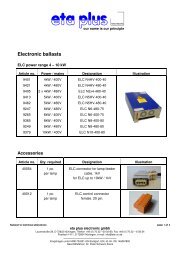

UV- TECHNOLOGY Technical Documentation ELC PE22 / PE32

UV- TECHNOLOGY Technical Documentation ELC PE22 / PE32

UV- TECHNOLOGY Technical Documentation ELC PE22 / PE32

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

���<br />

our name is our principle<br />

�<br />

<strong>UV</strong>-<br />

<strong>TECHNOLOGY</strong><br />

<strong>Technical</strong> <strong>Documentation</strong><br />

<strong>ELC</strong> <strong>PE22</strong> / <strong>PE32</strong><br />

eta plus electronic gmbh<br />

Lauterstraße 29, D-72622 Nürtingen, Telefon +49 (0) 70 22 - 60 02-80, Fax +49 (0) 70 22 – 6 58 54<br />

Postfach 1411, D-72604 Nürtingen, e-mail: info@eta-uv.de<br />

––––––––––––––––––––––––––––<br />

Eingetragen unter HRB 724321 AG Stuttgart, USt.-Id.-Nr. DE 146267800<br />

Geschäftsführer: Dr. Peter Schwarz-Kiene

<strong>ELC</strong> ® („Electronic Lamp Control“) is a registered trademark of<br />

IST Metz GmbH.<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations

Contents page I<br />

Contents<br />

1 Safety ................................................................................................. 1<br />

1.1 Definition of Symbols.................................................................................1<br />

1.2 Safety Advice ..............................................................................................1<br />

1.3 Correct operation........................................................................................2<br />

1.4 Extended use ..............................................................................................2<br />

2 Description of functions................................................................... 3<br />

3 Installation......................................................................................... 4<br />

3.1 Mounting of casing.....................................................................................4<br />

3.1.1 Vertical installation position ............................................................................5<br />

3.1.2 Horizontal installation position ........................................................................6<br />

3.2 Connection ..................................................................................................7<br />

3.3 Control- and bus connections .................................................................11<br />

3.4 Comments on the safety functions of the <strong>ELC</strong> ......................................14<br />

3.4.1 Safety relay...................................................................................................14<br />

3.4.2 Initialisation signal.........................................................................................15<br />

3.5 Configuration ............................................................................................15<br />

3.5.1 Setting up the PROFIBUS address...............................................................16<br />

3.5.2 Checking the PROFIBUS connection ...........................................................17<br />

3.5.3 Setting lamp power via PROFIBUS ..............................................................18<br />

3.5.4 To read out <strong>ELC</strong> serial number and softwareversion....................................20<br />

4 Operation of <strong>ELC</strong> ............................................................................ 21<br />

4.1 Initial operation .........................................................................................21<br />

4.2 Switching on the <strong>ELC</strong>...............................................................................21<br />

4.3 Activating the safety circuits ...................................................................21<br />

4.4 Switching on the lamp..............................................................................21<br />

4.5 Dimming operation ...................................................................................23<br />

4.6 Standby operation ....................................................................................23<br />

4.7 Switching off the lamp..............................................................................23<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations

Contents page II<br />

5 Monitoring, warning, error, repair ................................................. 24<br />

5.1 Earth fault control.....................................................................................24<br />

5.2 Warning messages ...................................................................................25<br />

5.3 Error...........................................................................................................27<br />

5.3.1 Error messages ............................................................................................27<br />

5.3.2 Troubleshooting ............................................................................................28<br />

5.3.3 Resetting the error register ...........................................................................29<br />

5.4 Repair <strong>ELC</strong> ................................................................................................29<br />

6 <strong>Technical</strong> Data................................................................................. 30<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations

1 Safety page 1<br />

1 Safety<br />

1.1 Definition of Symbols<br />

�<br />

Stop (Stop Danger). This symbol warns of serious danger of severe injury to<br />

persons. It must be strictly observed.<br />

Attention (Warning). This symbol indicates information the non-observance of<br />

which can lead to extensive damage to property. The safety warning must be<br />

strictly observed.<br />

Information. This symbol indicates key information on use. Non-observance can<br />

lead to failure.<br />

1.2 Safety Advice<br />

The <strong>ELC</strong> must be installed and connected in compliance with existing<br />

regulations and practices. This is e.g. EN 60204-1 in Europe.<br />

Repairs on the <strong>ELC</strong> may only be carried out by the manufacturer.<br />

The installation and starting up may only be carried out by skilled electricians.<br />

Do not open the <strong>ELC</strong> before it is disconnected from the mains. BEWARE OF<br />

RESIDUAL VOLTAGE! The unit may still be live up to three minutes after it has<br />

been switched off.<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations

1 Safety page 2<br />

The <strong>ELC</strong> causes a leakage current greater than 3.5 mA!<br />

Safeguarding by means of leakage current protection type A and type AC<br />

according to IEC 60755 is not permitted!<br />

The <strong>ELC</strong> operates in principle as a frequency converter and is equipped with a<br />

mains filter whose leakage current could activate fuse protection.<br />

Contact to the grounding connector must always be ensured.<br />

Additional measures must be taken to ensure that there is no danger when<br />

touching the appliance. This could be by means of a universal leakage current<br />

protection type B, taking into consideration the increased response threshold, or<br />

by means of an independent equipotential connection.<br />

1.3 Correct operation<br />

The <strong>ELC</strong> is an electrical unit intended to be installed in the switch cabinets of<br />

industrial high-voltage power installations. It is conceived as an electronic ballast<br />

for the operation of lamps intended for this purpose.<br />

Any other use is deemed as misuse. The manufacturer will not assume liability<br />

for damage resulting from misuse.<br />

A pre-requisite for authorised operation of the <strong>ELC</strong> is the observance of both the<br />

operating and maintenance instructions and the safety advice.<br />

1.4 Extended use<br />

Extended use beyond the operating specifications as stated is not permitted.<br />

