Nuclear Grade HEPA Filters - Flanders/CSC

Nuclear Grade HEPA Filters - Flanders/CSC

Nuclear Grade HEPA Filters - Flanders/CSC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

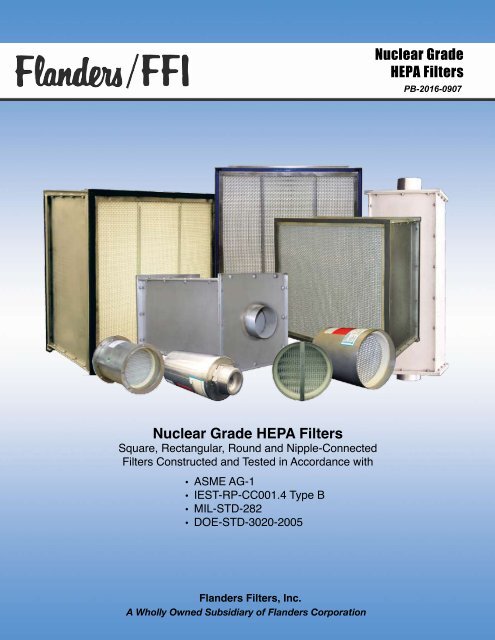

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong><br />

Square, Rectangular, Round and Nipple-Connected<br />

<strong>Filters</strong> Constructed and Tested in Accordance with<br />

• ASME AG-1<br />

• IEST-RP-CC001.4 Type B<br />

• MIL-STD-282<br />

• DOE-STD-3020-2005<br />

<strong>Flanders</strong> <strong>Filters</strong>, Inc.<br />

A Wholly Owned Subsidiary of <strong>Flanders</strong> Corporation<br />

<strong>Nuclear</strong> <strong>Grade</strong><br />

<strong>HEPA</strong> <strong>Filters</strong><br />

PB-2016-0907

Quality Assurance<br />

Any industry with dangerous process or exhaust<br />

gases and/or particulates has a vital concern<br />

for the health and safety of personnel. In addition<br />

to corporate concern, the United States<br />

Government has dictated that safety equipment<br />

meets minimum safety standards. Any equipment<br />

sold to meet these minimum standards must be<br />

manufactured using accepted Quality Control<br />

procedures.<br />

<strong>Flanders</strong> has developed a Quality Assurance<br />

program to assure the product or service meets<br />

these standards. This program addresses the entire<br />

range of <strong>Flanders</strong> involvement, including the<br />

purchase of raw materials, the shortage of these<br />

raw materials, incorporation of these materials<br />

into a product or service, testing this product or<br />

service, then, shipping to its destination.<br />

The <strong>Flanders</strong> Program has been audited many<br />

times, and each time the program has been accepted.<br />

An uncontrolled copy of the program<br />

manual is available with each request for Quality<br />

Assurance information. Like any dynamic document,<br />

the manual is continually being revised to<br />

include recent issues of standards and specifications<br />

in order that <strong>Flanders</strong> may use the latest<br />

state-of-the-art methods in providing its products<br />

and services.<br />

Quality Assurance Program<br />

© COPYRIGHT 2007 By<br />

<strong>Flanders</strong>/FFI Corporation<br />

531 <strong>Flanders</strong> FIlters Road • Washington, NC 27889<br />

The Quality Assurance Program at <strong>Flanders</strong> <strong>Filters</strong><br />

has been audited and approved numerous times<br />

by the <strong>Nuclear</strong> Utilities Procurement and Inspection<br />

Committee, NUPIC. This committee was<br />

established by nuclear electric utilities to ensure<br />

that suppliers of goods and services meet all applicable<br />

regulatory and quality requirements.<br />

Notes:<br />

1. As part of our continuing program to improve<br />

the design and quality of all our products, we<br />

reserve the right to make such changes without<br />

notice or obligation.<br />

2. <strong>Flanders</strong>, through its limited warranty, guarantees<br />

the products described herein will meet all<br />

specifications agreed to by the buyer and the<br />

seller.<br />

3. ASME N509 <strong>Nuclear</strong> Power Plant Air Cleaning<br />

Units and Components.<br />

4. ASME N510 Testing of <strong>Nuclear</strong> Air Treatment<br />

Systems.<br />

5. ASME AG-1 Code on <strong>Nuclear</strong> Air and Gas<br />

Treatment

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong><br />

NOTICE . . . Compliance with installation and operation<br />

standards must be met to ensure quality performance.<br />

<strong>HEPA</strong> filters are factory tested to meet the<br />

requirements of IEST-RP-CC001.4 filters<br />

Test results appear on both the filter label<br />

and the filter carton label. An additional<br />

quality assurance test report is kept on<br />

file and is available on request.<br />

<strong>Flanders</strong> <strong>Filters</strong>, Inc. (FFI) recommends<br />

that all <strong>HEPA</strong> filters be tested in place by<br />

qualified personnel to ensure that the filters<br />

have been correctly installed in the<br />

containment housing.<br />

<strong>Flanders</strong>/FFI service personnel are available<br />

for installations, supervision of installation,<br />

testing and certification of<br />

compliance to industry and government<br />

standards and instruction of the owner’s<br />

personnel in testing and maintenance<br />

procedures.<br />

<strong>Flanders</strong>/FFI does not guarantee that<br />

its equipment will operate at the performance<br />

levels given on the identfication<br />

labels or in the catalog specfications<br />

under all conditions of installation<br />

and use, nor does <strong>Flanders</strong>/FFI guarantee<br />

the suitability of its product for<br />

the particular end use which may be<br />

contemplated by the buyer.<br />

For best results, it is recommended<br />

that the buyer supply complete information<br />

about the operating conditions<br />

of the ventilation system to <strong>Flanders</strong>/<br />

FFI for evaluation.<br />

When the system components are<br />

supplied to the buyer or his agent for<br />

final installation and assembly in the<br />

field, it should be under the supervision<br />

of factory trained personnel.<br />

Failure to adhere to this recommendation<br />

or failure of the buyer to have filters<br />

timely retested and serviced will<br />

nullify or limit any warranties which<br />

might otherwise apply and may result<br />

in a compromised installation.<br />

IMPORTANT MESSAGE<br />

3

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong> - Table of Contents<br />

4<br />

Quality Assurance .........................................................................................Inside Front Cover<br />

Important Message ...................................................................................................................3<br />

General Information ..................................................................................................................6<br />

Comprehensive Factory Testing ......................................................................................6<br />

Retesting by DOE Filter Test Facility ..............................................................................7<br />

Design Qualification Tests ..............................................................................................7<br />

Seismic Qualification ......................................................................................................7<br />

Testing Service Available ...............................................................................................8<br />

Filter Design and Construction ...............................................................................................8<br />

Filter Medium .................................................................................................................8<br />

Two Types of Filter Pack Designs ..................................................................................8<br />

Sealants/Adhesive ..........................................................................................................9<br />

Case Material .................................................................................................................9<br />

Case Styles ....................................................................................................................9<br />

Faceguards ....................................................................................................................9<br />

Filter Selection ........................................................................................................................10<br />

Underwriters Laboratory UL 586 ..................................................................................10<br />

Filter Selection ..............................................................................................................10<br />

Standard Sizes and Capacities SEpArATOrlESS ® <strong>Filters</strong> ................................................11<br />

Standard SEPARATORLESS ® <strong>Filters</strong> ...........................................................................11<br />

Chart: Gel Seal <strong>Filters</strong> ..................................................................................................11<br />

Chart: Gasket Seal <strong>Filters</strong> ............................................................................................11<br />

SEpArATOrlESS ® Media packs .........................................................................................12<br />

Standard Sizes and Capacities ....................................................................................12<br />

Diagram: Dimension ....................................................................................................12<br />

Chart: 11-inch SEPARATORLESS ® Filter Element .......................................................12<br />

Chart: 4-inch SEPARATORLESS ® Filter Element .........................................................12<br />

Standard Sizes and Capacities Separator-Type <strong>Filters</strong> .....................................................13<br />

Chart: Gel Seal <strong>Filters</strong> ..................................................................................................13<br />

Chart: Gasket Seal <strong>Filters</strong> ............................................................................................13<br />

Chart: 11-inch Separator-Type Filter Element ..............................................................14<br />

Chart: 5 1/2-inch Separator-Type Filter Element .........................................................14<br />

