Meopta Industrial Park - Birkenast

Meopta Industrial Park - Birkenast

Meopta Industrial Park - Birkenast

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A Better View of the World<br />

Company profile

Vision Statement Historical Overview<br />

<strong>Meopta</strong> will build on it’s long tradition of quality opto-mechanical<br />

and opto-electronical skills to develop and produce the<br />

highest quality product by continuous improvement<br />

through technological and managerial<br />

innovation. We will strive to make <strong>Meopta</strong><br />

trademark a synonym of quality,<br />

performance and responsibility.<br />

Our goal will be to increase<br />

profitability, shareholder value and<br />

revenues while adhering to the highest<br />

ethical and legal standards, as well<br />

as environmental regulations.<br />

We will accomplish this by establishment of strategic<br />

partnership with suppliers and customers, whose reliance<br />

upon our capability and know-how will be increasing for significant<br />

mutual benefit. The capability of our associates is the key to achieving success. We will continually improve<br />

education, performance and satisfaction of all members of our team, since their pride in <strong>Meopta</strong> is the formula<br />

for our success. As a prominent employer and a partner of regional authorities, we will support improvement<br />

of our community’s standard of living and will enhance a consciousness<br />

about Prerov as the town of optics and opticians.<br />

„A Better View of the World“<br />

<strong>Meopta</strong> Prerov traces its roots back to the year 1933, when the Optikotechna company was established in Prerov.<br />

Initially, Optikotechna produced lenses and condensers, but quickly expanded its product line to include enlargers, composite<br />

lenses, single optics, binoculars, riflescopes, slide projectors and of course the well known Flexaret range of cameras.<br />

By 1936, Optikotechna established new facilities to accommodate the rapid expansion of its operation necessary to meet<br />

the growing demand for its products.<br />

During World War II, Optikotechna was forced to surrender control of its production to the German army. This change effectively<br />

stopped the production of all non-military products.<br />

After the war, the remaining company was renamed <strong>Meopta</strong>. A number of new and exciting products were designed and<br />

developed, which helped to quickly establish an excellent reputation for the new <strong>Meopta</strong> brand in world markets.<br />

However, in 1971 production was again refocused primarily on military products and continued this way until it was abruptly ended<br />

in 1989. At which time the sale of military products, which represented about 75 % of <strong>Meopta</strong>‘s business, was reduced to zero.<br />

In 1991, <strong>Meopta</strong> Prerov completed its first step toward privatization when it was established as a joint stock company („akciova<br />

spolecnost“). The company was formed by a single act in accordance with the founding plan of the state enterprise <strong>Meopta</strong><br />

Prerov, s.p. On March 21, 1991, <strong>Meopta</strong> was registered in the companies register at the District Court in Ostrava.<br />

<strong>Meopta</strong> currently occupies a 135 000 m 2 (1,450,000 sq ft) site. The built up areas yield 77 000 m 2 (830,000 sq ft) of floor space,<br />

including 26 000 m 2 (280,000 sq ft) of manufacturing area, which include state-of-the-art, high quality, air conditioned, dust free<br />

environments. The <strong>Meopta</strong> team that exists today is poised to utilize its extensive experience in research, design, development<br />

and production to provide superior service on many different levels from raw concept to finished goods.<br />

Trade Marks<br />

<strong>Meopta</strong> Prerov, a.s., is owner of total of 23 trade marks which are registered domestically as well as internationally. These<br />

include: <strong>Meopta</strong>, Axomat, Proximus, Belar, Opemus, Magnifax, Anagon, Anaret, Meoplan, Meosix and Sport.<br />

Milestones<br />

1933 Building enterpreneur Alois Benes founded Optikotechna company<br />

in Prerov, Dr. Mazurek constructed the first Czechoslovak enlarging lens.<br />

1934-1937 Optikotechna focused on darkroom equipment (mainly enlargers and lenses).<br />