The manufacturer will not assume liability if the equipment is used in any other<br />

way. The operator acts at his own risk.<br />

Any operation beyond the scope of the authorised operation is considered to be<br />

misuse.<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations

2 Description of functions page 3<br />

2 Description of functions<br />

The <strong>ELC</strong> is an electronic power supply unit for the operation of gas discharge lamps with<br />

electrical properties as described in chapter 6.<br />

In contrast to conventional ballasts (inductive lamp ballast or transformer or transformer with<br />

transductor), the lamp with an electronic ballast is operated with high frequency (approx.<br />

100 kHz). The lamp does not flicker and dimming is infinitely adjustable to a range between<br />

20 % and 100 % of the electric power or to between 15 % and 100 % of the <strong>UV</strong> radiation<br />

respectively.<br />

Dimming<br />

The possibility of dimming the lamp has two advantages. Firstly the lamp can be switched to<br />

minimum load (standby operation) during longer idle times and energy can thus be saved.<br />

Secondly the optimum lamp power can be determined and adjusted as appropriate.<br />

Power control<br />

The <strong>ELC</strong> offers a high level of lamp power constancy due to its integrated power control.<br />

Variations in operating voltage of ± 10 % do not affect lamp power.<br />

Ignition device<br />

When the lamp is switched on the <strong>ELC</strong> initiates trigger pulses to fire the lamp; a separate<br />

ignition device is not required.<br />

Other performance characteristics<br />

• High level of electrical efficiency.<br />

• Configuration, control and monitoring of the <strong>ELC</strong> is carried out via PROFIBUS-interface.<br />

• The <strong>ELC</strong> monitors the lamp cables for earth fault.<br />

• The lamp output potential is separated from that of the supply voltage.<br />

• The <strong>ELC</strong> is both short-circuit proof and safe in open circuit operation at the lamp output.<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations

3 Installation page 4<br />

3 Installation<br />

3.1 Mounting of casing<br />

The <strong>ELC</strong> must be installed in a control cabinet with at least IP 54 protection (see<br />

EN 60529). Operation without a control cabinet or in a control cabinet with a<br />

lower degree of protection is not permitted.<br />

It is only permitted to install the appliance in the positions described in 3.1.1 or<br />

3.1.2. When installed vertically, as described in Fig. 1, the control connections<br />

must be positioned at the bottom and supply connections at the top. Installation<br />

must allow for the minimum spacing.<br />

The <strong>ELC</strong> should not be mounted in the immediate proximity of sensitive<br />

electronic equipment. An appropriate distance must be maintained to scatter<br />

field transformers or other inductors.<br />

The flow of cool air for the <strong>ELC</strong> must be safeguarded. The ambient temperature<br />

must not exceed the values prescribed in chapter 6.<br />

Ventilation must be provided for the switch cabinet.<br />

The amount of air necessary is determined by the size and positioning of the<br />

switch cabinet, the total electrical losses and the external temperature. Please<br />

consult your switch cabinet manufacturer. For the recommended throughput of<br />

air please see the technical data in chapter 6.<br />

Impure cooling air could affect the functionality of the <strong>ELC</strong>. This can be avoided<br />

by installing a fine air filter.<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations

3 Installation page 5<br />

3.1.1 Vertical installation position<br />

Lufteintritt<br />

air entrance<br />

Lufteintritt<br />

air entrance<br />

Netzanschluß<br />

line input<br />

Lampenstecker<br />

lampconnection<br />

261 mm<br />

Steckerleiste für Steuersignale<br />

Oben<br />

top<br />

control connector<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

540 mm<br />

484 mm<br />

31 mm 200 mm<br />

31 mm<br />

Luftaustritt<br />

air exhaust<br />

Luftaustritt<br />

air exhaust<br />

Fig. 1: Assembly of the <strong>ELC</strong>, vertical installation position (all dimensions in mm).<br />

min. 150<br />

min. 150<br />

501 mm<br />

650 mm

3 Installation page 6<br />

3.1.2 Horizontal installation position<br />

Lufteintritt<br />

air entrance<br />

Lufteintritt<br />

air entrance<br />

261 mm<br />

Steckerleiste für Steuersignale<br />

control connector<br />

484 mm<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

min. 150<br />

650 mm<br />

501 mm<br />

Fig. 2: Assembly of the <strong>ELC</strong>, horizontal installation position (all dimensions in mm).<br />

min. 150

3 Installation page 7<br />

3.2 Connection<br />

L1<br />

L2<br />

L3<br />

N<br />

PE<br />

L1 L2 L3<br />

EVG<br />

out1 out2<br />

lamp assembly<br />

earthed lead network side<br />

automatic cutout<br />

power choke<br />

cable shield<br />

lamp feeder cable<br />

Fig. 3: Power connection <strong>PE22</strong> / <strong>PE32</strong><br />

Mains connection<br />

Fig. 4: Mains <strong>PE22</strong><br />

� <strong>PE22</strong>:<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

Fig. 3 shows the electrical installation.<br />

Operation of the ballasts requires a power<br />

choke in series (see technical data chapter<br />

6) in order to limit the total harmonic<br />

distortion of the line current to below 50%.<br />

The lamp feeder cable shielding must be<br />

connected to the <strong>ELC</strong>. To this end the<br />

connector has an EMC screw connection<br />

(also see: connection lamp cable).<br />

If wished, the shielding can also be<br />

connected to the lamp unit.<br />

The connection of mains supply cables and lamp feeder cables must be<br />

separated from control cables.<br />

Fig. 5: Mains <strong>PE32</strong><br />

The cross section of the<br />

earthed wire must be at least<br />

10 mm².<br />

The three phases must be<br />

provided with an automatic<br />

cutout.<br />

In order to avoid damaging the terminal pins, please do not exceed the following<br />

torque:<br />

L1, L2, L3: 1,5 – 1,8 Nm<br />

Grounding conductor: 3,0 – 4,0 Nm<br />

<strong>PE32</strong>:<br />

L1, L2, L3: 1,5 – 1,8 Nm<br />

Grounding conductor: 1,5 – 1,8 Nm

3 Installation page 8<br />

Connecting the lamp feeder cable<br />

�<br />

The lamp feeder cable must correspond with the cable parameters described in<br />