Chart: 2 3/4-inch Separator-Type Filter Element .........................................................14<br />

High Temperature Sealant .....................................................................................................15<br />

Separator-Type <strong>Filters</strong> ..................................................................................................16<br />

Supply or Exhaust Air 500ºF Gasket Seal or 390ºF Gel Seal ......................................16<br />

Chart: Separator-Type <strong>Filters</strong> Gel Seal and Gasket Seal .............................................16<br />

Exhaust Air Only 1000ºF ...............................................................................................16<br />

Chart: Separator-Type <strong>Filters</strong> Gasket Seal Only ..........................................................16

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong> - Table of Contents<br />

round <strong>Filters</strong> ...........................................................................................................................17<br />

Diagram: Flanges ........................................................................................................17<br />

Chart: SEPARATORLESS ® <strong>Filters</strong>, Standard Sizes ......................................................17<br />

Chart: Separator-Type <strong>Filters</strong> .......................................................................................17<br />

Gel Seal ........................................................................................................................18<br />

Gasket Seal ..................................................................................................................18<br />

Lifting Bails ...................................................................................................................18<br />

Faceguards ..................................................................................................................18<br />

Drilled Flanges ..............................................................................................................18<br />

UL 586 ...........................................................................................................................18<br />

Model Numbers and Specifications .............................................................................18<br />

Nipple-Connected <strong>Filters</strong> .......................................................................................................19<br />

Chart: N1 or N2 <strong>Filters</strong> with SEPARATORLESS ® Filter Elements, Standard Sizes ......19<br />

Chart: N1 or N2 <strong>Filters</strong> with Separator-Type Filter Elements, Standard Sizes ............19<br />

Design Features and Options ................................................................................................20<br />

Roughing Prefilter .........................................................................................................20<br />

Diagram: Prefilter ..........................................................................................................20<br />

Gasket Seal (N1 <strong>Filters</strong> Only) ........................................................................................20<br />

Diagram: Wood Case or Metal Case ............................................................................20<br />

Drilled Flanges ..............................................................................................................20<br />

Diagram: Nipple-Connected Flange .............................................................................20<br />

Diagram: Filter Face Flange .........................................................................................20<br />

Slip-On Flanges ............................................................................................................20<br />

Faceguards ..................................................................................................................20<br />

UL 586 (N1 and N2 <strong>Filters</strong>) ...........................................................................................20<br />

Model Numbers and Specifications .............................................................................20<br />

Model Number Designating Development ...........................................................................21<br />

Filter Model Number .....................................................................................................21<br />

To Order .......................................................................................................................21<br />

<strong>Nuclear</strong> Filter Size Designators ....................................................................................21<br />

Chart: Standard Size Designator ..................................................................................21<br />

Model Number Designating Chart .......................................................................................22<br />

Suggested Specifications ......................................................................................................23<br />

Environmental Condition .......................................................................................................24<br />

Packaging and Palletizing ............................................................................................24<br />

Diagram: Vertical Pleats ................................................................................................24<br />

receipt, Storage, Shelf life ...................................................................................................25<br />

Shelf Life Information ...................................................................................................25<br />

BlU-JEl ® Seal Data ...............................................................................................................26<br />

5

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: General Information<br />

Quality Assurance<br />

The Quality Assurance Program of <strong>Flanders</strong> <strong>Filters</strong>,<br />

Inc. (FFI) meets or exceeds the basic requirements<br />

of ASME NQA-1 and 10CFR50 APPENDIX B.<br />

Comprehensive Factory Testing<br />

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong> meet the requirements<br />

for performance, testing and construction<br />

specified in Section 4.2.2 of IEST-RP-CC001.4<br />

for Type B <strong>HEPA</strong> filters. This section describes<br />

performance levels and states, “A filter that has<br />

been tested for overall penetration at rated flow<br />

and at 20% of rated flow, in accordance with<br />

Section 9.1.1 (Mil Std-282). The minimum filter<br />

efficiency of encapsulated filter in this type is<br />

99.97% on 0.3µm particles.Every FFI <strong>Nuclear</strong><br />

<strong>Grade</strong> <strong>HEPA</strong> filter is factory tested for penetration<br />

and resistance to airflow at 100% of its rated air<br />

flow prior to shipment. These values are recorded<br />

on a barcoded serialized label that is applied to<br />

each filter. Additionally, filters rated at 75 cfm and<br />

greater are factory tested for penetration at 20% of<br />

rated airflow. (This test is commonly known as the<br />

two-flow test.) The maximum penetration allowed<br />

at either flow is 0.03%. In recent years, <strong>HEPA</strong> filter<br />

designs exceeding the original test methods for<br />

flow capacities have been developed. Therefore,<br />

<strong>Flanders</strong> uses one of two test methods to ensure<br />

the performance of <strong>Nuclear</strong> <strong>Grade</strong> <strong>Filters</strong>. They<br />

are described as follows:<br />

6<br />

The test method historically specified and use<br />

by <strong>Flanders</strong> for most <strong>Nuclear</strong> <strong>Grade</strong> filters is<br />

Mil-Std-282 (method 102.9.1). In this test an<br />

approved aerosol is used to generate a nearly<br />

monodisperse aerosol of approximately 0.3 micrometer<br />

diameter droplets. The penetration of<br />

the aerosol through the filter is measured with<br />

forward light scattering photometer. The measuring<br />

instrument specified by Mil-Std 282 is a<br />

Q-107 penetrometer. It was originally developed<br />

by the U.S. Army prior to 1950. The measuring<br />

instrument is limited by design to testing at flows<br />

ranging from 15 cfm to 1100 cfm. <strong>Flanders</strong> uses<br />

this instrument for all <strong>Nuclear</strong> <strong>Grade</strong> filters with<br />

rated air flows ranging from 15 cfm to 1100 cfm.<br />

For filters rated below 75 cfm, the 20% flow test<br />

cannot be performed accurately.<br />

FFI <strong>Nuclear</strong> <strong>Grade</strong> <strong>Filters</strong> are produced in square,<br />

rectangular, and nipple-connected designs.

HFATS Test<br />

Los Alamos National Laboratory developed an<br />

alternate test method in the 1980’s under contract<br />

to the U.S. Department of Energy (DOE).<br />

It is often referred to as the HFATS test (High<br />

Flow Alternative Test System). It was developed<br />

specifically to test filters rated at airflows higher<br />

than 1100 CFM, but it can be used for lower<br />

flows. It is only limited by the size of the system<br />

fan and the aerosol generator output. This method<br />

was later standardized in the publication of a<br />

recommended practice, IEST-RP-CC007.1, Testing<br />

ULPA <strong>Filters</strong>, published by the Institute of<br />

Environmental Sciences and Technology. Currently,<br />

ASME AG-1 Section FC allows for testing<br />

by this method. The filter is challenged with an<br />

acceptable polydispersed oil aerosol and the<br />

penetration through the filter is measured with<br />

a Laser Particle Counter. The Particle Counter<br />

counts and sizes individual droplets in a size<br />

range from 0.1 to 3.0 micrometers in diameter.<br />

The ratio of the downstream counts to the upstream<br />

counts in each size range is the penetration.<br />

Although this value is not equal to the<br />

penetration measured by the Q-107, research<br />

performed by Los Alamos National Laboratory<br />

verified it to be very similar and the method to<br />

be an acceptable alternative to the penetration<br />

measured by Mil-Std-282 Test Method.<br />

Since this system measures the penetration in<br />

each size range, and a <strong>HEPA</strong> filter penetration<br />

varies with particle size, the maximum allowable<br />

penetration is 0.03% for the most penetrating<br />

particle size (MPPS). <strong>Flanders</strong> <strong>Filters</strong> Inc. can<br />

