BREMERTON FLOATING WAVE ATTENUATOR

BREMERTON FLOATING WAVE ATTENUATOR

BREMERTON FLOATING WAVE ATTENUATOR

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

AMERICAN SOCIETY OF CIVIL ENGINEERS<br />

2007 REGION 8 PROJECT OF THE YEAR AWARDS<br />

PORT OF <strong>BREMERTON</strong><br />

<strong>BREMERTON</strong> <strong>FLOATING</strong> <strong>WAVE</strong> <strong>ATTENUATOR</strong><br />

AUGUST 29, 2008

Describe the Project’s pre-eminent qualifications for the Award in this category:<br />

o Scaled model tests and several iterations were used to develop optimum concept design<br />

o 12 individual floating bodies with a maximum weight of 950 tons were safely fabricated, launched,<br />

transported to the site via tug boats, and rigidly connected by post-tensioning in the water without<br />

leakage.<br />

o The 12 individual floating bodies behave as single floating structure moored with 50 different<br />

mooring lines.<br />

o Reid Middleton’s fine-tuned QC program allowed the wave attenuator to meet the appropriate<br />

freeboard, stability, and connection safety requirements.<br />

o Bremerton Floating Breakwater is the first large-size floating concrete breakwater in the state of<br />

Washington to use cast-in-place type, ready-mixed concrete from four different types of concrete<br />

mix in the fabrication.<br />

o The floating breakwater was also fabricated using a mix of lightweight sand imported from Colorado<br />

with normal fine aggregate.<br />

o The new wave attenuator serves as both a breakwater for the Bremerton Marina and a public<br />

waterfront park.<br />

o Unlike fixed-type breakwaters, the floating breakwater is fish friendly, as it allows fish and other<br />

marine species to pass freely underneath the structure. The new breakwater required a shorter inwater<br />

work-period than the fixed type because it was fabricated and transported on land, then<br />

launched in the water, and moved by tugboats to its final destination where the final installation<br />

occurred.<br />

o The floating structure is designed to last more than 50 years. It allows for minimum maintenance<br />

and maximum durability. Part of the inboard side of the breakwater will provide permanent moorage<br />

services for large boats, providing the Port with additional revenue.<br />

o Bremerton Floating Wave Attenuator/waterfront park will be equipped with unique light poles,<br />

benches, and sculptures.<br />

o Fly ash, an industrial byproduct, was used in the construction, which decreased the amount of<br />

cement in the concrete mixes by approximately 15%.<br />

o Plastic timber and Fiber Reinforced Plastics were used for ladder and rub-rails instead of natural<br />

timber and steel, which usually deteriorate and rust over time.<br />

DEADLINE: Close of Business AUGUST 29, 2008<br />

Submit three (3) copies of the completed nomination package to:<br />

Electronic submittals can also be made however please confirm to ensure they are received, if over<br />

10MB in size an FTP site will be made available for your submittal.<br />

A nomination package should include the following:<br />

Michael J. Barton, PE, PTOE, F.ASCE<br />

ASCE Chair Awards Committee, Region 8<br />

5210 E. Williams Circle, Suite 530<br />

Tucson, Arizona 85711<br />

michael.barton@hdrinc.com<br />

• A cover letter, signed by the nominator;<br />

• The Project’s background information;<br />

• A color photograph of the Project; and<br />

• Letters of recommendation supporting the nomination, but not required.<br />

The entire nomination package should not exceed 10 pages.<br />

Page 2 of 2

Excellence in Design<br />

Prior to design development and final design for construction, optimum concept design was selected<br />

throughout iterations with several experiments (scaled model tests) and analyses. Approximately 12 individual<br />

floating bodies with a maximum weight of 950 tons were safely launched and transported. These were then<br />

rigidly connected by post-tensioning in the water without any leakage. The 12 connected attenuator bodies<br />

behave as a single floating structure moored with 50 different mooring lines.<br />

Additional weights and wind areas for future artistic sculptures were evaluated and several counterweights<br />

and concrete benches were designed and installed, which allowed the Port of Bremerton to install actual<br />

benches and various artistic features once the breakwater was installed.<br />

Reid Middleton’s fine-tuned QC program allowed the wave attenuator to meet the appropriate freeboard,<br />

stability, and connection safety requirements by using a series of iterations with weight/buoyancy calculations,<br />

monitoring, and ballasting.<br />

Innovative Features<br />

The Bremerton Floating Breakwater is the first<br />

large-size floating concrete breakwater in the<br />

state of Washington to use cast-in-place type,<br />

ready-mixed concrete from four different types of<br />

concrete mix in the fabrication of the breakwaters.<br />

This was achieved by blending lightweight<br />

fine aggregate imported from Colorado with<br />

normal fine aggregate to meet the required<br />

target strength, free board, and stability.<br />

Contribution to Public Welfare & Safety<br />

The new wave attenuator will serve as both a breakwater for the Bremerton Marina and a public waterfront<br />

park. The public will enjoy a long waterfront park very close to Puget Sound water. Bremerton residents and<br />

visitors will have the opportunity to fish from the breakwater, walk, or sit and enjoy the views. There will also<br />

be many events and activities that will take place on the top surface of the floating attenuator. For example,<br />