chapter 6.<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

Components of the connector:<br />

connector module<br />

crimp contacts<br />

hood<br />

EMC cable gland with<br />

plastic insert<br />

Preparing the lamp feeder cable:<br />

• Remove sheath<br />

• Free metal braid and put over cable<br />

sheath<br />

• Insulate conductor<br />

7,5<br />

100 12<br />

(measurements in mm)<br />

A suitable contact crimping tool is required of<br />

the type:<br />

Amphenol group C146<br />

Part No.: VN01 025 0029 1C<br />

Closed crimp barrels (individual contacts)<br />

2.5mm

3 Installation page 9<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

Top: Correct crimp connection<br />

Middle: Stripped part of the wire too long,<br />

gap between insulation and crimp barrel too<br />

large<br />

Bottom: Stripped part of the wire too short<br />

because conductor is not visible through<br />

inspection hole.<br />

• Insert cable into the cable gland and<br />

bush casing<br />

• Insert crimp contacts into the connector<br />

module until they lock into place<br />

• Ensure that the shield evenly covers the<br />

plastic inset of the cable gland (360°<br />

contact)<br />

• Tighten EMC cable gland

3 Installation page 10<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

• Screw the module into the hood casing.<br />

The picture on the left shows the<br />

recommended orientation.<br />

The lamp feeder cable between the switch cabinet and lamp assembly must be laid<br />

protected. For the correct installation of the lamp assembly and lamp please observe the<br />

corresponding manufacturer’s instructions.

3 Installation page 11<br />

3.3 Control- and bus connections<br />

Fig. 6 Control and bus connections<br />

Fig. 7 Coding control plug<br />

All control circuits must be earthed upon installation.<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

The control and bus cables are connected to the<br />

underside of the casing (see Fig. 6) by means of the<br />

plug connections available as accessories.<br />

In order to minimise the danger of mixing up the control<br />

connectors, the sockets on the appliance have been<br />

coded with the red code profiles. They are positioned<br />

according to the following picture:<br />

When the control connectors are delivered they are not<br />

coded and cannot be connected in this condition! In<br />

order to code the control connector the corresponding<br />

code “nose” must be removed (see Fig. 7). Pin 1 is<br />

marked by means of a stamping:

3 Installation page 12<br />

Overview pin assignment<br />

The connector pin assignment is shown in Fig. 8 and will be explained in the following tables.<br />

X1.1 X1.2 X1.3 X3.1 X3.2 X3.3 X3.4<br />

INIT<br />

PIN<br />

SAFETY<br />

CONT1<br />

INIT<br />

GND<br />

SAFETY<br />

REL<br />

BUS<br />

VCC<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

BUS B BUS A BUS<br />

GND<br />

SAFETY PROFIBUS<br />

SAFETY<br />

CONT2<br />

SAFETY<br />

GND<br />

BUS<br />

VCC<br />

BUS B BUS A BUS<br />

GND<br />

X2.1 X2.2 X2.3 X4.1 X4.2 X4.3 X4.4<br />

Fig. 8 Connector strip for <strong>ELC</strong> control<br />

Pin assignment of initialisation signal<br />

Designation Number Description technical<br />

INIT PIN X1.1 Input initialisation signal for<br />

safety shutdown +24Vext.<br />

24V DC ± 10% external<br />

supply<br />

INIT GND X1.2 GND Reference potential for X1.1<br />

Pin assignment of safety relay<br />

Designation Number Description technical<br />

SAFETY REL X1.3 Control signal input safety relay<br />

+24V DC<br />

Control pulse (+24V DC ±<br />

10% / 35mA) for the safety<br />

relay in reference to X2.3<br />

(GND)<br />

SAFETY CONT1 X2.1 Feedback contact 1 safety relay NCC 24V / 4A<br />

SAFETY CONT2 X2.2 Feedback contact 2 safety relay NCC 24V / 4A<br />

SAFETY GND X2.3 GND Reference potential for X1.3<br />

(safety relay)

3 Installation page 13<br />

Pin assignment of PROFIBUS<br />

Designation Number Description technical<br />

BUS VCC X3.1 external supply voltage 5V<br />

isolated for PROFIBUS<br />

BUS B X3.2 Data line PROFIBUS B Bus signal B<br />

BUS A X3.3 Data line PROFIBUS A Bus signal A<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

+5V DC isolated, output for<br />

terminator<br />

BUS GND X3.4 GND isolated for PROFIBUS Shield connection PROFIBUS<br />

BUS VCC X4.1 external supply voltage 5V<br />

isolated for PROFIBUS<br />

BUS B X4.2 Data line PROFIBUS B Bus signal B<br />

BUS A X4.3 Data line PROFIBUS A Bus signal A<br />

+5V DC isolated, output for<br />

terminator<br />

BUS GND X4.4 GND isolated for PROFIBUS Shield connection PROFIBUS<br />

The PROFIBUS contacts of X3 and X4 are internally connected. According to requirements<br />

apply a terminator in compliance with PROFIBUS-Norm IEC 61158:<br />

Fig. 9: Termination of PROFIBUS

3 Installation page 14<br />

3.4 Comments on the safety functions of the <strong>ELC</strong><br />

Fig. 10: Safety circuits of the <strong>ELC</strong><br />

3.4.1 Safety relay<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

<strong>ELC</strong> with PROFIBUS feature<br />

two safety circuits, as shown<br />

schematically in Fig. 10:<br />

1. Safety relay K1 with<br />

feedback via the normally<br />

closed contact (paragraph<br />

3.4.1)<br />

2. Monitoring of the<br />

initialisation signal<br />

(paragraph 3.4.2)<br />

To set the <strong>ELC</strong> ready for operation, the safety relay K1 has to be activated by applying +24V<br />

to pin X1.3 and GND on pin X2.3.<br />

As long as the safety relay is not activated, lamp operation is not possible! There are two<br />

feedback paths:<br />

• a normally closed relay contact. It may be tapped on pins X2.1 and X2.2.<br />

• the [Warning Register] of the PROFIBUS-input-data (see below and paragraph 5.2:<br />

Bit 4 {Safety Relay Open})<br />

If the safety relay is deactivated during lamp operation, lamp operation will be shut down.<br />

After reactivating the safety relay, the lamp has to be restarted.