use this system to test filters that are rated at<br />

flows higher than 1100 CFM, if specified by the<br />

customer.<br />

retesting by DOE Filter Test Facilities<br />

DOE requires that nuclear facilities operated by<br />

DOE contractors have their <strong>HEPA</strong> filters retested<br />

at a Filter Test Facility operated for DOE. This<br />

service must be arranged by the buyer. <strong>Filters</strong><br />

rejected at the test station as not conforming to<br />

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: General Information<br />

the purchase specifications and determined not<br />

to have been damaged in shipment, will be replaced<br />

at no cost to the buyer. <strong>Filters</strong> must be<br />

shipped directly from the factory to the retest<br />

facility. If filters must be shipped to the retest<br />

facility, the requirement must be specified when<br />

quotations are requested. <strong>Filters</strong> requiring test<br />

will be quoted and sold to end user only. Upon<br />

successfully passing the testing at the retest facility,<br />

filters become the property of the end user<br />

or buyer. The end-user or buyer must arrange<br />

for their transport from the retest facility to the<br />

end-user’s site.<br />

Design Qualification Tests<br />

Design qualification testing is a key element of<br />

<strong>Nuclear</strong> <strong>Grade</strong> filters. Since there is a wide variety<br />

of filter types, sizes, and construction materials,<br />

purchasers shall clearly state required<br />

design qualification tests within their solicitations.These<br />

tests may include, but are not limited<br />

to those specified in ASME AG-1 Section<br />

FC-5100. Section FC tests are defined only for<br />

filter sizes specified in Table FC-4110 and may<br />

not be applicable for round and nippleconnected<br />

filter designs. AG-1 requires design qualification<br />

test to be performed by an independent<br />

laboratory within 5 years prior to shipment.<br />

<strong>Flanders</strong> has several models which meet these<br />

requirements; please consult the factory for the<br />

latest list of models which do. In addition, <strong>Flanders</strong><br />

has the capability to perform several of<br />

the FC-5100 qualification tests, in-house, under<br />

the <strong>Flanders</strong> quality assurance program. These<br />

tests may be helpful to the purchaser for qualifying<br />

designs which do not meet the full requirements<br />

of ASME AG-1. Please consult the factory<br />

for assistance in this matter.<br />

Seismic Qualification<br />

ASME AG-1 requires filters to be seismically<br />

qualified per the purchaser specified loadings.<br />

FFI has qualified various filter models per ASME<br />

AG-1 Section FC - 4300. The test qualification<br />

7

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Design and Construction<br />

was performed as follows: A <strong>HEPA</strong> filter was installed<br />

in a <strong>Flanders</strong>/<strong>CSC</strong> bag-in bag-out containment<br />

housing and subjected to simulated<br />

earthquake loading. No failure or damage was<br />

observed during or subsequent to the simulated<br />

event. The load exceeded the current requirements<br />

for UBC Zone 4 loading.<br />

Testing Service Available<br />

<strong>Flanders</strong> service personnel are available for installation,<br />

supervision of installation, filter testing<br />

and certification of compliance to industry and<br />

government standards, and instruction of the<br />

owner’s personnel in testing and maintenance<br />

procedures. Contact the factory for details.<br />

Filter Design and Construction<br />

Filter Medium<br />

The filter medium in FFI’s <strong>Nuclear</strong> <strong>Grade</strong> filter<br />

elements is glass (boron silicate microfiber)<br />

and contains a waterproofing binder which adds<br />

strength under both wet and dry conditions. FFI<br />

manufactures its own filter media to meet or exceed<br />

the requirements of ASME AG-1 Section<br />

FC, Mandatory Appendix FC-I. Approved media,<br />

formulated for resistance to airborne acids, are<br />

also available; consult the factory.<br />

Two Types of Filter pack Designs<br />

<strong>Flanders</strong> <strong>Filters</strong> Inc. manufacturers SEPARA-<br />

TORLESS ® <strong>HEPA</strong> <strong>Filters</strong> and conventional Separator-Style<br />

<strong>Filters</strong>. In a separator-style pack, the<br />

filter media is folded over corrugated aluminum<br />

separators with hemmed edges to separate the<br />

pleats of the filter pack.<br />

8<br />

<strong>HEPA</strong> <strong>Filters</strong> SEPARATORLESS ® <strong>HEPA</strong> filter with a<br />

formed, self-supporting pack<br />

<strong>Flanders</strong> <strong>Filters</strong> manufactures its own filter media,<br />

enabling us to develop a unique manufacturing<br />

process for the production of SEPARA-<br />

TORLESS ® <strong>HEPA</strong> <strong>Filters</strong>. In one manufacturing<br />

operation, <strong>Flanders</strong> <strong>Filters</strong> Inc. produces a selfsupporting<br />

and self-separating Media Pack. The<br />

SEPARATORLESS ® Filter offers many advantages<br />

over conventional separator-style <strong>HEPA</strong><br />

<strong>Filters</strong>:<br />

• More usable media area for longer service<br />

life and higher dust-holding capacity<br />

• Reduced cost of ownership due to longer<br />

service life<br />

• Maximum utilization of the media<br />

• 11 inches deep SEPARATORLESS ® Pack<br />

has approximately 400 sq. ft. of media as<br />

compared to 240 sq. ft. for a conventional<br />

separator-style filter.<br />

• Can handle some harsh environments<br />

which may attack aluminum separators<br />

• Media pack can be incinerated<br />

• Media is thicker than conventional media<br />

used in separator-style <strong>HEPA</strong> <strong>Filters</strong><br />

Conventional Separator-style <strong>HEPA</strong> filter with<br />

aluminum separators

Sealants/Adhesive<br />

Fire-retardant solid urethane is used to bond the<br />

filter element to its integral case. Maximum temperature<br />

rating for this sealant is 250°F.<br />

Case Material<br />

Plywood 3 /4 - inch fire-retardant plywood cases are<br />

ideal for many applications, and are easier to incinerate<br />

or breakdown for disposal than are metal<br />

case filters. However, they are not recommended<br />

for use in systems having high moisture content<br />

or high temperature: they may warp or support<br />

biological growth. Stainless steel case materials<br />

should be used in moisture-laden applications.<br />

Stainless Steel - 14-gauge Type 409 and 14-gauge<br />

Type 304 stainless steel cases are available. The<br />

Type 409 stainless steel replaced cadmium-plated<br />

and chromized steel. However, Type 409 material<br />

has a low resistance to caustic atmospheres. Type<br />

304 stainless steel is recommended for those applications.<br />

Case Style<br />

The technique used for sealing the filter in service<br />

determines the selection of the filter case style.<br />

(See illustrations.)<br />

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Design and Construction<br />

