AND PR<strong>OF</strong>ITABILITY<br />

FOR PARTS MACHINING IN SEVERAL<br />

MANUFACTURING SEGMENTS<br />

ROMI T 240 ROMI T 350 ROMI T 500<br />

Centers height mm 220 268 342<br />

Swing over cross slide mm 240 350 500<br />

Distance between centers m 0,5 / 1,0 1,5 2,25 / 3,25<br />

Spindle nose ASA L0 L0 L0<br />

Speed range rpm 45 ~ 2.240 40 ~ 2.000 35 ~ 1.800<br />

Power hp / kW 7,5 / 5,5 7,5 / 5,5 7,5 / 5,5<br />

ROMI ES 40 ROMI ES 40A ROMI ES 40B<br />

Centers height mm 250 325 420<br />

Swing over cross slide mm 305 450 640<br />

Distance between centers m 1,5 / 2,0 2,0 / 3,0 3 / 4 / 5<br />

Spindle nose ASA L1 L1 L1<br />

Speed range rpm 31.5 ~ 2.360 22.4 ~ 1.700 16 ~ 1.180<br />

Power hp / kW 15 / 11 15 / 11 15 / 11<br />

ROMI C 420 ROMI C 510 ROMI C 620<br />

Distance between centers m 0,5 / 1,0 1,5 1,0 / 2,0<br />

Swing over bed mm 430 520 620<br />

Spindle nose ASA A2-5” / A2-6” A2-6” / A2-8” A2-8” (geared) / A2-8” (direct drive)<br />

Speed range rpm 4 ~ 4.000 / 3 ~ 3.000 3 ~ 3.000 / 2 ~ 2.200 1 ~ 667 (range 1) / 1 ~ 1.800<br />

2 ~ 2.500 (range 2)<br />

Power hp / kW 10 / 7,5 15 / 11 25 / 18,5<br />

ROMI C 680 ROMI C 830<br />

Distance between centers m 2,0 / 3,0 2,0 / 3,0 / 4,0 / 5,0<br />

Swing over bed mm 680 850<br />

Spindle nose ASA A2-8” / A2-11” A2-11” / A2-15”<br />

Speed range rpm<br />

1 ~ 450 (range 1) / 1 ~ 250 (range 1)<br />

1 ~ 1.800 (range 2) / 1 ~ 1.000 (range 2)<br />

1 ~ 250 (range 1) / 1 ~ 198 (range 1)<br />

1 ~ 1.000 (range 2) / 1 ~ 755 (range 2)<br />

Power hp / kW 40 / 30 40 / 30<br />

ROMI C 1000 ROMI C 1000 (Big Bore - Ø 375mm)<br />

Distance between centers m 2,0 / 3,0 / 4,0 / 5,0 3,0<br />

Swing over bed mm 1.000 1.000<br />

Spindle nose ASA A2-11” / A2-20” A2-20”<br />

Speed ranges rpm<br />

1 ~ 250 (range 1 ) / 1 ~ 125 (range 1)<br />

1 ~ 1.000 (range 2) / 1 ~ 500 (range 2)<br />

1 ~ 125 (range 1)<br />

1 ~ 400 (range 2)<br />

Power hp / kW 40 / 30 40 / 30<br />

ROMI C 850H ROMI C 1100H ROMI C 1290H<br />

Distance between centers m 2,0 / 3,5 / 5,0 2,0 / 3,5 / 5,0 / 6,5 / 8,0 / 9,5 3,5 / 5,0<br />

Swing over bed mm 950 1.110 1.330<br />

Spindle nose ASA A2-15” A2-15“ / A2-20” A2-20”<br />

Speed range rpm 1 ~ 750 1 ~ 750 / 1 ~ 500 1 ~ 500<br />

Max. admissible weigth<br />

between centers at 50 rpm<br />

kg 15.000 15.000 15.000<br />

Power hp / kW 72 / 53 72 / 53 72 / 53<br />

ROMI C 1300H / C 1600H ROMI C 1800H / C 2100H ROMI C 2200H / C 2600H<br />

Distance between centers m 3,5 / 5,0 / 6,5 / 8,0 / 9,5 / 11 / 12,5 4 / 5,5 / 7 / 8,5 / 10 4 / 6 / 8 / 10 / 12<br />