3 Installation page 15<br />

3.4.2 Initialisation signal<br />

Furthermore lamp operation will not be allowed unless +24V are applied to pin X1.1 and<br />

GND on pin X1.2. This is an additional monitoring function for the safe operation of the<br />

installation. The status of pin X1.1 is visualized in the [Warning Register] of the PROFIBUSinput-data<br />

(see below and paragraph 5.2: Bit 7 {Init Signal Ok}).<br />

If the initialisation signal is deactivated during lamp operation, lamp operation will be shut<br />

down. After re-applying the initialisation signal, the lamp has to be restarted.<br />

3.5 Configuration<br />

Communication between <strong>ELC</strong> and installation control is carried out via PROFIBUS DPV0.<br />

The <strong>ELC</strong> represents a non-modular DPV0-Slave, the installation control functions as the<br />

Master.<br />

For configuration, control and monitoring of the <strong>ELC</strong> 16 input registers (Master receiving data<br />

from <strong>ELC</strong>) were implemented, as well as 6 output registers (Master sending data to <strong>ELC</strong>).<br />

For registers overlapping more than one byte, the byte order was determined according to<br />

”Big-Endian“.<br />

The preset baud rate is recognized automatically by the <strong>ELC</strong>. Software supports all baud<br />

rates from 9.6kBit to12MBit; tested values can be taken from the technical data in chapter 6<br />

(limitations may be caused by the connector).<br />

The necessary adjustments during the installing of the <strong>ELC</strong> will be explained in this<br />

paragraph, the adjustments for lamp operation will follow in chapter 4.<br />

PROFIBUS-input-data (<strong>ELC</strong> → Master)<br />

Byte-<br />

Nr.<br />

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

Name [<strong>ELC</strong><br />

Serial<br />

Number]<br />

[Software<br />

Version]<br />

[<strong>ELC</strong><br />

Nominal<br />

Power]<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

[Error<br />

Register]<br />

PROFIBUS-output-data (Master → <strong>ELC</strong>)<br />

Byte-<br />

Nr.<br />

Name [Power<br />

Set<br />

Value]<br />

0 1 2 3 4 5<br />

[Installed<br />

Lamp<br />

Power]<br />

[Lamp<br />

Control]<br />

[Reserved]<br />

[Warning<br />

Register]<br />

[Lamp<br />

Status]<br />

[Actual<br />

Power]<br />

[Actual<br />

Voltage]<br />

[Actual<br />

Current]<br />

[Reserved]

3 Installation page 16<br />

3.5.1 Setting up the PROFIBUS address<br />

Fig. 11: LED status (red left, green right) and rotary coding switch for low and high nibble<br />

The PROFIBUS address must be set using the rotary coding switches.<br />

The address space extends from 01hex to 7Dhex (corresponding to 1 to 125), whereby low and<br />

high nibble are allocated according to Fig. 11. Each address may be used only once per<br />

installation.<br />

The address is adopted when current is applied to the <strong>ELC</strong> (paragraph 4.2). If the appliance<br />

is already under power supply, it must first be disconnected.<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations

3 Installation page 17<br />

3.5.2 Checking the PROFIBUS connection<br />

The Status-LED (Fig. 11) may be used to check the successful connection of <strong>ELC</strong> and<br />

Master and furthermore the existence of an error (<strong>ELC</strong> not ready for operation):<br />

LED red<br />

(left)<br />

LED green<br />

(right)<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

Status Corrective action<br />

off on <strong>ELC</strong> ready for operation,<br />

PROFIBUS-connection ok<br />

off blinking <strong>ELC</strong> ready for operation, no<br />

PROFIBUS-connection<br />

blinking on <strong>ELC</strong> not ready for<br />

operation, PROFIBUSconnection<br />

ok<br />

blinking blinking <strong>ELC</strong> not ready for<br />

operation, no PROFIBUSconnection<br />

Check plug contact, bus<br />

termination (see paragraph 3.3),<br />

check address and panelprogramming.<br />

The error cause detected by the<br />

<strong>ELC</strong> may be read out in the Error<br />

Register (see paragraph 5.3.1)<br />

Detach <strong>ELC</strong> from mains and<br />

restart.<br />

blinking off Internal error. Detach <strong>ELC</strong> from mains and<br />

restart.<br />

off off Internal error or no supply. Check power supply

3 Installation page 18<br />

3.5.3 Setting lamp power via PROFIBUS<br />

PROFIBUS-output-data (Master → <strong>ELC</strong>)<br />

Byte-<br />

Nr.<br />

0 1 2 3 4 5<br />

Name [Power<br />

Set<br />

Value]<br />

[Installed<br />

Lamp<br />

Power]<br />

[Lamp<br />

Control]<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

[Reserved]<br />

The set value for lamp power has to be written into the register [Power Set Value]. The<br />

<strong>ELC</strong>’s output power is defined by the control characteristic of Fig. 12.<br />

Lamp power<br />

<strong>ELC</strong>-nominalpower<br />

20% <strong>ELC</strong>-nominal-power<br />

Fig. 12: Control characteristic<br />

20% <strong>ELC</strong>-nominal-power <strong>ELC</strong>-nominalpower<br />

The lamp power can be set in steps of 32 W.<br />

[Power Set<br />

Value]<br />

The <strong>ELC</strong>’s nominal power is written into the register [<strong>ELC</strong> Nominal Power] of the<br />

PROFIBUS-input-data:<br />

PROFIBUS-input-data (<strong>ELC</strong> → Master)<br />

Byte-<br />

Nr.<br />

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

Name [<strong>ELC</strong><br />

Serial<br />

Number]<br />

[Software<br />

Version]<br />

[<strong>ELC</strong><br />

Nominal<br />

Power]<br />

[Error<br />

Register]<br />

[Warning<br />

Register]<br />

[Lamp<br />

Status]<br />

[Actual<br />

Power]<br />

[Actual<br />

Voltage]<br />

[Actual<br />

Current]<br />

[Reserved]