Gel Seal — Metal case gel seal filters have a fabricated<br />

channel ( 3 /4” wide x 3 /4” deep) located on<br />

one face. Wood case filters have a routed channel<br />

( 3 /8” wide x 3 /4” deep) on one face.<br />

BLU-JEL ® Seal was developed by <strong>Flanders</strong> and<br />

is the standard gel seal material.<br />

Gasket Seal — Metal case gasketed filters are provided<br />

with flanges for the placement of the gasket<br />

as specified by the customer. On wooden cases,<br />

the gasket is applied to the face of the case.<br />

Gasketed filters for normal service are supplied<br />

with closed cell sponge neoprene ( 1 /4” x 3 /4”).<br />

High-temperature filters require the special sealants<br />

described on page 15. Specify upstream,<br />

downstream, or both for the location of the gasket<br />

or gel seal within the model number.<br />

Faceguards<br />

The Gel Seal The Gasket Seal<br />

A knife edge in the filter housing mates into a gel<br />

filled channel provided on the filter. <strong>Flanders</strong> invented<br />

the fluid seal in response to requirements<br />

for an absolute seal in the most critical applications.<br />

In most cases, gel seal filters are also easier and<br />

quicker to change out than gasketed filters.<br />

Filter<br />

Gel Seal<br />

Channel<br />

Knife Edge<br />

BLUE-JEL ® Seal<br />

The standard faceguard materials are 23-gauge<br />

4 x 4 mesh, welded galvanized dipped steel or<br />

18-gauge Type 304 stainless steel. Faceguards<br />

protect the media, but are not a guarantee against<br />

damage caused by mishandling.<br />

Note: Specify faceguard location as upstream, downstream<br />

or both.<br />

Filter<br />

Gasket<br />

Seal<br />

A filter clamping mechanism is typically used to<br />

maintain sealing pressure on gasketed filters.<br />

Gasket seals have a tendency to develop bypass<br />

leaks, primarily because of compression set.<br />

9

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Filter Selection<br />

Underwriters laboratory, Ul 586<br />

To be UL 586 classified, filters must be submitted<br />

to Underwriters Laboratories for extensive<br />

testing including spot flame, and environmental<br />

exposure to heated air. A UL 586 classification is<br />

accepted by the DOE as meeting the Heated Air<br />

and Spot Flame Test requirements in ASME AG-1<br />

for <strong>Nuclear</strong> <strong>Grade</strong> filters.<br />

UL labels are optional. Some high-temperature<br />

filters, and filters larger than 24” x 30” x 11 1 /2” ,<br />

are not eligible for UL 586.<br />

Filter Selection<br />

1. Standard SEPARATORLESS ® maximum height<br />

is 24-inches. When specifying a filter size,<br />

the first dimension is always the height of the<br />

filter (the dimension parallel to the pleat of the<br />

medium); the second dimension is always the<br />

width of the filter; and, the third dimension is<br />

the filter depth.<br />

2. The filter sizes in Table FC-4110 do not include<br />

all sizes offered by manufacturers or requested<br />

by users today. The table is limited to nine (9)<br />

sizes, perceived by the American Society of<br />

Mechanical Engineers (ASME) to be standard.<br />

For special sizes, not addressed by the table,<br />

contact the factory.<br />

3. Of the sizes appearing in Table FC-4110, the<br />

GG-F (24” x 24” x 11 1 /2”) and GG-D (24” x 24”<br />

x 5 7 /8 ”) are the largest. Capacities for other<br />

sizes are computed from one of these two,<br />

depending on the filter element depth of the<br />

unlisted filter and its effective face area relative<br />

to the listed size. (The face area is obtained<br />

by subtracting two inches from the height and<br />

width dimensions to allow for the thickness of<br />

the case and the pack-to-case sealant.)<br />

4. 11 1 /2” deep filters are generally selected for<br />

service where a minimum amount of space<br />

relative to a maximum amount of airflow is<br />

required. Most often this is required in builtup<br />

banks, walk-in plenums, or side-access<br />

housings. <strong>Flanders</strong>’ GG-F size filter is most<br />

frequently selected.<br />

10<br />

5. If filters are operated at higher flows, efficiency<br />

can decrease and resistance will increase.<br />

Care should be taken if the customer is planning<br />

to operate a filter at higher than the rated<br />

capacity to determine if hostile environmental<br />

factors, such as combined high operating flow<br />

rate, water vapor condensation, and/or acid<br />

vapors, will cause filter failure. For example,<br />

water condensate on the filter media could<br />

plug the element, causing failure.<br />

A Z-drawing will be developed and become the<br />

size designator, in the model number for any filter<br />

which has special construction or testing requirements<br />

which are not covered in the Style Code<br />

System. Example: Z07123<br />

Important Note:<br />

GG-F filters with SEPARATORLESS ® media packs<br />

are sold as Size 5, 6 or 7. Unless customer specifies<br />

to the contrary, the filter is tested and sold as<br />

Size 5 (1000 cfm @ 1.0” w.g. maximum).<br />

“T”-clip on alignment mechanism<br />

(T-clips are factory installed.)

Standard SEpArATOrlESS ® <strong>Filters</strong><br />

Insert the desired Filter Size Designator from<br />

the charts on page 12 at the end of the model<br />

number.<br />

( Example: T-007-W-43-05-NU-51-23-GG-FU5)<br />

Gel Seal <strong>Filters</strong><br />

Media Pack Depth<br />

(inches)<br />

4<br />

11<br />

11<br />

Typical model numbers specifying filters with<br />

galvanized or stainless steel faceguards on both<br />

faces and with either BLU-JEL ® Seal or a neoprene<br />

gasket located on the upstream face are<br />

addressed below.<br />

Gasket Seal <strong>Filters</strong><br />

Type 409 S/S T-007-W-42-05-NU-51-13-_ _-FU5<br />

Type 304 S/S T-007-W-43-05-NU-51-23-_ _-FU5<br />

3 /4” Fire-Retardant Plywood T-007-W-04-05-NU-51-13-_ _-FU5<br />

Type 409 S/S T-007-U-42-05-NU-51-13-_ _-FU5<br />

Type 304 S/S T-007-U-43-05-NU-51-23-_ _-FU5<br />

3 /4” Fire-Retardant Plywood T-007-U-04-05-NU-51-00-_ _-FU5<br />

Note: “T” prefix in model number indicates T-clip requirement for gel seal-type filters used in sideaccess<br />

housings. (See gel seal photo on page 10.)<br />

Gasket Seal <strong>Filters</strong> Size, Material and Model Number<br />

Media Pack Depth<br />

(inches)<br />

5 1 /2<br />

11<br />

11<br />

Gel Seal <strong>Filters</strong> Size, Material and Model Number<br />

Case Filter Material<br />

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Filter Selection<br />

Model Number<br />

(typical)<br />

Type 409 S/S T-007-D-42-05-NU-51-13-_ _-DU5<br />

Type 304 S/S T-007-D-43-05-NU-51-23-_ _-DU5<br />

3 /4” Fire-Retardant Plywood T-007-D-04-05-NU-51-13-_ _-DU5<br />

Case Filter Material Model Number<br />

(typical)<br />

Type 409 S/S 0-007-D-42-03-NU-11-13-_ _-DU5<br />

Type 304 S/S 0-007-D-43-03-NU-11-23-_ _-DU5<br />

3 /4” Fire-Retardant Plywood 0-007-D-04-00-NU-11-13-_ _-DU5<br />

Type 409 S/S 0-007-W-42-03-NU-11-13-_ _-FU5<br />

Type 304 S/S 0-007-W-43-03-NU-11-23-_ _-FU5<br />

3 /4” Fire-Retardant Plywood 0-007-W-04-00-NU-11-13-_ _-FU5<br />

Type 409 S/S U-007-U-42-05-NU-51-13-_ _-FU5<br />

Type 304 S/S U-007-U-43-05-NU-51-23-_ _-FU5<br />

3 /4” Fire-Retardant Plywood U-007-U-04-05-NU-51-00-_ _-FU5/<br />

11

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: SEPARATORLESS ® Filter Selection<br />

Standard Sizes and Capacities<br />

<strong>Flanders</strong> manufactures standard square and<br />

rectangular <strong>Nuclear</strong> <strong>Grade</strong> filters in a variety of<br />

sizes and capacities. (Sizes and capacities for<br />

Round and Nipple connected filters are listed<br />

in their respective sections in this bulletin.) The<br />

type (SEPARATORLESS ® or Separator-Type) and<br />

depth of the filter element is a primary factor in<br />

filter capacity.<br />

NOTE: The maximum allowable resistance at<br />

the Nominal Rated Capacity is 1.0-inch w.g. (or<br />

1.3-inch w.g. for certain sizes listed in ASME<br />

AG-1, Section FC, Table FC-4110).<br />

SEPArATorLESS ® Filter Sizes and Capacities<br />

12<br />

Filter Size<br />

(designator)<br />

SEPArATorLESS ® Filter Sizes and Capacities<br />

Dimensions<br />

H W D<br />

(inches)<br />

Capacities<br />

(cfm)<br />

Maximum Initial<br />

resistance<br />

(inches w.g.)<br />

CC-F 12 12 11 1 /2 200 1.0<br />

CC-F 12 12 11 1 /2 250 1.3<br />

CG-F 12 24 11 1 /2 455 1.0<br />

GC-F 24 12 11 1 /2 455 1.0<br />

GE-F 24 18 11 1 /2 725 1.0<br />

GG-F 24 24 11 1 /2 1000 1.0<br />

GG-F 24 24 11 1 /2 1250 1.3<br />

GG-F 24 24 11 1 /2 1500 1.3<br />

GN-F 24 30 11 1 /2 1275 1.0<br />

Filter Size<br />

(designator)<br />

4-inch SEPArATorLESS ® Filter Element<br />

Dimensions<br />

H W D<br />

(inches)<br />

W<br />

Capacities<br />

(cfm)<br />

H<br />

Pack<br />

Dept<br />

D<br />

Maximum Initial<br />

resistance<br />

(inches w.g.)<br />

BB-D 8 8 5 7 /8 50 1.3<br />

CC-D 12 12 5 7 /8 125 1.3<br />

GE-D 24 18 5 7 /8 375 1.0<br />

GG-D 24 24 5 7 /8 500 1.0<br />

GN-D 24 30 5 7 /8 625 1.0

Standard Separator-Type <strong>Filters</strong><br />

Insert the desired Filter Size Designator from the<br />

charts on page 12 at the end of the model number.<br />

(The Size Designator indicates whether a 5 1 /2- inch<br />

or 11-inch filter element is being ordered.) Typical<br />

model numbers specifying filters with galvanized<br />

Gel Seal <strong>Filters</strong><br />

Media Pack Depth<br />

(inches)<br />

5 1 /2<br />

11<br />

or stainless steel faceguards on both faces and<br />

BLU-JEL ® Seal or a neoprene gasket located on<br />

the upstream face are addressed below.<br />

Gasket Seal <strong>Filters</strong><br />

Note: “T” prefix in model number indicates T-clip requirement for gel seal-type filters used in<br />

side-access housings. (See gel seal photo on page 10)<br />

Media Pack Depth<br />

(inches)<br />

5 1 /2<br />

11<br />

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Separator Filter Selection<br />

