About The Design Lab - Rensselaer Polytechnic Institute

About The Design Lab - Rensselaer Polytechnic Institute

About The Design Lab - Rensselaer Polytechnic Institute

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

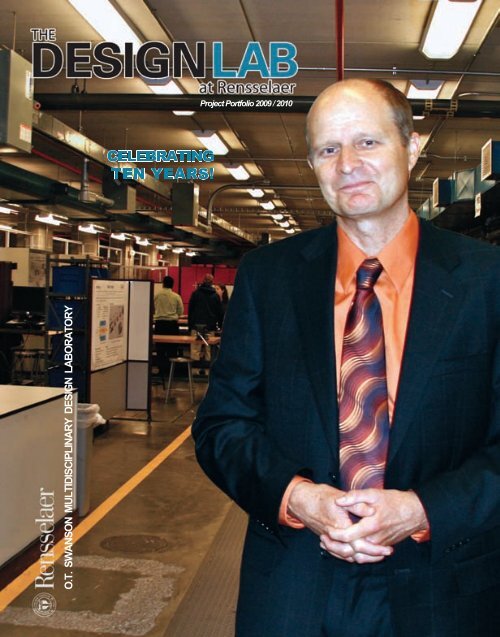

SCHOOL OF ENGINEERING<br />

O.T. SWANSON MULTIDISCIPLINARY DESIGN LABORATORY<br />

CELEBRATING<br />

TEN YEARS!<br />

Project Portfolio 2009 / 2010

Bob Swanson and Cynthia Shevlin visiting <strong>The</strong> <strong>Design</strong> <strong>Lab</strong><br />

happy to to see all the progress after 10 years.<br />

Photo credit: <strong>Rensselaer</strong> / Barry Stein

Copyright © 2010<br />

<strong>Rensselaer</strong> <strong>Polytechnic</strong> <strong>Institute</strong><br />

All rights reserved.<br />

No part of this publication may be<br />

reproduced, stored in a retrieval system<br />

or transmitted in any form by any means<br />

electronic, mechanical, photographic,<br />

recording or otherwise without<br />

written permission of the<br />

<strong>Rensselaer</strong> <strong>Polytechnic</strong> <strong>Institute</strong>.<br />

3<br />

5<br />

7<br />

8<br />

9<br />

10<br />

11<br />

13<br />

14<br />

15<br />

16<br />

17<br />

19<br />

21<br />

23<br />

25<br />

27<br />

29<br />

31<br />

33<br />

34<br />

35<br />

37<br />

39<br />

Contents<br />

Director’s Letter<br />

Balance Assist System - General Dynamics<br />

Smart Grid - GE<br />

Structural Wind Turbine Nacelle - GE<br />

Two Piece Wind Turbine Blade - GE<br />

Wind Turbine Interaction - GE<br />

WInd Turbine Tower Concepts - GE<br />

Quantity Sensor Redesign - Hamilton Sundstrand<br />

Parallel Processing for Radar Analysis - Lockheed Martin<br />

Bearing Life - DRS<br />

Camera Study<br />

Automatic Font Identification - Monotype Imaging<br />

Hybrid Actuator - Northrop Grumman<br />

Managing Information Overload - SAIC<br />

Senior Friendly Shopping Cart - Albany Guardian Society<br />

Biometrics - RPI<br />

<strong>Design</strong> for Sustainabiltiy - RPI<br />

Blind Assembly - NABA<br />

Balance Ball System - RPI<br />

Biomass Scope Study - KNUST<br />

Culturally Situated <strong>Design</strong> Tools - RPI<br />

Leopard Tracking - Stellenbosch<br />

<strong>The</strong> Staff and Faculty<br />

<strong>About</strong> <strong>The</strong> <strong>Design</strong> <strong>Lab</strong>

<strong>The</strong> entrance to <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> where students meet<br />

with their project teams.<br />

Photo credit: <strong>Rensselaer</strong> / Barry Stein

Dear Friends:<br />

Thanks to a generous gift from Robert Swanson and his wife Cynthia Shevlin, the O.T. Swanson<br />

Multidisciplinary <strong>Design</strong> <strong>Lab</strong>oratory was built and opened its doors in the Spring of 2001 to a small<br />

cadre of students who participated in “real-world” industry sponsored projects. This year we<br />

celebrate our ten-year anniversary with this special inaugural issue of the <strong>Design</strong> <strong>Lab</strong> Projects<br />

Portfolio.<br />

Since its inception, the <strong>Design</strong> <strong>Lab</strong> has been a showcase facility for the School of Engineering.<br />

In the past ten years the <strong>Design</strong> <strong>Lab</strong> has successfully implemented an internationally recognized<br />

design program. Over 10,000 students have participated in project-based experiences since <strong>The</strong><br />

<strong>Design</strong> <strong>Lab</strong> was first opened. Every year over 600 sophomore level engineering students take<br />

Introduction to Engineering <strong>Design</strong> in the <strong>Design</strong> <strong>Lab</strong> in preparation for their senior level capstone<br />

design experience. Drawing upon <strong>Design</strong> <strong>Lab</strong> resources, students address some of the world’s<br />

major problems, while they learn about teamwork, communication and the design process.<br />

Over 400 senior-level engineering students from biomedical, computer systems, electrical, electric<br />

power, industrial, materials, and mechanical engineering work on multidisciplinary capstone design<br />

teams each year. <strong>The</strong> projects highlighted in the following pages show the results of our 2009-2010<br />

projects. As you review each project, I’m sure the level of effort, attention to detail, ingenuity, and<br />

overall quality of results from our students will impress you. Underlying the pages, which present<br />

the objectives, approach and results for each project, is the excitement and enthusiasm felt by each<br />

student as they eagerly engage in important projects with the support of our sponsors, faculty, and<br />

staff.<br />

Since its inception, we have conducted over 100 sponsored projects. We employ a team of full and<br />

part time faculty and staff who operate the lab and support our students. <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> brings<br />

together a multitude of resources, programs, courses, curriculum, and people that have lead to<br />

<strong>Rensselaer</strong>’s recognition by Business Week magazine as one of the top 60 design schools in the<br />

world!<br />

As always thank you for your support and best wishes.<br />

Mark<br />

Mark Steiner<br />

Director, <strong>The</strong> <strong>Design</strong> <strong>Lab</strong>

4 <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> at <strong>Rensselaer</strong><br />

Students on the Balance Assist team, perform a<br />

system calibration prior to a demonstration.

