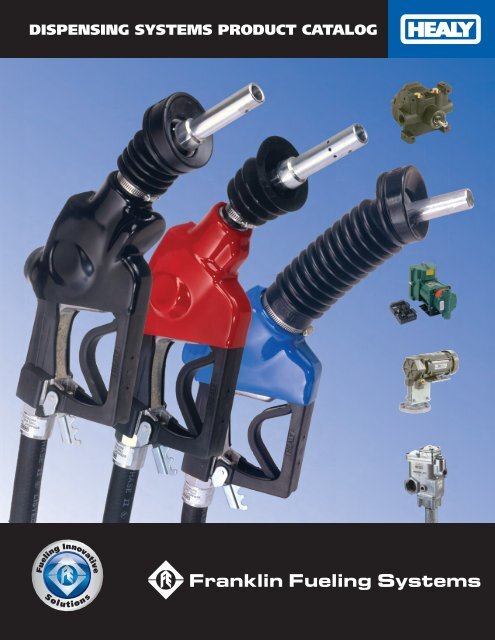

DISPENSING SYSTEMS PRODUCT CATALOG

DISPENSING SYSTEMS PRODUCT CATALOG

DISPENSING SYSTEMS PRODUCT CATALOG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>DISPENSING</strong> <strong>SYSTEMS</strong> <strong>PRODUCT</strong> <strong>CATALOG</strong><br />

Dispensing<br />

Systems

Dispensing<br />

Systems<br />

Model 900 Series<br />

EVR Nozzle<br />

— Enhanced Vapor<br />

Recovery Certifi ed<br />

Model 800 Series<br />

Onboard<br />

Refueling Vapor<br />

Recovery (ORVR)<br />

Nozzle<br />

Model 600 Series<br />

Bootless Nozzle<br />

Model 400 Series<br />

Onboard<br />

Refueling Vapor<br />

Recovery (ORVR)<br />

Nozzle<br />

ABOUT OUR <strong>PRODUCT</strong>S<br />

Franklin Fueling Systems designs, develops, manufactures and markets Healy Stage II<br />

Vapor Recovery Systems. Healy Stage II gasoline dispensing systems are designed<br />

and certifi ed to reduce vehicle refueling vapor emissions by a minimum of 95%.<br />

We provide the petroleum industry with leading edge Stage II technology that is<br />

cost-effective, reliable and compliant with all mandated domestic and international<br />

regulations. We constantly strive to improve our existing technology as well as<br />

develop new products and standards with an eye to the future of Stage II vapor<br />

recovery.<br />

Since 1983, when Healy Systems invented the world’s fi rst vacuum-assist vapor<br />

recovery system, our dispensing products have been in continuous service<br />

throughout the world. Since that time, Healy Systems has remained the leader in<br />

design and development of new Stage II technologies that contribute to cleaner air<br />

and a healthier environment.<br />

Franklin Fueling Systems Healy products are proven performers and are responsible<br />

for many Stage II industry fi rsts, including the fi rst vacuum-assist system to be<br />

certifi ed ORVR compatible and the fi rst to test and pass the current California<br />

Enhanced Vapor Recovery (EVR) certifi cation.<br />

Healy Systems has both dispenser mounted and central vacuum sources along with<br />

a variety of top quality nozzles and accessories. With a range of Stage II products<br />

and a long standing reputation for durability and performance, customers can feel<br />

confi dent in selecting Franklin Fueling Systems Healy equipment.<br />

VP1000 Series<br />

Dispenser-<br />

Mounted Vacuum<br />

Source<br />

VP1200 Series<br />

Self Contained<br />

Suction Pump<br />

Dispenser-<br />

Mounted Vacuum<br />

Source<br />

9000 Series<br />

Mini-Jet Central<br />

Vacuum Pump<br />

VP500<br />

Central Vacuum<br />

Vane Pump<br />

VP500C/1 or<br />

VP500C/2<br />

Cabinet Models<br />

= CARB Certifi ed = TÜV/Healy Certifi ed

ENHANCED VAPOR RECOVERY —<br />

CARB CERTIFIED<br />

Model 900 Series EVR Nozzle<br />

Enhanced Vapor Recovery Certifi ed<br />

Dispensing<br />

Systems<br />

The most effi cient and durable gasoline nozzle on the market today, the 900 Series<br />

boasts high quality, durability and state of the art engineering designed to reduce<br />

emissions caused by liquid retention and spillage associated with other Stage II<br />

nozzles. The 900 Series nozzle meets all EVR and ORVR specifi cations required by the<br />