Gel Seal <strong>Filters</strong> Size, Material and Model Number<br />

Case Filter Material Model Number<br />

(typical)<br />

Type 409 S/S T-007-C-42-05-NU-51-13 -_ _- DU5<br />

Type 304 S/S T-007-C-43-05-NU-51-23 -_ _- DU5<br />

3 /4” Fire-Retardant Plywood T-007-C-04-05-NU-51-13 -_ _- DU5<br />

Type 409 S/S T-007-C-42-05-NU-51-13 -_ _- FU5<br />

Type 304 S/S T-007-C-43-05-NU-51-23 -_ _- FU5<br />

3 /4” Fire-Retardant Plywood T-007-C-04-05-NU-51-13 -_ _- FU5<br />

Gasket Seal <strong>Filters</strong> Size, Material and Model Number<br />

Case Filter Material Model Number<br />

(typical)<br />

Type 409 S/S 0-007-C-42-03-NU-11-13 -_ _- DU5<br />

Type 304 S/S 0-007-C-43-03-NU-11-23 -_ _- DU5<br />

3 /4” Fire-Retardant Plywood 0-007-C-04-00-NU-11-13 -_ _- DU5<br />

Type 409 S/S 0-007-C-42-03-NU-11-13 -_ _- FU5<br />

Type 304 S/S 0-007-C-43-03-NU-11-23 -_ _- FU5<br />

3 /4” Fire-Retardant Plywood 0-007-C-04-00-NU-11-13 -_ _- FU5<br />

13

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Standard Separator-Type Filter Selection<br />

Standard Separator-Type Filter Sizes and Capacities<br />

14<br />

Filter Size<br />

(designator)<br />

11-inch Separator-Type Filter Element<br />

Dimensions<br />

H W D<br />

(inches)<br />

Capacities<br />

(cfm)<br />

Maximum Initial<br />

Resistance<br />

(inches w.g.)<br />

CC-F 12 12 11 1 /2 200 1.0<br />

CC-F 12 12 11 1 /2 250 1.3<br />

CG-F 12 24 11 1 /2 455 1.0<br />

GC-F 24 12 11 1 /2 455 1.0<br />

GE-F 24 18 11 1 /2 725 1.0<br />

GG-F 24 24 11 1 /2 1000 1.0<br />

GG-F 24 24 11 1 /2 1250 1.3<br />

GG-F 24 24 11 1 /2 1500 1.3<br />

GN-F 24 30 11 1 /2 1275 1.0<br />

Filter Size<br />

(designator)<br />

5 1 /2 -inch Separator-Type Filter Element<br />

Dimensions<br />

H W D<br />

(inches)<br />

Capacities<br />

(cfm)<br />

Maximum Initial<br />

Resistance<br />

(inches w.g.)<br />

BB-D 8 8 5 7 /8 50 1.3<br />

CC-D 12 12 5 7 /8 125 1.3<br />

GE-D 24 18 5 7 /8 375 1.0<br />

GG-D 24 24 5 7 /8 500 1.0<br />

GN-D 24 30 5 7 /8 625 1.0<br />

Filter Size<br />

(designator)<br />

2 3 /4-inch Separator-Type Filter Element<br />

Dimensions<br />

H W D<br />

(inches)<br />

Capacities<br />

(cfm)<br />

Maximum Initial<br />

Resistance<br />

(inches w.g.)<br />

BB-A 8 8 3 1 /16 25 1.3

Standard High-Temperature <strong>Filters</strong><br />

<strong>Flanders</strong> manufactures <strong>HEPA</strong> filters for<br />

applications with high temperature requirements<br />

up to 1000°F (540°C) for exhaust<br />

air only and 500°F (260°C) for supply<br />

air. They do not meet all the qualification<br />

requirements of ASME-AG1 Section FC. Hightemperature<br />

filters are available with gasket<br />

or gel seal. (<strong>Filters</strong> with BLU-JEL ® Seal have<br />

a maximum service temperature of 392°F.)<br />

Gasketed filters for high temperature service<br />

are supplied with silicone sponge gaskets<br />

( 1 /4 inch thick x 3 /4 inch wide). High Temperature<br />

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong> meet the<br />

requirements of IEST-RP-CC001.4 for Type B<br />

<strong>Filters</strong> and are tested in accordance with MIL-<br />

Std-282. Two types of high temperature <strong>HEPA</strong><br />

filters are offered. The choice should be carefully<br />

made in accordance with the proposed<br />

filter service requirements for the specific<br />

application.<br />

Silicone Sealant (Designator NE)<br />

This is a high-temperature room-temperature<br />

vulcanizing (RTV) silastic-sealant silicone<br />

compound rated for continuous service up to<br />

500°F/260°C (supply air).<br />

NOTE: This high-temperature sealant is UL 586<br />

classified; however, it does not meet all the qualification<br />

requirements of ASME-AG1 Section FC.<br />

“NE” filters are eligible for UL586 labels.<br />

Glass pack Sealant (Designator NG)<br />

The glass pack seal is rated for continuous<br />

service up to 1000°F/540°C in exhaust air applications<br />

only and with separator-type filter<br />

elements only. A mat of submicron glass fibers<br />

creates a seal when compressed between the<br />

filter pack and filter case. The glass packing is<br />

not an adhesive seal but a mechanical seal that<br />

functions much as the glass fiber medium of the<br />

filter itself.<br />

Additional angle stiffeners are added to prevent<br />

the filter pack from slipping at high pressure<br />

drops.<br />

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: High-Temperture<br />

NOTE: Labels are not attached to 1000°F high<br />

temperature filters.<br />

NOTE: Due to the possibility of the glass pack<br />

seals shedding glass fibers, the glass pack sealant<br />

should be used for exhaust systems only.<br />

NOTES: _____________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

____________________________________________<br />

___________________________________________<br />

15

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: High Temperature<br />

Supply or Exhaust Air<br />

500° F Maximum (Gasket Seal) or 390°F<br />

Maximum (Gel Seal)<br />

Insert the desired Filter Size Designator from the<br />

chart on page 14 at the end of the model number.<br />

Typical model numbers specifying filters with<br />

16<br />

Media Pack<br />

Depth<br />

(inches)<br />

5 1 /2<br />

11<br />

galvanized or stainless steel faceguards on both<br />

faces and with BLU-JEL ® Seal (for gel seal filters)<br />

or silicone sponge (for gasket seal filters) located<br />

on the upstream face are addressed below.<br />

Separator-Type <strong>Filters</strong>, Case Material and Model Number<br />

Case Filter<br />

Material<br />

Type 409 S/S T-007-C-42-05-NE-51-13-_ _-DU5 0-007-C-42-03-NE-31-13-_ _-D<br />

Type 304 S/S T-007-C-43-05-NE-51-23-_ _-DU5 0-007-C-43-03-NE-31-23-_ _-D<br />

Type 409 S/S T-007-C-42-05-NE-51-13-_ _-FU5 0-007-C-42-03-NE-31-13-_ _-F<br />

Type 304 S/S T-007-C-43-05-NE-51-23-_ _-FU5 0-007-C-43-03-NE-31-23-_ _-F<br />

Exhaust Air Only - 1000° F Maximum<br />

Media Pack<br />

Depth<br />

(inches)<br />

5 1 /2<br />

11<br />

Model Number<br />

Gel Seal<br />

(Max. 390° F, 200° C)<br />

Separator-Type <strong>Filters</strong> Only<br />

Case Filter<br />

Material<br />

Model Number<br />

Gasket Seal<br />

(Max. 390° F, 200° C)<br />

Type 409 S/S 0-007-C-42-03-NG-00-23-_ _-D<br />

Type 304 S/S 0-007-C-43-03-NG-00-23-_ _-D<br />

Type 409 S/S 0-007-C-42-03-NG-00-23-_ _-F<br />

Type 304 S/S 0-007-C-43-03-NG-00-23-_ _-F<br />

Model Number<br />

Gasket Seal<br />

(Max. 500° F, 260° C)<br />

Note: “T” prefix in model number indicates T-clip requirement for gel seal-type filters used in<br />

side-access housings. (See gel seal photo on page 10)<br />

Insert the desired Filter Size Designator, from the charts on page 14, at the end of the model number.<br />