Purpose<br />

Current Balance System<br />

Medium Weight Shock Machine<br />

• Currently equipment is loaded and placed on balance<br />

stands<br />

• Load is adjusted manually until system appears<br />

balanced<br />

• Process is very time consuming<br />

5 <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> at <strong>Rensselaer</strong><br />

Balance Assist System<br />

Team: Ron Carl (ELEC), James Edward Gryzbek (MECL), Matt LaBounty (MECL), Karl Meyer (MGTE), Graham Ostrander (MECL),<br />

Alex Peach (ELEC), John Petsche (MECL), Jonathan Proule (MGTE)<br />

Semester Objectives<br />

Deliver a system that:<br />

• Determines shock plate adjustments for one shot<br />

balance<br />

• Includes load measuring support stands compatible<br />

with MWST<br />

• Includes improved <strong>Lab</strong>VIEW program<br />

Project History<br />

Prototype <strong>Lab</strong>VIEW GUI<br />

• Developed proof of concept<br />

• <strong>Design</strong>ed and constructed initial prototype<br />

• <strong>Design</strong>ed <strong>Lab</strong>VIEW program to operate system<br />

• Wrote step by step operation manual<br />

Technical Results<br />

<strong>Design</strong>: Mechanical<br />

Plunger Balance Stand<br />

Electrical<br />

• NI USB-9239 – 4-channel, 24-bit Analog Input Module<br />

• Honeywell Model 3270 Load Cell<br />

• Requirements<br />

• 5,000 lb. load capacity<br />

• Maximum of 3 5 inches in diameter<br />

• At least 0.1% of full scale accuracy<br />

• Output in range of �5 volts<br />

DAQ Enclosure DAQ Load Cell<br />

Analysis<br />

• System concept proven via mock stands with digital<br />

scales and two categories of testing<br />

• Teeter-totter System � Use one scale to give<br />

baseline of compatibility<br />

• Four Scale Test � Use four scales as a proof of<br />

theory in reducing margin of error(and associated<br />

cycle time)<br />

• Repeated proof of concept with load cells to ensure<br />

quality of production and applicability of design<br />

Accomplishments<br />

Mechanical<br />

• Manufactured four balance stands for<br />

practical application that incorporate<br />

load cell technology<br />

<strong>Lab</strong>VIEW Software<br />

Project Engineer: Mark Anderson (<strong>The</strong> <strong>Design</strong> <strong>Lab</strong>), Chief Engineer: Richard Alben (Dept. of Mechanical, Aerospace & Nuclear Eng);<br />

Submarine Balancing Equipment<br />

It is necessary to test major pieces of equipment for<br />

placement on submarines for the ability to withstand shock.<br />

This equipment, weighing multiple tons, is placed on top of<br />

a shock test machine.<br />

Part of this setup involves balancing the equipment to be<br />

tested so that it does not damage itself, the machine or<br />

nearby personnel.<br />

<strong>The</strong> students developed a system of load cells to be placed<br />

at the machine and a <strong>Lab</strong>VIEW software package that<br />

reduced the time needed for this setup by up to 75% during<br />

the course of the semester.<br />

<strong>The</strong> Balance Assist team standing behind their load cell system.<br />

• New Features:<br />

• Visual Aids<br />

• Real time System Status<br />

Indicators<br />

• Automatic Suggested<br />

• Use of Counterweights<br />

• Simple GUI<br />

• Enables Quick and Easy<br />

Balance Procedure<br />

2010 Project Portfolio 5

6 <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> at <strong>Rensselaer</strong><br />

GE student teams including Nacelle, 2-piece Blade, Tower<br />

re-design, their professors, project engineers and sponsor mentors.<br />

© General Electric Company. Used by permission.

Smart Grid - PHEV Impact Study<br />

Robin Lafayette(EPOW), Jia Ma(CSYS), Norma-Ester Medina(MGMT), Justin Metzger(ELEC), Sabrina Moore(EPOW), Sam Ostrow(EPOW), Hao Ruan(ELEC)<br />

Project History<br />

A plug-in hybrid electric vehicle (PHEV) automobile design<br />

contains:<br />

� Electric motor<br />

� Internal combustion engine w/ rechargeable batteries<br />

Purpose:<br />

�To observe and analyze the impact of PHEVs on<br />

the power grid<br />

�Research for future project application<br />

Current Semester Objective:<br />

�Build a simulation to identify the optimal load<br />

schedule for a transformer and the effect on<br />

the thermal properties.<br />

<strong>The</strong> PHEV is an electric vehicle with a<br />

� Gas-tank backup reducing the emissions<br />

<strong>The</strong> cost of electricity for PHEV<br />

� Estimated to be less than one quarter of the cost of fuel<br />

Technical Results (Load):<br />

�23.6% loaded 1.25x the transformers rated load<br />

�9.26% remained overloaded for 5 hours of more<br />

© General Electric Company. Used by permission.<br />

Some models of PHEVs can:<br />

� Travel up to 300 miles on a single charge<br />

� Be fully recharged in one night<br />

(Ex. Toyota Prius, Ford Escape, Chevy Volt, and Tesla)<br />

Technical Results (<strong>The</strong>rmal):<br />

�For most scenarios, top oil temperature doesn’t<br />

exceed normal range (120 degrees Celsius)<br />

Hourly Temperature (C)<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

Rated Load: 37.5kW January, Albany NY<br />

Project Engineer: Mark Anderson (<strong>The</strong> <strong>Design</strong> <strong>Lab</strong>), Chief Engineer: Cheng Hsu (Dept. of Industrial & Systems Eng.)<br />

Power Distribution Systems<br />

As electric cars and hybrid vehicles are adopted by<br />

consumers, they will impact the power distribution systems.<br />

Based on consumer patterns, this will likely create different<br />

and varying electric loading scenarios<br />

that must be accounted for.<br />

<strong>The</strong> student team successfully developed a simulation tool to<br />

help model these variations.<br />

Accomplishments:<br />

�Load schedule optimization tool built using excel<br />

�User interface constructed using <strong>Lab</strong>VIEW<br />

�Output screens for thermal calculations using<br />

<strong>Lab</strong>VIEW<br />

With this tool set, the user can better understand how these<br />

loads may impact the grid at the neighborhood level and can<br />

thus plan accordingly.<br />

30<br />

20<br />

10<br />

0<br />

1 2 3 4 5 6 7 8 9 10 11 12 3 14 15 16 17 18 9 20 21 22 23 4<br />

© General Electric Company. Used by permission.<br />

Average<br />

Max<br />

Min<br />

Next Steps:<br />

�<strong>The</strong>oretical<br />

•Reduction of modeling assumptions to<br />

improve realism<br />

•Expansion of modeling area<br />

•Better VI to model simulation could be<br />

utilized<br />

�Practical<br />

•Physical representation of model<br />

•Improved communication between<br />

utilities, dealerships and vehicle owners<br />

•Modify HMI to include PHEVs<br />

2010 Project Portfolio 7

Present Nacelle Showing Bedplatemounted<br />

Gearbox, Shaft, generator and<br />

Yaw Bearing Surrounded by a<br />

Composite shell<br />

Project Scope<br />

1. Develop Structural Nacelle concepts<br />

•will allow direct mounting of a<br />

Wind Turbine Drive Train<br />

Components (Gearbox, Shaft,<br />

Bearing, generator, Yaw Bearing)<br />

•Provide protection, and allow<br />

maintenance, resist wind loads<br />

2. Down-select 2-3 concepts<br />

3. Develop CAD Models for selected<br />

concepts and Baseline (Bedplate<br />

type design)<br />

4. Develop Structural analysis models<br />

5. Perform structural analysis (static)<br />

6. Develop <strong>Design</strong> Trade-Off curves in<br />

design space<br />

Baseline Loading Model<br />

Wind Turbine <strong>Design</strong><br />

8 <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> at <strong>Rensselaer</strong><br />

Dean Baker (MECL), Kaitlyn Calaluca (MS&E), Rima Deveikyte (MECL), Betsy Green (MECL, Bryant Johnson (MECL),<br />

Julienne <strong>Lab</strong>recque (MS&E), Robert Middleton (MS&E), Ethan Rudolph (MECL), Philip Scangas (MECL), Oliver Williams (MECL)<br />