California Air Resources Board (CARB).<br />

EVR/ORVR Certifi ed (CARB)<br />

Highest quality, most effi cient nozzle available<br />

Reliable and low maintenance<br />

CARB Certifi ed for Use With Executive Order Tank Type<br />

VR-201<br />

UST<br />

VP1000 Series Vacuum Pump<br />

VR-202<br />

UST<br />

G-70-191-AA<br />

UST<br />

9961 Clean Air Separator (CAS)<br />

The Healy Systems Clean Air Separator prevents excess emissions and product loss by<br />

controlling gasoline storage tank pressure. The unit works in combination with Healy<br />

ORVR/EVR type nozzles as part of a system that increases overall performance and<br />

effi ciency.<br />

High reliability and maintenance free<br />

No mechanical moving parts<br />

No electrical connections needed<br />

10 year warranty<br />

CARB Certifi ed for Use With Executive Order Tank Type<br />

Healy 900 EVR Nozzle<br />

Enhanced Vapor<br />

Recovery Components<br />

900 EVR Nozzle<br />

VP1000 Vacuum Pump<br />

Clean air separator<br />

VR-201<br />

VR-202<br />

UST<br />

UST

Dispensing<br />

Systems<br />

Model 900 Series<br />

EVR Nozzle<br />

Enhanced Vapor<br />

Recovery Certifi ed<br />

The most effi cient and<br />

durable gasoline nozzle on<br />

the market today. The 900<br />

series boasts high quality,<br />

durability and state of the<br />

art engineering designed to<br />

reduce emissions caused by<br />

liquid retention and spillage.<br />

The 900 series nozzle is ORVR<br />

and EVR certifi ed by the<br />

California Air Resources Board<br />

(CARB).<br />

EVR/ORVR certifi ed (CARB)<br />

Highest quality, most effi cient nozzle available<br />

Reliable and low maintenance<br />

Model 600 Series<br />

Bootless Nozzle<br />

The 600 Bootless Vapor<br />

Recovery Nozzle is the<br />

international standard for<br />

Stage II components. For use<br />

on new or existing dispensers.<br />

It can be installed with<br />

both central and dispenser<br />

mounted vacuum sources.<br />

Highest quality<br />

Bootless design<br />

Easy to use<br />

STAGE II VAPOR RECOVERY NOZZLES<br />

CARB Certifi ed for Use With Executive Order Tank Type<br />

VR-201 UST<br />

VP1000 Series Vacuum Pump VR-202 UST<br />

G-70-191-AA UST<br />

CARB Certifi ed for Use With Executive Order Tank Type<br />

9000 Mini-Jet<br />

G-70-165 UST<br />

VP500 Vane Pump<br />

G-70-165 UST<br />

VP1000 Series Vacuum Pump G-70-183 UST<br />

Model 800 Series<br />

Onboard Refueling<br />

Vapor Recovery<br />

(ORVR) Nozzle<br />

Converts any new or<br />

existing dispenser to a CARB<br />

certifi ed system for ORVR<br />

compatibility. ORVR detection<br />

is built into the nozzle, and<br />

there is no need for a backend<br />

processor.<br />

Highest quality<br />

ORVR compatible for<br />

underground tank systems<br />

without the need for a<br />

back-end processor<br />

Reliable and effi cient<br />

CARB Certifi ed for Use With Executive Order Tank Type<br />

VP1000 Series Vacuum Pump G-70-191 UST<br />

Model 400 Series<br />

Onboard Refueling<br />

Vapor Recovery<br />

(ORVR) Nozzle<br />

The fi rst nozzle to receive<br />

CARB certifi cation for<br />

ORVR compatibility. For use<br />

on central vacuum vapor<br />

recovery systems and in<br />

aboveground storage tank<br />

applications. ORVR and vapor<br />

fl ow controls are built into<br />

the nozzle.<br />

ORVR compatible<br />

Aboveground tank installation<br />

Underground tank installation<br />

CARB Certifi ed for Use With Executive Order Tank Type<br />

9000 Mini-Jet<br />

G-70-186 UST<br />

VP500 Vane Pump<br />

G-70-186 UST<br />

9000 Mini-Jet<br />

G-70-187 AST<br />

VP500 Vane Pump<br />

G-70-187 AST<br />

Type 100 Jet Pump<br />