Model numbers specifying filters with stainless steel faceguards on both faces are addressed below.<br />

Note: Not available in gel seal.<br />

NOTE: These filters are shipped without gaskets, since none of<br />

the standard gasket materials are rated for 1000°F service. However,<br />

two woven glass gaskets may be provided with the filter if<br />

requested. The gaskets are shipped unattached and must be installed<br />

with the filter. Filter Labels are also shipped unattached.

ound <strong>Filters</strong><br />

Round <strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> filters are available<br />

with <strong>Flanders</strong>’ SEPARATORLESS ® filter element<br />

and with separator-type elements. Cases are<br />

made of 14 gauge Type 304 or Type 409 stainless<br />

steel, and are available for both gasket or fluid seal<br />

applications. Round filters are also manufactured<br />

for high temperature applications. (See page 15<br />

for information on high-temperature sealants.)<br />

Round <strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> filter components are<br />

materials specified in ASME AG-1 but the filters<br />

are not tested for rough handling, wet over pressure,<br />

or heated air or spot flame as required by<br />

that specification. <strong>Flanders</strong> performs acceptance<br />

testing of penetration and resistance only.<br />

ro<br />

(No<br />

Flange)<br />

r1<br />

(Single<br />

Flange)<br />

Filter Size<br />

(designator)<br />

Filter Size<br />

(designator)<br />

X<br />

Y<br />

Airflow<br />

Airflow<br />

Standard flange placement for a single flange<br />

rolled filter is upstream. Contact factory for alternate<br />

placement.<br />

r2<br />

(Double<br />

Flange)<br />

r5<br />

(Gel<br />

Seal)<br />

SEpArATOrlESS ® <strong>Filters</strong> Standard Sizes (contact factory for special sizes)<br />

X<br />

Dimensions<br />

Y<br />

(inches)<br />

Z<br />

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Round <strong>Filters</strong><br />

X<br />

Separator-Type <strong>Filters</strong><br />

Filter Element<br />

Depth<br />

(inches)<br />

Nominal rated<br />

Capacities<br />

(cfm)<br />

Airflow<br />

Z Z<br />

X<br />

Airflow<br />

Maximum Initial<br />

resistance<br />

(inches w.g.)<br />

Dimensions Filter Element Nominal rated<br />

X Y Z Depth Capacities<br />

(inches)<br />

(inches)<br />

(cfm)<br />

B 6 5 /8 8 8 4 35 1.0<br />

C 10 5 /8 12 8 4 100 1.0<br />

Maximum Initial<br />

resistance<br />

(inches w.g.)<br />

A 6 5 /8 8 5 1 /4 3 1 /16 20 1.0<br />

B 6 5 /8 8 8 5 1 /2 35 1.0<br />

C 10 5 /8 12 8 5 1 /2 100 1.0<br />

Y<br />

Y<br />

X<br />

X<br />

17

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Round <strong>Filters</strong><br />

Gel Seal<br />

Gel Seal filters are supplied with a 5 /8 -inch<br />

x 11 /16 -inch deep channel on one face only. The<br />

channel is factory-filled with <strong>Flanders</strong>’ BLU-JEL ®<br />

sealant.<br />

Note: Designate R5 Case Style. Standard channel<br />

location is upstream. (Face of flange)<br />

Gasket Seal<br />

18<br />

Channel<br />

Gaskets are made from 1 /4-inch x 3 /4 -inch closed<br />

cell neoprene material. Gaskets may be located<br />

on either side of the upstream flange. Contact<br />

factory for downstream flange location.<br />

Note: Designate R1 (one flange) or R2 (2 flanges)<br />

Case Style and specify location of the gasket as<br />

face of flange, back of flange, face and back of<br />

flange or faces of both flanges in the model number.<br />

Detail any special placement requirements.<br />

Gasket Location<br />

Face of Flange Back of Flange<br />

lifting Bails<br />

Optional lifting bails are available for easy filterremoval<br />

in special applications.<br />

Note: Specify the “B” prefix in the filter modelnumber.<br />

Faceguards<br />

The standard faceguard materials<br />

are 23-gauge 4 x 4<br />

inch mesh, welded galvanized<br />

dipped steel or 18-gauge Type<br />

304 stainless steel. Faceguards<br />

protect the media, but are not a guarantee against<br />

damage caused by mishandling.<br />

Note: Specify faceguard location as upstream,<br />

downstream or both.<br />

Drilled Flanges<br />

Drilled flanges are available<br />

as an option. <strong>Flanders</strong>’<br />

standard pattern is<br />

eight (8) 5 /16-inch diameter<br />

holes equally spaced<br />

and centered on a 7 3 /8 -inch diameter bolt circle<br />

for sizes A and B, or a 11 5 /16 -diameter bolt circle<br />

for size C filters.<br />

Note: Use the ‘D’ prefix in the model number.<br />

Ul 586<br />

For UL 586 classifiication, filters must be submitted<br />

to Underwriters Laboratories for extensive testing<br />

including spot flame and exposure to heated air.<br />

A UL 586 classification listing is accepted by<br />

DOE for meeting the Heated Air and Spot Flame<br />

Test Requirement of <strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> filters.<br />

NOTE: UL labels are optional and are applied only<br />

if specified by the buyer.<br />

Model Numbers and Specification<br />

Note: To write a specification for Round <strong>Filters</strong>, use<br />

the Designating Charts on pages 21 and 22 for determining<br />

the model number. Fill in the numbered<br />

locations in the Suggested Specification Text on<br />

page 23 with the model number and other appropriate<br />

selections from the listing on page 17.

Nipple Connected <strong>Filters</strong><br />

Nipple Connected <strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> filters are<br />

available with one (N1) or two (N2) nipple connections,<br />

and with SEPARATORLESS ® or separatortype<br />

filter elements. Case materials are 14-gauge<br />

Type 304 and 14-gauge Type 409 stainless steel<br />

and 3 /4 - inch fire retardant plywood. High temperature<br />

models are also available. (See page 15 for<br />

information on sealants.) Nipple-Connected filters<br />

are made of materials specified in ASME AG-1 but<br />

are not tested for rough handling, wet over pres-<br />

N1 <strong>Filters</strong><br />

Typical Metal Case Filter Illustrated<br />

X<br />

H<br />

W<br />

Filter Size<br />

(designator)<br />

BB-D 8 8 10 8 8 14 4 3 1 1 /2 50 1.3<br />

CC-D 12 12 12 12 12 18 4 4 1 1 /2 125 1.3<br />

CC-F 12 12 16 12 12 20 11 4 1 1 /2 200 1.0<br />

CC-F 12 12 16 12 12 20 11 4 1 1 /2 250 1.3<br />

GG-D 24 24 12 24 24 14 4 12 4 500 1.0<br />

GG-F 24 24 16 24 24 20 11 12 4 1000 1.0<br />

GG-F 24 24 16 24 24 20 11 12 4 1250 1.3<br />

GG-F 24 24 16 24 24 20 11 12 4 1500 1.3<br />

Filter Size<br />

(designator)<br />

N1 <strong>Filters</strong><br />

H W D<br />

(inches)<br />

N1 <strong>Filters</strong><br />

H W D<br />

(inches)<br />

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Nipple Connected <strong>Filters</strong><br />