Space Frame <strong>Design</strong> II<br />

1. 3.<br />

53,000 kg<br />

2.<br />

29,900 kg<br />

22,900 kg<br />

14,900 kg<br />

Bedplate Improvements<br />

Space Frame <strong>Design</strong> I<br />

4.<br />

Benefits:<br />

• Even stress distribution<br />

• Low principal stresses<br />

• High Stiffness<br />

• Low weight<br />

Network <strong>Design</strong><br />

Monocoque (Unibody) <strong>Design</strong><br />

© General Electric Company. Used by permission.<br />

Drawbacks:<br />

• Manufacturability<br />

• Weld construction<br />

• Ball joints<br />

• Requires a skin<br />

Ribbed monocoque design<br />

Corrugated sandwich structure<br />

Results from panel testing<br />

CTQs: Critical to Quality<br />

Stress<br />

Stiffness<br />

Weight/Cost<br />

Vibration<br />

Fatigue<br />

Transportability<br />

Manufacturability<br />

Maintainability<br />

Project Engineer: Scott Miller(<strong>The</strong> <strong>Design</strong> <strong>Lab</strong>), Chief Engineer: Richard Alben (Dept. of Mechanical, Aerospace & Nuclear Eng)<br />

A wind turbine nacelle is typically an environmental cover<br />

protecting the subsystems within the wind turbine machine<br />

head. <strong>The</strong> machine head is the bus-sized structure that sits<br />

on top of the wind turbine tower.<br />

It supports the turbine rotor and power transmission and<br />

generation components such as the rotor shaft, gearbox,<br />

coupling, generator, and bearings. <strong>The</strong> machine head<br />

internal components are mounted on a massive metal<br />

bedplate, which also holds the composite material nacelle.<br />

<strong>The</strong> goal was to provide quantitative information on novel<br />

nacelle design concepts to help the customer decide whether<br />

to launch a commercialization effort.<br />

To this end, GE asked the team to tap a diverse range of<br />

mechanical design concepts and fabrication techniques<br />

from other industries, while applying wind specific design<br />

constraints.<br />

<strong>The</strong> GE 4.0-110 turbine<br />

• Able to sustain weight of<br />

generator, gearbox, and rotor<br />

• Able to distribute stress<br />

throughout nacelle<br />

• Maximum deflection of the<br />

shaft is<br />

• 0-1 degrees<br />

• Optimized for minimum<br />

weight through FEA<br />

• Effects from machinery, yaw<br />

bearing, nacelle due to winds<br />

• Able to withstand cyclic<br />

loading<br />

• Assess the effects of crack<br />

propagation<br />

• Define a process of<br />

transportation<br />

• Define a process of<br />

manufacturing<br />

• Able to access interior of<br />

nacelle<br />

Performance Criteria<br />

<strong>The</strong> nacelle should deflect less than 1 degree<br />

at the tip of the shaft (35 mm)<br />

Next Semester Plans<br />

• Fatigue and Vibration analysis<br />

• Honeycomb sandwich structure research<br />

and analysis<br />

• Application of sandwich structures to<br />

optimize weight reduction and strength<br />

• Exploration of modified spaceframe<br />

options<br />

• Research on spaceframe shell thickness<br />

• Continuation of network design<br />

© General Electric Company. Used by permission.

Project Goal<br />

<strong>Design</strong> a one of two feasible junctions for a<br />

two piece 50+ meter wind turbine blade<br />

Junction Criteria<br />

1. Transfer all loads on blade in such a way<br />

that failure is predicted to occur outside<br />

of junction area before junction fails<br />

2. Maintain current performance by<br />

minimizing weight addition and<br />

additional drag<br />

3. Additional manufacturing costs must be<br />

justifiable by transportation and<br />

assembly cost savings<br />

Governing Physics<br />

For bolt and adhesive analysis<br />

Bolt Thread shear stress<br />

Bolt Tensile stress<br />

Bolt shear stress<br />

Adhesive shear stress<br />

Adhesive peel strength<br />

t<br />

t<br />

Pos t on 1<br />

Loca ion # Loca ion # Lo at on # Loc on #<br />

1 2 3 4<br />

cr cal end ng 6 3 0 46 0 0<br />

m d po nt b nding 0 26 4 2 0 26 4 2<br />

ax al 13 8 13 8 13 8 13 8<br />

pre oad 17 6 17 6 17 6 17 6<br />

jo nt c nt ipe al 0 11 0 11 0 11 0 1<br />

Total 38 07 36 17 31 77 35 71<br />

Green Energy Initiatives<br />

Two-Piece Wind Turbine Blade<br />

Jeremy Crouse, (MECL) Jonathan White (MECL), Colin Danek (MECL), Rob Houliston (MS&E), Tricia Kent (MS&E),<br />

Alex Robb (MECL), Charlie Russo (MECL), David Kozak (MECL), Andrew Abrew (MS&E), Manny Lavin (MECL)<br />

S ess MPa<br />

Model Development-CAD/FEA<br />

Worm Screw Bolt<br />

Physical Testing<br />

Using Instron Machine<br />

2 5<br />

2<br />

1 5<br />

1<br />

0 5<br />

0<br />

0 5<br />

0 35<br />

0 3<br />

0 25<br />

0 2<br />

0 15<br />

0 1<br />

0 05<br />

0<br />

0<br />

Bo t Material Dens ty vs UTS<br />

S ress vs St a n or Var ous Prototypes<br />

0 05 0 1 0 5 0 2 0 25 0 3 0 35<br />

Stra n (mm)<br />

A hes ve on Bu t J in in She r<br />

A hes ve on Dov ta l o nt n T ns on<br />

B l ed Lap n Shear<br />

A hes ve on Bu t J in in Ten i n<br />

Do e ai Shear<br />

Do e ai Shea 2<br />

A hes ve She r<br />

A hes ve She r 2<br />

B l But Jo nt<br />

Wo msc ew en ion<br />

C-Channel adhesive<br />

w/square dovetails<br />

© General Electric Company. Used by permission.<br />

C-Channel adhesive<br />

w/angled dovetails<br />

Project Engineer: Casey Goodwin (<strong>The</strong> <strong>Design</strong> <strong>Lab</strong>), Chief Engineer: Gregory Hampson (Dept. of Mechanical, Aerospace & Nuclear Eng)<br />