3 Installation page 19<br />

PROFIBUS-output-data (Master → <strong>ELC</strong>)<br />

Byte-<br />

Nr.<br />

Name [Power<br />

Set<br />

Value]<br />

0 1 2 3 4 5<br />

[Installed<br />

Lamp<br />

Power]<br />

[Lamp<br />

Control]<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

[Reserved]<br />

To limit the maximum output power, use the register [Installed Lamp Power] (see Fig. 13).<br />

This function is appropriate if the nominal power of the lamp is lower than the nominal power<br />

of the <strong>ELC</strong>.<br />

Lamp power<br />

<strong>ELC</strong>-nominalpower<br />

[Installed Lamp<br />

Power]<br />

20% <strong>ELC</strong>-nominal-power<br />

Fig. 13: Limited output power characteristic<br />

�<br />

20% <strong>ELC</strong>-nominal-power Installed lamp<br />

power<br />

<strong>ELC</strong>-nominalpower<br />

Sollleistungs-<br />

[Power<br />

vorgabe<br />

[Power<br />

vorgabe<br />

Set<br />

Value]<br />

[Power<br />

Value]<br />

[Power Set<br />

Value]<br />

The control characteristic of Fig. 12 comes into effect, if the register [Installed<br />

Lamp Power] is<br />

• not set<br />

• below 20% of <strong>ELC</strong> nominal power<br />

• above <strong>ELC</strong> nominal power

3 Installation page 20<br />

3.5.4 To read out <strong>ELC</strong> serial number and softwareversion<br />

These data may be accessed via display or PROFIBUS and may be of interest e.g. for<br />

service and in case of a defect.<br />

PROFIBUS-input-data (<strong>ELC</strong> → Master)<br />

Byte-<br />

Nr.<br />

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

Name [<strong>ELC</strong><br />

Serial<br />

Number]<br />

↓<br />

[Software<br />

Version]<br />

[<strong>ELC</strong><br />

Nominal<br />

Power]<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

[Error<br />

Register]<br />

[Warning<br />

Register]<br />

[Lamp<br />

Status]<br />

[Actual<br />

Power]<br />

Byte 2 Byte 1 Byte 0<br />

[Actual<br />

Voltage]<br />

[Actual<br />

Current]<br />

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0<br />

consecutive number<br />

month year<br />

[<strong>ELC</strong> Serial Number] is indicated by the first three registers. The exact division of the bits<br />

into year, month and consecutive number is defined by the brackets.<br />

Example: 01F30516 stands for: consecutive number = 62, month = 6 and year = 5.<br />

[Software Version] contains the currently installed software version. The high nibble<br />

represents the main version (e.g. 10), the low-nibble the secondary version (e.g. 2).<br />

Accordingly the example Version 10.2 is written as A216.<br />

[Reserved]

4 Operation of <strong>ELC</strong> page 21<br />

4 Operation of <strong>ELC</strong><br />

4.1 Initial operation<br />

• The operative parameters of the <strong>ELC</strong>, such as the scope of the trigger pulse when<br />

switching on the lamp, are set by the manufacturer.<br />

• You must always ensure that the correct lamp type is used (see chapter 6) and that all<br />

wireing is properly connected!<br />

4.2 Switching on the <strong>ELC</strong><br />

• The <strong>ELC</strong> is switched on by applying the operating voltage and the 24V supply.<br />

4.3 Activating the safety circuits<br />

• Activate the safety relay<br />

• Apply the initialisation signal<br />

4.4 Switching on the lamp<br />

PROFIBUS-output-data (Master → <strong>ELC</strong>)<br />

Byte-<br />

Nr.<br />

0 1 2 3 4 5<br />

Name [Power<br />

Set<br />

Value]<br />

[Installed<br />

Lamp<br />

Power]<br />

[Lamp<br />

Control]<br />

↓<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

[Reserved]<br />

Bit 7 6 5 4 3 2 1 0<br />

Name n/a n/a n/a n/a n/a n/a Clear<br />

Error<br />

Start<br />

Lamp<br />

• Before starting the lamp it is necessary to write the desired lamp power into the register<br />

[Power Set Value] in Watts. To transfer the lamp and its surrounding into a thermally<br />

stable condition, it is recommended to choose the maximum lamp power for [Power Set<br />

Value] during the lamp warm-up period.<br />

• To ignite the lamp set the {Start Lamp}-Bit in register [Lamp Control] to 1.<br />

• {n/a}: not available. These bits are reserved for future applications.

4 Operation of <strong>ELC</strong> page 22<br />

�<br />

�<br />

�<br />

Power must be applied to the <strong>ELC</strong> for at least 2 seconds before attempting to<br />

fire the lamp.<br />

In case of an error the <strong>ELC</strong> will not try to ignite the lamp. After eliminating the<br />

error the [Error Register] has to be cleared additionally (see paragraph 5.3).<br />

As long as the safety circuits are not activated the <strong>ELC</strong> will not try to ignite the<br />

lamp (see paragraph 5.2).<br />

During warm-up the lamp power stays at a very low level over a longer period of time and<br />

after approximately 60 seconds rapidly increases to its nominal power. The lamp is operated<br />

with increased current until the nominal power is reached. The actual condition of the lamp<br />

may be read out from register [Lamp Status] of the PROFIBUS-input-data:<br />

PROFIBUS-input-data (<strong>ELC</strong> → Master)<br />

Byte-<br />

Nr.<br />

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

Name [<strong>ELC</strong><br />

Serial<br />

Number]<br />

[Software<br />

Version]<br />

[<strong>ELC</strong><br />

Nominal<br />

Power]<br />

Bits in use in register [Lamp Status]:<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

