RIB-ROOF - Zambelli GmbH & Co. KG

RIB-ROOF - Zambelli GmbH & Co. KG

RIB-ROOF - Zambelli GmbH & Co. KG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MADE IN GERMANY<br />

Systems at a glance<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

metal roofi ng systems

This vision shapes the <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng<br />

system. Our top priority was, and remains so today,<br />

to provide metal roofi ng that is unbelievably<br />

simple and quick to install. This has led to our<br />

system solutions with a clever installation technique<br />

that is combined with the highest product<br />

quality and excellent operating effi ciency. This is<br />

<strong>RIB</strong>-<strong>ROOF</strong> METAL <strong>ROOF</strong>ING SYSTEMS<br />

TURNING VISIONS INTO REALITY<br />

Making progress. No detours.<br />

Only few steps of procedure.<br />

why <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng systems will enable<br />

you to immediately achieve the right results. With<br />

its wide range of roofi ng variety, different metals<br />

and surfaces, <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng systems offers<br />

architectural freedom combined with perfect<br />

functionality. Take advantage of the manifold<br />

possibilities of a time-tested system.<br />

commercial building<br />

Matzleinsdorf<br />

for the central train station in Vienna<br />

Please watch the video clip<br />

on the subject:<br />

Direct link for mobile phones<br />

with QR-code application<br />

material<br />

aluminium<br />

stucco-embossed<br />

3

THE BASIS OF SUCCESS<br />

ACHIEVE EXTRAORDINARY AIMS<br />

4<br />

<strong>RIB</strong>-<strong>ROOF</strong><br />

METALLDACH<br />

SYSTEME<br />

Allgemeine bauaufsichtliche Zulassung<br />

<strong>RIB</strong>-<strong>ROOF</strong> Speed 500 Gleit-Falz-Profi ldach<br />

Stahl: Nr. Z-14.1-473<br />

Aluminium: Nr Z-14.1-474<br />

EU-Konformitätserklärung<br />

MADE IN GERMANY www.zambelli.de<br />

<strong>Zambelli</strong> has more than 50 years hands-on experience<br />

in the fi eld of metal roofs.<br />

The <strong>Zambelli</strong> Group is shaped by its expert craftmanship<br />

while striving for perfection and with the<br />

courage to head in new, often diffi cult directions.<br />

The brothers Franz and Carlo <strong>Zambelli</strong> Sopalu, both<br />

expert plumbers and experienced in tin-coating,<br />

founded the company in 1957 as a craftman‘s<br />

establishment. At that time their specialisation was<br />

building construction and the renovation of church<br />

roofs. Through numerous patents and registered<br />

designs the founding fathers spurred the company<br />

forward.<br />

MADE IN GERMANY<br />

Within only two generations the company evolved<br />

into an internationally active industrial enterprise<br />

in the metalworking sector with more than 800<br />

employees at nine locations in six countries. Part<br />

of the group includes <strong>Zambelli</strong> <strong>RIB</strong>-<strong>ROOF</strong> <strong>GmbH</strong><br />

& <strong>Co</strong>. <strong>KG</strong>: with over 30 years of manufacturing<br />

experience and over 15 million square meters of<br />

roof surfacing that has been made so far. It is now<br />

one of Europe´s leading producers of metal roofi ng.

A SAFE SYSTEM SOLUTION<br />

DOING THINGS IN THE RIGHT WAY<br />

The characteristics of <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng systems<br />

are cleverness and simplicity.<br />

<strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng systems is distinguished<br />

by the innovative sliding slot connection with<br />

its own sliding clip system. The high degree of<br />

prefabrication substantially reduces construction<br />

time. In comparison with conventional standing<br />

seam profi les, <strong>RIB</strong>-<strong>ROOF</strong> offers maximum security<br />

in planning the installation and in its functionality.<br />

Strakerjahn-school<br />

Lübeck<br />

material<br />

aluminium<br />

colour caoted “Patina matt”<br />

5

245 mm<br />

6<br />

Get on your roof – using <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng systems this is not a problem at all.<br />