G-70-187 AST

STAGE II VAPOR RECOVERY DISPENSER-<br />

MOUNTED VACUUM SOURCES<br />

VP1000 Series<br />

Dispenser-Mounted<br />

Vacuum Source<br />

One vacuum pump per<br />

dispenser supplies both<br />

sides, reducing long term<br />

maintenance costs. The<br />

VP1000 has been designed<br />

to satisfy the vapor recovery<br />

needs of a blender or nonblender<br />

dispenser. Simple<br />

installation with no excavation minimizes downtime and<br />

labor. Connects to the dispenser with a simple interface<br />

module without costly software changes or electronic board<br />

replacement. The most cost-effective dispenser-mounted<br />

vacuum-assist system on the market today.<br />

Compatible with new and existing dispensers<br />

Small size: 10.12” × 7.12” × 5.38”<br />

Underground tank installations<br />

CARB Certifi ed for Use With Executive Order Tank Type<br />

Healy 900 EVR Nozzle<br />

VR-201<br />

VR-202<br />

UST<br />

UST<br />

Healy 800 ORVR Nozzle<br />

G-70-191 UST<br />

Healy 600 Bootless Nozzle<br />

G-70-183 UST<br />

VP1200 Series Self<br />

Contained Suction<br />

Pump Dispenser-<br />

Mounted Vacuum<br />

Source<br />

Approvals<br />

TÜV Approved<br />

Dispensing<br />

Systems<br />

Similar to the VP1000, except<br />

powered by a suction pump<br />

motor. One pump supplies<br />

both sides. Simple installation<br />

with no excavation minimizes<br />

downtime and labor; ideal<br />

for retrofi tting new or existing dispenser, installs easily on a<br />

bracket or attached to the frame of the unit. High vacuum<br />

level assures clearing of fl ooded vapor hoses.<br />

Small size: 5.25” × 5” × 4.38”<br />

Compatible with new and existing dispensers<br />

International approvals - contact Healy<br />

VP1000 Installation VP1200 Installation

Dispensing<br />

Systems<br />

9000 Series Mini-Jet<br />

Central Vacuum Pump<br />

The popular, non-electric<br />

Mini-Jet offers the ultimate in<br />

versatility utilizing an existing<br />

STP’s product fl ow to create<br />

vacuum for vapor recovery.<br />

One Mini-Jet can handle two<br />

dual sided dispensers or four<br />

fueling positions. Additional<br />

Mini-Jets can be added for<br />

larger sites. Provides high<br />

reliability and low maintenance. High vacuum level assures<br />

clearing of fl ooded vapor hoses.<br />

No electrical hook-up<br />

No moving parts creating vacuum<br />

Installs in standard existing STP tank sump<br />

VP500/C1 or<br />

VP500C/2 Cabinet<br />

Models<br />

STAGE II VAPOR RECOVERY CENTRAL<br />

VACUUM SOURCES<br />

CARB Certifi ed for Use With Executive Order Tank Type<br />

Healy 600 Bootless Nozzle<br />

G-70-165 UST<br />

Healy 400 ORVR Booted Nozzle G-70-186 UST<br />

Healy 400 ORVR Booted Nozzle G-70-187 AST<br />

The VP500 cabinet<br />

models provide the same<br />

performance specifi cations<br />

as the 500B but operate<br />

inside an attractive stainless<br />

steel cabinet designed to be<br />

mounted separately, remote<br />

of the gasoline storage tanks.<br />

The C/1 contains one vacuum<br />

pump with a capacity of 5<br />

dual sided dispensers or 10 fueling positions.<br />

The C/2 model contains two vacuum pumps within the same<br />

stainless steel cabinet but increase the systems vapor recovery<br />

capacity to 10 dual sided dispensers or 20 fueling positions.<br />

Flexible installation options<br />

Low cost installation and operation<br />

Reliability and low maintenance<br />

CARB Certifi ed for Use With Executive Order Tank Type<br />

Healy 600 Bootless Nozzle<br />

G-70-165 UST<br />

Healy 400 ORVR Booted Nozzle G-70-186 UST<br />

Healy 400 ORVR Booted Nozzle G-70-187 AST<br />

VP500 Central<br />

Vacuum Vane Pump<br />