[Error<br />

Register]<br />

[Warning<br />

Register]<br />

[Lamp<br />

Status]<br />

↓<br />

[Actual<br />

Power]<br />

[Actual<br />

Voltage]<br />

[Actual<br />

Current]<br />

Bit 7 6 5 4 3 2 1 0<br />

Name n/a n/a n/a n/a n/a Lamp<br />

Ignition<br />

• Bit 2 {Lamp Ignition}: during the ignition phase of the lamp the ”ignition“ bit is set (value =<br />

1, otherwise 0).<br />

• Bit 1 {Run Up}: during warm-up of the lamp the “run-up“-bit is set (value = 1, otherwise 0).<br />

• Bit 0 {Lamp On}: as soon as the lamp has reached the required power and lamp voltage<br />

is in a steady state, the ”lamp-on“-bit will be set (value = 1, otherwise 0).<br />

Further operation data of the continuous operation state may be read out from the registers<br />

[Actual Power], [Actual Voltage] and [Actual Current]:<br />

• [Actual Power] returns the actual power in Watts.<br />

• [Actual Voltage] gives account of the actual lamp voltage in Volts.<br />

• [Actual Current] contains the actual current in Ampère*10 with an accuracy of 100 mA<br />

(e.g.: [Actual Current] = 12 means 1,2 A).<br />

Run<br />

Up<br />

[Reserved]<br />

Lamp<br />

On

4 Operation of <strong>ELC</strong> page 23<br />

4.5 Dimming operation<br />

After having reached nominal operation the desired lamp power can be infinitely adjusted.<br />

• Enter the desired power in Watts in register [Power Set Value].<br />

�<br />

A set value of less than 20% of the <strong>ELC</strong>-nominal-power will automatically be<br />

increased by the <strong>ELC</strong> to 20% of the <strong>ELC</strong> nominal- power.<br />

4.6 Standby operation<br />

During longer idle times the <strong>ELC</strong> can be switched to standby operation. The lamp is operated<br />

at minimum power but can be brought up to nominal power within a few seconds.<br />

• Standby operation corresponds to 20% of the <strong>ELC</strong> nominal power. This can be attained<br />

by setting the register [Power Set Value] at a value equal to or lower than 20% of <strong>ELC</strong><br />

nominal power.<br />

The warm-up time from standby operation to nominal operation depends on the lamp's<br />

ambient conditions. If cooling is too intensive during dimming operation, the acceleration time<br />

is prolonged.<br />

4.7 Switching off the lamp<br />

• The lamp is switched off by setting the {Start Lamp}-bit to 0 in register [Lamp Control].<br />

�<br />

In order to avoid heat accumulation in the <strong>ELC</strong> the power supply should be left<br />

on for a few minutes. Before restarting, the lamp must be sufficiently cooled<br />

down as it cannot be fired otherwise.<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations

5 Monitoring, warning, error, repair page 24<br />

5 Monitoring, warning, error, repair<br />

5.1 Earth fault control<br />

Supplementary to the safety functions of paragraph 3.4 which prevent danger to the<br />

operator, the earth fault control of the <strong>ELC</strong> lamp circuit represents another monitoring<br />

function.<br />

Lamp<br />

R_error<br />

Error Register<br />

PROFIBUS-connection<br />

Fig. 14: Earth fault monitoring<br />

Earth Fault Bit<br />

PROFIBUS input data (<strong>ELC</strong> → Master)<br />

Byte-<br />

Nr.<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

An earth fault occurs when the isolation resistance<br />

R_error (see Fig. 14) drops below approx. 200 kOhm.<br />

The <strong>ELC</strong> will shut down the lamp automatically in<br />

case of an earth fault.<br />

In order for the earth fault control to function properly<br />

it is essential that the <strong>ELC</strong> is connected as<br />

prescribed, particularly the earth connectors.<br />

An earth fault is reported by the {Earth Leakage<br />

Fault}-bit in the [Error Register] (in normal<br />

operation status the bit value is 0).<br />

Earth fault monitoring is also active if the lamp is not<br />

running. However the error message will only be<br />

effectuated when trying to start the lamp.<br />

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

Name [<strong>ELC</strong><br />

Serial<br />

Number]<br />

[Software<br />

Version]<br />

[<strong>ELC</strong><br />

Nominal<br />

Power]<br />

[Error<br />

Register]<br />

Byte 6<br />

↓<br />

[Warning<br />

Register]<br />

[Lamp<br />

Status]<br />

[Actual<br />

Power]<br />

[Actual<br />

Voltage]<br />

Bit 15 14 13 12 11 10 9 8<br />

Name n/a n/a Lamp<br />

Power<br />

Low<br />

internal internal Earth<br />

Leakage<br />

Fault<br />

[Actual<br />

Current]<br />

internal internal<br />

[Reserved]

5 Monitoring, warning, error, repair page 25<br />

Byte 7<br />

Bit 7 6 5 4 3 2 1 0<br />

Name Lamp<br />

Voltage<br />

High<br />

�<br />

internal Bus<br />

Connection<br />

Error<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

internal <strong>ELC</strong><br />

Temperature<br />

High<br />

internal Main<br />

Voltage<br />

Low<br />

internal<br />

In order to avoid an unwanted reaction of the earth fault control during faultless<br />

operation, the isolation resistance of the lamp cables and all lamp connectors<br />

must be greater than 10 MΩ.<br />

5.2 Warning messages<br />

The bits in the [Warning Register] are divided into two groups:<br />

• Group1-Nibble: the bits 0-3 represent critical operating conditions of the lamp. However<br />

they won’t shut down the lamp.<br />

• Group2-Nibble: If a bit in the Group2-nibble (bits 4-7) is set, the lamp cannot be started<br />

or will be shut down during operation.<br />

The bits of the [Warning Register] will automatically be reset as soon as the triggering status<br />