In the year 1978 the <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng systems<br />

received the fi rst authorisation approved by the building<br />

authorities. This means tested quality and safety:<br />

conventional standing seam profi les<br />

Leverage<br />

effect<br />

A metaloid connection<br />

between<br />

the upper shell<br />

of the roof and<br />

the supporting<br />

shell of the roof<br />

(trapezoidal<br />

sheet)<br />

65 mm<br />

180 mm<br />

Despite wide clip distances a <strong>RIB</strong>-<strong>ROOF</strong> roof is still<br />

walkable and self-supporting. This is an advantage<br />

you will appreciate for renovation projects.<br />

<strong>RIB</strong>-<strong>ROOF</strong> standard clip<br />

heat<br />

By installing<br />

standard clips<br />

onto distance<br />

constructions the<br />

high leverage<br />

effect between<br />

the upper shell<br />

and the supporting<br />

shell is<br />

omitted.<br />

Low thermal<br />

bridge effect

BUILT SAFELY –<br />

LONG TERM PROTECTION<br />

✔ No lever action of the sliding clip on the<br />

roofi ng with pressure and tensile loads that<br />

might arise from dilatation*<br />

✔ Sliding seam and sliding clip allow for<br />

dilatation of the profi le sheet, thus avoiding<br />

tension in metal roofs<br />

✔ The “Clicking into Place Mechanic” ensures<br />

permanent connection to the profi le sheet<br />

through closed linkage<br />

✔ Self-supporting and walkable<br />

✔ Permanent waterproofi ng through<br />

impenetrable installation with no<br />

transverse joints<br />

✔ Impenetrable installation of fi ttings<br />

onto the profi l sheet substructure<br />

✔ Additional item diffusion-open layer possible<br />

without to change the roof construction<br />

✔ With high wind-drag loads, e.g. in coastal<br />

and mountainous regions a suitable<br />

solution of system fi ttings<br />

can be selected<br />

Clip bar for a safe execution<br />

of the fi xed point<br />

* Dilatation (from Latin dilatare = extend, expand)<br />

is a term used in physics to denote linear<br />

expansion due to heat or warmth.<br />

Airport “SkyWorld Plaza”<br />

Hamburg<br />

material<br />

aluminium<br />

stucco-embossed<br />

protective plating on both sides<br />

forced curved<br />

95 m length of profi le sheets<br />

execution of a fi xed point<br />

by using a clip bar<br />

THE <strong>RIB</strong>-<strong>ROOF</strong> PRINCIPLE<br />

BENEFIT FROM EXPERIENCES<br />

7

8<br />

Direct installation of the clips<br />

Using the <strong>RIB</strong>-<strong>ROOF</strong> standard clip you can pull up.<br />

On your marks, get set, go! With <strong>RIB</strong>-<strong>ROOF</strong> metal<br />

roofi ng systems you can use the single clips to save<br />

time otherwise spent on extensive measuring and<br />

pre-assembly. The uniquely developed sliding clip<br />

is screwed directly into the profi le sheet. Fast work<br />

is possible. Mistakes in measuring are avoided.<br />

<strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng systems always provide<br />

different optimal clamping applications. The optimised<br />

Profi le-Clip geometry stays in place perfectly<br />

no matter the type of roof construction or substructure<br />

under each sheet. In this way, material expansion<br />

caused by possible changes in temperature can<br />

be balanced out. This is a superior advantage of the<br />

<strong>RIB</strong>-<strong>ROOF</strong> system when laying long sheet panels.<br />

While others are still fl anging, you can already see the result.<br />

All you need to install <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng<br />

systems are hands that can tackle work. It is<br />

not necessary to join the standing seams again<br />

neither a mechanical fl anging is necessary. This<br />

makes it possible to install the roofs perennial.<br />

No pre-assembly necessary<br />

Furthermore the profi le sheets are not rigidly<br />

coupled so a thermal expansion is possible.<br />

You can be absolutely sure that your <strong>RIB</strong>-<strong>ROOF</strong> roof<br />

will keep the shape over years.<br />

Have a closer look at<br />

installation principle <strong>RIB</strong>-<strong>ROOF</strong> Speed 500.<br />