<strong>The</strong> GE Wind Energy business was created as a result<br />

of the Ecomagination and Green Energy initiatives at GE<br />

Energy. GE currently has over 12,000 1.5MW wind turbines<br />

in operation worldwide. <strong>The</strong> next generation machine, the<br />

GE 2.5MW product is expected to grow substantially in<br />

market share. GE is continuously striving for creative ways<br />

to design, update, or redesign components for improved<br />

performance and low cost, and delivers customer value via<br />

a cost effective product that meets or exceeds requirements.<br />

Longer wind blades are able to capture more of the wind’s<br />

energy than shorter ones. However, large blades are very<br />

difficult to transport. Two-piece blade designs, with the<br />

ability to assemble them in two halfs in the field would<br />

address this problem. However, the biggest challenge is<br />

to have a junction design that is structurally robust and<br />

aerodynamically equivalent to a pristine “un-jointed”, single<br />

piece blade.<br />

t in<br />

© General Electric Company. Used by permission.<br />

St a n<br />

St e s (k a)<br />

C-Channel + adhesive<br />

Overlap Length<br />

25 0<br />

0 000 5<br />

0 0004<br />

20 0<br />

0 000 5<br />

0 0003<br />

15 0<br />

0 000 5<br />

0 0002<br />

10 0<br />

0 000 5<br />

5 0<br />

0 0001<br />

0 000 5<br />

0<br />

0<br />

0 0 5 1 1 5 2 2 5<br />

eng h (m)<br />

Bolts in Shear Dovetail Adhesive Shear Adhesive Bolts in Tension<br />

*Physical Testing was used to confirm results of calculations<br />

and Finite element analysis<br />

St ain<br />

M x Von M es<br />

St e s X<br />

St e s Y<br />

St e s Z<br />

2010 Project Portfolio 9

Analysis Assumptions<br />

•All towers are assumed to be 100m tall<br />

unless otherwise specified<br />

•Drag force from wind has been simplified to<br />

drag on three flat surfaces with the width and<br />

length of the blades<br />

•No moment due to Nacelle and blades<br />

•Yield Strength of steel 250 Mpa<br />

•No torsional load<br />

•Specific cost of steel $3.3/kg<br />

•Steel Density 7800kg/m 3<br />

Cost ($x1,000,000)<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

Stress (MPa)<br />

$1.60<br />

$1.40<br />

$1.20<br />

$1.00<br />

$0.80<br />

$0.60<br />

$0.40<br />

$0.20<br />

$0.00<br />

Modular Panel <strong>Design</strong><br />

•Friction connections (bolts and plates) instead of welds<br />

•Material savings after eliminating ring flanges<br />

•Cutting of plates may be less expensive than welding<br />

Structural:<br />

•Main Metric is Total Stress<br />

•Unless specified otherwise tower height is 100m<br />

•Total= Bending Stress Axial Stress<br />

•Modeled as:<br />

• Hollow steel cylinder<br />

• Constant diameter<br />

• Constant wall thickness<br />

•Main factors are wall thickness and height<br />

•Torsion and fatigue not considered in initial analysis<br />

Cost<br />

•Mass connection plates and bolts neglected<br />

Total Stress vs. Height<br />

(Diameter =3.5m, Wind Speed = 20m/s)<br />

Steel Y eld St ength<br />

80 90 100 110 120<br />

Height (m)<br />

Cost vs. Wall Thickness<br />

(H=100m, D=3.5m, Wind Speed=20m/s)<br />

Kyle Allen (MECL), Drew Shamyer (MECL), Alex Gage (MS&E), Brian Severino (MECL), CJ Vincent )(MECL),<br />

.025m Wall<br />

Th ckness<br />

.030m Wall<br />

Th ckness<br />

.035m Wall<br />

Th ckness<br />

.040m Wall<br />

Th ckness<br />

.045m Wall<br />

Th ckness<br />

0.020 0.025 0.030 0 035 0.040 0.045 0.050<br />

Wa l Thickness (m)<br />

Tower of Power<br />

Michael Hughes (MECL), Tyler Scully (MECL), John Vinueza (MECL)<br />

Total Stress vs. Wind Speed<br />

450<br />

400<br />

Semimonocoq<br />

350<br />

300<br />

250<br />

ue Stress<br />

Lattice w/ Skin<br />

Stress<br />

Modular Pane Steel Yield Strength<br />

200<br />

Stress<br />

Hybrid Base<br />

150 Stress<br />

I Beam Lattice<br />

100<br />

50<br />

0<br />

Stress<br />

0 10 20<br />

Wind Speed (m/s)<br />

30<br />

Stress (MPa)<br />

Stress (MPa)<br />

Cost ($x1,000,000)<br />

120<br />

100<br />

80<br />

60<br />

40<br />

Lattice With Skin<br />

Structural<br />

•Modeled as:<br />

• 4 posts with .5” thick skin (skin<br />

does not support bending<br />

loads)<br />

• Tower length and width held<br />

constant as the dimensions at<br />

the center of pressure<br />

• Bending moment calculated<br />

using drag on blades as well as<br />

tower<br />

Cost<br />

•Lattice neglected in cost model<br />

Total Stress vs. Height<br />

Base W dth 7m<br />

Base W dth 10m<br />

Base W dth 13m<br />

80 100 120<br />

Height (m)<br />

4<br />

3 5<br />

3<br />

2 5<br />

2<br />

1 5<br />

1<br />

0 5<br />

0<br />

Cost vs. Base Width<br />

5 6 7 8 9 10 11 12 13<br />

Base Width (m)<br />

© General Electric Company. Used by permission.<br />

Semi-Monocoque<br />

Wind Speed vs. Maximum Stress in a<br />

Structural<br />

467<br />

4m Diameter Tower<br />

0.700<br />

Number of Beams vs. Cost<br />

•Properties of W14x99 I-Beam<br />

used<br />

•Modeled as:<br />

•Vertical I – Beams Only<br />

•Beams evenly spaced apart<br />

•Beams centroids placed at radius<br />

of tower<br />

417<br />

367<br />

317<br />

267<br />

217<br />

167<br />

117<br />

67<br />

Steel Y eld St ength<br />

0.600<br />

0.500<br />

0.400<br />

0.300<br />

0.200<br />

0.100<br />

17<br />

0.000<br />

Cost<br />

0 10 20 30<br />

0 5 10 15 20<br />

•Mass of stab lization rings and<br />

Wind Speed (m/s)<br />

Number of Beams<br />

bolts neglected<br />

15 Beam Towe 12 Beam Towe 10 Beam Towe<br />

I-Beam Lattice<br />

Structural:<br />

•Modeled as four vertical I-beams with skin<br />

around it<br />

•Effects of lattice connection plates and<br />

taper neglected<br />

• Properties of W27x178 I-Beams used<br />

unless specified otherwise<br />

Cost:<br />

•<strong>The</strong> lattice the connection plates and<br />

taper were neglected for cost analysis<br />

•Skin material was assumed to be steel<br />

Hybrid Base<br />

Structural<br />

•Modeled as:<br />

•Cylindrical tower of only<br />

concrete<br />

•Induced stresses assumed to<br />

be the same as a 00m tall<br />

concrete tower<br />

Cost<br />

•Modeled as:<br />

•Cylindrical tower of concrete<br />

with 1’’ thick steel shell<br />

Some towers are 30 feet in diameter in order to support the machine head, rotor and blades.<br />

10 <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> at <strong>Rensselaer</strong> © General Electric Company. Used by permission.<br />

Stress (MPa)<br />

8 Beam Towe 6 Beam Towe<br />

Project Engineer: Casey Goodwin (<strong>The</strong> <strong>Design</strong> <strong>Lab</strong>), Chief Engineer: Daniel Lewis (Dept. of Materials Science & Eng.)<br />

<strong>The</strong> tower of a wind turbine carries the Machine Head and<br />

the Rotor plus the Blade. Typically, large wind turbines utilize<br />

tubular steel towers, lattice towers, or concrete towers.<br />

Guyed tubular towers are only used for small wind turbines.<br />

More recently, we see Hybrid Towers in use. Each has its<br />

advantages and drawbacks.<br />

All towers are required to function under random wind<br />

loading (fatigue). <strong>The</strong>y are also required to survive under<br />

what is known as “Fifty Year Gust Loads”.<br />

<strong>The</strong> team proposed a solution to meet the needs of fatigue,<br />

life, strength, stiffness, natural frequency, buckling and other<br />

requirements.<br />

Stress (MPa)<br />

Cost($x1,000,000)<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

$0.00<br />

Total Stress vs. Tower Height<br />

(t=0.25in, D=4m, Wind Speed=20m/s)<br />

50 60 70 80 90 100 110 120 130 140 150<br />

Tower He ght (m)<br />

Cost vs. Height<br />

(D=4m)<br />

50 75 100 125 150<br />

Tower Height (m)<br />

t=.125 n<br />

t=.25 n<br />

t=.5 n<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

Stress (MPa)<br />

Cost ($x1,000)<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Cost ($x1,000,000)<br />