Swing over bed mm 1.300 / 1.600 1.800 / 2.150 2.210 / 2.580<br />

Spindle nose ASA A2 - 15” / A2 - 20” A2-20” A2-20”<br />

Speed range rpm 1 ~ 1.000 / 1 ~ 500 1 ~ 500 / 1 ~ 300 1 ~ 500 / 1 ~ 300<br />

Max. admissible weigth<br />

between centers at 50 rpm<br />

kg 15.000 / 22.000 30.000 50.000<br />

Power hp / kW 114 / 84 114 / 84 155 / 114<br />

ROMI ROMI ROMI ROMI ROMI ROMI<br />

VT 1400 VT 2000 VT 2500 VT 3000 VT 5000 VT 6000<br />

Maximum cutting diameter mm 1.600 2.200 2.700 3.400 6.000 7.000<br />

Maximum swing diameter mm 1.800 2.300 2.800 3.500 6.000 7.000<br />

Chuck diameter mm 1.400 2.000 2.500 3.000 5.000 6.000<br />

Speed range rpm 1 ~ 335 1 ~ 248 1 ~ 180 1 ~ 100 1 ~ 60 1 ~ 50<br />

Max. admissible weight kg 12.000 18.000 25.000 25.000 90.000 90.000<br />

Power hp / kW 114 / 84 114 / 84 114 / 84 114 / 84 145 / 108 145 / 108

EXTRA - HEAVY<br />

DUTY CNC LATHES<br />

ROMI UTR / UTP<br />

SERIES<br />

TURNING CENTERS<br />

ROMI GL SERIES<br />

TURNING CENTERS<br />

ROMI G SERIES<br />

VERTICAL<br />

MACHINING CENTERS<br />

ROMI D SERIES<br />

WWW.ROMI.COM<br />

ROMI UTR 800 ROMI UTR 1200 ROMI UTR 1600 / 2000<br />

Distance between centers m 3,5 / 5 / 6,5 / 8 / 9,5 4 / 5,5 / 7 / 8,5 / 10 4 / 6 / 8 / 10 / 12<br />

Maximum cutting diameter mm 800 1.200 1.600 / 2.000<br />

Max. admissible weight<br />

between centers at 50 rpm<br />

kg 22.000 30.000 50.000<br />

Spindle nose ASA Special Special Special<br />

Power hp / kW 100 / 75 200 / 150 200 / 150<br />

ROMI UTP 800 ROMI UTP 1000 / 1300 ROMI UTP 1600 / 2000<br />

Distance between centers m 4 / 5,5 / 7 / 8,5 / 10 4 / 6 / 8 / 10 / 12 4 / 6 / 8 / 10 / 12<br />