1937 Optikotechna built new facilities for production in suburb of Prerov.<br />

1939-1945 Optikotechna supplied military optical equipment for German army<br />

(rangefinders, periscopes, binoculars, riflescopes).<br />

1946 Optikotechna renamed to <strong>Meopta</strong> national enterprise<br />

1947-1970 <strong>Meopta</strong> became one of the biggest enlarger manufacturers<br />

worldwide and the only cinema projector manufacturer<br />

in Cenral/East Europe<br />

1953 The Institute for research and development of optic and precision<br />

mechanic was established in Prerov.<br />

1971 There was a rapid increase of military production for Warsaw Pact<br />

(up to 75 % of total turnover).<br />

1988 <strong>Meopta</strong> renewed riflescopes production, decreasing military production.<br />

1990 <strong>Meopta</strong> military program decreased to 0 %, <strong>Meopta</strong> became separate<br />

subsidiary join stock companies.<br />

1992 <strong>Meopta</strong> fully privatised and remains the only optical enterprise in Czech<br />

republic. Became a supplier of major optical companies worlwide.<br />

2003 <strong>Meopta</strong> companies merged to one law, organization<br />

and business subject again.

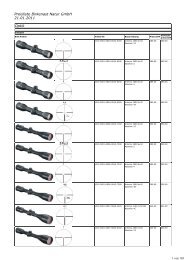

Products<br />

Sports Optics<br />

The Artemis 2000/2100, Artemis 3000/31000 and Meostar R1/R1 RD aiming riflescopes are one<br />

of the most sophisticated riflescope lines with the widest assortment of both fixed and variable<br />

scopes. The 2000 line utilizes a solid steel body to maximize durability and shock resistance.<br />

Designed with the user in mind these scopes are easy to use in the field or at the range, offer<br />

superior edge-to-edge optical quality and are guaranteed to be fog proof and waterproof for the life<br />

of the product. The 3000 series riflescopes are designed to be lightweight and durable - one piece<br />

body construction based on aluminium alloy. In additon to these two big innovations <strong>Meopta</strong> also<br />

moved the reticle to the rear focal plain. Making this series ideal for big game hunting of Africa or<br />

North America.<br />

Meostar R1 belongs to a new generation of riflescopes and has been developed by combining<br />

old world craftsmanship with state-of-the-art technology and materials. It is made only from the<br />

highest-grade aircraft aluminium alloy material available, in addition to bead blasting the exterior<br />

before the „Elox“anodizing process to ensure an extremely durable and non-reflective black matte<br />

outer finish. The light transmission per glass surface has been dramatically improved with new<br />

proprietary IMB-5501 anti reflective coatings and a unique ION assisted applications process,<br />

which ensures increased light transmission of 99.8% per glass surface.<br />

A New optical category for <strong>Meopta</strong> in 2005, The Meostar binoculars are a culmination of our long<br />

extensive experience with designing and manufacturing top quality, state–of–the–art professional<br />

grade optical products for many different industries including riflescopes and spotting scopes.<br />

The Meostar name denotes that these binoculars are our premier or flag ship line and as such<br />

utilize only the finest materials available in conjunction with some of the most advanced<br />

state-of-the-art processes in their construction. Designed and built to satisfy even the most<br />

demanding professional or enthusiast, these new binoculars offer superior light transmission,<br />

accurate color definition and crisp edge to edge image clarity, putting them on par with some<br />

ofEurope‘s most elite binoculars.<br />

The HA 70, HA/HS 75 and TGA 75 are monocular spotting scopes designed, above all, for<br />

birdwatchers, natueviewrs, target shooters and hunters.<br />

Meostar S1-75 APO (provided with APO objectives) are devoted to the most exigent customers.<br />

These scopes have been designed to reduce secondary color aberration and assure brilliant<br />

crystal clear images under even the most difficult light conditions and are ideally suited for taking<br />

long distance photos. The eyepieces for <strong>Meopta</strong> TGA 75, <strong>Meopta</strong> HA/HS 75 and Meostar S1 are<br />

mutually interchangeable except for the 30x WA-R ranging eyepiece, which can only be used with<br />

the TGA75.<br />

Darkroom equipment<br />

The <strong>Meopta</strong> enlargers have been designed to produce black and white or color prints from<br />

negatives from 24 x-36 mm up to 65x90mm. There is a-wide variety of <strong>Meopta</strong> enlargers<br />

accessories (colour and multigrade heads, timers, exposure equipment, easels, rotary<br />

trimmers, negative carriers etc.), including <strong>Meopta</strong> enlarging lenses Belar, Anaret and Meogon.<br />

