HD Dealer News Issue 3.indd - Hastings Deering

HD Dealer News Issue 3.indd - Hastings Deering

HD Dealer News Issue 3.indd - Hastings Deering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

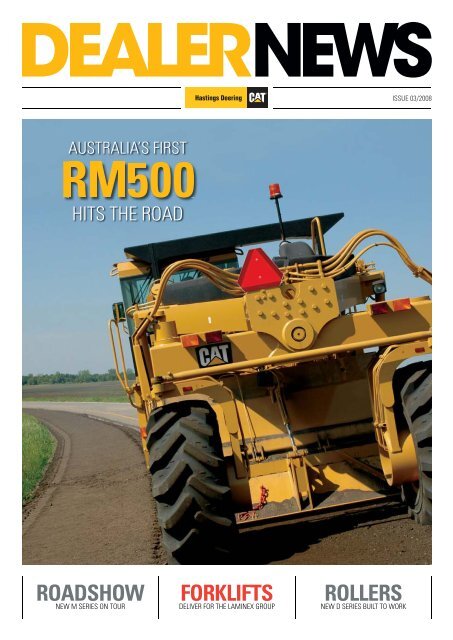

RM500<br />

AUSTRALIA’S FIRST<br />

HITS THE ROAD<br />

ROADSHOW FORKLIFTS ROLLERS<br />

NEW M SERIES ON TOUR<br />

DELIVER FOR THE LAMINEX GROUP<br />

NEW D SERIES BUILT TO WORK<br />

ISSUE 03/2008

FORWARD MINING.<br />

For Caterpillar ® and <strong>Hastings</strong> <strong>Deering</strong> it’s more than just words. It’s a way of doing business.<br />

It comes through every idea, every Cat product, every product support solution we can provide.<br />

Together we innovate, lead, move... FORWARD.<br />

For more information on our range<br />

of mining machines<br />

CALL 131 228<br />

www.hastingsdeering.com.au

FOREWORD<br />

Scott Cameron<br />

Managing Director<br />

Welcome to the third edition of DEALER NEWS where we continue<br />

to bring our customers’ success stories and general information<br />

about <strong>Hastings</strong> <strong>Deering</strong> and Cat products.<br />

Business for <strong>Hastings</strong> <strong>Deering</strong> continues at a robust pace<br />

with mining and construction sectors continuing to develop at<br />

unprecedented rates. In spite of several global warning signs,<br />

the local outlook remains very encouraging with continuing<br />

government commitment to investment in Queensland<br />

infrastructure and the fl ow on to growth in the mining sector that<br />

this investment will facilitate.<br />

Our workforce at <strong>Hastings</strong> <strong>Deering</strong> is expanding rapidly to meet<br />

this record demand. With many new staff and record numbers<br />

of apprentices we are ever vigilant about the need to continue<br />

to improve the safety culture within our organisation. Our safety<br />

performance is improving and we will continue to work hard<br />

to achieve our goal of zero injuries. Safety programs that were<br />

instituted some three years ago have made a difference with<br />

lost time injuries reducing by more than 60% together with solid<br />

improvements in reportable injuries and injury severity. Safety is a<br />

journey that is our top priority for both staff and customers.<br />

Training is always a high priority at <strong>Hastings</strong> <strong>Deering</strong> and we are<br />

continuing to invest in people and training facilities. With the<br />

release of many new products such as the M Series Motor Grader<br />

(featured in this issue), we have also beefed up our customer<br />

operator and service training to ensure that user productivity can<br />

be maximised.<br />

As this edition of <strong>Dealer</strong> <strong>News</strong> goes to print, service staff have<br />

started moving into the completed fi rst stage of our new Mackay<br />

facility. Darren Woodward and his team have done a terrifi c job in<br />

constructing a world class facility to meet and exceed Caterpillar<br />

owner’s requirements in Mackay and the Bowen Basin. Stage<br />

2 will see the construction of a new parts warehouse and main<br />

offi ces which are scheduled for completion in the fi rst half of 2009.<br />

There are a number of exciting articles in this edition including<br />

the delivery of the fi rst Cat RM500 Rotary Mixer machine in<br />

Australia. This unit was delivered to Diamantina Shire Council in<br />

Western Queensland for use in soil / cement applications in road<br />

maintenance and stabilizing applications.<br />

As another fi nancial year comes to a close, we at <strong>Hastings</strong><br />

<strong>Deering</strong> take this opportunity to thank you, our customer, for your<br />

continuing confi dence in the products we sell and the services we<br />

provide and we look forward to working with you to make your<br />

coming year even better.<br />

Scott Cameron<br />

ON THE COVER: The RM500 lands in Australia.<br />

CONTENTS<br />

04<br />

06<br />

08<br />

12<br />

17<br />

18<br />

24<br />

28<br />

30<br />

32<br />

36<br />

40<br />

BOOST FOR COPPABELLA<br />

New Caterpillar 793 Fleet gets to work<br />

DIAMANTINA SHIRE<br />

The delivery of Australia’s fi rst RM500<br />

AUSTCHROME EXPANDS<br />

Reclamation and repair options for components<br />

BRANCH EXPANSIONS<br />

Setting the pace for <strong>Hastings</strong> <strong>Deering</strong>’s future growth<br />

MACHINE SECURITY<br />

DataDotDNA technology comes to the heavy industry sector<br />

NEWS FROM THE CAT RENTAL STORE<br />

The latest news and additions<br />

THE GRADER ESCAPE<br />

The M Series hits the road<br />

NEW CAT ROLLER LINE-UP<br />

Built to work<br />

PART EXCHANGE & REMAN<br />

The options and differences clearly explained<br />

SERVICE SOLUTIONS<br />

<strong>Hastings</strong> <strong>Deering</strong> - the difference counts<br />

MACHINE SPECS<br />

The range in detail<br />

THE REPORTER<br />

The latest news from around the network<br />

03

04<br />

COPPABELLA BOOSTED BY<br />

NEW CATERPILLAR<br />

793 FLEET<br />

Located 140 kilometres south-west of Mackay in the Bowen Basin, Coppabella Mine is one<br />

of three mining operations managed by the independent Queensland based Macarthur Coal.<br />

Coppabella has a relatively short history having been developed from a greenfi elds prospect<br />

to a coal producing mine in the late 1990s. Overburden removal at the site commenced in<br />

July 1998 with the fi rst coal mined three months later.<br />

The site’s mining operations are carried out 24 hours a day,<br />

seven days a week with the principal product being low<br />

volatile pulverised coal injection coal (PCI coal) for use in<br />

the production of steel. Caterpillar ® machines are heavily<br />

involved in Coppabella’s operations and are an integral part<br />

of the pre-strip and dragline operation and the coal fl eet.<br />

Coppabella’s General Manager - Senior Site Executive<br />

Paul Smallbone said the ground conditions at the site are<br />

ideally suited to the Cat fl eet of mining trucks, dozers,<br />

graders and loaders.<br />

“We have an excellent relationship with <strong>Hastings</strong> <strong>Deering</strong><br />

at the mine site which dates back from previous contractors,”<br />

he said. “I would have to say that we are Caterpillar tragics

when it comes to equipment selection. We believe they are<br />

the Rolls Royce (of equipment).”<br />

Currently, the Caterpillar fl eet at Coppabella consists of ten<br />

789 mining trucks, ten 793 mining trucks, fi ve D11 tractors,<br />

three motor graders, an 834 wheel dozer and a 994 wheel<br />

loader. Mr Smallbone said the site moves approximately<br />

50 million BCM of dirt and produces about 6Mt of<br />

ROM coal per annum thus compelling the operation to<br />

commission ten 793 mining trucks in the twelve months<br />

from October 2007.<br />

“The 793s are used in the pre-strip operations,” said<br />

Mr Smallbone, “They are a good truck, easy to drive and do<br />

the job.” Equipped with the “X” Body for Caterpillar mining<br />

trucks which favours durability over maximum payloads<br />

Mr Smallbone said the matching exercise between the<br />

trucks and the site’s PH 41000C shovel had been great.<br />

<strong>Hastings</strong> <strong>Deering</strong> believes superior products deserve superior<br />

support and has worked closely with Macarthur Coal to<br />

confi gure the trucks to meet the required applications.<br />

“We have an excellent product support supervisor and<br />

account manager from <strong>Hastings</strong> <strong>Deering</strong> who provide excellent<br />

diagnostic and support service to the site,” said Mr Smallbone,<br />

“With full back up during the commissioning of the machines<br />

and the readiness to go that extra bit for Coppabella, if we have<br />

a problem, we know there is always a solution on the way.”<br />

Well placed to take advantage of the strong world steel market<br />

and growth in worldwide demand for coal, Macarthur Coal’s<br />

vision for the future is to be the leading independent Australian<br />

coal company. Mr Smallbone thinks Coppabella’s future is<br />

looking pretty bright in this respect. The site will be lifted to<br />

full output once infrastructure constraints are lifted and will<br />

need the equipment to respond to that he said.<br />

<strong>Hastings</strong> <strong>Deering</strong> has the knowledge, experience, training and<br />

tooling necessary to handle all customer needs, and ongoing<br />

support will help ensure the continuing success of the<br />

Caterpillar fl eet at Macarthur Coal’s Coppabella Mine.<br />

05

06<br />

DIAMANTINA SHIRE TAKES<br />

DELIVERY OF<br />

AUSTRALIA’S FIRST<br />

RM500<br />

Diamantina Shire is a progressive remote Queensland shire located in the state’s far south-west.<br />