•Concrete estimated to cost $2.78 per ft 3<br />

and 2400kg/m 3<br />

•Cold rolled steel is estimated to cost<br />

$1.5 per lb (Albany Steel)<br />

Bending Stress vs. Wall Thickness<br />

0 0.5 1 1.5 2 2.5 3<br />

Wall Thickness (m)<br />

Cost vs. Wall Thickness<br />

0 0.5 1 1.5 2 2.5<br />

Wall Thickness (m)

Vision and Scope<br />

Develop models for the interaction of wind turbines to improve<br />

spacing and operational strategies to maximize power generated<br />

from wind farms. <strong>The</strong>se models will strengthen GE s position as a<br />

supplier of wind turbine equipment and wind farm design services.<br />

GE Wind Turbine Interaction<br />

Kyle Barden (MECL), Alex Field (MGMT), Chris Fiore (MECL), Chris Jones (MECL), Erik Jurgensen (MECL), Hyunkyu Kim (ELEC), Steve Knapp (MECL), Alec Marshall (MECL), Philip Reed (MECL)<br />

© General Electric Company. Used by permission.<br />

Current Objectives<br />

1. Implement improved Cp and higher TSR rotor designs supplied by GE.<br />

2. Characterize the performance of the improved model wind turbines in the<br />

wind tunnel. Variables tested will be wind speed, TSR, and yaw angle to measure<br />

thrust and wake profiles.<br />

3. Implement visualization techniques to better understand and analyze wake<br />

effects.<br />

Tower System Improvements<br />

Results<br />

Rotor <strong>Design</strong>s and Manufacturing<br />

Old Tower New Tower<br />

•Ability to check motor<br />

overheating<br />

•Redundant thrust<br />

readings<br />

•Better signal<br />

processing<br />

New Nacelle<br />

•Enabled thrust<br />

measurement<br />

•Better aerodynamics<br />

•Stronger nacelle<br />

Code Modifications<br />

Old Interface<br />

Circuitry Upgrades<br />

•No voltage interaction<br />

between dynos<br />

•Increased power<br />

capacity<br />

•Higher tolerance<br />

resistors<br />

•Individual power<br />

supplies<br />

•Modular face plates<br />

New Interface<br />

��<br />

Wind Tunnel Set Set-up up<br />

� �<br />

� �<br />

� �<br />

� �<br />

�� �<br />

�� �<br />

������ ���������� ���� ����� ������� ����<br />

�� �<br />

�� �� �� � �<br />

���<br />

� �<br />

Faulhaber 1331<br />

Faulhaber Faulhaber 2232<br />

GWS RS-385SH RS 385SH<br />

�<br />

�<br />

�<br />

�<br />

�<br />

� � �<br />

�<br />

�<br />

Fall ‘09 Rotor<br />

Dynamometer Selection<br />

GE <strong>Design</strong>ed Rotor, ABS<br />

Team <strong>Design</strong>ed Rotor GE <strong>Design</strong>ed Rotor, SLA Material Deflection Comparison<br />

•Higher RPM motors<br />

•Higher current motors<br />

Old Circuitry New Circuitry<br />

Project Engineer: Scott Miller (Core Engineering), Chief Engineer: Richard Alben (Dept. of Mechanical, Aerospace & Nuclear Eng)<br />

Improving Wind Farms<br />

��<br />

���<br />

���<br />

���<br />

���<br />

����<br />

����<br />

����<br />

����<br />

����<br />

��� ����� �� ��� �������� ������ �������<br />

Wind turbines are typically clustered in “wind farms” of 5 to<br />

more than 100 machines. It is desirable to space the turbines<br />

widely enough apart that the available wind energy for each<br />

turbine is only slightly reduced by the action of other turbines<br />

in the wind farm. But widely spaced turbines mean less power<br />

for a given land area. <strong>The</strong>se interactions include both wake<br />

effects from up-wind turbines and also up-flow disturbances<br />

from down-wind turbines.<br />

<strong>The</strong> goal of this project was to develop an improved<br />

understanding of these interactions and, in partiticular,<br />

determine if the overall system performance of the wind farm<br />

can be improved by accounting for the interactions, instead<br />

of just trying to optimize each turbine individually.<br />

GE asked us to study the effects of interaction for other rotors,<br />

especially some with higher efficiencies, and also study the<br />

physical and data acquisition enhancements to our system.<br />

����<br />

� �<br />

���<br />

���<br />

���<br />

�<br />

�<br />

�<br />

�<br />

4-bladed rotor<br />

•Smoke visualization capable<br />

•Blade end effects/Axial induction<br />

factor<br />

•Reduced angular velocity<br />

•<strong>The</strong>oretical higher Cp<br />

Flow Visualization Techniques<br />

Fall ‘09 Results<br />

New Smoke<br />

•Experimenting with<br />

Visualization<br />

more effective<br />

visualization techniques<br />

GE rotor<br />

•<strong>The</strong>oretical higher Cp/TSR<br />

Each wind turbine has an effect on the ones next to it or behind it.<br />

© General Electric Company. Used by permission.

12 <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> at <strong>Rensselaer</strong><br />

Students on the Hamilton Sundstrand team presenting designs<br />

for measuring the volume inside devices within a space station.

Measuring Volume In Outer Space<br />

Quantity Sensor Redesign<br />

Craig Eaton (MS&E), Burton Francis (MECL), Richard Grebe (MECL), Adam Jankauskus (ELEC), Lukas Leinhard (MECL),<br />

Jeffery Musante (ELEC), Arvind Ramachandran (MS&E), Michelle Santospirito (MGMT)<br />

Background Information<br />

<strong>The</strong> Hamilton Sundstrand Bellows Accumulator is a tank used for storing liquid in<br />

aerospace life support systems applications. Inside the accumulator, a quantity<br />

sensor determines the volume of the liquid present by measuring the<br />

displacement of the bellows. <strong>The</strong> current device, a string potentiometer, fails too<br />

frequently because of launch vibrations. A new measurement device is needed.<br />

Measurement Results<br />

Figure 1 shows a simulation of<br />

ideal experimental output.<br />

Figures 2 and 3 show actual laser<br />

and ultrasonic measurements,<br />

respectively. Note that the laser<br />

most closely resembles the ideal<br />

system.<br />

Figure 1 Figure 2<br />

Figure 3<br />

Systems that are used in space applications must be<br />

stable and reliable while deployed for up to 30 years. It is<br />

necessary to measure the volume of fluid in the various<br />

systems on the space station platforms.<br />

For approximately ten years the sponsor had been<br />

considering various technologies but had not selected an<br />

alternative.<br />

One student team successfully identified promising<br />

technologies that could be used to replace the current<br />

measurement technology. <strong>The</strong> second student team then<br />

found workable and readily available hardware for two of<br />

the potential technologies and performed a gage reliability<br />

and repeatability analysis on a prototype system they<br />

designed and constructed. As a result, they were able to<br />

prove that both selected technologies were viable for the<br />

application.<br />

Loop Fluid<br />

(Water, Urine,<br />

Coolant)<br />

Results:<br />

• <strong>The</strong> laser is a more precise measuring device.<br />

• <strong>The</strong> ultrasonic sensor is a more accurate, robust, and reliable measurement system.<br />