Provides the ultimate in<br />

central vacuum versatility.<br />

115/230 VAC — 50/60 HZ<br />

application. High vacuum<br />

level assures clearing<br />

of fl ooded vapor hoses.<br />

Available in two versions.<br />

VP500B for mounting in<br />

a STP sump. Handles ten<br />

fueling positions or a typical site with fi ve nozzles in full-fl ow<br />

operation.<br />

Flexible installation options<br />

Low cost installation and operation<br />

Unsurpassed low maintenance<br />

CARB Certifi ed for Use With Executive Order Tank Type<br />

Healy 600 Bootless Nozzle<br />

G-70-165 UST<br />

Healy 400 ORVR Booted Nozzle G-70-186 UST<br />

Healy 400 ORVR Booted Nozzle G-70-187 AST<br />

VP500 Vane Pump<br />

9000-02 Mini-Jet

HOSES AND SYSTEM ACCESSORIES<br />

Coaxial Hoses and Hose Accessories<br />

A<br />

B<br />

C<br />

D<br />

E<br />

G<br />

75B Series Coaxial Hose<br />

Manufactured with a swivel on each end to provide the<br />

ease of handling customers prefer. Inverted coaxial design<br />

reduces hose size and the steel braided, premium, abuseresistant<br />

outer hose assures long service life and low<br />

maintenance. Available in up to 20 foot lengths.<br />

75B-008-F2F2 Pigtail<br />

Standard inverted coaxial “whip hose”.<br />

75B-010-S4F2 Balance-Type Pigtail<br />

Adapter-type whip hose allows direct connection to the<br />

balance hose outlet without the need for a hose adapter.<br />

8701VV Breakaway<br />

Full product and vapor shut-off, with 350 pound<br />

separation force. Spare shear screw allows ease of fi eld<br />

repair in the event of a drive off.<br />

807 Swivel Breakaway<br />

Breakaway and nozzle swivel in one. Allows for easier far<br />

side fueling. Full product and vapor path shut-off, with 350<br />

pound separation force. Spare shear screw allows ease of<br />

fi eld repair in the event of a drive off.<br />

H<br />

E<br />

A<br />

D<br />

B<br />

Dispenser and System Accessories<br />

C<br />

F<br />

Dispensing<br />

Systems<br />

F CX6-A Non-Vapor-Ready Dispenser Hose Adapter<br />

Converts a non-vapor-ready conventional dispenser thread<br />

to Healy’s inverted coaxial hose thread.<br />

G CX6-VV3A Non-Vapor-Ready Multiproduct Dispenser<br />

Hose Adapter<br />

Converts a non-vapor-ready high-hose multiproduct<br />

dispenser to Healy’s inverted coaxial hose thread.<br />

H<br />

609 Thread Adapter<br />

Converts M-34 metric hose outlet thread to Healy’s<br />

inverted coaxial hose thread.

Dispensing<br />

Systems<br />

Franklin Fueling Systems manufactures<br />

reliable and proven fi eld-tested Healy<br />

products. The products described in this<br />

catalog offer these premium features:<br />

SYSTEM MONITOR<br />

9000 Series Mini-Jet with 600 Series Bootless Nozzle<br />

VP500 Series Vane Pump<br />

9000 Series Mini-Jet with 400 Series ORVR Nozzle<br />

VP500 Series Vane Pump<br />

FFS-0053 9.06<br />

Nozzles<br />

Low cost installation<br />

Low cost operation<br />

Durable spout tips<br />

Flow control safety features<br />

Maximum fl ow rates<br />

Field serviceable external parts<br />

G-70-165<br />

G-70-165<br />

G-70-186<br />

G-70-187<br />

6280A Vapor<br />

Recovery<br />

Monitoring<br />

System<br />

Continuously monitors<br />

system performance in<br />

accordance with CARB<br />

specifi cations.<br />

For use with Healy<br />

Central Vacuum Vapor<br />

Recovery Systems only.<br />

CARB Certifi ed for Use With Executive Order Tank Type<br />

UST<br />

UST<br />

AST<br />

Vacuum Sources<br />

Low cost installation<br />

Low cost operation<br />

Low maintenance<br />

High vacuum levels to ensure clearing<br />

of fl ooded vapor hoses<br />

Easy access to fi eld serviceable parts