Spanning some 95,000 kilometres – an area twice the size of Denmark - the region is known<br />

as the Channel Country and consists of the two main centres of Bedourie and Birdsville<br />

and the third town of Betoota.<br />

As harsh as the landscape in the region may seem, it is rated<br />

as having some of the best cattle fattening areas in Australia<br />

with 14 cattle stations operating within the shire boundaries.<br />

The shire’s wealth lies within its cattle industry and natural<br />

environment but is probably most renowned for the Birdsville<br />

Races; the annual horse meet which sees the region’s<br />

population swell and marks the start of the famous<br />

Birdsville track.<br />

Diamantina Shire Council has just taken delivery of a<br />

Caterpillar ® RM500 Rotary Mixer Machine which is designed<br />

for full depth reclamation and soil stabilisation applications.<br />

The RM500 is Caterpillar’s latest and most powerful model in<br />

rotary mixers. It is capable of mixing and reclaiming in-place<br />

asphalt to a maximum depth of 508 millimetres and has an<br />

on-board computer controlled water system capable of<br />

spraying 379 to 1,895 litres per minute.

The council expects to achieve great effi ciencies with road<br />

maintenance and construction by employing the new level<br />

of technology.<br />

Two international experts from Caterpillar; Shanghai based<br />

Technical Support Representative in Caterpillar Paving Industry<br />

Victor Xu and Bangkok based Marketing Support Consultant for<br />

Caterpillar Asia Pacifi c Global Paving Bob McClaran<br />

visited Bedourie to train the council operators and support<br />

staff. <strong>Hastings</strong> <strong>Deering</strong> Sales Representative Grant Samson<br />

and Product Support Representative Bernie Reis both from<br />

Mt Isa, were also on hand to assist in the delivery and training<br />

for the new machine.<br />

The council anticipates using the machine for soil/cement<br />

applications in road maintenance and stabilisation applications<br />

to achieve strong, durable road bases on the 1,591 kilometres<br />

of unsealed roads and 145 kilometres of sealed roads within<br />

the shire.<br />

Mr McClaran said, “It’s great to see this innovative<br />

technology being employed by Diamantina Shire,<br />

a remote outback Queensland Council.<br />

“They are a true leader in trying to achieve effi ciency in<br />

road maintenance and construction methodology.”<br />

This was echoed by Mr Samson who said, “This is the fi rst<br />

new RM500 model delivered in Australia and within the<br />

Asian region.<br />

“The acquisition of this machine by the Diamantina Shire<br />

is typical of its progressive view of developing the shire by<br />

maintaining a robust fl eet of the latest and most effi cient<br />

plant and equipment.”<br />

Training comprised maintenance, operation and application and<br />

in-depth operator training on the latest technology of on-board<br />

automated controls was provided by Bob and Victor both in the<br />

boardroom and out in the fi eld.<br />

“After only a few hours of hands-on experience, the operators<br />

displayed confi dence in the operation of this new machine.”<br />

said Mr Xu.<br />

The fi rst job the stabilisation machine will undertake is<br />

a very signifi cant upgrade of the Bedourie Airport runway.<br />

The strip is being lengthened by 300 metres to a total length<br />

of 1.8 kilometres. Council’s Director of Works, Kevin Barr,<br />

who is very pleased with council’s decision to acquire the<br />

RM500 said, “We will be overlaying the airstrip surface with<br />

150mm of crushed gravel and using the RM500 to mix and<br />

stabilise the material to create a new surface that when sealed<br />

will be capable of handling larger passenger aircraft.”<br />

With a project timeframe of approximately two months<br />

the new stabilisation machine will be instrumental in<br />

meeting the deadline; a task which traditional methods<br />

would struggle to complete.<br />

Mr McClaran stated, “This is an innovative application<br />

for this machine. I think this is technology than can be<br />

utilised throughout Australia for the upgrading of runways<br />

and highways.”<br />

Mayor Cr. Robbie Dare is pleased with the RM500 and<br />

commented, “Council has over many years enjoyed a<br />

strong working relationship with <strong>Hastings</strong> <strong>Deering</strong> in Mt Isa.<br />

“They are always available to provide ongoing support<br />

for our fl eet. Grant Samson who is the representative that<br />

services remote areas in Queensland is always willing to<br />

provide advice and assistance to Council regarding the<br />

latest earthmoving technology.<br />

“In the past, the council has proven to be at the fore when<br />

it comes to buying the best and most productive equipment.<br />

“We were the fi rst Shire in Australia to take delivery of<br />

a Caterpillar D9R dozer.”<br />

The new RM500 Rotary Mixer is a 540 horsepower model<br />

and has a Tier 3 engine with 8% more horsepower than the<br />

RM350B. It also has upgrades in traction, weight balance,<br />

serviceability, versatility, and productivity. Key features include<br />

full-time all-wheel drive, large tyres with aggressive tread,<br />

two speed ranges (work and transport), and electronic gear<br />

selection. The all-wheel-drive system features two independent<br />

variable-displacement propel pumps that supply balanced<br />

oil fl ow to the front and rear drive motors. The combination<br />

rotor is designed to handle both asphalt reclamation and<br />

soil stabilisation.<br />

07

08<br />

EXPANDING REPAIR<br />

OPTIONS FOR<br />

COMPONENTS<br />

Located in Mackay, AustChrome is a wholly owned subsidiary of <strong>Hastings</strong> <strong>Deering</strong> and has<br />

been the market leader in the reclamation and repair of worn components within the mining,<br />

construction and engineering sectors for over 14 years. AustChrome specialises in component<br />

reclamation, where worn components can gain a second, third or, in some cases even a<br />