• Both sensors work in the system and greatly surpass the sponsor’s standards in terms of<br />

percent error of full scale.<br />

Recommendations:<br />

• Hamilton should re-evaluate their error standards.<br />

• <strong>The</strong> sponsor should choose laser for immediate use and precision.<br />

• <strong>The</strong> sponsor should choose ultrasonic and research a calibration method for a more<br />

accurate and reliable measurement system.<br />

Hamilton Sundstrand Bellows Accumulator<br />

Bellows<br />

Gas Charge<br />

(Air, Nitrogen,<br />

Helium)<br />

Our Working Prototype<br />

(a.) 4” x 48” hydraulic cylinder<br />

(a.) 3/8” threaded rod<br />

(b.) Ruler mounted to piston<br />

(c.) 3/8” threaded rod actuation of piston driven by<br />

power drill<br />

(d.) Cylinder mounted on 80 x 20 struts<br />

(e.) Sensors mounted directly to cylinder, radially<br />

constrained by cap fitted in cylinder bore<br />

(f.) Spring braces used to consistently reproduce holding<br />

pressure of sensor caps to cylinder<br />

Project Objectives:<br />

1) Create a working prototype of a<br />

Hamilton Sundstrand Bellows<br />

Accumulator.<br />

2) Test the performance of laser and<br />

ultrasonic distance sensors in the<br />

accumulator for use as a<br />

replacement for their current<br />

sensor.<br />

3) Decide which technology best<br />

suits the sponsor’s needs and<br />

recommend which technology to<br />

move forward with.<br />

(b.) Power drill attachment position<br />

(c.) Socket ratchet attachment position<br />

(d.) Intermediate block connecting<br />

linear actuator to piston<br />

Project Engineer: Mark Anderson (<strong>The</strong> <strong>Design</strong> <strong>Lab</strong>), Chief Engineer: Daniel Lewis (Dept. of Materials Science & Eng.)<br />

Students meeting with the mentors at Hamilton Sundstrand.<br />

2010 Project Portfolio 13

14 <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> at <strong>Rensselaer</strong><br />

Parallel Processing for Radar Analysis<br />

Team: Eric Allen (CSYS), Bryan Bessen (ELEC), Daniel Branken (CSYS), Jonathan Jesuraj (CSYS), Matthew Kloepfer (ELEC),<br />

Jonathan Marini (CSYS), Alexandru Radocea (CSYS), Joseph Sgarlata (ELEC), Daniel Sullivan (ELEC), Brandon <strong>The</strong>tford (CSYS)<br />

Project Purpose: Determine how different methods of processing radar signals can speed up the analysis and performance of a radar system algorithm provided by Lockheed Martin.<br />

This has been explored by comparing results of single and multiple Graphical Processing Units (GPUs) against a Central Processing Unit (CPU) implementation.<br />

Technical Requirements:<br />

•Examine average run times versus<br />

number of objects in scene<br />

•Determine average runtime versus<br />

CPU/ GPU resources<br />

Radar Algorithm:<br />

W(f) RCS(f)<br />

s(t ) S(f) HMF(f) scp(t) fft() conj() ifft() ifftshift()<br />

H<br />

S(f)<br />

MF(f) • W(f) • RCS(f)<br />

Provided Algorithm<br />

Simulink Model of Algorithm<br />

System Inputs and Output:<br />

Amp ude<br />

Amp de<br />

2<br />

1 5<br />

1<br />

0 5<br />

0<br />

-0 5<br />

1<br />

-1 5<br />

2<br />

0 50 100 50 00 2 0 3 0 3 0 400 450 500<br />

1 5<br />

1<br />

0 5<br />

0<br />

-0 5<br />

( )<br />

T me s)<br />

Fr quecny<br />

Input Chirp Signal s(t) W(f) Filter<br />

RCS ) Noi e<br />

1<br />

0 0 5 1 1 5 2 2 5 3 3 5<br />

Fr quecny<br />

x 10<br />

Radar Cross Section, RCS(f)<br />

4<br />

0 0 5 1 1 5 2 2 5 3 3 5<br />

x 10 4<br />

W f) F ter<br />

1<br />

0 9<br />

0 8<br />

0 7<br />

0 6<br />

0 5<br />

0 4<br />

0 3<br />

0 2<br />

0 1<br />

0<br />

Amp ude<br />

Amp de<br />

4<br />

x 10<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Sc ( )<br />

0 0 5 1 1 5 2 2 5 3 3 5<br />

x 10 4<br />

0<br />

T me s)<br />

Output Signal Scp(t) How a GPU Splits Up Work<br />

Doing the parallel calculation<br />

V1 VR = V1 * V2<br />

V2 1 2 3 4 . . .<br />

1 2 3 4 . . .<br />

V R [1] = V1[1] * V2[ ]<br />

Returns Per Second<br />

2 500<br />

2 000<br />

1 500<br />

1 000<br />

500<br />

0<br />

7,000<br />

6,000<br />

5,000<br />

4,000<br />

3,000<br />

2,000<br />

1,000<br />

0<br />

*<br />

*<br />

*<br />

*<br />

*<br />

*<br />

1 2 3 4 . . .<br />

VR *<br />

*<br />

*<br />

*<br />

*<br />

*<br />

V R [4] = V1[4] * V2[4]<br />

GPU P ocesso<br />

GPU vs. mGPU vs. CPU - Returns Per Second<br />

8,000<br />

GPU - 16K<br />

GPU - 32K<br />

GPU - 64K<br />

mGPU - 16K<br />

mGPU - 32K<br />

mGPU - 64K<br />

CPU - 16K<br />

CPU - 32K<br />

CPU - 64K<br />

y = 16.002ln(x) 207.8<br />

R² = 0.989<br />

512 4 096 32,768 262,144 2,097 152<br />

Number of Elements (log8 scale)<br />

1 8 64 512 4,096 32,768<br />

Number of Returns Processed<br />

Radar System Performance Improvement<br />

Loops X/N<br />

returns until<br />

processed<br />

<strong>Design</strong><br />

Splitting Work Between Multiple GPUs<br />

X RCS(f)’s on CPU<br />

X/N Returns X/N Returns X/N Returns<br />

GPU 1 GPU 2 . . . GPU N<br />

X S cp(t)’s on CPU<br />

Each GPU is responsible for an equal number of returns and they all perform<br />

calculations in parallel to each other and return the results to the CPU.<br />

Technical Results<br />

Project Engineer: Mark Anderson (<strong>The</strong> <strong>Design</strong> <strong>Lab</strong>) , Chief Engineer Junichi Kanai (Dept. of Electrical, Computer, & Systems Eng.)<br />

In the design of radar systems it is important to accurately<br />

model and simulate various conditions. Modern radar<br />

systems utilize computers to analyze the received signals.<br />

Simulation testing is an extremely computer intensive effort<br />

and requires significant time investment, thus reducing<br />

both the fidelity and the quantity of analysis that can be<br />

performed.<br />

<strong>The</strong> student team was able to study the algorithms used<br />

and re-implement them using the processing power found<br />

in a typical graphics card (GPU).<br />

<strong>The</strong> students were able to offer performance improvements<br />

of 2-3 times for some cases and much more overall – using<br />

a $100 PC card!<br />

Time (ms)<br />

Vector Size vs. Time for CPU vs. GPU GPU vs. mGPU vs. CPU - Time per Return<br />