Watch the following video clip:<br />

Direct link for mobile phones<br />

with QR-code application

SAVING TIME –<br />

BUILDING AS EFFICIENTLY<br />

AS POSSIBLE<br />

✔ Immediate start of installing the profi le<br />

sheets as there is no pre-assembly<br />

of clips necessary<br />

✔ Calculation errors as well as measuring<br />

errors can be excluded totally as the<br />

profi le sheet pretends the perfect position<br />

for the clip<br />

✔ Quick process of construction without<br />

fi nal mechanical fl anging<br />

✔ Installation is even possible at low<br />

temperature<br />

✔ Production and curving of the profi le sheets<br />

is also possible directly at construction site<br />

Norma-supermarket<br />

Hünstetten-Kesselbach<br />

material<br />

aluminium colour coated<br />

RAL 9006 whitealuminium<br />

THE <strong>RIB</strong>-<strong>ROOF</strong> PRINCIPLE<br />

BENEFIT FROM EXPERIENCES<br />

Record breaking:<br />

1200 m 2 in 3 hours<br />

Optimisation of costs and deadlines is an important factor<br />

when having to construct a supermarket as quickly as<br />

possible - normally it already takes 4 months from laying<br />

the foundation to opening day – an important aspect<br />

to consider. That is why Aldi, Lidl, Norma as well as the<br />

Rewe and Edeka groups all rely on <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng<br />

systems. With over 100 projects in Germany and Europe,<br />

it is not only the time-tested quality and the wide range<br />

of material that have made <strong>RIB</strong>-<strong>ROOF</strong> one of the favorite<br />

producers of roofi ng systems. It is also the simple installation<br />

design without any complicated adjustment and<br />

pre-setting up of clips that give our system an unbeatable<br />

advantage in time. The roof profi le of this Norma<br />

Supermarket was put into place by 11 technicians in only<br />

three hours.<br />

9

Football stadium:<br />

“Wörtherseestadion<br />

Klagenfurt”<br />

material<br />

aluminium<br />

stucco-embossed<br />

conical curved<br />

10<br />

One system – varied creation<br />

✔ Adaptable to the ground plan of a building<br />

and the roof shape<br />

✔ Two different profi les choosable:<br />

Speed 500 and 465. Available in different<br />

shapes and executions<br />

✔ Flat roof; applicable from 1.5 ° roof pitch<br />

✔ All lengths of profi le sheets are possible<br />

to produce; execution without transverse<br />

impact and overlapping of profi le sheets<br />

The football stadium of Klagenfurt was honored with the “IOC/IAKS Award Bronze 2009”<br />

<strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng systems are as fl exible<br />

as our customer requires.<br />

The roof shapes the character of the entire<br />

structure. It defi nes the style and infl uences the<br />

impact on the viewer. <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng systems<br />

allows room for your own ideas. <strong>RIB</strong>-<strong>ROOF</strong><br />

metal roofi ng systems can be adapted exactly to<br />

fi t ground plan and roof geometry. Two <strong>RIB</strong>-<strong>ROOF</strong><br />

systems, Speed 500 und 465, with different<br />

profi le sheet designs are available. All lengths of<br />

profi le sheets can be used with both systems because<br />

they are laid without any transverse joints.<br />

Almost anything is possible with <strong>RIB</strong>-<strong>ROOF</strong> metal<br />