Air Flow<br />

Filter<br />

pack<br />

D<br />

Z<br />

N2 <strong>Filters</strong><br />

H W D<br />

(inches)<br />

N2 <strong>Filters</strong><br />

H W D<br />

(inches)<br />

Y H<br />

sure, or heated air or spot flange as required by<br />

that specification. <strong>Flanders</strong> performs acceptance<br />

testing for penetration and resistance prior to attachment<br />

of cover plates.<br />

N2 <strong>Filters</strong><br />

Typical Wood Case Filter Illustrated<br />

X Z<br />

X Y Z<br />

(inches)<br />

X Y Z<br />

(inches)<br />

W D<br />

Nominal Rated<br />

Capacity<br />

(cfm)<br />

Nominal Rated<br />

Capacity<br />

(cfm)<br />

Air Flow<br />

Filter<br />

pack<br />

N1 or N2 <strong>Filters</strong> with SEpArATOrlESS ® Filter Elements, Standard Sizes<br />

Max. Initial<br />

Resistance<br />

(Inches w.g.)<br />

N1 or N2 <strong>Filters</strong> with Separator-Type Filter Elements, Standard Sizes<br />

Max. Initial<br />

Resistance<br />

(Inches w.g.)<br />

BB-A 8 8 8 8 8 12 3 1 /16 2 1 1 /2 25 1.3<br />

BB-D 8 8 10 8 8 14 5 1 /2 3 1 1 /2 50 1.3<br />

CC-D 12 12 12 12 12 18 5 1 /2 4 1 1 /2 125 1.3<br />

CC-F 12 12 16 12 12 20 11 4 1 1 /2 200 1.0<br />

CC-F 12 12 16 12 12 20 11 4 1 1 /2 250 1.3<br />

GG-D 24 24 12 24 24 14 5 1 /2 12 4 500 1.0<br />

GG-F 24 24 16 24 24 20 11 12 4 1000 1.0<br />

Note: Standard Nipple-placement for N1 Filter is downstream. Contact factory for alternate placement. When<br />

ordering N1 or N2 filters, specify size of nipple connections if <strong>Flanders</strong>’ standard sizes (see “Y” dimension) are<br />

not appropriate for your application.<br />

Y<br />

19

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Design Features and Options<br />

Roughing Prefilter<br />

The case depth dimension of N1 filters may be<br />

extended 2-inches to accommodate a roughing<br />

prefilter. Indicate the ‘P’ prefix in the model number<br />

to specify this option. A special size designator is<br />

required. Contact the factory for details.<br />

Note: Prefilter must be shipped loose for UL 586<br />

listed units.<br />

20<br />

Prefilter or Prefilter<br />

Gasket Seal<br />

Gaskets are made from 1 /4 -inch thick x 3 /4 -inch<br />

wide closed cell neoprene material. Specify location<br />

of the gasket as upstream or downstream, in<br />

the filter model number.<br />

Wood Case<br />

Drilled Flanges<br />

Metal Case<br />

Standard flanges may be located on the open<br />

face or on the nipple connection. These flanges<br />

may be drilled in a standard pattern or according<br />

to customer specifications.<br />

Air Flow<br />

Nipple-Connection Flange<br />

Filter Face Flange<br />

Air Flow 3/4 inch<br />

Single-Turn<br />

Flange<br />

<strong>Flanders</strong>’ standard patterns are as follows: 5 /16 -inch<br />

diameter holes equally spaced and centered on the<br />

filter face flange, or equally spaced and centered<br />

on the nipple-connection flange.<br />

Slip-On Flanges<br />

Optional 150 pound slip-on flanges for pipe nipple<br />

connections shall be available in Type 304 stainless<br />

steel, and in any standard IPS size. Note:<br />

Other sizes and types of flanges are available per<br />

customer specifications.<br />

Faceguards<br />

The standard faceguard materials are 23-gauge<br />

4 x 4 mesh, welded galvanized dipped steel or<br />

18-gauge Type 304 stainless steel. Faceguards<br />

protect the media, but are not a guarantee against<br />

damage caused by mishandling.<br />

Note: Specify faceguard location as upstream,<br />

downstream or both.<br />

Ul 586 (N1 and N2 <strong>Filters</strong>)<br />

To be UL 586 classified, filters must be submitted<br />

to Underwriters Laboratories for extensive testing<br />

including spot flame and exposure to heated air. A<br />

UL 586 listing is accepted by DOE for the Heated<br />

Air and Spot Flame Test Requirement of <strong>Nuclear</strong><br />

<strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>. UL labels are optional and<br />

are applied only if specified by the buyer.<br />

Model Numbers and Specification<br />

Note: To write a specification for Nipple-Connected<br />

<strong>Filters</strong>, use the Designating Charts on pages 21<br />

and 22 to determine the model number. Fill in the<br />

numbered locations in the Suggested Specification<br />

text on page 23 with the model number and<br />

other appropriate selections from the listing on<br />

page 12 for SEPARATORLESS® or page 14 for<br />

Separator-type.<br />

Note: Nipple-connected filters are not intended<br />

to serve as containment housings.

Model Number Development<br />

The Filter Model Number<br />

The design and construction of <strong>Flanders</strong>’ <strong>Nuclear</strong><br />

<strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong> are coded within the filter<br />

model number, which contains the following information:<br />

Hardware—Clips, handles, bails, etc.<br />

Filter Medium—Standard or acid resistant.<br />

Pack Type—SEPARATORLESS ® or separatortype.<br />

Case Material—Stainless Steel or wood.<br />

Case Style—Gel or Elastomer gasket seal designs.<br />

Sealant—Material used to seal pack to case<br />

Gasket Type/Location<br />

Faceguard Type/Location<br />

Filter Size Code<br />

UL Code—For filters requiring UL labels. (standard<br />

size filters only.) For odd size or filters requiring a<br />

“Z” drawing, the UL Code must be specified separate<br />

from the filter Model Number.<br />

Example:<br />

To order:<br />

Specify the desired filter: Refer to the model<br />

number charts in this bulletin and/or to the Model<br />

Number Designating Chart on page 22. Separately<br />

list and explain any required options or any requirements<br />

not addressed by the filter model number.<br />

<strong>Nuclear</strong> Filter Size Designators<br />

Standard Size <strong>Filters</strong> are designated using the following<br />

Alphanumeric Code for the Height, Width<br />

and Depth of the Filter:<br />

Standard Size Designator<br />

Height and Width<br />

Designators<br />

(inches)<br />

B = 8 A = 3 1 /16<br />

C = 12 D = 5 7 /8<br />

E = 18 D2= 7 7 /8<br />

G = 24 F = 11 1 /2<br />

N = 30 F2 = 13 1 /2<br />

U = 11 3 /8<br />

Y = 23 3 /8<br />

Example:<br />

GG-F = 24” H x 24” W x 11 1 /2 D<br />

Depth<br />

(inches)<br />

T - 007 - U - 43 - 05 - NU - 51 - 23 - GG - FU5<br />

Hardware<br />

Filter Medium<br />

Pack Style<br />

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Model Number Development<br />

Case Material<br />

Case Style<br />

Sealant<br />

Gasket Type/<br />

Location<br />

Faceguard<br />

Type/Location<br />

Filter Size<br />

Code<br />

UL Code<br />

21

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Model Number Designating Chart<br />

22<br />

Special<br />

Hardware<br />

options<br />

Filter<br />

Media<br />

Pack<br />

Type<br />

Case<br />

Material<br />

Case<br />

Style<br />

Pack to<br />

Case<br />

Sealant<br />

Gasket<br />

Type/<br />

Location<br />

Faceguard<br />

Material/<br />

Location<br />

Filter<br />

Size<br />

UL Code<br />

None 0<br />

Lifting Bail (for Round <strong>Filters</strong>) B<br />

Drilled Flanges D<br />

2” Extended Case for Roughing Prefilter P<br />

Extractor T-Clips for Fluid Seal Filter T<br />

U-Handles on Wood-frame <strong>Filters</strong> for <strong>Flanders</strong> G1- housings<br />

Non-woven glass paper (boron silicate microfiber) 99.97% minimum<br />

U<br />

efficiency 007<br />

Same as 007, with additional treatment for resistance to HF 003<br />

Same as 007, with additional treatment for resistance to NHO3 010<br />

4” deep filter pack (SEPARATORLESS ® ) D<br />

11” deep Pureform ® DYN-E2 filter pack (SEPARATORLESS ® ) U<br />

11” deep filter pack (SEPARATORLESS ® ) W<br />

Pleated flat sheet with corrugated aluminum separators C<br />

14-gauge Type 409 Stainless Steel (Bolted Construction) 42<br />

14-gauge Type 304 Stainless Steel (Bolted Construction) 43<br />

14-gauge Type 304L Stainless Steel (Bolted Construction) 12<br />

14-gauge Type 316 Stainless Steel (Bolted Construction) 13<br />

14-gauge Type 316L Stainless Steel (Bolted Construction) 15<br />

3/4” fire-retardant plywood 04<br />

‘Box-Type’ Construction (for Wood <strong>Filters</strong>) 00<br />

Double-turn Flanges, both Faces (for Metal <strong>Filters</strong>) 03<br />

Channel for Gel Seal on One Face (Wood or Metal <strong>Filters</strong>) 05<br />