fourth life through the latest repair techniques.<br />

Priding themselves on providing state of the art repairs,<br />

AustChrome offers customers customised solutions for<br />

individual requirements. Repair options available to<br />

customers include:<br />

Machining Services<br />

Hard Chrome Plating:<br />

The AustChrome facility boasts the most advanced and<br />

environmentally friendly hard chroming facilities in Australia.<br />

Specifi cally designed to accommodate hydraulic cylinders<br />

and suspension groups up to off highway mining trucks<br />

and face shovels.<br />

Maximum component diameter: 400mm<br />

Maximum component length: 5,500mm<br />

Hard Chroming utilises a process of electro plating, using a<br />

conforming anode to achieve a consistent plating fi nish. The<br />

chrome material is then polished to a like new fi nish. Hard<br />

chroming is the traditional repair for hydraulic components<br />

restoring the fi nish of the component to the original factory<br />

specifi cations from a salvaged core material.<br />

HVOF:<br />

High Velocity Oxygen Fuel (HVOF) system is designed to produce<br />

high-pressure reclamation coatings of extreme quality and<br />

hardness. Allowing for greater fl exibility of repair options for<br />

large components, not only for cylinder rods, this technology<br />

can also be used to reclaim any cylindrical product e.g.<br />

wheel ends.<br />

LaserFusion:<br />

AustChrome was the fi rst supplier in Australia to use<br />

LaserFusion technology in the repair and remanufacture of<br />

hydraulic components. AustChrome uses a high power direct<br />

ductile laser (HPDDL) system to produce a pure undiluted alloy<br />

coating 12mm in width and up to 2mm in depth of material per<br />

pass. This enables many new material processing applications<br />

to be explored. Damaged components previously not<br />

reclaimable can now be successfully reclaimed to a like<br />

new fi nish. The process can also be utilised to achieve:<br />

Cladding and surface engineering<br />

Minimal distortion<br />

Low dilution of material<br />

A completely dense surface<br />

Corrosion resistant properties

Hard facing<br />

Excellent wear protection<br />

Increased surface hardness<br />

Highly reproducible<br />

Heat treating<br />

Chemical free, dry process<br />

Selective surface hardening<br />

Precise control of parameters<br />

Casing depth is controllable for exacting fi nishes<br />

Welding / Hybrid Welding<br />

Laser beam profi le is ideal for precise seam welding<br />

Spatter free welds<br />

Ability to join super alloys<br />

Ability to weld dissimilar alloys such as aluminium,<br />

nickel and cobalt<br />

LaserFusion creates a molecular bond with the original surface<br />

material, creating a completely dense component with superior<br />

wear characteristics.<br />

Over the past 12 months, AustChrome has undergone<br />

signifi cant changes as a company. Management’s<br />

main focus was to increase capacity and improve job<br />

turnarounds which have been achieved through a<br />

two prong strategy of productivity improvement and<br />

infrastructure expansion.<br />

Productivity improvements have been driven through<br />

focusing on improvements in workfl ow, increasing<br />

the ownership of the production processes by the<br />

employees, and improved communication and<br />

transparency between management and the fl oor.<br />

AustChrome has implemented a series of strategies<br />

to achieve these goals focusing on developing cell<br />

based production teams, with each team given specifi c<br />

performance based key performance indicators which<br />

are recorded each month and subsequently analysed at<br />

monthly cell meetings.<br />

In conjunction with the productivity based improvement<br />

initiatives, AustChrome has been moving ahead with a<br />

capacity expansion project. The project is being done<br />

in four stages –<br />

Construction and installation of new thermal<br />

spray facilities<br />

Expansion of workshop 2<br />

Expansion of chroming capacity<br />

Expansion of administration blocks<br />

The superior hardening properties associated with LaserFusion<br />

are greater than both hard chroming and Cat Advanced Surface<br />

Technology however there are pricing differentiations.<br />

AustChrome is positioned to offer a fully comprehensive<br />

range of component repair, reclamation, and manufacture<br />

of components to original equipment manufacturer<br />

specifi cations.<br />

Repair options include but are not limited to:<br />

Hydraulic Rods and Cylinders<br />

Wheel Ends and Bearings<br />

Spindles<br />

Through these forms of component reclamation, customers are<br />

able to extend their components life cycle not only on hydraulic<br />

components but on many other products where a wear surface<br />

is required. Contact your product support representative or your<br />

nearest <strong>Hastings</strong> <strong>Deering</strong> branch for further details.<br />

Upon completion, AustChrome will have two<br />

workshops housing the two production divisions.<br />

Workshop 1 will house the Reclamation Engineering<br />

Division. This facility will accommodate the wide<br />

range of reclamation technologies from hard chroming<br />

through to LaserFusion with all associated machine<br />

tools to reclaim a variety of components including<br />

industrial rolls, fi nal drive components, transmission<br />

components and pinion gears. Workshop 2 will house<br />

the Hydraulic Engineering Division, a dedicated<br />

workshop focusing on servicing, repair and<br />

manufacture of hydraulic groups and components.<br />

With all the changes taking place within the company,<br />

management took the opportunity to change the face of<br />

AustChrome to refl ect its image as a modern company<br />

delivering superior service. AustChrome’s new logo will<br />

be launched upon completion of the new facilities.<br />

09

10<br />

NQHH COUNTS ON CAT<br />

North Queensland mining hub Mount Isa proudly lays claim to being the largest city in the<br />

world sprawling some 40,977 square kilometres. It was here in 1998 that Matt Yapp established<br />

North Queensland Heavy Haulage (NQHH), a company that has grown over the years at a rate<br />

that could almost rival the growth of Mount Isa itself.<br />

Today, NQHH has a fl eet in excess of 30 trucks which haul<br />

across Australia. Although heavy haulage is the company’s<br />

mainstay, NQHH has branched into the heavy crane market in<br />

association with both North West Cranes in Mt Isa and<br />

Brisbane Lift and Shift in the state’s south. This has allowed<br />

NQHH the ability to offer its customers an in-house complete<br />

lift & move capability. Heavy haulage however, will always<br />

be the focus of NQHH, a fact confi rmed by the company’s<br />

recent acquisition of Rocklea Carrying.<br />

Matt has worked in the heavy haulage industry his whole life,<br />

initially spending time as a driver before starting up his own<br />

business. The one constant which has remained throughout his<br />

career is his love of Caterpillar engines. So far 15 of his trucks<br />

run with Cat ® engines with his most recent addition –<br />

a 200 tonne rated Kenworth T908 prime mover – fi tted with<br />

the C15 ACERTTM 550hp engine at 1850 lb-ft torque.<br />

For fl eets and owner/operators alike, the Cat C15 ACERT<br />

remains the heavy-duty engine of choice, delivering a level<br />

of performance, low operating costs, rugged reliability and<br />

resale value unmatched by any other engine on the road today.<br />

ACERT technology is a complete engine approach that has all<br />

of the components working together to lower emissions and<br />

give owners what they need.<br />

Proven with B-Double, double and triple road trains, and heavy<br />

haulage, ACERT technology is fl exible in the way it can be used.<br />

Indeed there isn’t any need for a radical change in the way<br />

trucks are geared, typically just one diff ratio taller. As part of<br />

the systems approach to design that created ACERT technology,<br />

starting torque has been increased and so lift-off will always<br />

be perfect.<br />

A proud Cat advocate, Matt claims to bleed yellow blood and<br />

believes Cat engines are the best in the industry. The new<br />

prime mover has been aptly name “Heart of Gold” and sports<br />

the registration plate “ACERT” – certainly an indication of<br />

Matt’s passion for the Cat brand.<br />

Matt is a fi rm believer in reciprocal trade and NQHH has<br />

been a haulage supplier to <strong>Hastings</strong> <strong>Deering</strong> for many years.<br />

A signifi cant percentage of his work is derived from <strong>Hastings</strong><br />

<strong>Deering</strong> as he transports machines from the Archerfi eld site<br />

throughout the branch network in Queensland and the<br />

Northern Territory.

“I’ve always had great service from <strong>Hastings</strong> with the engine<br />

side of things,” said Matt, “And I’m proud of the service that<br />

I can provide for them in return.”<br />

North Queensland Heavy Haulage has a reputation within<br />

the transport industry of having exceptionally well presented<br />

���������������������������������<br />

CALL 131 228<br />

www.hastingsdeering.com.au<br />

“state-of-the-art” equipment operated by a dedicated team of<br />

operators. Driver Mark Stevens has been handed the reins to<br />

the new “Heart of Gold” which will no doubt turn some heads<br />

as it moves Caterpillar machines of all shapes and<br />

sizes throughout the country.<br />

INSIST ON THE BEST<br />

Caterpillar ® is the only original<br />

equipment manufacturer to design<br />

and produce their own line of filters<br />

and fluids<br />

Only Cat filters and fluids can offer the design<br />

specification required to meet factory<br />

�������������������<br />

������������������������<br />

����������������������������<br />

����������������������<br />

Using genuine Cat fluids and filters results in:<br />

�����������������������<br />

��������������������<br />

������������������������������<br />

11

12<br />

BRANCH EXPANSIONS<br />

SET THE PACE FOR GROWTH<br />

MACKAY<br />

The construction of the new <strong>Hastings</strong> Park facility in Mackay<br />

is well underway and is set to fulfi ll its design promise of being<br />

an environmentally friendly complex combining space and<br />

modern architecture.<br />

Mackay’s new facility is being built on an 8.2 hectare site in<br />

the new FKP Industroplex Estate adjacent to the Bruce Highway.<br />

Group Facilities Manager, Cliff Melvin managed the <strong>Hastings</strong><br />

<strong>Deering</strong> input and cooperation with consultancy fi rm G<strong>HD</strong>,<br />

to design and document the facility before going to tender for<br />

Stage 1 in June 2007. FK Gardner and Sons was successful<br />

in winning the tender and commenced construction work in<br />

August 2007.<br />

Stage 1 is scheduled for completion in July 2008 and includes<br />

the mining and construction workshop with an attached service<br />

administration, a workshop oil store, general maintenance shed,<br />

machine wash facility and the utility building housing a track<br />

repair bay, idler and A.R.M. bays, a general fabrication shop and<br />

sandblast and paint booths.<br />

The design focused on a number of key aspects, including<br />

master-planning the site to gain optimum land usage for<br />

current and future growth. The layout was developed to provide<br />

functional relationships and traffi c fl ows between operational<br />

areas on the site. It incorporated effi cient traffi c separation<br />

through segregated entries at the north and east for public and<br />

heavy traffi c respectively. In addition, the latest technologies in<br />

water recycling systems to the wash bay areas and rainwater<br />

harvesting components were adopted and signifi cant storm<br />

water quality controls through on-site bio retention systems<br />

were incorporated to minimise environmental impacts.<br />

Area Manager Darren Woodward said the new site at <strong>Hastings</strong><br />

Park would supply the much needed work premises for <strong>Hastings</strong><br />

<strong>Deering</strong> to service customers in the area.<br />

“Mackay city is experiencing rapid growth not only due to<br />

increased mining activity but also general construction,”<br />

he said, “It’s really going ahead and we needed suffi cient<br />

space to accommodate our growing operations and give<br />

customers the service they expect from us.”

