Winning Big in the R&D 100 Awards Competition - Oak Ridge ...

Winning Big in the R&D 100 Awards Competition - Oak Ridge ...

Winning Big in the R&D 100 Awards Competition - Oak Ridge ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

State of <strong>the</strong> Laboratory<br />

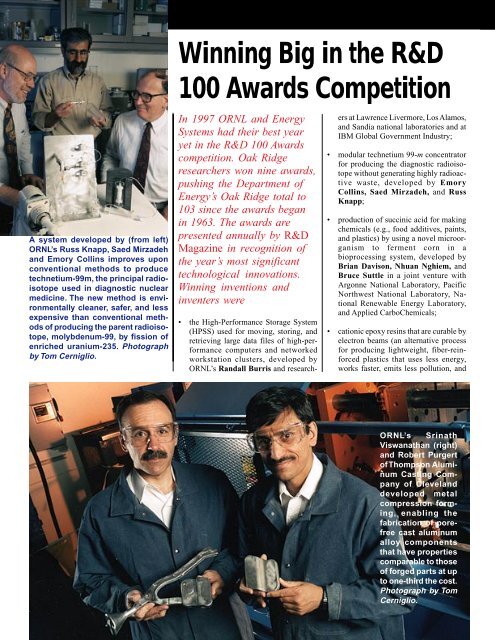

A system developed by (from left)<br />

ORNL’s Russ Knapp, Saed Mirzadeh<br />

and Emory Coll<strong>in</strong>s improves upon<br />

conventional methods to produce<br />

technetium-99m, <strong>the</strong> pr<strong>in</strong>cipal radioisotope<br />

used <strong>in</strong> diagnostic nuclear<br />

medic<strong>in</strong>e. The new method is environmentally<br />

cleaner, safer, and less<br />

expensive than conventional methods<br />

of produc<strong>in</strong>g <strong>the</strong> parent radioisotope,<br />

molybdenum-99, by fission of<br />

enriched uranium-235. Photograph<br />

by Tom Cerniglio.<br />

62<br />

<strong>W<strong>in</strong>n<strong>in</strong>g</strong> <strong>Big</strong> <strong>in</strong> <strong>the</strong> R&D<br />

<strong>100</strong> <strong>Awards</strong> <strong>Competition</strong><br />

In 1997 ORNL and Energy<br />

Systems had <strong>the</strong>ir best year<br />

yet <strong>in</strong> <strong>the</strong> R&D <strong>100</strong> <strong>Awards</strong><br />

competition. <strong>Oak</strong> <strong>Ridge</strong><br />

researchers won n<strong>in</strong>e awards,<br />

push<strong>in</strong>g <strong>the</strong> Department of<br />

Energy’s <strong>Oak</strong> <strong>Ridge</strong> total to<br />

103 s<strong>in</strong>ce <strong>the</strong> awards began<br />

<strong>in</strong> 1963. The awards are<br />

presented annually by R&D<br />

Magaz<strong>in</strong>e <strong>in</strong> recognition of<br />

<strong>the</strong> year’s most significant<br />

technological <strong>in</strong>novations.<br />

<strong>W<strong>in</strong>n<strong>in</strong>g</strong> <strong>in</strong>ventions and<br />

<strong>in</strong>venters were<br />

• <strong>the</strong> High-Performance Storage System<br />

(HPSS) used for mov<strong>in</strong>g, stor<strong>in</strong>g, and<br />

retriev<strong>in</strong>g large data files of high-performance<br />

computers and networked<br />

workstation clusters, developed by<br />

ORNL’s Randall Burris and research-<br />

ers at Lawrence Livermore, Los Alamos,<br />

and Sandia national laboratories and at<br />

IBM Global Government Industry;<br />

• modular technetium 99-m concentrator<br />

for produc<strong>in</strong>g <strong>the</strong> diagnostic radioisotope<br />

without generat<strong>in</strong>g highly radioactive<br />

waste, developed by Emory<br />

Coll<strong>in</strong>s, Saed Mirzadeh, and Russ<br />

Knapp;<br />

• production of succ<strong>in</strong>ic acid for mak<strong>in</strong>g<br />

chemicals (e.g., food additives, pa<strong>in</strong>ts,<br />

and plastics) by us<strong>in</strong>g a novel microorganism<br />

to ferment corn <strong>in</strong> a<br />

bioprocess<strong>in</strong>g system, developed by<br />

Brian Davison, Nhuan Nghiem, and<br />

Bruce Suttle <strong>in</strong> a jo<strong>in</strong>t venture with<br />

Argonne National Laboratory, Pacific<br />

Northwest National Laboratory, National<br />

Renewable Energy Laboratory,<br />

and Applied CarboChemicals;<br />

• cationic epoxy res<strong>in</strong>s that are curable by<br />

electron beams (an alternative process<br />

for produc<strong>in</strong>g lightweight, fiber-re<strong>in</strong>forced<br />