<strong>Meopta</strong> objectives high resolution and excellent contrast with edge-to-edge sharpness for both<br />

color and black and white prints will satisfy both the demanding amateur and the professional<br />

photographer.<br />

35mm cinema projectors<br />

MEO 5 XB1e and MEO 5 XB3e are professional cinema projectors designed for projecting 35mm films<br />

with optical sound recording including Dolby analog and digital readers with RED LED. The projectors<br />

enable projection of all currently used formats: 1:1.37; 1:1.66; 1:1.85 and 1:2.35. The turret holder<br />

of auxilliary lenses (hand or motor driven) enables an arbitrary combination of three formats.<br />

Military equipment<br />

The main <strong>Meopta</strong> products in the military branch are passive night vision and daylight devices<br />

for combat vehicles. Night vision systems are using 2nd+ generation of intensifier tubes which<br />

provide easy observation of the terrain and do not tire the observer's-eyes.<br />

OEM Capabilities<br />

Are you looking for a-cost-effective, prompt, reliable, high quality solution for your ideas ?<br />

<strong>Meopta</strong> Prerov is a-powerful partner for OEM Products (Original Equipment Manufacturers). Our customers include some of the<br />

world's-leading optical firms. We provide our customers with full engineering services, materials management, manufacturing,<br />

assembly services, in-house testing and worldwide distribution. Our product development process is designed to ensure<br />

accurate, reliable delivery of your product within your schedule and requirements.<br />

<strong>Meopta</strong> works with the customer through several phases:<br />

Initial Concept<br />

<strong>Meopta</strong> and the OEM customer develop a-detailed understanding of the product requirements and customer needs. Our<br />

specialized teams with representatives of engineering, marketing, finance, purchasing and distribution are dedicated to create<br />

solutions, solving problems and fill demands throughout the entire process from first idea to final delivery of the product.<br />

<strong>Meopta</strong>’s customer can place reliance on our support and leadership at every phase of project, not just some aspects.<br />

Preliminary Design<br />

Detailed analysis of Initial Concept are the input for the Preliminary Design stage. <strong>Meopta</strong> has nearly 70 years experience<br />

with optical systems calculation, modular transfer functions calculations, tolerance analysis, automatic corrections of optical<br />

systems, as well as, design of mechanical parts. Our engineers provide recommendations for optimum components choises<br />

in order to design products for quality, functionality, manufacturability and serviceability. Offering the lowest total cost and the<br />

highest quality of products is our goal. Developing team co-operate in frequently exchange of drawings, photos, samples and<br />

other information for the best performance of goals. In some cases we visit our customer's-facilities to better understand the<br />

requirements. <strong>Meopta</strong>'s research and development department has implemented ISO 9001 Quality Management System and<br />

is certified since 1999.<br />

Available Design Software<br />

PTC/ProENGINEER 2000i, AUTO CAD 97 LT,<br />

ZEMAX optical design software<br />

MEOPTA software for:<br />

• Modulation transfer function calculations<br />

• Tolerance analysis incl. decentricity<br />

• Automatic corrections of optical systems<br />

Prototyping and Testing<br />

<strong>Meopta</strong> offers a full range of prototype manufacturing from CNC milling, turning, grinding, electro-erosive<br />

engineering, to complete optical processing and assembly capable to prepare sample parts or final product.<br />

This versatility allows the customer to test basic characteristic, system operation and identify some refinements.<br />

We develop manufacturing, assembly, test and calibration procedures for the product with compliance<br />

to customer specification.<br />

Testing laboratory of <strong>Meopta</strong> Prerov include optical testing processes:<br />

• Image Plane Resolution, Field Curvature, Distortion,<br />

• Chromatic and Spherical Aberration, Astigmatism,<br />

• Temperature and Humidity<br />

• Vibration, Schock and Drop<br />

• Accelerated Mechanical Life<br />

• Force and Displacement Analysis<br />

• Reliability Estimation

OEM Capabilities OEM Capabilities<br />

<strong>Meopta</strong> has implemented ISO 9001 and its QM System is certified.<br />

