Air Conditioning Compressors - Delphi

Air Conditioning Compressors - Delphi

Air Conditioning Compressors - Delphi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

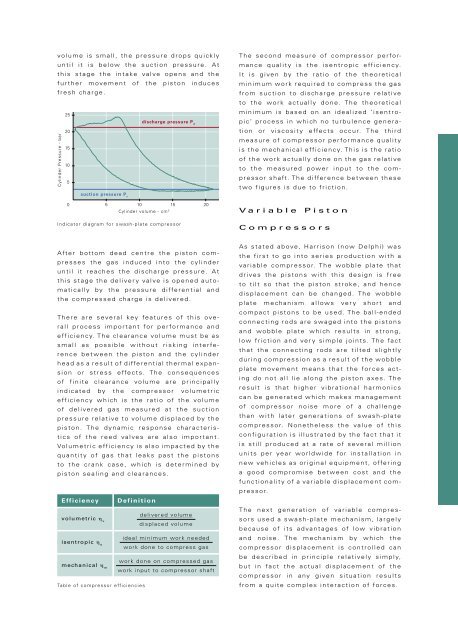

vo l u m e i s s m a l l , t h e p r e s s u r e d r o ps quickly<br />

u n t i l i t i s b e l ow t h e s u c tion p r e ssure. At<br />

t h i s s t a g e t h e i n t a ke valve o p e n s and the<br />

f u r t h e r m ove m e n t o f t h e p iston induces<br />

f r e s h ch a r g e .<br />

Cylinder Pressure - bar<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

suction pressure P s<br />

discharge pressure P d<br />

5 10<br />

15 20<br />

Cylinder volume - cm 3<br />

I n d i c a t o r d i a g r a m fo r s wa s h - p l a t e c ompressor<br />

A ft e r b o ttom d e a d c e n t re t h e p iston com-<br />

p r e s s e s t h e g a s i n d u c e d i n t o t h e cylinder<br />

u n t i l i t r e a ch e s t h e d i s charge p r essure. At<br />

t h i s s t a g e t h e d e l i ve r y valve i s o p e ned auto-<br />

m a t i c a l l y by t h e p r e s s u r e d i ffe r e ntial and<br />

t h e c o m p r e s s e d ch a r g e is delive r ed.<br />

Th e r e a r e s eve r a l key fe a tu r e s o f this ove -<br />

r a l l p r o c e s s i m p o r t a n t for p e r fo rmance and<br />

e ff i c i e n c y. Th e c l e a r a n c e volume must be as<br />

s m a l l a s p o s s i b l e w i t h o u t risking interfe -<br />

r e n c e b e t we e n t h e p i s t on a n d t h e cylinder<br />

h e a d a s a r e s u l t o f d i ffe r e n tial t h e r mal expan-<br />

s i o n o r s t r e s s e ffe c t s . Th e c o nsequences<br />

o f f i n i t e c l e a r a n c e vo l u m e a r e p rincipally<br />

i n d i c a t e d by t h e c o m p r essor volumetric<br />

e ff i c i e n c y w h i ch i s t h e ratio o f t he volume<br />

o f d e l i ve red g a s m e a s u red a t t h e suction<br />

p r e s s u r e relative t o vo l ume displaced by the<br />

p i s t o n . Th e d y n a m i c r e s p o nse characteris-<br />

t i c s o f t h e r e e d va l ve s are a lso i mport ant.<br />

Vo l u m e t r i c e ff i c i e n c y i s a lso impacted by the<br />

q u a n t i t y o f g a s t h a t l e a k s p ast t he pistons<br />

t o t h e c r a n k c a s e , w h i ch is d e t e rmined by<br />

p i s t o n s e a l i n g a n d c l e a r a nces.<br />

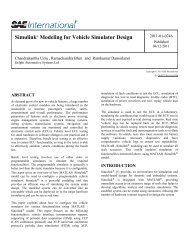

E ff i c i e n c y D e f i n i t i o n<br />

volumetric η v<br />

isentropic η s<br />

mechanical η m<br />

Ta b l e o f c o m p r e s s o r e ff i c i e n c i e s<br />

delivered volume<br />

displaced volume<br />

ideal minimum work needed<br />

work done to compress gas<br />

work done on compressed gas<br />

work input to compressor shaft<br />

The second measure of compressor perfor-<br />

mance qualit y is the isentropic efficiency.<br />

It is given by the ratio of the theoretical<br />

minimum work required to compress the gas<br />

from suction to discharge pressure relative<br />

to the work actually done. The theoretical<br />

minimum is based on an idealized ‘isentro-<br />

pic’ process in which no turbulence genera-<br />

tion or viscosit y effects occur. The third<br />

measure of compressor performance qualit y<br />

is the mechanical efficiency. This is the ratio<br />

of the work actually done on the gas relative<br />

to the measured power input to the com-<br />

pressor shaft. The difference bet ween these<br />

t wo figures is due to friction.<br />

V a r i a b l e P i s t o n<br />

C o m p r e s s o r s<br />

As st ated above, Harrison (now <strong>Delphi</strong>) was<br />

the first to go into series production with a<br />

variable compressor. The wobble plate that<br />

drives the pistons with this design is free<br />

to tilt so that the piston stroke, and hence<br />

displacement can be changed. The wobble<br />

plate mechanism allows ver y short and<br />

compact pistons to be used. The ball-ended<br />

connecting rods are swaged into the pistons<br />

and wobble plate which results in strong ,<br />

low friction and ver y simple joints. The fact<br />

that the connecting rods are tilted slightly<br />

during compression as a result of the wobble<br />

plate movement means that the forces act-<br />

ing do not all lie along the piston axes. The<br />

result is that higher vibrational harmonics<br />

can be generated which makes management<br />

of compressor noise more of a challenge<br />

than with later generations of swash-plate<br />

compressor. Nonetheless the value of this<br />

configuration is illustrated by the fact that it<br />

is still produced at a rate of several million<br />

units per year worldwide for inst allation in<br />

new vehicles as original equipment, offering<br />

a good compromise bet ween cost and the<br />

functionalit y of a variable displacement com-<br />

pressor.<br />

The next generation of variable compres-<br />

sors used a swash-plate mechanism, largely<br />

because of its advant ages of low vibration<br />

and noise. The mechanism by which the<br />

compressor displacement is controlled can<br />

be described in principle relatively simply,<br />

but in fact the actual displacement of the<br />

compressor in any given situation results<br />

from a quite complex interaction of forces.