Bremerton’s annual blackberry festival on Labor Day will take place here.<br />

Compatibility with the Environment<br />

Port of Bremerton<br />

Floating Wave Attenuator<br />

Project Description<br />

2007 ASCE Region 8 Project of the Year Awards<br />

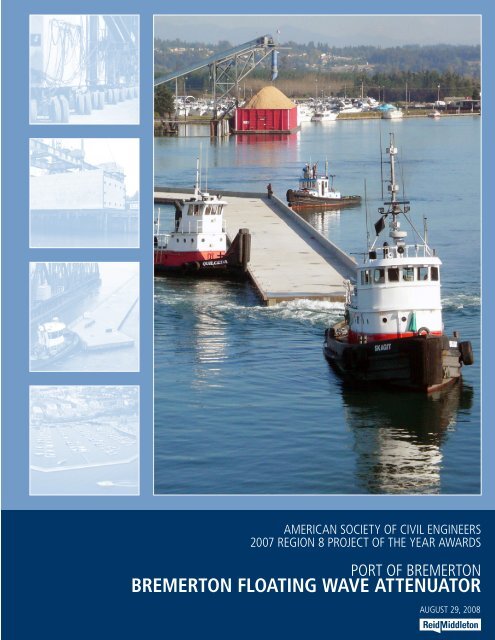

Unlike fixed-type breakwaters (wave walls or mound<br />

type), the floating breakwater is especially fish<br />

friendly, as it allows fish and other marine species to<br />

pass relatively freely underneath the structure. The<br />

new breakwater also required a shorter in-water<br />

work-period than the fixed type because it was<br />

fabricated and transported on land, then launched<br />

in the water, and moved by tugboats to its final<br />

destination where the final installation occurred.

Cost-Effectiveness<br />

Port of Bremerton<br />

Floating Wave Attenuator<br />

Project Background<br />

The durable floating structure is designed to last more than 50 years providing long side-tie moorage spaces<br />

for large boats. The breakwater design was cost-performance effective. It allows for minimum maintenance<br />

and maximum durability. Part of the inboard side of the breakwater will provide permanent moorage services<br />

for large boats, providing the Port with additional revenue. Additionally, a surface area lease plan of the<br />

breakwater may be created by the Port of Bremerton for events that take place at the breakwater site.<br />

Aesthetics<br />

Unlike many massive fixed-type breakwaters, the<br />

Bremerton Floating Wave Attenuator/waterfront park will<br />

be equipped with unique light poles (same ones used in<br />

downtown Bremerton), secured side-tie moorage areas<br />

for large boats, benches, and sculptures. It is a beautiful<br />

modern floating waterfront park.<br />

Effective Use of Materials<br />

Durable high-performance, lightweight materials were<br />

used in the successful construction of the Port’s new<br />

floating wave attenuator. High strength, corrosion-resistant<br />

reinforcement was used at critical locations enhancing the structural capacity and durability. Lighweight<br />

fine aggregate imported from Colorado as well as fly ash, an industrial byproduct, were used in the construction,<br />

which decreased the amount of cement in the concrete mixes. More than 10 different grout materials<br />

and 10 different polymeric adhesives were used for post-tensioning, body connections, waterproofing, hardware<br />

installation, and patching. Plastic timber and FRP (Fiber Reinforced Plastics) were used for ladder and<br />

rub-rails instead of using natural timber and steel, which usually deteriorate and rust over time.<br />

2007 ASCE Region 8 Project of the Year Awards

3/64" = 1'-0"<br />

3/64" = 1'-0"<br />

3/64" = 1'-0"

�������<br />

Port of Bremerton Floating Wave Attenuator - Breakwater & Mooring Lines Layout<br />

ASCE Region 8 Project of the Year Awards<br />

����<br />

���������<br />

����� ����� ������ ���������<br />

������� ������� �����<br />

����<br />

����� ���� ������� ���������<br />

����<br />

��� �� �� ��<br />

Figure<br />

����� ����� ������ ���������<br />

����� ����<br />

Port of Bremerton Floating Wave Attenuator - Mooring Line Side Elevation<br />

ASCE Region 8 Project of the Year Awards<br />

Figure 2

Photo 1: Wave attenuator model tests at Oregon State University wave lab.

Photo 2 (above): 950-ton individual body being transported from casting to launching site.<br />

Photo 3 (above): 135 foot-long individual body being launched.

Photo 4: 450 foot-long bent body being towed to Bremerton Marina site.

Photo 5: Aerial photo of the Bremerton Floating Wave Attenuator and expanded marina.