Stage 2 is scheduled to start in July and be completed by<br />

February 2009 and is to include the main administration<br />

building, the parts warehouse and the balance of the civil works.<br />

MT ISA<br />

FK Gardner and Sons was also successful in winning the Mt Isa<br />

branch expansion project which is well underway in the North<br />

Queensland mining hub. Stage 1 includes a new fabrication<br />

and warranty parts storage shed located to the north of the<br />

existing main workshop. Upgrading of the capacity of fi re<br />

hydrant mains, drainage and the electrical supply has also been<br />

included, facilitating further expansion potential in the future.<br />

The proposed stage 2 of the project is to extend the new<br />

workshop by a further two bays resulting in a workshop with<br />

far greater capacity in an ever growing mining industry. A new<br />

amenities building is also proposed in the Stage 2 development.<br />

Branch Manager Andrew Revell said the expansion is<br />

necessary as the branch has outgrown the current facility<br />

due to signifi cant growth in mining and associated activity in<br />

the region. “The new workshop will improve job effi ciency,<br />

job quality, contamination control, safety and working<br />

conditions for our staff,” he said, “These are all of core<br />

importance in day to day operations.”<br />

Further branch expansions and upgrades within the <strong>Hastings</strong><br />

<strong>Deering</strong> branch network just completed or in progress include:<br />

Townsville – Stage 1 – Warehouse extension including<br />

hose shop, car park and hydrant upgrade just completed and<br />

the Stage 2 works of a workshop and car park extension<br />

about to begin.<br />

Toowoomba – Stage 1 – Warehouse and hose shop<br />

completed, Stage 2 – Consisting of a central amenities and<br />

lunch room just completed with a offi ce refurbishment as<br />

Stage 3 starting mid July 2008.<br />

Hutchisons was successful in winning the tender to construct<br />

the new parts reception and warehouse at the Toowoomba<br />

branch which was opened in late 2007. Toowoomba Branch<br />

Manager Greg Arthy said the expansion has helped boost<br />

business for the branch insofar that the increased fl oor space<br />

can accommodate more line items for customers.<br />

“The expansion has made things much easier for the branch<br />

and will be great in supporting our existing business in<br />

Toowoomba,” he said.<br />

13

14<br />

FIRST M SERIES<br />

MOTOR GRADER FOR THE<br />

NORTHERN TERRITORY<br />

Sixty-one years after Harold <strong>Hastings</strong> <strong>Deering</strong> obtained the Caterpillar ® agency in Alice Springs, his<br />

legacy in the Northern Territory continues with the very fi rst sale of the revolutionary<br />

M Series 140M motor grader into the Territory.<br />

Established in November 1998, Gilbert Earthmoving Pty Ltd<br />

took delivery in March of the new grader. The company has not<br />

wasted any time in putting it straight to work in arguably one of<br />

the toughest environments in the world, the Tanami Desert.<br />

With an ever growing fl eet of equipment including a D6R, 950G,<br />

CS563E, PS300C, six prime movers, (three with Cat C15 engines),<br />

water tankers, a 140G, 140H and now the new 140M, Gilbert<br />

Earthmoving are leading the way in grader technology in the<br />

Northern Territory. Interestingly, the delivery of the new machine<br />

was also a unique opportunity to view the evolutionary changes<br />

of the 140 type motor grader.<br />

Primarily involved in the civil construction, earthworks and<br />

transportation industries, Director of Gilbert Earthmoving, Paul<br />

Gilbert is a staunch supporter of Caterpillar equipment and in<br />

particular, the M Series graders.<br />

“The new grader is a very valuable addition to our fl eet,” he said.<br />

“Currently the grader is allocated to the Tanami Road upgrade in<br />

some of the toughest environment in Australia. It will most<br />

defi nitely be involved in any associated works in the future<br />

where fi nal trimming is required.”<br />

Working in some of the most remote parts of Australia has<br />

made Paul Gilbert’s decision in choosing Caterpillar products<br />

easy. “Gilbert Earthmoving has expanded over the last ten years,<br />

and amongst our extensive fl eet, most of our machines are Cat.<br />

I have found that the Cat machines have superior reliability and<br />

performance, and I have a good rapport with my rep, Brett Lenz<br />

which helps.”<br />

The ability to keep his fl eet moving is a key factor when<br />

the conditions are as tough as they are in the red centre.<br />

“Due to our remoteness, we have purchased Cat for the<br />

excellent backup parts and service we get from<br />

<strong>Hastings</strong> <strong>Deering</strong>. I am so impressed by the 140M that<br />

I have already placed an order for my second one.”

OPERATOR TRAINERS<br />

UP TO THE CHALLENGE<br />

Recently, the <strong>Hastings</strong> <strong>Deering</strong> Institute of Training hosted the Australasian Caterpillar dealers’<br />

operator trainers for the Cat ® <strong>Dealer</strong> Instructor Challenge. The challenge is an initiative held<br />

annually by Caterpillar to assess the competence of dealer operators in the areas of skill,<br />

application, current knowledge and training delivery techniques.<br />

A Caterpillar Trainer challenges each participating<br />

operator to deliver at a benchmark level which equates to world<br />

best practice in each of the key areas.<br />

Successful participants are awarded the title of<br />

Certifi ed <strong>Dealer</strong> Instructor and qualify to deliver the Caterpillar<br />

Curriculum Operator Training courses from<br />

the US based Equipment Training Solutions.<br />

When asked the reasons for participation in the<br />

challenge and the benefi ts of attending, <strong>HD</strong>IT Training and<br />

Development Manager Mark Duffi e said,<br />

“<strong>Hastings</strong> <strong>Deering</strong> Operators participate in the challenge<br />

primarily to pass and know they are at the top of their game.”<br />

“As a business we support the challenge as a continuous<br />

improvement process.”<br />

“Trainers must continue to deliver Cat curriculum<br />

courses and attend new product training each year<br />

to keep up to date and maintain the Cat <strong>Dealer</strong><br />

Instructor accreditation.”<br />

“Customers can be assured they are getting the<br />

best available training in the industry,” said Mark,<br />

“It’s a combination of the latest happening around the world<br />

along with tried and true techniques that work.”<br />

All of <strong>Hastings</strong> <strong>Deering</strong> trainers passed the Cat <strong>Dealer</strong><br />