roofi ng systems.<br />

Photography: Stadtpresse Klagenfurt / Horst

THE SYSTEM AT A GLANCE<br />

<strong>RIB</strong>-<strong>ROOF</strong> Speed 500<br />

Standard width = 500 mm; special width is possible<br />

THE ARCHITECTURAL FREEDOM<br />

TAKING NEW PATHS<br />

straight conical curved (convex) curved (concave)<br />

conical curved (convex)<br />

<strong>RIB</strong>-<strong>ROOF</strong> 465<br />

Standard width = 465 mm<br />

straight curved (convex) curved (concave)<br />

bended curved<br />

(that means that in equal distances<br />

the profi le sheet has a bend)<br />

11

metal trade<br />

Grassmayr<br />

Innsbruck<br />

material<br />

steel sheet with<br />

an aluminiumzinc<br />

coating<br />

conical<br />

12<br />

MATERIALS<br />

Steel<br />

galvanised and coil coated on both sides:<br />

Top side: 25μm RAL-colours; underside: light protective laquer<br />

Aluminium<br />

mill fi nish; coil coated on both sides:<br />

Top side: 25μm RAL-colours; underside: light protective laquer<br />

Aluminium<br />

mill fi nish / stucco-embossed<br />

Aluminium<br />

mill fi nish / stucco-embossed,<br />

protective plating on both sides<br />

Aluminium-zinc<br />

steel sheet with aluminium-zinc coating<br />

corrosion protection class III<br />

Titanium zinc<br />

mill fi nish or pre-weathered<br />

<strong>Co</strong>pper<br />

TECU ®<br />

SPECIAL SURFACES<br />

Patina look<br />

Zinc look<br />

Stucco-embossed patina matt<br />

The individual grade<br />

for your construction project<br />

Use your advantage by using <strong>RIB</strong>-<strong>ROOF</strong> metal<br />

roofi ng systems with its wide range of materials<br />

and surfaces. Only tested materials are used.<br />

<strong>Zambelli</strong> takes an external control carried out by<br />

the Institute for Material Testing Hannover (MPA).<br />

Therefore a high corrosion resistance and long<br />

operating life are guaranteed.

Create highlights!<br />

The surfaces zinc-look or stucco-embossed patina<br />

matt give your roof a look of high quality. For<br />

everyone who has courage for colour:<br />

For the materials steel and aluminium there is<br />

additionally the whole range of RAL-colours for a<br />

coating in different qualities available.<br />

THE ARCHITECTURAL FREEDOM<br />

TAKING NEW PATHS<br />

residential building<br />

Ottweiler<br />

material<br />

aluminium<br />

colour coated RAL 3009<br />

curved<br />

residential and commercial building<br />

Marburg<br />

material<br />

titanium-zinc<br />

pre-weathered<br />

curved<br />

13

offi ce building Wilo<br />

NL-Westzaan<br />

material<br />

aluminium<br />

stucco-embossed<br />

curved<br />

14<br />

Individual planned –<br />

world wide appreciated.<br />

<strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng systems provide the<br />

perfect solution for a wide clientele. From functional<br />

buildings for the industry; trade and craft to<br />

modern housing and housebuilding up to architecturally<br />

impressive representative buildings for<br />

institutions and infrastructure. It doesn´t matter<br />

whether it is a new construction or a renovation.<br />

<strong>RIB</strong>-<strong>ROOF</strong> will put your requirements and wishes<br />

world wide into practice.<br />

Photography: Jannes Linders Photographer

Centres of mobility –<br />

realised world wide.<br />

The society is in motion. Due to the higher traffi c<br />

volumes airports; train stations and public buildings<br />

often reach their capacity limits. In these cases<br />

construction projects have to be realized trouble-<br />

THE ARCHITECTURAL FREEDOM<br />

TAKING NEW PATHS<br />

free; without increasing budgets and absolutely in<br />

time. <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng systems are impressive<br />

where others only have to prove themselves.<br />

Airport<br />

Budapest Ferihegy<br />

material<br />

aluminium<br />

colour coated with<br />

PVDF-coating RAL 9006<br />

curved<br />

15

central train station<br />

Frankfurt/Main<br />

material<br />

aluminium<br />

stucco-embossed<br />

curved<br />

rfen.dddde<br />

www.referenzen-surfen.de<br />

wwwwww.rrefee<br />

16<br />

Start now<br />

our virtual “sightseeing tour” via Google Earth.<br />

With Google Earth you can take a ride through the<br />

world of <strong>RIB</strong>-<strong>ROOF</strong> metal roofs.<br />

Have a close look at several <strong>RIB</strong>-<strong>ROOF</strong> projects.<br />

<strong>Co</strong>me and fi nd out the architectural masterwork<br />

yourself, clever calculated industrial buildings and<br />

well studied special constructions.