Preliminary Drawing Package<br />

Output of design, prototyping and testing phases is a-preliminary drawing package including hardcopy drawings of optical<br />

components, mechanical parts and assemblies, bill of materials, procedures and testing protocols. We provide these documents<br />

as an AutoCAD or ProEngineer files according to customer preferences. Sample or prototypes, we can send the design to<br />

customer’s facility for in-house testing (if required).<br />

Pilot Production<br />

<strong>Meopta</strong> resolves manufacturing issues, pursues opportunities for cost reduction, and scales up for production. Final qualification<br />

of the device is obtained. We provide complete turnkey service for tooling procurement by our tooling department for each step<br />

of serial production and quality control. Testing of these tools (cutting tools, gauges, pressing and bending tools, drilling clamps,<br />

special assembly gauges, collimators, moulds etc.), and making processing procedures are the next steps of evaluating and<br />

preparing for mass production.<br />

Manufacturing<br />

The <strong>Meopta</strong> offers all the essential resources for manufacture of optical components, mechanical parts, subassemblies,<br />

assemblies and final opto-mechanical products or systems.<br />

Mechanical Parts<br />

<strong>Meopta</strong> uses classical and CNC engineering for production of high precision mechanical components. Our CNC equipment<br />

include Steinel BZ 20, Heckler-Koch BA 20, Maho, MOOG, Matra VMC 850A, MATRA JET 32 and HAAS VFO 20HP CNC milling<br />

machines, Hyundai Hit 8S, Hyundai Hit 18 S, Hyundai 20 M, Spinner PD-CNC, Matra FTC-10, Weiller Praktikus and Tarex CNC<br />

lathes, classical lathes, milling machines, grinding machines, drilling machines and various pressing machines. The painting<br />

facilities at <strong>Meopta</strong> include areas for masking, painting, and baking. Painting includes enamel, epoxy, polyurethane and lacquer.<br />

Anodizing technologies have available a wide range of finishes for stell, aluminum and brass including zinc, nickel, chrome, tin,<br />

cooper, black oxide coating and phosphate coating.<br />

Optical Components<br />

<strong>Meopta</strong> is capable of producing large quantities of various types of<br />

optical elements - spherical lenses, prisms, prism assemblies, plano<br />

optics, filters, mirrors etc. <strong>Meopta</strong> optic elements are used for laser,<br />

medical, military, aerospace and commercial technologies.<br />

<strong>Meopta</strong> has state-of-the-art technology for complete optical processing<br />

including glass cutting, sawing, grinding and polishing, edging and<br />

shaping and thin film coating. <strong>Meopta</strong> uses optical machines LOH,<br />

Schneider, Optotech, Lapmaster and <strong>Meopta</strong>, cleaning machine<br />

Naicotec, vacuum coating devices Balzers and Leybold and many others.<br />

For quality control we use spherical interferometers Zygo, Schneider<br />

and <strong>Meopta</strong>, plano interferometers Zeiss and Moeller Wedel. Antireflex<br />

coating is inspected by UV spectrophotometers Perkin Elmer and by<br />

spectrofotometers for infrared and visible range.<br />

Assembly<br />

Highly qualified employees in our assembly departments have long time experience with final assembly of many types of optomechnical<br />

products for commercial, industrial, medical and military use. <strong>Meopta</strong> produces, for example lenses (enlarging,<br />

projection, scanning, printing, for x-ray devices etc.), cameras, slide projectors, movie projectors, profileprojector, riflescopes,<br />

spotting scopes, enlargers, night vision devices, opthalomological testing devices, luminometers, surveying laser equipment etc.<br />

During production, we continue to work with the customer to be sure the product is meeting their requirements.<br />

Toolshop<br />

<strong>Meopta</strong> has a-strong capabilities in tool design and production.<br />