Instructor Challenge.<br />

15

16<br />

CAT FORKLIFTS A POSITIVE<br />

STEP FOR SUCCESS<br />

Landsborough based Transportable Shade Sheds has had such success in its short history<br />

that the business has spawned an additional company – Oz Future Fuels – and prospects<br />

have never been better for both companies.<br />

Established in 2001, Transportable Shade Sheds sells large<br />

shade sheds for workshop areas and machinery cover to<br />

many mines and councils throughout Australia. In addition,<br />

the company manufactures a range of environmental storage<br />

sheds for chemicals, acids, fl ammables and lube/waste oil.<br />

The success of the waste oil storage shed arm of the business<br />

with councils and mining companies nationally led to the<br />

development of Oz Future Fuels, an offshoot company which<br />

reduces mining sites’ waste oil stockpiles through recovery,<br />

re-use and recycling.<br />

Allan Lear is the Director of both Transportable Shade Sheds<br />

and Oz Future Fuels and said the companies provide a well<br />

committed service with strong environmental advantages<br />

particularly to the niche customers of Oz Future Fuels.<br />

<strong>Hastings</strong> <strong>Deering</strong> has supplied forklift machinery for the<br />

companies since inception with Transportable Shade Sheds<br />

recently taking delivery of a new DP30N. Equipped with<br />

Caterpillar’s new ‘presence detection system,’ the new machine<br />

is part of the N Series of forklifts which set the new industry<br />

standard for reliability, operator productivity and safety.<br />

“We have purchased a number of forklifts from<br />

<strong>Hastings</strong> <strong>Deering</strong>,” said Allan, “The equipment is reliable<br />

and the back up service is great.”<br />

Oz Future Fuels took out the Environmental Innovation Award<br />

at the 2007 Excellence in Business Awards for the Sunshine<br />

Coast. With 350 councils using their waste oil collection<br />

facilities around Australia, the company is keen to further<br />

expand their oil collection and recycling in the mining industry.<br />

Onsite re-use of recycled waste products including waste<br />

engine oil, black jack and oily water provides signifi cant<br />

fi nancial savings and future carbon credits for<br />

mining companies.<br />

Waste oil recycling and environmental fuel technology<br />

focusing on innovation has been a very expensive business<br />

to set up due to infrastructure costs and the public education<br />

process necessary to encourage reduce, recycle, re-use and<br />

renewable energy consumption said Mr Lear.<br />

“Mines, trucking companies and councils have embraced many<br />

technologies for onsite full cycle management of oil products<br />

with advantages both economically and environmentally”,<br />

he said.<br />

Caterpillar ® forklifts are adaptable performers for Transportable<br />

Shade Sheds and Oz Future Fuels and given the resounding<br />

success of both companies, this collaboration looks set to<br />

continue into the future.

MACHINE SECURITY<br />

A STEP AHEAD<br />

<strong>Hastings</strong> <strong>Deering</strong> is leading the way in addressing machine theft and the associated costs by<br />

introducing DataDotDNA Technology to the heavy industry sector. From August, all new machines will<br />

incorporate the innovative “VIN Dot” spray application in what is a fi rst for Australian Cat ® dealers.<br />

The “VIN Dot” spray technology has been described as<br />

“world’s best practice for vehicle identifi cation” and has been<br />

introduced as a standard security feature for manufacturers/<br />

distributors including Porsche, BMW, Subaru and Ford<br />

Performance Vehicles. More than 500,000 Australian vehicles<br />

are now protected by DataDotDNA. Once applied, the clear<br />

lacquer contains the unique vehicle identifi ers which are invisible<br />

to the naked eye, demonstrating the system which has<br />

revolutionised attitudes on security marking.<br />

Construction Sales Manager Bruce Becker said the technology<br />

adds value for customers and will be available on attachments<br />

and new machines.<br />

“Although not a big issue in the heavy industry sector yet,<br />

stealing and rebirthing is a big concern in the motor industry<br />

and with the introduction of DataDotDNA technology, police<br />

have been more successful with the recovery and identifi cation<br />

of stolen vehicles,” he said.<br />

“We are future proofi ng. Each machine fi tted with DataDotDNA<br />

will be listed on police fi les so enabling identifi cation through<br />

analysis more easily when recovered from a theft.”<br />

Actual Size (1mm)<br />

Mr Becker said the spray is applied on machines in areas that<br />

make it impossible for removal even through sand blasting or<br />

pressure cleaning.<br />

“There is a problem in this industry with theft of smaller<br />

machines and machine attachments,” he said,<br />

“Using DataDotDNA on machines and tools will make it easy for<br />

parts to be recovered and tracked back to the original machine.”<br />

Mr Becker said industry groups Civil Contractors Federation<br />

(CCF) and the Construction and Mining Equipment Industry Group<br />

(CMEIG) as well as police departments Australia wide, have<br />

backed having DataDotDNA fi tted to heavy industry machines<br />

due to the increased incidence of theft across the industry.<br />

<strong>Hastings</strong> <strong>Deering</strong> has become the industry benchmark for this<br />

initiative to be followed throughout Australia and anticipates<br />

the technology will go a long way to assisting customers in<br />

protecting their equipment.<br />

Magnifi ed DataDotDNA<br />

17

18<br />

NEWS FROM THE CAT RENTAL STORE<br />

Established in 1942, Golding Contractors is one of<br />

Queensland’s oldest and largest privately owned<br />

companies, with fi ve offi ces and a workforce of some<br />

1,800 people across the State. Golding has extensive<br />

experience in providing all aspects of open-cut mining<br />

and civil works services to clients throughout Australia<br />

and most recently was responsible for undertaking the<br />

earthworks and civil construction for the second stage<br />

of the Yarwun Alumina Refi nery (formerly known as the<br />

Comalco Alumina Refi nery) as a joint venture partner<br />

for Rio Tinto.<br />

Located 10 kilometres north-west of Gladstone, the<br />

Yarwun Stage 2 project consists of excavating two million<br />

cubic metres of cut to fi ll. The magnitude of the project<br />

called for reliable equipment that could manage the bulk<br />

earthworks jobs with ease. The automatic choice for<br />

Golding Contractors was Caterpillar. The Cat Rental Store ®<br />

assisted by providing machinery of various size and types<br />

and currently Golding is operating over 90 pieces of plant<br />

on site, the majority of which were supplied by Cat Rental.<br />

“We have found Cat Rental rates beat nearly any other<br />

competitor and their plant is generally the most recent<br />

models,” said Golding Contractors Project Engineer<br />

Andrew Strachan.<br />

“Combine this with their friendly service and expedient<br />

back up service and I’d say they are unbeatable.”<br />

Mr Strachan said Golding Contractors has been happy to<br />

deal with The Cat Rental Store on the Yarwun Alumina<br />

Refi nery project and will continue to use Caterpillar<br />

equipment for the 3 year term of the massive project.<br />

Congratulations to the Cat Rental team in Gladstone for<br />

reaching a fl eet total in excess of 120 machines. Under<br />

the leadership of Greg McIntosh and with the support of<br />

the Rockhampton branch’s service department, the store<br />

has grown from a fl eet of fi ve machines in 2005 to the<br />

present day fi gure.<br />

BRIEF<br />

In response to demand for the innovative joystick<br />

technology of the M Series motor graders,<br />

The Cat Rental Store has added eight of the new<br />

machines to the rental range.

Unit CRS1000 rolled off the rental assembly line and on hand to receive the new unit from equipment assembly were from<br />

left Manager-Cat Rental Services Reg Knowles, Group Marketing Manager David Hotham, <strong>Hastings</strong> <strong>Deering</strong> Managing<br />

Director Scott Cameron and Used Equipment Manager Matt Long. The milestone machine, a Cat 966H was commissioned<br />

by Cemex Australia to work on a site in Townsville.<br />

BRIEF<br />

SAFElink Alliance Human Resource and Performance<br />

Manager Dallas Knight recently accepted three<br />

trophies for safety, performance and innovation<br />

from The Cat Rental Store. The SAFElink Alliance<br />

is a joint venture between Leighton Contractors<br />

Pictured with Geoff (left) is<br />

Townsville Area Manager John Ritchie.<br />

and BMD Constructions who are working on the<br />

government funded Ipswich Motorway Upgrade.<br />

The alliance has approximately 30 machines on hire<br />

from The Cat Rental Store and utilises Cat machinery<br />

from subcontractors and the Leighton fl eet.<br />

Geoff Ronalds was recently appointed Rental<br />

Account Manager for The Cat Rental Store in Townsville.<br />

Geoff made the move to North Queensland in March after<br />

spending four years in Brisbane in Rental Coordinator and<br />

Rental Administration Supervisor roles. Covering the rental<br />

market from Townsville to Mt Isa, Geoff is heading an<br />

aggressive growth campaign in the region which aims<br />

to have in excess of 100 machines in the fl eet by the<br />

end of 2008.<br />

19

20<br />

CAT FORKLIFTS DELIVER<br />

FOR THE LAMINEX GROUP<br />

The Laminex Group is Australia’s leading marketer, distributor and manufacturer of premium<br />

decorative surfaces including laminates, solid surfaces, stone decorative panels, timber veneers<br />

and locally produced raw wood panels. The company has an extensive national distribution<br />

network in Australia with dedicated distribution centres that specialise in customer service and<br />

design selection, and over 8,000 marketing and information display centres in independent outlets.<br />