plastics that uses less energy,<br />

works faster, emits less pollution, and<br />

ORNL’s Sr<strong>in</strong>ath<br />

Viswanathan (right)<br />

and Robert Purgert<br />

of Thompson Alum<strong>in</strong>um<br />

Cast<strong>in</strong>g Company<br />

of Cleveland<br />

developed metal<br />

compression form<strong>in</strong>g,<br />

enabl<strong>in</strong>g <strong>the</strong><br />

fabrication of porefree<br />

cast alum<strong>in</strong>um<br />

alloy components<br />

that have properties<br />

comparable to those<br />

of forged parts at up<br />

to one-third <strong>the</strong> cost.<br />

Photograph by Tom<br />

Cerniglio.<br />

<strong>Oak</strong> <strong>Ridge</strong> National Laboratory REVIEW

ORNL’s Amy D<strong>in</strong>dal and Mike Sigman<br />

developed methylated sol-gel sorbent,<br />

a product for detect<strong>in</strong>g airborne<br />

pollutants such as carc<strong>in</strong>ogens and<br />

<strong>in</strong>dustrial effluents. Because of its<br />

chemical and <strong>the</strong>rmal stability, <strong>the</strong><br />

new product is expected to do <strong>the</strong> job<br />

more efficiently and at lower cost<br />

than air sampl<strong>in</strong>g traps on <strong>the</strong> market.<br />

Photograph by Tom Cerniglio.<br />

may be less costly than conventionally<br />

used <strong>the</strong>rmal cur<strong>in</strong>g), developed by<br />

Chris Janke, George Dorsey (Y-12<br />

Plant), Stephen Havens (ORISE), and<br />

V<strong>in</strong>cent Lopata (Atomic Energy of<br />

Canada);<br />

• methylated sol-gel sorbent for detect<strong>in</strong>g<br />

airborne carc<strong>in</strong>ogens and o<strong>the</strong>r <strong>in</strong>dustrial<br />

pollutants, developed by Michael<br />

Sigman, Amy D<strong>in</strong>dal, and George<br />

Wachob of Supelco Incorporated;<br />

• metal compression form<strong>in</strong>g used to<br />

make possible pore-free cast alum<strong>in</strong>um<br />

alloy components that have properties<br />

comparable to those of forged parts at<br />

up to one-third <strong>the</strong> cost, developed by<br />

ORNL’s Randall Burris teamed with<br />

researchers at Lawrence Livermore,<br />

Los Alamos, and Sandia national laboratories<br />

and at IBM Global Government<br />

Industry to develop <strong>the</strong><br />

High-Performance Storage System<br />

(HPSS). HPSS is designed to manage<br />

enormous amounts of data produced<br />

and used <strong>in</strong> modern high-performance<br />

comput<strong>in</strong>g, data collection<br />

and analysis, imag<strong>in</strong>g, and enterprise<br />

environments. Photograph by Tom<br />

Cerniglio.<br />

ORNL’s Robert Lauf (left) and Don Bible developed <strong>the</strong> Vari-Wave, a flexible<br />

microwave heat<strong>in</strong>g system for laboratory research, analytical test<strong>in</strong>g, and<br />

process development for <strong>in</strong>dustries produc<strong>in</strong>g or us<strong>in</strong>g advanced materials.<br />

Applications of Vari-Wave <strong>in</strong>clude process<strong>in</strong>g advanced polymers and<br />

composites, as well as cur<strong>in</strong>g adhesives and encapsulants <strong>in</strong> electronic<br />

packag<strong>in</strong>g assemblies. Photograph by Curtis Boles.<br />

Sr<strong>in</strong>ath Viswanathan and Robert<br />

Purgert (Thompson Alum<strong>in</strong>um Cast<strong>in</strong>g<br />

Company of Cleveland);<br />

• Vari-Wave, a microwave heat<strong>in</strong>g <strong>in</strong>strument<br />

that dramatically reduces cur<strong>in</strong>g<br />

time (from two hours to three m<strong>in</strong>utes)<br />

of adhesives and polymers used <strong>in</strong> <strong>the</strong><br />

production of circuit boards and components,<br />

developed by Bob Lauf, Don<br />

Bible (both of ORNL) Zak Fathi, Mike<br />

Hampton, and Ralph Stevens, all of<br />

Lambda Technologies of Morrisville,<br />

N.C.;<br />

• Enclosed Space Detection System that<br />

detects vibrations from <strong>the</strong> heartbeat of<br />

a person hid<strong>in</strong>g <strong>in</strong> a vehicle, developed<br />

by Leo Labaj, Michael Bath, Vivian<br />

Baylor, Michael Carroll, Mike Fuller,<br />

Tim Hickerson, Tom McCoig, and Richard<br />

Pack, all of <strong>the</strong> Y-12 Plant, and<br />

by ORNL’s Bill Dress and Stephen<br />

Kercel;<br />

• carbon-free metal-ceramic composite<br />

crucible for melt<strong>in</strong>g high-purity metals,<br />

such as uranium and copper, us<strong>in</strong>g <strong>in</strong>duction<br />

heat<strong>in</strong>g, developed by Marv<strong>in</strong><br />

Morrow (Y-12 Plant), James Kiggans,<br />

Jr. (ORNL), Cressie Holcombe (retired<br />

from Y-12 Plant), and Don Rexford of<br />

Blausch Precision Ceramics of Albany,<br />

New York.<br />

Numbers One and Two, 1998 63