GPU - 16K<br />

GPU - 32K<br />

GPU<br />

GPU - 64K<br />

mGPU - 16K<br />

CPU<br />

3,500<br />

mGPU - 32K<br />

Log F t (GPU)<br />

y = 195 44x0 1618<br />

R² 0 9789<br />

3,000<br />

mGPU - 64K<br />

CPU - 16K<br />

Powe F t (CPU)<br />

CPU - 32K<br />

2,500<br />

CPU - 64K<br />

Time (µsec)<br />

1,000,000<br />

Time (ms)<br />

2,000<br />

1,500<br />

1,000<br />

500<br />

0<br />

100,000<br />

10,000<br />

1,000<br />

100<br />

10<br />

[ Whe e mGPU mu t ple GPUs ( n this c se 2 GPU ) ]<br />

1<br />

1 8 64 512 4 096 32,768<br />

Number of Returns Processed<br />

GPU vs. mGPU vs. CPU - Returns vs. Time<br />

GPU - 64K<br />

mGPU 16K<br />

mGPU - 32K<br />

mGPU 64K<br />

CPU - 1 K<br />

CPU - 32K<br />

CPU - 6 K<br />

1 4 16 64 256 1,024 4 096<br />

Number of Returns Processed<br />

Time �<br />

How Our Algorithm is Processed<br />

CPU<br />

GPU<br />

Allocate Memory and<br />

copy Data for RCS(f)’s<br />

Limited by CPU RAM size<br />

→ s(t) and W(f) data transfer to GPU →<br />

FFT on s(t)<br />

S(f) x S*(f) x W(f)<br />

→ RCS(f) data transfer to GPU →<br />

Loop until all Multiply RCS(f)’s * HMF(f) returns are<br />

processed IFFT on Scp(f)’s and shift<br />

← Scp(t) data transfer to CPU ←<br />

Return Scp(t)’s Pre-computed<br />

to save time<br />

Return to CPU<br />

when no more<br />

RCS(f)’s<br />

Semester Objectives Met:<br />

•Generation of universal test data<br />

•Agreement among multiple models of<br />

radar systems<br />

•Detailed timing and performance<br />

analysis<br />

•Accuracy analysis<br />

Conclusion:<br />

•Use of GPUs increases throughput by<br />

2-6 times over our CPU implementation<br />

•Algorithm easily parallelized on GPU<br />

•Scales linearly across two GPUs<br />

Next Steps:<br />

•Summation of RCS before signal chain<br />

to improve runtime<br />

•Address potential RCS input bottlenecks<br />

to keep up with GPU processing<br />

•Evaluate effects of different GPUs on<br />

performance<br />

Lockheed Martin team standing in front of their poster inside <strong>The</strong> <strong>Design</strong> <strong>Lab</strong>.

Effects of Stray Currents on Bearing Life<br />

Lun Chen (ELEC), Dan Frydryk (MS&E), Colin Haynes (MS&E), Nodari Ivanov (MECL),<br />

Seth Jones (ELEC), Jason Livingston (MECL), Bryan Scala (MGMT), Josh Smolensky (MECL), John Velonis (ELEC)<br />

Purpose Test Capability<br />

<strong>Design</strong>, construct, and deliver an<br />

apparatus which will test and analyze the<br />

effects of stray currents on bearing life.<br />

Technical <strong>Design</strong> Approach<br />

• Parallel processing<br />

• Communica^on<br />

• Redundancy<br />

• Keep It Simple<br />

Transforma^on of <strong>Design</strong><br />

Instrumenta^on<br />

• Max Load: 0-‐950 at 150psi<br />

• Voltage Range: 0-‐30v<br />

• Amperage: 0-‐10A<br />

• Signal Frequency: 60-‐10,000Hz<br />

• Rota^on Speed: 2000 rpm variable<br />

drive<br />

System Features<br />

• Safe opera^on with cau^on labels<br />

• Custom <strong>Lab</strong>view UI with controls<br />

• Easy to assemble 8020 base<br />

• Plug and play measurement<br />

devices<br />

• Removable collar for easy access<br />

• Con^nuous variable drive<br />

Monitoring and Sensing<br />

• Temperature<br />

> Supports J-‐types and many others<br />

• Vibra^on<br />

> Accepts analogue and digital inputs<br />

• Oscilloscope<br />

> Maximum sampling rate of 50Ms/s,<br />

50MHz bandwith<br />

• Accelera^on<br />

> Range of -‐1.7 to 1.7g, Sensi^vity of<br />

1000mV/g, 2kHz bandwith<br />

Project Engineer: ScoL Miller (Core Engineering), Chief Engineer: Richard Alben (Dept. of Mechanical, Aerospace & Nuclear Eng)<br />

Military/Commercial Machinery Systems<br />

DRS Power Technology, Inc (DRS-PTI) provides engineering<br />

and manufacturing services for military and commercial<br />

machinery systems. This includes mechanical equipment<br />

modeling, naval machinery inspection, and the design and<br />

fabrication of advanced electric machinery<br />

<strong>The</strong> goal for the semester was to design and build a test<br />

system, and to do initial experiments with that system to<br />

understand the effects of stray currents on bearing life.<br />

<strong>The</strong> bearing must be easily removed so that the cumulative<br />

damage within the bearing can be measured. A variety<br />

of different bearing types were tested in the rig, including<br />

journal, roller and ball bearings with both grease fittings and<br />

continuous oil lubrication.<br />

Specific values for rotational speed, applied forces and<br />

overall scale of the test system were defined as part of the<br />

system requirement definition task.<br />

Bearing Life team standing behind their prototype.<br />

2010 Project Portfolio 15

Purpose<br />

Our objec*ve is to develop a camera<br />

system to replace the current imaging<br />

system for a surgical device in order to<br />

reduce system cost and increase image<br />

clarity and resolu*on.<br />

Semester Objec:ves<br />

<strong>Design</strong> a camera system which meets<br />

or exceeds the following requirements:<br />

Camera Sensor Requirements<br />

• Size – appropriate for surgical applicaOon<br />

• Type – relevant technology<br />

• ResoluOon – be[er than exisOng systems<br />

Light Source IntegraOon*<br />

• Current light source or LEDs (*Not the focus of the<br />

project but necessary for the final system and to<br />

perform the system test on the prototypes.)<br />

IntegraOon with Current Surgical Device<br />

• Size – appropriate for successful integraOon<br />

• Safety – for use in surgical applicaOons and<br />

sterilizaOon processes currently used.<br />

• OrientaOon – to provide the correct viewing angle<br />

for the camera system to ensure an unobstructed<br />

view of the surgical site.<br />

Biomedical Engineering Scope<br />

16 <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> at <strong>Rensselaer</strong><br />

Camera Study Project<br />

Team: Adam Brooks (BME), Jim Croke (EE), Bill Simmons (EE), Jon Todzia (EE),<br />

Elizabeth Tozer (EE), Tina Verderosa (EE), Harrison Wang (IME), Claire Woot de Trixhe (IME)<br />

<strong>The</strong> decision matrix (to<br />

the right) compares<br />

several camera systems<br />

in order to determine the<br />

best one suited to this<br />

project.<br />

Note: Camera System 3<br />

was uOlized due to the<br />

unavailability of Camera<br />

System 1.<br />

Technical Results<br />

Ranking<br />

1 (best) to<br />

4 (worst)<br />

Chief Engineer: Junichi Kanai PhD (ESCE); Project Engineer: Mark Anderson (<strong>Design</strong> <strong>Lab</strong>)<br />