The Queensland head offi ce and distribution centre in Murarrie<br />

spans 24,500 square metres and approximately 150 tonnes of<br />

material is moved in and out of this site across two shifts each<br />

day. Such demand requires dependable equipment which can<br />

withstand constant operation and Caterpillar ® equipment was<br />

the company’s fi rst choice.<br />

State Operations and Services Manager Mr Jeff Willis said<br />

The Laminex Group chose to operate Cat forklifts for their solid<br />

build, excellent engine, their reliability and the after sales<br />

service from <strong>Hastings</strong> <strong>Deering</strong>.<br />

“Cat forks are very reliable and rarely let us down,” said<br />

Mr Willis, “Our operators often comment on the ease of<br />

operation and the cabin comfort levels.”<br />

The distribution centre operates seven Cat forklifts in total<br />

– four GPE 35 models, two GP 40 models, and one GP 45<br />

model. Six GPE 35 forklifts operate elsewhere in the company’s<br />

Queensland branch network. Each machine is customised to<br />

best suit The Laminex Group’s needs with 5.5m two stage<br />

masts and the allowance for wide carriage fi tment.<br />

As with any successful business, The Laminex Group’s<br />

products are in high demand and move quickly from the<br />

distribution centres to statewide branches and customer<br />

factories. Safety is paramount in the company’s daily<br />

operations and the range of safety features incorporated in<br />

the Cat forklifts has been impressive.<br />

“The forklifts allow plenty of room for fi tment of aftermarket<br />

devices such as mast leveling gauges, fi re extinguishers and<br />

analogue weight gauges,” said Jeff, “<strong>Hastings</strong> <strong>Deering</strong> has<br />

also customised our forks with painted counterweights,<br />

hi-viz tape on the mast and rear and fl uoro seatbelts.”<br />

<strong>Hastings</strong> <strong>Deering</strong> is on hand for The Laminex Group to supply<br />

any new machine requirements in addition to product, parts<br />

and service support.<br />

“<strong>Hastings</strong> <strong>Deering</strong> is very easy to deal with,” said Mr Willis,<br />

“They listen to our needs and can organise any additional<br />

fi tments we require prior to delivery.”<br />

“All in all, the combination of Caterpillar forklifts coupled with<br />

the excellent before and after sales service of <strong>Hastings</strong> <strong>Deering</strong><br />

provides us with a very price competitive package.”<br />

After successfully leading the rationalisation and integration<br />

of the decorative surfaces and wood panels industry,<br />

The Laminex Group is well positioned as the market leader<br />

with strong earnings and a solid platform for growth. Together<br />

with Caterpillar forklifts and <strong>Hastings</strong> <strong>Deering</strong>, the company’s<br />

high standard in the building industry is only set to lift.

D SERIES SMALL<br />

HYDRAULIC EXCAVATORS<br />

Forged from genuine Caterpillar quality comes a new generation of small hydraulic excavators.<br />

Strong growth in the small hydraulic excavator market over<br />

the last couple of years has set the path for the introduction<br />

of Caterpillar’s new line up of D Series machines. Built on<br />

the strong reputation of the C Series , the new range of<br />

machines offers world-class performance with increased<br />

digging forces, improved fuel effi ciency, enhanced lifting<br />

capability, exceptional controllability and industry-leading<br />

cycle times.<br />

The new D Series range is second to none and includes six<br />

distinct models between 7.5 and 17.5 tonne operating weight.<br />

Each model offers the design and build forged from genuine<br />

Caterpillar quality providing superior performance and<br />

versatility in every earthmoving application.<br />

For more informatioin on the new D Series, call<br />

<strong>Hastings</strong> <strong>Deering</strong> on 131 228.<br />

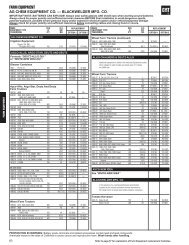

D SERIES SMALL HYDRAULIC EXCAVATOR SPECS<br />

307D 308D CR 311D LRR 312D 314D CR 315D L<br />

Engine Mitsubishi 4M40-TL Mitsubishi 4M40-TL Cat C4.2 ACERT Cat C4.2 ACERT Cat C4.2 ACERT Cat C4.2 ACERT<br />

Net Engine Power 40 kW / 54 hp 41.5 kW / 56.5 hp 60 kW / 80 hp 67 kW / 90 hp 86 kw / 115 hp<br />

Machine Arrangement<br />

Body Conventional Compact Radius Reduced Radius Conventional Compact Radius Conventional<br />

Undercarriage Standard Standard Long Standard or Long Standard or Long Long<br />

Drive Train<br />

Blade Blade Blade Blade Blade Blade<br />

Travel Speed - High - km/h 5 5 5.1 5.5 5.5 5.6<br />

Gradeability (max) - degrees 35 35 35 35 35 35<br />

Hydraulics<br />

Auxillary Circuit - Primary L/min 128 128 117 127 122 150<br />

Auxillary Circuit - Secondary L/min 64 64 58.5 63.5 61 75<br />

Digging Force - Stick std - kN 36 39 55 66 65 80<br />

Digging Force - Bucket - kN 49 60 90 96 88 114<br />

Weights & Dimensions *<br />

Operating weight - kg 7560 8930 12610 13060 14550 17345<br />

Machine width - mm 2290 2320 2490 2490 2490 2490<br />

Maximum Reach at ground level - mm 6150 6900 7900 8170 8630 8750<br />

Maximum Dig Depth - mm 4050 4180 5390 5540 5490 6070<br />

Track width - mm 450 450 500 500 500 500<br />

* Operating weight calculated with steel tracks, bucket, operator, full fuel tank and auxillary lines.<br />

* Weight is subject to machine confi guration<br />

* Reach and dig depth specifi cations exclude quick hitch attachment<br />

21

22<br />

UNDERSTANDING<br />

S∙O∙S ANALYSIS AND<br />

ELEMENTAL ANALYSIS<br />

SM<br />

<strong>Hastings</strong> <strong>Deering</strong> operates one of Queensland’s largest and most specialised oil<br />

sampling laboratory. We know that maintaining your equipment is one of your top priorities.<br />

Industry experience shows that the one of the simplest and most inexpensive ways to<br />

minimise costly repairs and downtime and maximise equipment life is to regularly sample<br />

and test the fl uids that are the lifeblood of your equipment.

Oil analysis and elemental analysis consists of a series of<br />

tests that give a report on a machine’s oil condition and<br />

any contaminates in the oil.<br />

Oil Analysis<br />

As oil condition can be used to rate a machine’s compartment<br />

health, <strong>Hastings</strong> <strong>Deering</strong> conducts tests which are performed<br />

to monitor machine lubricant conditions and contaminates.<br />

Infra Red Spectroscopy (IR) – (Monitors oil degradation)<br />

Soot (St) – a by product of combustion, high soot result<br />

indicates problems with air induction or fuel system.<br />

This is used only on engines.<br />

Oxidation (O) – effected by overheating and blowby, causes<br />

and promotes sludges and varnishes which in turn affect<br />

lubricants performance.<br />

Sulphation (S) – monitors sulphur products which may cause<br />

corrosion to bearings and internal parts related to sulphur<br />

content in diesel fuel. This is used only on engines.<br />

Nitration (N) – monitoring nitrates which can be affected by<br />

extended oil change periods and excessive aeration of the oil.<br />

Viscosity – (Monitors fl uids’ internal friction)<br />

A Viscosity test will:<br />

Ensure correct oil type is used to service the compartment<br />

and identify possible compartment oil transfer (ie example<br />

Hydraulic oil to transmission compartment via a damaged<br />

hydraulic pump shaft seal).<br />

Identify viscosity of oil in a compartment.<br />

Elemental Analysis<br />

Elemental Analysis monitors contamination and gives a<br />

report on wear metals & additive concentrations.<br />

The instrument known as ICP-OES (Inductively Coupled<br />

Plasma Optical Emission Spectrometer) is used to conduct an<br />

elemental analysis test which is used to monitor wear metals<br />

that include copper, iron, chrome, lead, aluminium, silicon, tin<br />

and nickel. The metals are mixed into a variety of combinations<br />

called alloys which are then used to build components found in<br />

Caterpillar ® equipment.<br />

Additive package that includes calcium, zinc, magnesium,<br />

phosphorous, molybdenum.<br />

Dirt and coolant contamination includes aluminium, silicon,<br />

sodium, potassium.<br />

Different combinations of these wear metals can identify wear<br />

of certain parts or contamination in a compartment.<br />

Particle Counting – monitors fl uid cleanliness.<br />

A particle counting test counts the number of particles in<br />

certain size ranges (6 and 14 micron) in one millilitre of fl uid.<br />

These results are compared to Caterpillar’s recommended<br />

cleanliness code limits (ISO4406).<br />

Physical tests are used to monitor:<br />

Water within the oil (reports from 0.1% to > 5%)<br />

Fuel dilution in diesel engines only (reports greater than 3%)<br />

Visual deposits – viewed under a magnifying glass to identify<br />

visual debris (ie visible dirt or magnetic debris)<br />

PQ (Particle Quantifying) Index – reports rerrous debris<br />

23

24<br />

THE GRADER ESCAPE<br />

THE M SERIES ROADSHOW<br />

November 2007 saw <strong>Hastings</strong> <strong>Deering</strong> embark on the biggest product launch since introduction<br />

of the G Series grader range in the mid 70s. The reason? The new M Series range of graders<br />

had arrived in Australia and was set to make an unprecedented impression on the road building<br />

industry. For two months, a dedicated team of Hasting <strong>Deering</strong> staff travelled throughout<br />

