McNair Research Journal - University of St. Thomas

McNair Research Journal - University of St. Thomas

McNair Research Journal - University of St. Thomas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Science<br />

2.1 Summary <strong>of</strong> findings on corn-based ethanols<br />

2.1.1. Findings from Oliviera et al.<br />

In the first <strong>of</strong> the presented works, (Oliviera et al, 2005), a very detailed<br />

study was carried out which compared ethanol produced in Brazil to that<br />

in the U. S. The analysis included energy balances from corn-ethanol<br />

production as well as impacts on carbon dioxide emissions. While much<br />

<strong>of</strong> the data that was used in this article came from disparate and at times<br />

disagreeing sources, the authors used reasonable compromise estimates.<br />

The compromise estimates were adopted for items such as corn yield and<br />

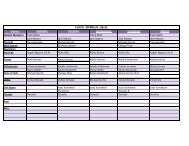

energy input for ethanol processing, among others. A summary <strong>of</strong> the<br />

findings from this paper are presented in Table 1. The table shows two<br />

important sets <strong>of</strong> data. The first set deals with the production rate <strong>of</strong> corn<br />

ethanol using modern farming techniques and equipment. Included here<br />

is the ethanol yield (liters) per hectare. In addition, the present author has<br />

calculated the percentage <strong>of</strong> corn cropland which would be required if all<br />

U.S. transport fuel was produced by corn ethanol.<br />

The second portion <strong>of</strong> the table shows information related to the carbon<br />

dioxide emissions from farming, processing, and transporting corn-based<br />

ethanol. Account is made for the uptake <strong>of</strong> carbon dioxide into the soil,<br />

which remains after crop harvest. It is seen that nearly 4000 kg <strong>of</strong> carbon<br />

dioxide are emitted for each hectare. When this carbon dioxide emission<br />

rate is applied to the required cropland for complete conversion to cornbased<br />

ethanol, it is seen that more than 800 gigagrams <strong>of</strong> carbon dioxide<br />

would be emitted.<br />

If the emitted carbon dioxide <strong>of</strong> Table 1 is compared with the emissions<br />

which occur when only gasoline is used, it is found that use <strong>of</strong> corn-based<br />

ethanol results in a 44% reduction <strong>of</strong> greenhouse gases. For this calculation,<br />

it was estimated that each U.S. car releases, on average, 5,732 kg <strong>of</strong><br />

carbon dioxide per year so that the accumulated emissions for the U.S<br />

amount to 1.46 x 1012 kg per year. Finally, using the data from Oliviera,<br />

it is seen that the net energy benefit <strong>of</strong> corn-based ethanol is 1.1, so that<br />

10% more energy is harvested than is required for all stages <strong>of</strong> growing,<br />

production, and transportation <strong>of</strong> ethanol. The small net energy yield<br />

resulted in the determination that if petroleum fuels were to be<br />

completely displaced by ethanol, it would require 600% <strong>of</strong> the available<br />

corn cropland.<br />

Oliviera et al. concludes that the potential for corn-ethanol to displace<br />

large portions <strong>of</strong> petroleum-based gasoline is very limited by the small<br />

increase <strong>of</strong> energy and by the other secondary problems posed by corn<br />

agriculture, including soil erosion and groundwater usage. In fact, the authors<br />

conclude that if the entire U.S. automotive fleet were to be powered<br />

by E85 fuel, it would require all the available U.S. cropland by year 2012.<br />

This scenario is obviously not viable for fuel production. An alternative<br />

scenario is presented wherein other agricultural sources are used for<br />

ethanol production, such as biomass residual, logging waste, etc. This<br />

alternative approach is mentioned briefly in the work but the concept is<br />

not developed further.<br />

Fushcia-Ann Hoover<br />

Replacements for Petroleum-Based Fuels<br />

2.1.2. Findings from Hill et al.<br />

The next presented analysis is taken from a 2006 publication from the<br />

Proceedings <strong>of</strong> the National Academy <strong>of</strong> Sciences (Hill et al., 2006) which<br />

also provides detailed information regarding both the harvested outputs<br />

and required inputs to produce corn-based ethanol using currently available<br />

farming practices and technologies. The paper compares corn ethanol<br />

to biodiesel created from soybeans. In brief, the findings indicate that the<br />

net energy yield for corn-based ethanol is 6% and overall, greenhouse gas<br />

emissions from ethanol are 12% less than that which would occur if<br />

gasoline were the exclusive fuel. When credit was awarded to corn<br />

coproducts, the net energy benefit rose to 1.28 (28% more energy output<br />

than required for farming, production, and transportation). Similar to the<br />

findings <strong>of</strong> Oliviera, Hill’s results lead to the conclusion that if petroleum<br />

fuels were to be completely displaced by ethanol, it would require more<br />

farmland than is currently used for corn production (833%). Meanwhile,<br />

biodiesel created from soybeans resulted in a much higher net energy<br />

benefit (93%), however the energy yield was so small that there is no<br />

potential for soybean biodiesel to displace an appreciable amount <strong>of</strong><br />

petroleum diesel.<br />

The marginal improvements which are available from corn-based ethanol<br />

led to the authors’ conclusion that corn-based ethanol provides a very<br />

small greenhouse gas reduction yet exposes the U.S. to other environmental<br />

and human health impacts from the various stages <strong>of</strong> farming and<br />

production. These negative impacts include the release <strong>of</strong> other airborne<br />

pollutants, water run<strong>of</strong>f, and pesticide use. It was the conclusion <strong>of</strong> the<br />

authors that corn ethanol and soybean diesel are not viable alternatives to<br />

petroleum fuels. They further promote the investigation <strong>of</strong> cellulosic<br />

ethanol, such as those discussed later in this report. They report that<br />

cellulosic ethanol production has the advantage <strong>of</strong> being grown on<br />

marginally productive land with very low energy inputs. The authors<br />

encourage the further study <strong>of</strong> cellulosic replacement <strong>of</strong> petroleum fuels.<br />

2.1.3. Findings from Patzek<br />

A very complete and detailed analysis <strong>of</strong> the thermodynamics <strong>of</strong> the entire<br />

corn-ethanol cycle, which includes a discussion <strong>of</strong> the energy requirements<br />

and energy analysis, is presented in (Patzek, 2004). The author pays<br />

particular attention to farming techniques that are required to maintain<br />

the sustainability <strong>of</strong> cropland. For instance, the author evaluates all major<br />

fertilizers and even considers the age <strong>of</strong> manufacturing plants, which<br />

create various fertilizer ingredients. Patzek discusses the large variations in<br />

energy requirements with location. It was shown that corn farming in the<br />

states <strong>of</strong> Iowa and Indiana require much greater electricity inputs than<br />

does farming in Illinois and South Dakota. Other very detailed discussions<br />

are given to energy requirements for human labor, transportation,<br />

and machinery construction. The author’s detailed discussions are<br />

presented alongside a comparison <strong>of</strong> the then-available literature results to<br />

facilitate a critical analysis <strong>of</strong> the findings. In summary, Patzek concludes<br />

that corn-based ethanol production is not a viable solution for displacing<br />

petroleum-made fuels. His conclusion is based on a number <strong>of</strong> factors,<br />

primary among which is the negative energy yield rate. Among the key<br />

24 <strong>University</strong> <strong>of</strong> <strong>St</strong>. <strong>Thomas</strong> <strong>McNair</strong> <strong>Research</strong> <strong>Journal</strong>