Join it!<br />

Check out our website and see how <strong>RIB</strong>-<strong>ROOF</strong><br />

sheets are produced and set exactly into<br />

place on location with a system of mobile rollforming<br />

machines. A short video will show you<br />

the unique advantages when roofi ng a large area.<br />

Watch the following<br />

video clip here:<br />

Direct link for mobile phones<br />

with QR-code application<br />

mobile rollforming<br />

Mobile rollforming –<br />

globally active.<br />

Moving forward means overcoming barriers.<br />

Our mobile rollforming machines are making<br />

this possible. Profi le sheets 33 meters or longer<br />

can be rollformed and produced directly at<br />

construction site.<br />

THE ARCHITECTURAL FREEDOM<br />

TAKING NEW PATHS<br />

Exact measuring to fi t special projects can also be<br />

done with this technique. <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng<br />

systems move any construction project quickly<br />

and effi ciently forward, anywhere in the world.<br />

17

18<br />

new trade fair halls<br />

Karlsruhe<br />

material<br />

aluminium<br />

stucco-embossed<br />

curved<br />

fi tness gym<br />

Attendorn<br />

material<br />

aluminium<br />

stucco-embossed<br />

bended curved

<strong>RIB</strong>-<strong>ROOF</strong> offers a wide range of facade design<br />

with a variety of material, colours and surfacing<br />

possibilities. Different types of profi les as well as<br />

numerous embossing options with small bending<br />

radius make distinctive building silhouettes<br />

possible. Furthermore, the building surface has a<br />

clearly structured appearance with <strong>RIB</strong>-<strong>ROOF</strong> ele-<br />

THE ARCHITECTURAL FREEDOM<br />

TAKING NEW PATHS<br />

Modern architectural concepts lift barriers<br />

between roofs and facades.<br />

ments installed both vertically or horizontally: This<br />

is a design possibility that embodies any facade<br />

with a high degree of elegance. The impenetrable<br />

installation of all elements and accessories ensures<br />

a fl awless facade since there are no visible<br />

mounting parts.<br />

Hengelo,<br />

Pop- en Cultuurcentrum<br />

Metropool<br />

material<br />

aluminium colour coated<br />

RAL 9006 whitealuminium<br />

curved<br />

19

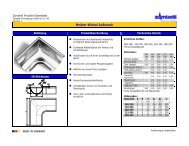

<strong>RIB</strong>-<strong>ROOF</strong> SYSTEM ACCESSORIES<br />

TO PERFECT DETAILS<br />

20<br />

Safety on the roof!<br />

Working on the roof must be approached with<br />

special care, particularly as building engineering<br />

services are more frequently being installed on<br />

roof surfaces. That is why building laws have been<br />

changed since 1998 to ensure that owners and<br />

contractors take more responsibility to avoid the<br />

high number of accidents due to falling off, or<br />

through, roofs when carrying out repair, inspection<br />

or cleaning work.<br />

<strong>RIB</strong>-<strong>ROOF</strong> has its own special system of security<br />

features to prevent accidents on new buildings<br />

and, of course, to upgrade and retrofi t metal roofs<br />

that have already been built. With this system you<br />

can fulfi ll your responsibilities as building owners<br />

and contractors easily and quickly.<br />

Take advantage of a tried-and-true system with a wide spectrum<br />

of accessory features and numerous individual solutions.<br />

Perfection can be found in even the smallest<br />

detail. It goes without saying that you will<br />

achieve your goal in the most direct way possible.<br />

<strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng systems provide you with<br />

a comprehensive range of functional features to<br />

fi t all of your building and roofi ng requirements.<br />

Shapely surfacing for the roof ridge, eaves or<br />

rainwater pipe and gableboard will<br />

optimise the overall impression. Roof penetration<br />

for artifi cial ventilation, roofl ight domes, or<br />

chimneys can be realised according to all norm and<br />

security standards. Snow guard system, lightning<br />

protection, walkway and tread support as well<br />

as <strong>RIB</strong>-<strong>ROOF</strong>´s specially developed and tested fall<br />

arrest system are completing the system.