Queensland in a custom fi tted exhibition truck. Along for the ride were the revolutionary<br />

new 140M motor grader and two grader simulators to give visitors a feel for the new<br />

joystick control technology.<br />

Toowoomba, the gateway to the to the Darling Downs and<br />

Western Queensland – was the fi rst stop for the troupe and<br />

the city showgrounds housed the initial unveiling of the<br />

machine to a host of customers from the greater Toowoomba<br />

region. Many had heard about the new motor grader<br />

revolutionary controls from magazine articles, direct mail<br />

information or from visiting the dedicated Cat ® M Series<br />

website. However, very few were aware of the many other<br />

major changes built into the new line-up of machines.<br />

The most obvious change was the new cab with unprecedented<br />

blade visibility. Other changes included the ACERT TM Engine<br />

with variable horse power in every gear, componentised<br />

differential assembly, top adjusting circle wear inserts,<br />

adjustable top blade slide shoes, relocated hydraulic pump,<br />

all new 416 litre ground refuelling fuel tank and hydraulic<br />

service brakes.<br />

“We had been eagerly anticipating the arrival of the new<br />

M Series machines and on seeing them in the iron, we were<br />

even more impressed at the improvements Cat had built in,”<br />

said Government and Local Government Sales Manager<br />

Mark Courtenay.<br />

The fi rst leg of the roadshow continued west to the commercial<br />

hub of Goondiwindi, the township of St George and onto the<br />

centres of Roma and Charleville. The Western region’s rivers,<br />

gardens and historical attractions provided a striking backdrop<br />

for the distinctive Caterpillar yellow of the 140M as it wound its<br />

way north to the state’s central highlands region. Covering a<br />

further 1,500 kilometres of territory, the roadshow passed<br />

through Blackall, Springsure, Emerald, Clermont, Barcaldine,<br />

Longreach and Winton taking in the area’s diverse agriculture,<br />

spectacular national parks, sweeping plains and some of<br />

Queensland’s oldest and newest towns.

The grader then headed north-west toward the heart of<br />

Queensland visiting Boulia, Mt Isa and Cloncurry. The region’s<br />

scorching conditions did nothing to stop the progress of the<br />

roadshow as the team crossed the arid landscape stopping next<br />

in Richmond, a township which rests on Queenslands longest<br />

river, the Flinders. Richmond Shire Council had been operating<br />

a fl eet of 12 Caterpillar machines to maintain the network of<br />

outback roads in the region and was particularly impressed<br />

with the revolutionary new M Series. Following the completion<br />

of the roadshow, the council voted to purchase two new 140M<br />

machines which very quickly became welcome additions to the<br />

grader fl eet.<br />

As it weaved its way towards the North Queensland coast,<br />

the M Series roadshow stopped by Julia Creek, Normanton,<br />

Croydon and Georgetown before touching down in the tourist<br />

mecca of Cairns. The roadshow team took some much needed<br />

R&R at this point taking in the regions secluded beaches,<br />

lush rainforests and unique wildlife. Not to be stopped short<br />

however, the roadshow soon continued again with<br />

renewed energy.<br />

After stopping in Cooktown, Atherton and Tully, the journey<br />

continued south along the coast stopping in Townsville and the<br />

centres of Charters Towers and Hughendon before reaching<br />

the Mackay region. Visitors from the greater Mackay region<br />

converged on the city’s showgrounds to see the new machine<br />

and experience the innovative new operating system.<br />

“We were taken by the enthusiasm of operators both young<br />

and old who adapted to the new control system in only<br />

minutes,” said Mark, “Having two simulators made for<br />

some interesting competition between operators.”<br />

The roadshow continued its homebound journey passing<br />

through Rockhampton, Bundaberg, Hervey Bay, Gympie and<br />

the Sunshine Coast before making the fi nal stop at Caboolture<br />

where visitors from Brisbane’s north and the surrounds took the<br />

opportunity to see the machine. The roadshow culminated with<br />

a cruise down the Brisbane River on the prestigious MiCat in<br />

late February. Current grader owners were invited aboard the<br />

catamaran which held two graders, the grader simulators and<br />

various other new Cat machines.<br />

Over the two month period, the M Series roadshow covered<br />

in excess of 10,000 kilometres throughout Queensland.<br />

Almost 2,000 operators and workshop staff across 42 towns<br />

state wide inspected the new 140M and tried their hand at<br />

the simulators.<br />

In the uncompromising world of machine quality and<br />

performance, Cat motor graders have established a superior<br />

worldwide legacy of leadership since 1928. Supplying the right<br />

solution to meet your needs and providing a return on your<br />

investment have been the keys to Caterpillar’s success.<br />

The new M Series represents a revolution in operational<br />

effi ciency, visibility, service ease and overall productivity,<br />

while continuing the legacy of high quality you can trust.<br />

This revolutionary motor grader sets the new standard for<br />

design innovation, leveraging superior technology across the<br />

entire machine.<br />

Developed through extensive customer input and fi eld testing,<br />

Cat M Series motor graders deliver absolute value in all the<br />

areas of your business that matter the most: effi ciency,<br />

productivity, quality and safety.<br />

132 <strong>Hastings</strong> <strong>Deering</strong> customers received M Series<br />

thermos fl asks as prizes after successfully answering<br />

quiz questions correctly. Customers were invited to visit the<br />

www.catmseries.com web site and participate in an online quiz.<br />

Almost 60% of the Australian prize winners came from<br />

Queensland. The promotion was a fantastic success with<br />

over 7,000 people visiting the M Series web site during the<br />

competition. Congratulations to all our winners.<br />

25

26<br />

LEADING THE WAY IN<br />

CATERPILLAR ADVANCED<br />

SURFACE TECHNOLOGY<br />

<strong>Hastings</strong> <strong>Deering</strong> is leading the way with new Caterpillar ® component reclamation technology.<br />

Caterpillar Advanced Surface Technology (CAST ® ) utilises high velocity oxygen fuel (HVOF)<br />

technology and patented Caterpillar composite materials to achieve a highly dense,<br />

mechanically bonded and hardened surface used in hydraulic component reclamation.

The CAST process utilises various combinations of<br />

nickel chromium and tungsten carbide to achieve specifi c<br />

performance parameters determined by the environment in<br />

which the components are working. “This allows customers<br />

to customise their component reclamation to achieve<br />

maximum wear and performance characteristics dependent<br />

on the specifi c site environment and conditions,” said<br />

<strong>Hastings</strong> <strong>Deering</strong> Hydraulics Marketing Specialist<br />

