WKG pipes - Duktus

WKG pipes - Duktus

WKG pipes - Duktus

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Information about <strong>WKG</strong> <strong>pipes</strong><br />

Areas of use<br />

Pipelines at risk of frost, e.g.:<br />

� Bridge with pipelines<br />

� Pipelines laid above ground<br />

� Pipelines laid in the ground with minimal depth of covering<br />

� Pipelines at risk of heat loss.<br />

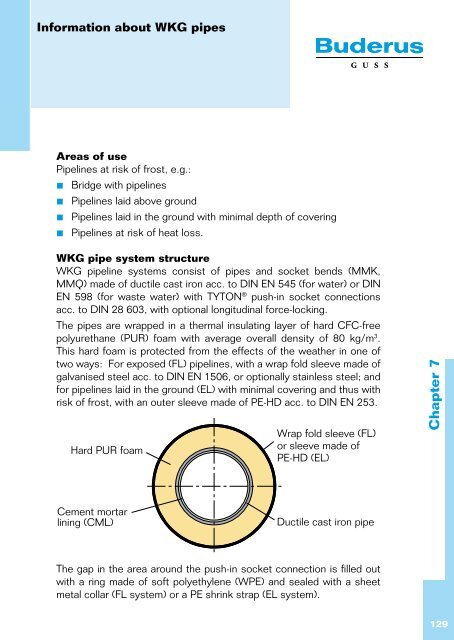

<strong>WKG</strong> pipe system structure<br />

<strong>WKG</strong> pipeline systems consist of <strong>pipes</strong> and socket bends (MMK,<br />

MMQ) made of ductile cast iron acc. to DIN EN 545 (for water) or DIN<br />

EN 598 (for waste water) with TYTON ® push-in socket connections<br />

acc. to DIN 28 603, with optional longitudinal force-locking.<br />

The <strong>pipes</strong> are wrapped in a thermal insulating layer of hard CFC-free<br />

polyurethane (PUR) foam with average overall density of 80 kg/m 3 .<br />

This hard foam is protected from the effects of the weather in one of<br />

two ways: For exposed (FL) pipelines, with a wrap fold sleeve made of<br />

galvanised steel acc. to DIN EN 1506, or optionally stainless steel; and<br />

for pipelines laid in the ground (EL) with minimal covering and thus with<br />

risk of frost, with an outer sleeve made of PE-HD acc. to DIN EN 253.<br />

The gap in the area around the push-in socket connection is filled out<br />

with a ring made of soft polyethylene (WPE) and sealed with a sheet<br />

metal collar (FL system) or a PE shrink strap (EL system).<br />

Chapter 7<br />

129