ECOLOGICAL AND ECONOMICAL CONSTRUCTION AND RENOVATION<br />

ACT RESPONSIBLY<br />

Using New Potential Effectively:<br />

Generating Energy with Photovoltaic and Solar Modules.<br />

Mounting photovoltaic and solar modules onto a<br />

rooftop increases value in a sustainable manner.<br />

Whether it is a new building, roof renovation or<br />

upgrading an older structure, <strong>RIB</strong>-<strong>ROOF</strong> metal<br />

roofi ng systems allow you to choose from a wide<br />

variety of possibilities: Elevated or modules that<br />

are parallel to the roof, UniSolar fi lm laminate is<br />

directly installed on the roof surface or mounted<br />

on plates. The solar-laminated option blends in<br />

decently and is ideal for curved and rounded roof<br />

forms. We would be happy to show you how to<br />

get the most out of your roof. Just contact us!<br />

21

22<br />

While others are still looking for answers,<br />

we have already solutions.<br />

None of us should close our eyes to the challenges<br />

of climate change. <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng<br />

systems pay off not only from a fi nancial point of<br />

view. Ecologically speaking, <strong>RIB</strong>-<strong>ROOF</strong> also always<br />

fi nds the right solution, for example, by using<br />

renewable resources such as wood for distance<br />

construction, thereby reducing emission by decreasing<br />

thermal bridges.

ECOLOGICAL AND ECONOMICAL CONSTRUCTION AND RENOVATION<br />

ACT RESPONSIBLY<br />

EnEV 2009 German Energy Saving Ordinance:<br />

<strong>Co</strong>mpliance without requiring additional measures<br />

Energy reduction measures put high demands on<br />

new buildings and renovation of older structures.<br />

While energy-reducing measures are required<br />

by several of the metal roofi ng systems that<br />

are currently available on the market in order to<br />

fulfi ll legal requirements, <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng<br />

systems need no further adjustment. A <strong>RIB</strong>-<strong>ROOF</strong><br />

surface has optimal values concerning thermal<br />

Technology and progress in harmony with nature<br />

This has always been our goal for supply and<br />

disposal which is why our products not only<br />

always use state-of-the-art technology, but are<br />

integrated with quality and our own environmental<br />

management system. We are continually<br />

developing our manufacturing technology further<br />

in order to achieve a longer life for our products<br />

along with optimal energy recovery, therefore<br />

transmittance, without any further complicated<br />

additional measures such the installation of<br />

thermoclips serving as thermal bridges, as recently<br />

shown by studies from the “Forschungsinstitute für<br />

Wärmeschutz e.V.”.<br />

Buildings with <strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng system<br />