Round Filter with No Flange RO<br />

Round Filter with One Upstream Flange R1<br />

Round Filter with Two Flanges R2<br />

Round Filter with Face Channel for Gel Seal R5<br />

N1 Filter - One Downstream Nipple Connection N1<br />

N2 Filter - Two Nipple Connections N2<br />

Fire-Retardant Solid Urethane NU<br />

RTV Silastic Silicone for High Temperature <strong>Filters</strong> NE<br />

Glass Packing for 1000°F Exhaust Filter NG<br />

TYPE (1st Box) LoCATIoN (2nd Box)<br />

0. None 4. Glass packing<br />

1. Neoprene 5. BLU-JEL ® Seal 0. None 2. Downstream face<br />

3. Silicone sponge X. (Special Material) 1. Upstream face 3. Both faces<br />

TYPE (1st Box) LoCATIoN (2nd Box)<br />

0. None 0. None 2. Downstream face<br />

1. 23-Gauge Galvanized Steel 1. Upstream face 3. Both faces<br />

2. 18-gauge Stainless Steel<br />

X. (Special Material)<br />

Seven spaces are allotted for filter size codes, although all<br />

spaces may not be required. Standard size designators<br />

(GG-F, etc.) are entered flush left, including dashes. Special<br />

sizes (Alphanumeric Designators and Z-drawings) are entered<br />

flush left with the prefixes (no dashes)<br />

G G — F<br />

EXAMPLE:<br />

NOTE: UL Code is entered flush left in the remaining boxes. USE this UL Code when applicable:<br />

U5 for UL 586.(Does not apply for Z-drawings)<br />

T<br />

—<br />

0 0 7 —<br />

4 —<br />

4 3 —<br />

0 5 —<br />

N U —<br />

5 1 —<br />

2 3 —<br />

U 5

Suggested Specifications<br />

The filters shall be model *(1) <strong>Nuclear</strong> <strong>Grade</strong> as<br />

manufactured by <strong>Flanders</strong> <strong>Filters</strong>, Inc. Washington,<br />

NC. The filter medium shall be all glass with<br />

a wet strength, water-repellent binder in accordance<br />

with ASME AG-1 Section FC, Mandatory<br />

Appendix FC-I.<br />

To Specify SEpArATOrlESS ® Filter Element:<br />

Each filter element shall be constructed without<br />

the use of spacers of any kind, including separators,<br />

tape, string or strips of medium, by pleating<br />

a continuous sheet of a formed, corrugated<br />

medium back and forth upon itself so that it is<br />

self-supporting.<br />

To Specify SEpArATOr-Type Filter<br />

Element:<br />

Each filter element shall be constructed by pleating<br />

a continuous flat sheet of medium over corrugated<br />

.0015 inch minimum thick aluminum spacers<br />

whose edges have been hemmed to resist tearing<br />

the medium at the fold.<br />

The element shall be permanently bonded to a<br />

*(2) integral case with a fire-retardant urethane<br />

sealant. The perimeter of the filter face shall have<br />

*(3) to seal it to its mounting device in service.<br />

Construction of the filter shall be in a accordance<br />

with the essential construction requirements of<br />

ASME AG-1 (latest issue).<br />

Each filter shall be tested, while encapsulated,<br />

for resistance to airflow and penetration in accordance<br />

with ASME AG-1 Section FC 5200 at the<br />

nominal rated capacity listed in table FC-4110-1<br />

and at 20% of that capacity for penetration only<br />

(filters with rated capacity of 75 cfm or higher).<br />

The penetration at both flows shall not exceed<br />

0.03%. (This paragraph may not apply to Round,<br />

N1 or N2 filters.)<br />

The <strong>HEPA</strong> filters shall comply with the performance<br />

requirements as listed in ASME<br />

AG-1 Section FC-5200. Each filter and filter<br />

carton shall bear identical labels indicating<br />

the filter model number, the serial number,<br />

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Suggested Specifications<br />

test air-flow direction and the resistance and<br />

penetration readings at test flow taken for the<br />

filter on the manufacturer’s Q107 penetrometer<br />

or HFATS System. In addition, the manufacturer<br />

shall provide a filter test report and a Certification<br />

of Compliance report.<br />

The manufacturer shall, upon request, submit<br />

evidence that its filters have been qualified in accordance<br />

with ASME AG-1 or can reasonably be<br />

expected to do so.<br />

<strong>Filters</strong> that are 24” x 12” x 6” and larger shall be<br />

packaged one filter per carton. Each filter shall<br />

be encased in a flanged, tightfitting alignment<br />

cushion sleeve that fits within the carton, leaving<br />

a dead-air space on four sides of the filter. The<br />

top and the bottom of the filter shall be protected<br />

with a cushion or comparible cushon design to<br />

avoid the deleterious effects of shock, vibration,<br />

physical damage, water vapor, salt spray, condensation,<br />

and weather during shiping, handling, and<br />

storage. Linerboard cartons shall be strapped to<br />

a <strong>Flanders</strong> Type 2 pallet with 3 /8-inch wood facing<br />

on both faces.<br />

Model Numbers and Specification<br />

Fill in the numbered locations on the Suggested<br />

Specification Text by selecting from the corresponding<br />

category below:<br />

*(1) Filter model number<br />

(See page 22)<br />

*(2) Case material<br />

14-gauge, Type 409 stainless steel (bolted)<br />

14-gauge, Type 304 stainless steel (bolted)<br />

14 gauge, Type 304L stainless steel (bolted)<br />

14-gauge, Type 316 stainless steel (bolted)<br />

14-gauge, Type 316L stainless steel (bolted)<br />

3 /4-inch thick fire-retardant plywood<br />

*(3) Case style<br />

No flanges<br />

Two double turn flanges<br />

A 3 /4-inch channel with gel sealant<br />

A single metal-nipple connection<br />

Two metal-nipple connections<br />

23

<strong>Nuclear</strong> <strong>Grade</strong> <strong>HEPA</strong> <strong>Filters</strong>: Environmental Conditions<br />

Environmental Conditions<br />

Heat resistance<br />

In high-temperature applications, filter media will<br />

exhibit a significant loss of strength after the binder<br />

burns off. (This normally occurs in the 300°-325°F<br />

range.) <strong>Flanders</strong> recommends only separator style<br />

filters be used in high temperature applications.<br />

<strong>Filters</strong> not specifically designed for high temperature<br />

applications are nevertheless constructed<br />

from self-extinguishing or noncombustible components<br />

and will withstand periodic temperatures<br />

up to continuous 250°F with no noticeable change<br />

in pressure drop or penetration. However, extended<br />

service under such conditions can cause<br />

accelerated aging of organic materials and may<br />

subsequently contribute to filter failure.<br />

Humidity and Water resistance<br />

<strong>HEPA</strong> filter media will tolerate high humidity (95%<br />

±5%) and some direct wetting, but excessive<br />

moisture, either from airborne droplets or condensation,<br />

can plug the filter and result in failure<br />

by over-pressure. Wood cases are unsuitable for<br />

high-moisture conditions, since wood expands or<br />

warps when wet, and supports biological growth<br />

under humid conditions. Metal case filters are<br />

more suitable for moisture laden atmospheres.<br />

Because aluminum separators can corrode in<br />

some environments and slough particles downstream<br />

of the filter, SEPARATORLESS ® filters are<br />

also recommended for moist conditions, except<br />

in high-temperature or caustic applications.<br />

Chemical resistance<br />

All materials have good resistance to most organic<br />

solvents and are resistant to many weak organic<br />

and inorganic alkalies and acids. Exposure to<br />

acids such as HF, and those with NOx radicals<br />

occurs in nuclear systems fairly often and with<br />

varying degrees of impact (HF attacks glass). Information<br />