has been resolved.<br />

PROFIBUS-input-data (<strong>ELC</strong> → Master)<br />

Byte-<br />

Nr.<br />

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

Name [<strong>ELC</strong><br />

Serial<br />

Number]<br />

[Software<br />

Version]<br />

[<strong>ELC</strong><br />

Nominal<br />

Power]<br />

[Error<br />

Register]<br />

[Warning<br />

Register]<br />

↓<br />

[Lamp<br />

Status]<br />

[Actual<br />

Power]<br />

[Actual<br />

Voltage]<br />

[Actual<br />

Current]<br />

Bit 7 6 5 4 3 2 1 0<br />

Name Init<br />

Signal<br />

Ok<br />

n/a Lamp<br />

Ignition<br />

Failed<br />

Safety<br />

Relay<br />

Open<br />

Group 2:<br />

Lamp operation not<br />

possible<br />

n/a n/a Run<br />

Up<br />

Long<br />

Group 1:<br />

No shut<br />

down<br />

[Reserved]<br />

Lamp<br />

Voltage<br />

Low

5 Monitoring, warning, error, repair page 26<br />

Bit 0: The {Lamp Voltage Low}-bit is set if the burning voltage of the lamp falls<br />

below its minimum (set by the manufacturer). This bit will be reset if the lamp<br />

voltage exceeds the minimum.<br />

Bit 1: The {Run Up Long}-bit is set if the warm up of the lamp takes longer than<br />

expected. Reset occurs as soon as the {Start Lamp}-bit in register [Lamp<br />

Control] is set to 0 (the lamp being thus actively shut down by the operator<br />

via the PROFIBUS output data).<br />

Bit 4: The {Safety Relay Open} bit is set if the safety relay is not closed (e.g. on<br />

emergency shutdown). There are two different cases:<br />

• If in register [Lamp Control] {Start Lamp} bit is 0, the {Safety Relay<br />

Open} bit is automatically reset as soon as the safety relay is closed.<br />

• During lamp operation ({Start Lamp}=1 in [Lamp Control]) the {Safety<br />

Relay Open} bit remains set and the lamp will be shut down by the <strong>ELC</strong>.<br />

In this case {Safety Relay Open} will only be reset if {Start Lamp} in<br />

[Lamp Control] is reset and the safety relay has been closed.<br />

Bit 5: If the <strong>ELC</strong> cannot ignite the lamp the {Lamp Ignition Failed} bit will be set<br />

and remains in this status as long as {Start Lamp}=1 in [Lamp Control]. The<br />

{Lamp Ignition Failed} bit is reset as soon as {Start Lamp} in [Lamp<br />

Control] is reset.<br />

Bit 7: The {Init Signal Ok} bit reflects the status of the Init-Pin X1.1 of the<br />

initialisation signal (see paragraph 3.4.2).<br />

• {Init Signal Ok}=1 means 24 V on X1.1, the lamp may be ignited and<br />

operated normally.<br />

• {Init Signal Ok}=0 means 0 V on X1.1, the lamp cannot be operated.<br />

To render the <strong>ELC</strong> operational again in case {Init Signal Ok}=0 the<br />

initialisation signal on X1.1 has to be 24V and the start signal {Start Lamp}<br />

has to be reset.<br />

Bit 2, Bit 3 und Bit 6: {n/a} bits (not available) are reserved for future applications.<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations

5 Monitoring, warning, error, repair page 27<br />

5.3 Error<br />

5.3.1 Error messages<br />

Effects of an error:<br />

• The lamp will be immediately shut down,<br />

• In case of an error the red Status-LED is blinking (s. Fig. 11),<br />

• Bits in the [Error Register] will be set as soon as the correspondent error occurs.<br />

PROFIBUS-input-data (<strong>ELC</strong> → Master)<br />

Byte-<br />

Nr.<br />

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15<br />

Name [<strong>ELC</strong><br />

Serial<br />

Number]<br />

[Software<br />

Version]<br />

[<strong>ELC</strong><br />

Nominal<br />

Power]<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

[Error<br />

Register]<br />

[Warning<br />

Register]<br />

Byte 6<br />

↓<br />

[Lamp<br />

Status]<br />

[Actual<br />

Power]<br />

[Actual<br />

Voltage]<br />

Bit 15 14 13 12 11 10 9 8<br />

Name n/a n/a Lamp<br />

Power<br />

Low<br />

Byte 7<br />

internal internal Earth<br />

Leakage<br />

Fault<br />

[Actual<br />

Current]<br />

internal internal<br />

Bit 7 6 5 4 3 2 1 0<br />

Name Lamp<br />

Voltage<br />

High<br />

internal Bus<br />

Connection<br />

Error<br />

internal <strong>ELC</strong><br />

Temperature<br />

High<br />

internal Main<br />

Voltage<br />

Low<br />

internal<br />

Bit 1: An error of the mains is recorded in the {Main Voltage Low}-bit if the mains<br />

voltage falls below the allowed minimum (see chapter 6) during lamp<br />

operation.<br />

Bit 3: The {<strong>ELC</strong> Temperature High} bit is set as soon as the acceptable<br />

temperature is exceeded.<br />

Bit 5: If the PROFIBUS connection is interrupted during lamp operation the {Bus<br />

Connection Error} bit is set. Additionally the green Status-LED (see Fig. 11)<br />

is blinking, or completely off as soon as the internal communication of the <strong>ELC</strong><br />

is interrupted.<br />

Bit 7: If the burning voltage of the lamp is too high the {Lamp Voltage High} bit is<br />

set.<br />

[Reserved]

5 Monitoring, warning, error, repair page 28<br />

Bit 10: The {Earth Leakage Fault}-bit is set if a leakage current to ground on Rerror<br />

(see paragraph 5.1) is detected.<br />

Bit 13: If the lamp extinguishes on its own during lamp operation, the {Lamp Power<br />

Low} bit is set.<br />

Bit 0, Bit 4, Bit 6, Bit 8, Bit 9, Bit 11, Bit 12: bits for analysis by the manufacturer..<br />