are good for both the environment and your bank<br />

account.<br />

thickness of insulation 180 mm 180 mm for 0.240 W/m 2 K<br />

description of construction<br />

<strong>RIB</strong>-<strong>ROOF</strong> Speed 500<br />

installation by using standard<br />

clips onto a double layer<br />

wooden underconstruction<br />

construction 1*<br />

<strong>RIB</strong>-<strong>ROOF</strong> Speed 500<br />

by using a clip border onto a<br />

walkable heat insulation<br />

construction 2<br />

<strong>RIB</strong>-<strong>ROOF</strong> by using standard clips<br />

onto double layer Z-profi les<br />

construction 3<br />

onto a single layer Z-profi le<br />

construction 4<br />

* calculation according to DIN EN ISO 6946<br />

(adjustment of<br />

calculation B1-17/97)<br />

B = 1.20 m<br />

Heat transfer<br />

coeffi cient for the<br />

quiet areas<br />

Heat transfer<br />

coeffi cient including<br />

thermal bridges<br />

avoiding risks to the environment.<br />

The <strong>Zambelli</strong> company was awarded with<br />

the Bavarian State Prize in 2004 which<br />

was a successful confi rmation of our<br />

responsible way we deal with<br />

nature and environmental<br />

resources.<br />

required thickness<br />

of insulation to<br />

reach EnEV 2009<br />

chart 1; line 4a<br />

W/(m 2 x K) W/(m 2 x K) mm<br />

B = 1.19 m 0.189 0.204** 160<br />

B = 1.80 m 0.188 0.202** 160<br />

B = 1.80 m 0.189 0.229** 180<br />

B = 1.20 m 0.189 0.262** 200<br />

**Source: FIW 18.03.2010 each value is calculated with the heat insulation 180 mm and WLG 035<br />

(exception: walkable heat insulation for construction 2 is WLG 040)<br />

0.189 0.432** 250<br />

23

Staff Support of Installation<br />

If things get tough, then we all work together!<br />

Particularly with large projects both in Germany<br />

and internationally, installation companies like<br />

using our staff to help with the mounting of<br />

<strong>RIB</strong>-<strong>ROOF</strong>.<br />

They are able to profi t in two ways:<br />

■ Knowledge transfer through experienced<br />

specialists<br />

■ On schedule project development<br />

Vienna Airport “Skylink Vienna”<br />

Wien<br />

material<br />

aluminium<br />

stucco-embossed<br />

conical curved<br />

MODULAR PROJECT SUPPORT<br />

MOVING FORWARD TOGETHER<br />

Our team of experts is always at your disposal,<br />

at any time, anywhere.<br />

Implementing architectural visions often means<br />

going over rocky roads to achieve one´s goals.<br />

Know-how is needed as well as practical experience.<br />

Our comprehensive range of services is<br />

based on our roots as a skilled trade business<br />

when we started in 1957 as a plumbing and<br />

roofer company. From our large projects, our<br />

engineers and skilled experts know exactly what<br />

is important. We work together with you on the<br />

planning and successful installation of customised<br />

<strong>RIB</strong>-<strong>ROOF</strong> metal roofi ng.<br />

25

26<br />

Projecting<br />

Only those who plan practical will reach a perfect result. Our team will support you with the following<br />

services already during the preliminary phase of a project:<br />

■ Preparation of detailed solution proposals<br />

■ Support in detailed CAD planning<br />

■ Preparation of individual specifi cations<br />

■ Development of special solutions, specifi cations and construction of sample roof structures<br />

■ Statics and physical construction advice<br />

■ Preparation of cost estimations and support for calculation themes<br />

■ Solution proposals for a perfect scheduling of the project<br />

Calculation hotline<br />

Some issues can not wait. Especially when it is about the receipt of an offer promptly.<br />

Therefore our consult for calculations will gladly be at your disposal via telephone.<br />

So do not hesitate to contact us at any time.

<strong>Co</strong>nstruction <strong>Co</strong>ordination, Site Supervision and Installation Support<br />

Planning and carrying out complex projects and international construction always presents huge challenges.<br />

Our roof experts give their support to building owners, planners and construction companies, depending on the<br />

needs of each particular situation, in the following ways:<br />

<strong>Co</strong>nstruction planning and coordination<br />

■ Setting up roofi ng plans and details as well as developing customised solutions<br />

■ Planning project details<br />

■ Ascertaining necessary materials, setting up a time schedule, making a list of parts<br />

■ Project leadership (human resources, costs and construction schedule monitoring)<br />

Installation Support<br />

■ Carrying out Training for Installation<br />

■ Supervision of construction and quality assurance on-site<br />

■ Allocation of installation experts<br />

■ Logistcal support (e.g. creating a Just-in-Time-supply plan)<br />

■ Allocation of special traverse equipment to lift profi le sheets up to 80 m total length<br />

■ Carrying-out Alu-Welding for roof penetration<br />

■ Allocation of trained staff for abestos removal TRG 42<br />

■ Installation of fall arrest systems<br />

MODULAR PROJECT SUPPORT<br />

WALKING PATHS TOGETHER<br />

installation<br />

Airport Lviv<br />

Ukraine<br />

2010<br />

27

<strong>RIB</strong>-<strong>ROOF</strong><br />

Metal roofi ng systems<br />

Roof Drainage Shelving Systems Industrial<br />

Metal Works<br />

Telefon<br />

Fax<br />

E-mail<br />

www<br />

<strong>Zambelli</strong><br />

<strong>RIB</strong>-<strong>ROOF</strong> <strong>GmbH</strong> & <strong>Co</strong>. <strong>KG</strong><br />

Hans-Sachs-Straße 3 + 5<br />

D-94569 Stephansposching<br />

+49 (0) 99 31 8 95 90 - 0<br />

+49 (0) 99 31 8 95 90 - 49<br />

rib-roof@zambelli.de<br />

zambelli.de<br />

03|2011 Errors and printing mistakes are reserved.