Maximum cutting diameter mm 750 1.000 / 1.300 1.600 / 2.200<br />

Max. admissible weight<br />

between centers at 50 rpm<br />

kg 30.000 50.000 100.000 / 105.000<br />

Spindle nose ASA Special Special Special<br />

Power hp / kW 200 / 150 200 / 150 300 / 220<br />

ROMI GL 170G ROMI GL 240 / ROMI GL 240M<br />

Maximum cutting diameter mm 170 300 / 260<br />

Maximum cutting length mm - 400<br />

Spindle nose ASA A2-5” A2-5” / A2-6”<br />

Speed range rpm 6 ~ 6.000 6 ~ 6.000 / 4 ~ 4.500<br />

Power hp / kW 15 / 11 20 / 15<br />

ROMI GL 280 / ROMI GL 280M ROMI GL 350 / ROMI GL 350M<br />

Maximum cutting diameter mm 340 / 280 400 / 390<br />

Maximum cutting length mm 540 1.140<br />

Spindle nose ASA A2-6” / A2-8” A2-6” / A2-8”<br />

Speed range rpm 4 ~ 4.500 / 3 ~ 3.500 4 ~ 4.500 / 3 ~ 3.500<br />

Power hp / kW 25 / 18,5 25 / 18,5<br />

ROMI G 30 / ROMI G 30M<br />

Maximum cutting diameter mm 320<br />

Maximum cutting length mm 1.020<br />

Spindle nose ASA A2-8”<br />

Speed range rpm 3 ~ 3.000 / 2 ~ 2.500<br />

Power hp / kW 30 / 22<br />

ROMI G 550 / ROMI G 550M<br />

Maximum cutting diameter mm 550<br />

Maximum cutting length mm 1.300<br />

Spindle nose ASA A2-8” A2-11” A2-15”<br />

Speed range rpm 2 a 2.500 2 ~ 2.000 1 ~ 1.500<br />

Power hp / kW 50 / 37<br />

ROMI ROMI ROMI ROMI ROMI<br />

D 600 D 800 D 800AP D 1000 D 1000AP<br />

Spindle taper ISO 40 40 40 40 40<br />

Table longitudinal travel - (X axis) mm 600 800 800 1.020 1.020<br />

Table traverse travel - (Y axis) mm 530 530 530 610 610<br />

Headstock travel - (Z axis) mm 580 580 580 640 640<br />

Speed range rpm<br />

7 ~ 7.500<br />

10 ~ 10.000<br />

7 ~ 7.500<br />

10 ~ 10.000<br />

7 ~ 7.500<br />

10 ~ 10.000<br />

12 ~ 12.000<br />

6 ~ 6.000<br />

10 ~ 10.000<br />

8 ~ 8.000<br />

10 ~ 10.000<br />

12 ~ 12.000<br />

Power hp / kW 20 / 15 20 / 15 23,6 / 17,6 25 / 18,5 25 / 18,5<br />

ROMI<br />

D 1000AP (DIRECT DRIVE)<br />

ROMI D 1250<br />

ROMI D 1250AP ROMI D 1500<br />

Spindle taper ISO 40 40 40 40 50<br />

Table longitudinal travel - (X axis) mm 1.020 1.270 1.270 1.530<br />

Table traverse travel - (Y axis) mm 610 610 610 760<br />

Headstock travel - (Z axis) mm 640 640 640 760<br />

Speed range rpm 15 ~ 15.000<br />

6 ~ 6.000<br />

10 ~ 10.000<br />

8 ~ 8.000<br />

10 ~ 10.000<br />

12 ~ 12.000<br />

8 ~ 8.000<br />

10 ~ 10.000 6 ~ 6.000<br />

12 ~ 12.000<br />

Power hp / kW 25 / 18,5 20 / 15 25 / 18,5 30 / 22

ROMI INVESTS IN TECHNOLOGY <strong>OF</strong> ITS PRODUCTS,<br />

SERVICES AND FACILITIES TO INCREASE MORE AND MORE<br />

THE COMPETITIVENESS <strong>OF</strong> ITS CUSTOMERS<br />

<strong>TRADITION</strong> AND RELIANCE<br />

ESTABLISH A COMMITTED<br />

RELATIONSHIP WITH THE<br />

CUSTOMERS<br />

When you buy a <strong>Romi</strong> machine, you buy<br />

more than one machine, you buy a reliable<br />

and effective manufacturing solution.<br />

Only a company with more than 80 years<br />

experience, having already produced<br />

more than 150.000 machines, can be fully<br />

permanently committed to the satisfaction<br />

of its customers.<br />

A relationship of trust with its customers<br />

is one of the greatest <strong>Romi</strong> values. <strong>Romi</strong>,<br />

always at the customers side.<br />

RESEARCH & DEVELOPMENT ENSURE<br />

THE CONSTANT TECHNOLOGY UPDATING<br />

<strong>OF</strong> THE ROMI PRODUCTS<br />

The area of R&D - Research and Development is constantly<br />

working on the machine technology for providing excellent<br />

productivity and profitability results to the customers.<br />

<strong>Romi</strong> machines incorporate the best of worldwide technology<br />

and offer reliable and effective solutions for small, medium and<br />

large companies.<br />

<strong>Romi</strong>, developing technology to increase competitiveness.<br />

ILLUSTRATIVE IMAGE / EQUIPPED WITH OPTIONAL<br />

Celebration of 150.000 machines produced - plant 16, in Santa Bárbara d’Oeste,SP, Brazil<br />