Bit 2, Bit 14 und Bit 15: {n/a} bits (not available) are reserved for future<br />

applications.<br />

5.3.2 Troubleshooting<br />

Troubles Possible causes Corrective action<br />

Bit 1: mains voltage too low mains voltage drop or<br />

fluctuations<br />

Bit 3: <strong>ELC</strong>-temperature too<br />

high<br />

Bit 5: No bus connection Bus termination faulty,<br />

loosend connector<br />

Bit 7: Burning voltage of the<br />

lamp too high<br />

Bit 10: Earth fault in lamp<br />

circuit<br />

Bit 13: Lamp extinguishes<br />

on its own<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

Check connections and mains<br />

voltage (if possible)<br />

Ambient temperature too high Check fans of cabinet<br />

(direction of air current, change<br />

filter mats)<br />

Check termination and<br />

connector<br />

Lamp type not correct Check lamp type and switch<br />

lamp<br />

Bad wiring on the lamp, high<br />

air humidity, polluted cables or<br />

connections<br />

Cooling too strong or lamp<br />

defect<br />

Check lamp wiring and<br />

isolation resistance (if<br />

possible)<br />

Reduce cooling or replace<br />

lamp

5 Monitoring, warning, error, repair page 29<br />

5.3.3 Resetting the error register<br />

Each error has to be acknowledged by setting the {Clear Error} bit in register [Lamp<br />

Control] to “1”. First of all set the {Start Lamp} bit in register [Lamp Control] to 0. Then<br />

only the transgression of the {Clear Error} bit from “0” to “1” can reset the [Error Register].<br />

After the PROFIBUS has transmitted the [Lamp Control] Register (check e.g. via the [Error<br />

Register]: if error eliminated all error bits are „0“ again) and after an <strong>ELC</strong> internal<br />

synchronisation time of additional 15 ms, the {Clear Error}-bit has to be reset to „0“.<br />

PROFIBUS-output-data (Master → <strong>ELC</strong>)<br />

Byte-<br />

Nr.<br />

Name [Power<br />

Set<br />

Value]<br />

0 1 2 3 4 5<br />

5.4 Repair <strong>ELC</strong><br />

[Installed<br />

Lamp<br />

Power]<br />

[Lamp<br />

Control]<br />

↓<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

[Reserved]<br />

Bit 7 6 5 4 3 2 1 0<br />

Name n/a n/a n/a n/a n/a n/a Clear<br />

Error<br />

Start<br />

Lamp<br />

Only the manufacturer is permitted to repair the <strong>ELC</strong>. In case of failure please contact the<br />

following address:<br />

eta plus electronic gmbh<br />

Lauterstraße 29<br />

D-72622 Nürtingen<br />

Tel: +49 7022 / 6002-80<br />

Fax: +49 7022 / 65854<br />

e-mail: Info@eta-uv.de

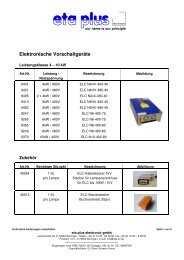

6 <strong>Technical</strong> Data page 30<br />

6 <strong>Technical</strong> Data<br />

General data <strong>ELC</strong><br />

Power choke Uk = 4%<br />

Power factor Typ. 0.88<br />

at Uk = 4% of the upstream power choke<br />

Power efficiency Typ. 0.94<br />

Mains frequency 50 / 60 Hz<br />

Tolerance mains voltage nominal voltage ± 10 %<br />

Recommended air throughput<br />

for cabinet ventilation<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

300 m 3 / h per <strong>ELC</strong> installed at ∆T = 10 K<br />

Control range approx. 20 - 100 %<br />

Firing voltage / duration < 3500 V / < 1 sec.<br />

Protection IP 20<br />

Permissible pollution pollution severity 2 according to VDE 0110<br />

Permissible humidity relative atmospheric humidity 80 %, non-condensing<br />

Dimensions (H x W x D) approx. 650 x 261 x 484 mm<br />

Installation position vertical (lamp and power connection at the top; control connections at the<br />

bottom) or horizontal respecting the minimum spacing in 3.1<br />

Baud rate Tested up to 500kBit<br />

EMC EN 55011<br />

EN 61000-3-3<br />

EN 61000-6-2<br />

Safety EN 50178<br />

Leakage current Leakage current > 3 mA, see chapter 1 “Safety“

6 <strong>Technical</strong> Data page 31<br />

Type specific data (nominal values)<br />

Typ <strong>ELC</strong><br />

<strong>PE22</strong>-400-210<br />

<strong>ELC</strong> <strong>PE22</strong>_<strong>PE32</strong>-V2.2-09.11-GB Subject to technical alterations<br />

<strong>ELC</strong><br />

<strong>PE32</strong>-400-280<br />

Power supply 3 x 400 V 3 x 400 V<br />

Supply current 38,2 A 57,0 A<br />

Max. supply current 42,6 A 62,6 A<br />

Weight approx. 29 kg approx. 37 kg<br />

Line protection * 50 A 63 A<br />

Max. ambient<br />

temperature<br />

in operation<br />

Max. ambient<br />

temperature<br />

during storage and<br />

transportation<br />

0°C bis +45°C 0°C bis +40°C<br />

-20°C bis +70°C -20°C bis +70°C<br />

before initial operation leave at<br />

least 4 hrs at room temperature<br />

Lamp output 22 kW 32 kW<br />

Lamp voltage 2100 V 2800 V<br />

Tolerance lamp voltage ± 5 % ± 5 %<br />

*Line protection: 3-channel automatic cut-out characteristic C<br />

Lamp feeder cable: approved types and lengths<br />

�<br />

The use of cable types which have not been approved by the manufacturer can<br />

lead to malfunction. The possibility of damage to the electronic ballast cannot be<br />

excluded.<br />

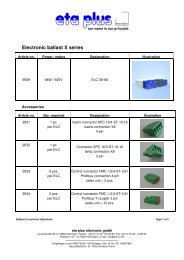

Article no. Type <strong>ELC</strong> <strong>PE22</strong>-400-210 <strong>ELC</strong> <strong>PE32</strong>-400-280<br />

8067<br />

Lamp feeder cable 4kV<br />

2x2.5 mm²<br />

external-Ø 13,5 mm<br />

5-40 m 5-40 m<br />

The data refers to distance between <strong>ELC</strong> and lamp.