The tooling department is qualified in technology, programming and<br />

measuring of:<br />

• pressing tools for cutting, bending and drawing<br />

plates and sheets, combined tools, forming<br />

tools drilling clamps<br />

• forms for thermoplastic injection moulding<br />

• lenght gauges, thread rings<br />

• cutting tools for rotation working and surfacing<br />

• optical measuring instruments (collimators),<br />

their reparing, including producting<br />

replacement optical parts<br />

• repairs of workshop microscopes<br />

and profile projectors<br />

• preparation of production of<br />

spherical and plane optics<br />

• turning and milling work, grinding, electroerosion<br />

machining, driling and grinding precision of holes,<br />

machining on CNC machines Fehlmann Pikomax<br />

90, Hyundai HiT 8 S, Hyundai SPT V800<br />

• 3D-measurment capabilities<br />

at Browne & Sharpe DEA machine

<strong>Meopta</strong> <strong>Industrial</strong> <strong>Park</strong><br />

Legend<br />

Certain entire buildings and portions of other buildings will be available for new tenants at the <strong>Meopta</strong> industrial park<br />

Manufacturing Facility<br />

Synergy<br />

Manufacturing Facility<br />

Manufacturing Facility<br />

Tenants will have the benefits of working with the other companies in the <strong>Industrial</strong> <strong>Park</strong>. Several of the current tenants are<br />

customers of or suppliers to other tenants and joint ventures between tenants at the <strong>Park</strong> have been established. <strong>Meopta</strong> makes<br />

available its expertise to assist and serve new tenants in the <strong>Industrial</strong> <strong>Park</strong>.<br />

<strong>Meopta</strong> will use its experience, reputation and contacts to help tenants with:<br />

• Dealing with governmental agencies to obtain all available benefits<br />

• Providing translation services<br />

• Providing an available skilled labor pool<br />

• Providing security<br />

• Use of <strong>Meopta</strong>’s video tele-conferencing facility<br />

• Research and Development for optical and mechanical products<br />

• Establishing purchasing and marketing networks<br />

Manufacturing Facility<br />

Common Facility<br />

Manufacturing Facility<br />

Office Building<br />

Storage Area<br />

Multipurpose Building<br />

Multipurpose Building<br />

The <strong>Meopta</strong> companies have a world-wide customer base. Tenants in the <strong>Industrial</strong> <strong>Park</strong> will have access to this source<br />

to market appropriate products. <strong>Meopta</strong> will also consider being a strategic partner for the right start-up company or affiliate of<br />

an established Company.<br />

Professional and service tenants<br />

Professional and service tenants seeking to provide legal. accounting, public relations, insurance, computer and other services<br />

to the <strong>Park</strong>’s industrial tenants will find state of the art office space available in our Administrative Building.<br />

Doing business in The Czech Republic<br />

The Czech Republic welcomes development. Substantial incentives, including: corporate tax relief, job-creation grants, and<br />

training and re-training grants are available and Meotpa will assist tenants in-the-<strong>Park</strong> to obtain them.<br />

According to a-recent survey by the European Commission, the Czech workforce is better able to-communicate in foreign<br />

languages than is the labor force in other Central European countries. <strong>Meopta</strong> maintains a-list of available qualified personnel<br />

and will provide this list to tenants in the <strong>Park</strong> and will assist them with other Human Resources matters.<br />

In May, 2004, the Czech Republic will become a-member of the European Union. Products manufactured in the Czech Republic<br />

will be available for shipment to the other members of the European Union free of tariffs or trade restrictions.<br />

PŘEROV<br />

The <strong>Meopta</strong> <strong>Industrial</strong> <strong>Park</strong> is located in Přerov which is 2.5 hours from Vienna, 3 hours from Prague, and-4.5-hours from Warsaw<br />

and Budapest. CzechRail and other European railways provide frequent passenger service and cargo service to Přerov. Excellent<br />

technical schools and the Palacky University are located in-the-Přerov area.<br />

The <strong>Meopta</strong> <strong>Industrial</strong> <strong>Park</strong> provides the ideal location and facilities for your company.

<strong>Meopta</strong> - optika, s.r.o.<br />

Kabelíkova 1, 750 02 Přerov, Czech Republic<br />

Tel: +420 581 241 111, Fax: +420 581 242 222<br />

meopta@meopta.com, www.meopta.com