Luke Sexton.<br />

How Caterpillar Advanced Surface<br />

Technology works:<br />

The rod or component undergoes salvage and is straightened<br />

if required. New and salvaged rods are then profi le blasted to<br />

remove the outer coating of the rod. This prepares the surface<br />

for the CAST process which requires a rough or aggregated<br />

surface to ensure a strong bond to the parent material. Once<br />

the rod is prepared, the process begins. Using the applicator,<br />

combustible gases are heated to near 5,000 deg F (2,760 deg C).<br />

At this temperature, fi ne metal particles are merged and<br />

accelerated through the nozzle at more than three times the<br />

speed of sound. This process creates the mechanical bond that<br />

melds the two surfaces together creating a coating up to three<br />

times stronger than chrome. Upon completion, the rough surface<br />

is ground down to “like new” factory specifi cations.<br />

The rod is then polished to create a chrome like fi nish.<br />

Features of CAST:<br />

• High and controlled coating density<br />

• Ultra high bond strength with parent materials<br />

• High and controlled coating hardness<br />

• Coating thickness exceeds 12mm<br />

• Chrome like smooth surface fi nish<br />

• Non porous surface fi nish<br />

CAST Benefi ts:<br />

Extended component life<br />

From fi eld and laboratory tests, it has been demonstrated<br />

that CAST can extend component life by up to three times<br />

that of chrome<br />

Extended seal life<br />

Lab test using Cat seals and CAST resurfaced rods last<br />

up to 50% longer<br />

Quick repair turn around (one quarter the time it takes<br />

to chrome)<br />

Superior wear characteristics<br />

Because the alloy created by CAST is harder than chrome,<br />

it prevents greater resistance to scratching, pitting,<br />

dinting, and scoring<br />

Environmentally friendly<br />

CAST by-products (over spray) can be reused and there are no<br />

dangerous chemicals as with hard chroming<br />

Not only for hydraulic cylinder rods, CAST can be used to<br />

reclaim anything cylindrical e.g.:<br />

Wheel Ends<br />

Gears<br />

Spindles<br />

<strong>Hastings</strong> <strong>Deering</strong> CAST capabilities include:<br />

• Two remotely operated robotic CAST spray guns<br />

• Tandem spray mounts which double production capabilities<br />

• Custom built spray and profi le blast facility<br />

(ensures quality for coatings)<br />

• 24 / 7 production<br />

• Contamination controlled work environments<br />

27

28<br />

NEW ROLLER LINE-UP<br />

BUILT TO WORK<br />

Since the introduction of vibrating self propelled rollers into the Cat ® product line-up over<br />

13 years ago, the machines have developed a reputation on job sites synonymous with the<br />

Caterpillar brand. The new production line-up of vibratory soil compactors features the<br />

same industry-proven productivity and reliability that have made the E Series the preferred<br />

choice for earthmoving contractors. The operating weights range from 10.5 - 15.8 tonnes.<br />

There are many new features that make the production-class<br />

soil compactors more productive, comfortable, and simple to<br />

service. One of the most noticeable cosmetic changes is the<br />

updated model numbers and the new machine decals. Other<br />

changes include improved productivity and reliability. The class<br />

contains new engines that offer better serviceability, better<br />

reliability and less noise.<br />

SMOOTH DRUM<br />

ROLLER MODELS<br />

There are a number of optional extras available for the new<br />

class of machines including AccuGrade® compaction,<br />

an intelligent compaction solution that correlates compaction<br />

measurements with GPS positions to create detailed<br />

compaction maps of the work area.<br />

OLD MODEL NEW MODEL<br />

CS563E CS56<br />

CS573E CS64<br />

CS583E CS74<br />

CS663E CS76<br />

CS683E CS76 XT

Engine – The new production-class compactors are equipped<br />

with a six cylinder Cat C6.6 engine with ACERT TM Technology.<br />

The C6.6 engine provides 116kW (156hp) for the 56, 64, and 74<br />

models and 129kW (173hp) for the 76. All engines are rated at<br />

2,200rpm.<br />

The C6.6 offers enhanced durability and reliability compared<br />

to the 3056E. The engine block is thicker, many components<br />

feature more robust design than on previous engine designs,<br />

and the fuel system has been enhanced. The C6.6 provides<br />

more power for the 56, 64 and 74 models. The engines are<br />

also signifi cantly quieter, enhancing operator comfort.<br />

Propel System – High tractive effort, especially useful on<br />

steep slopes and loose underfoot conditions, helps increase<br />

production and expands the application range for the<br />

production-class machines. The propel system features a<br />

unique dual pump arrangement.<br />

The dual pumps provide required pressure and fl ow to the<br />

drum drive motor and axle-drive motor independently, so there<br />

is maximum torque and full-time tractive power to the drive<br />

motors regardless of footing or rolling resistance. Dual pumps<br />

also allow for excellent machine control on a grade in forward<br />

and reverse. A limited slip differential maximises rear wheel<br />

traction and is standard on all models.<br />

Vibratory System – One of the most signifi cant features of<br />

the production-class soil compactors is the unique pod-style<br />

vibratory system, which differentiates the machines from the<br />

competition. The drum contains two pod-style housings that<br />

enclose the patented eccentric weights.<br />

The pods have double shaft seals to help guard against<br />

contamination once installed. Because of the decreased risk of<br />

contamination and the use of synthetic oil, the change interval<br />

for the bearing lubrication is every three years or 3,000 hours,<br />

and no scheduled oil sampling is required. Should replacement<br />

be necessary, the pods can be quickly replaced to minimise<br />

downtime.<br />

Operator’s Station – The operator’s station offers superior<br />

comfort, visibility, and ease of operation. The operator station<br />

features a tilt steering column that can be moved to the desired<br />

position of the operator or out of the way for easy entrance<br />

and exit from the operator’s seat.<br />

A ROPS/FOPS canopy or a ROPS/FOPS cab is available.<br />

Machines equipped with a ROPS/FOPS canopy feature an<br />

operator’s platform enclosed by handrails with integrated<br />

angled foot rests. The footrests provide sure footing when<br />

operating on grades. The cab features more rear glass than<br />

previous designs, providing greater visibility to the tyre edge<br />

and the rear of the machine. The cab is radio ready and includes<br />

speakers, cable, mounting bracket, hardware, 24V/12V<br />

converter, a 12-Volt outlet and wiring. It does not include radio.<br />

Operator visibility to the rear of the machine is exceptional<br />

due to the hood design. The one-piece fi breglass hood provides<br />

excellent visibility from the operator’s station to the outside<br />

edge of the rear tyres and the rear of the machine. CS/CP56,<br />

64, 74, and 76 models feature an improved hood design with<br />

chamfered edges and reduced width. The rear bumper has been<br />

tucked in, providing better visibility to the rear of the machine.<br />

Engine airfl ow has been improved to prevent warm air from<br />

discharging on the operator’s station or towards the ground.<br />

This prevents operator discomfort and improves operator<br />

visibility by not contributing to the creation of dust clouds.<br />

Serviceability – The durable one-piece fi breglass hood tilts<br />

forward with the use of two sets gas charged struts located<br />

just inside the hood compartment. The hood can be locked<br />

when closed. Once the hood is opened, the entire engine<br />

compartment and cooling package is easily accessible.<br />

CS/CP56, 64, 74, and 76 models have a new fi breglass<br />

service panel that prevents debris from entering the engine<br />

bay but is easily removed to improve access to the engine.<br />

Other features that make servicing of these machines simple<br />

include O-ring face seal hydraulic fi ttings, grouped pressure<br />

test ports, S•O•S SM valves and remote grease points. Hydraulic<br />

hoses are held neatly in place with polyurethane routing blocks.<br />

The blocks separate hoses helping ensure that they do not rub<br />

on one another to provide long life and high reliability.<br />

The hitch features sealed-for-life bearings that never need<br />

greasing or maintenance. The steering cylinders feature<br />

remote grease fi ttings to simplify lubrication. The radiator is<br />

rear-mounted for easy access and service. The hydraulic oil<br />

cooler tilts for greater access to the radiator.<br />

All electrical wiring is colour-coded, numbered and labelled<br />

with component identifi ers to simplify troubleshooting.<br />

Nylon-braided wrap and all-weather connectors ensure<br />

high system reliability.<br />

29

30<br />

PARTS EXCHANGE<br />

AND REMAN OPTIONS<br />

<strong>Hastings</strong> <strong>Deering</strong> has continued to expand its offering of component repair options to<br />

better serve our customers needs. The following explains the general differences between<br />

the different ‘Repair, Exchange and New’ products offered by <strong>Hastings</strong> <strong>Deering</strong>.<br />

Repair: The component will be repaired by <strong>Hastings</strong> <strong>Deering</strong><br />

allowing the customer to keep their own iron and tailoring the<br />

repair to their needs and the <strong>Hastings</strong> <strong>Deering</strong> standard.<br />

The repair will be carried out on a time and material basis<br />

with the customer having the option to participate in determining<br />

the extent of the repair and parts replaced. Some component<br />

updates are at the customer’s discretion. The customer pays<br />

on a service department invoice at the conclusion of the<br />

component repair. This is a <strong>Hastings</strong> <strong>Deering</strong> <strong>Dealer</strong> Product.<br />

PEX: Parts Exchange Components were established to<br />