PRODUÇÃO SOBRE<br />

TRILHOS<br />

Turning centers assembly line, plant 16,<br />

in Santa Bárbara d’Oeste,SP, Brazil<br />

Machine tools engineering department.<br />

<strong>Romi</strong> Brazil<br />

Vertical machining centers assembly line, plant 16,<br />

in Santa Bárbara d’Oeste,SP, Brazil

NEW DISTRIBUTION CHANNELS IN EUROPE<br />

EASY ACCESS TO THE ROMI PRODUCTS, SALES AND AFTER SALES<br />

In order to strengthen its presence in<br />

Europe, <strong>Romi</strong> established new channels<br />

for distribution and services in Italy, UK,<br />

France and Spain.<br />

So, <strong>Romi</strong> extends support to its customers<br />

with pre and after-sales assistance, service<br />

and spare parts.<br />

APPLICATION ENGINEERING<br />

AND SALES SUPPORT<br />

The <strong>Romi</strong> application engineering teams are experts in manufacturing<br />

solutions. Providing extensive support for the best choice of machine tool<br />

and accessories suited to your needs, be it a machine or a production line.<br />

WWW.ROMI.COM<br />

<strong>Romi</strong> - Italy <strong>Romi</strong> - Sandretto - France<br />

<strong>Romi</strong> - Italy<br />

<strong>Romi</strong> - Sandretto - United Kingdon<br />

SERVICE AND SPARE PARTS<br />

<strong>Romi</strong> - Sandretto - Spain<br />

Service engineers and spare parts are available locally to guarantee quick<br />

assistance to its customers.

ROMI: WORLDWIDE PRESENCE<br />

Indústrias <strong>Romi</strong> SA<br />

Av Pérola Byington 56<br />

Santa Bárbara d’Oeste SP<br />

13453 900 Brazil<br />

Phone +55 (19) 3455 9199<br />

Fax +55 (19) 3455 1030<br />

export-mf@romi.com<br />

Sandretto UK Limited<br />

Leigh Road<br />

Swift Valley Industrial Estate<br />

Rugby<br />

CV21 1DS<br />

United Kingdom<br />

Phone +441788 544221<br />

Fax +441788 542195<br />

sales@sandretto.co.uk<br />

ILLUSTRATIVE IMAGE<br />

ROMI - FRANCE<br />

ROMI - ITALY<br />

ROMI - SPAIN<br />

ROMI - BRAZIL<br />

ROMI - UK<br />

A T R A D I T I O N O F I N N O V AT I O N W W W . R O M I . C O M<br />

<strong>Romi</strong> Machine Tools, Ltd<br />

1845 Airport Exchange Blvd<br />

Erlanger KY<br />

41018 USA<br />

Phone +1 (859) 647 7566<br />

Fax +1 (859) 647 9122<br />

sales@romiusa.com<br />

www.romiusa.com<br />

Sandretto Industrie SAS<br />

Parc de Genève, 240<br />

Rue Ferdinand Perrier 69800<br />

ST Priest<br />

France<br />

Phone 00 334 37 25 60 70<br />

Fax 00 334 37 25 60 71<br />

infos@sandretto.fr<br />

ROMI - GERMANY<br />

<strong>Romi</strong> Europa GmbH<br />

Wasserweg 19<br />

D 64521 Gross Gerau<br />

Germany<br />

Phone +49 (6152) 8055 0<br />

Fax +49 (6152) 8055 50<br />

sales@romi-europa.de<br />

Italprensas Sandretto S.A.<br />

Calle Comadrán, 15<br />

Pol.Ind.Can Salvatela<br />

C.P. 08210 Barberà del Vallès<br />

Spain<br />

Phone 34 93 848 4954<br />

Fax 34 93 718 7932<br />

info@italprensas.com<br />

<strong>Romi</strong> Italia srl<br />

Via Primo Levi 4<br />

10095 Grugliasco TO<br />

Italy<br />

Phone +39 (011) 410 1441<br />

Fax +39 (011) 411 7049<br />

macchineutensili@romi.com<br />

For additional and updated information visit our site: www.romi.com<br />

CE safety regulation compliance available only for the European Community or under request Consult availability of the products / features with your <strong>Romi</strong> representative<br />

<strong>Romi</strong> Industrial Site<br />

Santa Bárbara d’Oeste, SP<br />

Brazil