In many microscopic applications, the current approach to<br />

obtaining video is to use an endoscope.<br />

<strong>The</strong>se solid glass rods carry light to the location to be<br />

viewed and bring back the image. Endoscopes are fragile<br />

and expensive.<br />

New technologies are becoming available to create<br />

extremely small cameras – on the order of 3mm in diameter<br />

– about three times the size of a mechanical pencil lead.<br />

<strong>The</strong> students created a prototype package for such a<br />

camera and analyzed the technical challenges of bringing<br />

light to the viewing area and of obtaining sharply focused<br />

images.<br />

Camera<br />

System 1<br />

Camera<br />

System 2<br />

Camera<br />

System 3<br />

Ex s:ng<br />

System<br />

S ze<br />

(d amete ) 3 1 2 3<br />

L ghOng<br />

M n atu e<br />

LEDs<br />

None None<br />

Exte nal L ght<br />

Sou ce<br />

ResoluOon<br />

(p xels) 1 2 1 3<br />

Came a<br />

Cost 1 3 2 4<br />

V ewe<br />

Cost 1 3 2 4<br />

<strong>Design</strong> Progression and Component IntegraOon<br />

<strong>The</strong> images to the le_ and right follow<br />

the progression of the integraOon of<br />

the camera system s components.<br />

<strong>The</strong> system components include:<br />

• camera sensor<br />

• lighOng source<br />

• lens<br />

• casing<br />

To the right is the casing designs are<br />

the CAD renderings of the casing<br />

design progression.<br />

To the le_ are sample lens images and<br />

a picture captured during the lighOng<br />

source funcOonality test.<br />

<strong>The</strong> Performance Requirement<br />

table to the right listed the<br />

requirements which we aimed<br />

to confirm via tesOng. All<br />

items with check marks were<br />

tested and confirmed. TesOng<br />

procedures for Image Clarity<br />

need further development<br />

before accurate results can be<br />

found.<br />

Accomplishments<br />

� IdenOficaOon of appropriate camera chip<br />

� Proved the chip could be used for surgical applicaOons<br />

� Met or exceeded sponsor requirements<br />

� Developed a system that was cost effecOve<br />

� Developed a tesOng procedure<br />

Students assembling and bench testing a miniature camera.<br />

Performance Requirements<br />

Performance<br />

Requirement<br />

Confirmed<br />

Came a Ch p Type �<br />

Image ResoluOon �<br />

L ght Sou ce<br />

FuncOonal ty<br />

�<br />

Ch p FuncOonal ty �<br />

Integ aOon w th the<br />

Cu ent Su g cal System<br />

�<br />

Image Cla ty N/A<br />

Proposed camera system concept

Purpose<br />

Identify a particular font from a<br />

sample image<br />

Scenario: Customers (i.e. graphic artists) will<br />

upload a sample image (screenshot, digital<br />

photo, etc.) and our system will identify the<br />

closest font Monotype has available<br />

Semester Objectives<br />

• Creation<br />

attributes<br />

of a database to search for font<br />

• Ongoing population of the database with<br />

•<br />

attributes of different fonts for use in a tool<br />

prototype<br />

Development of an algorithm for separating<br />

characters within an image<br />

• Classification<br />

database<br />

of fonts by attributes within<br />

• Implementation of logic in a prototype tool that<br />

can identify a font based on attributes<br />

• Determination of tolerances for comparison<br />

method(s)<br />

• Evaluation of different comparison methods<br />

and recommendations on these methods<br />

• Final recommendations of project direction and<br />

documentation<br />

current semester<br />

on progress made during<br />

Consumer Electronics Devices<br />

Monotype Imaging pioneered mechanical typesetting in<br />

the 1880s. Currently, they license typographic solutions to<br />

consumer electronics device manufacturers, independent<br />

software vendors, creative professionals and leading<br />

corporations worldwide. <strong>The</strong>y also provide solutions for<br />

software applications and operating systems.<br />

Monotype Imaging asked the team to work on Automatic<br />

Font Identification. <strong>The</strong> goal was to enable a user to take<br />

a picture of a word, perhaps on a sign, or on a menu or<br />

document, and have a software process that can identify<br />

the set of closest matches from a known database of<br />

existing fonts.<strong>The</strong> team will need to work out a classification<br />

and matching system that can handle ten’s of thousands of<br />

differing fonts, and a user workflow that can enable a user<br />

to access this functionality over the web.<br />

Automatic Font Identification<br />

Team: Lindsay Flynn (MGMT), Karianna Haasch (MGMT), Stephen Mardin (CSYS/CSCI), Brian Michalski (CSYS), Dan Rothschild (CSYS/CSCI)<br />

Technical Results<br />

XOR Based Comparison:<br />

0.294<br />

Word Separation:<br />

Font Database:<br />

•2410 Fonts<br />

•13 Font Sizes<br />

•1933920 Samples<br />

•1.5GB w/ Indexes<br />

Ratio Intervals:<br />

0.5835<br />

Python GUI:<br />

Rat o Inte vals fo a ac oss d ffe ent fonts<br />

Accomplishments<br />

• Researched many possible methods for font<br />

identification<br />

• Developed 11 python modules to support<br />

•<br />

prototype and comparison engine<br />

Implemented XOR comparison method<br />

• Implemented ratio based comparison method<br />

• Developed PIC (character attribute)<br />

•<br />

classification system<br />

Created prototype program using XOR and ratio<br />

methods<br />

• <strong>Design</strong>ed and populated a database with<br />

•<br />

character information<br />

Implemented character separation for kerning<br />

and italics<br />

Next Steps<br />

• Continue development of character separation<br />

tool with emphasis on connected characters<br />

• Explore applying ratio tolerance test to input<br />

sample instead of database samples<br />

• Extract PIC attributes from sample characters<br />

• Explore weighted PIC attributes and additional<br />

unique attributes<br />

• Implement PIC-based comparison method<br />

• Expand XOR comparison to weight potions of a<br />

character<br />

• Optimize database indexes, resolve slow<br />

queries and lookups<br />

Project Engineer Junichi Kanai (Dept. of Electrical, Computer, & Systems Eng.), Chief Engineer: Cheng Cheng Hsu (Dept. of Industrial & Systems Eng.)<br />

2010 Project Portfolio 17

18 <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> at <strong>Rensselaer</strong><br />

Students meeting with Northrop Grumman<br />

before the poster presentation.<br />

Photo credit: <strong>Rensselaer</strong> / Barry Stein

Erika Schnitzler (MECL), Jeremy Betz (ELEC), Michael Flynn (MECL), Erik Sundberg (MS&E), William<br />

Philippin (MECL), Yau Chan (MGMT), Daniel Johnston (MGMT), Brent Biederman (MECL), Andrew Tergis (ELEC)<br />

Purpose: Create a prototype which includes both passive and active devices that will be tested in a serpentine inlet duct. A reliable flow control actuator<br />

in an aircraft intake duct would be beneficial in delaying separation, and promoting turbulent flow.<br />

Hybrid Flow Actuators – Isometric View<br />

Screw Drive Actuator<br />

with Micro Vane Locator<br />

Synthetic Jet Modules<br />

Subassembly – Exploded View<br />

Subassembly<br />

Next Step: Demonstrate current<br />

apparatus to Northrop Grumman;<br />

submit design for analysis and<br />

testing.<br />

Project Engineer: Scott M iller (Core Engineering), Chief Engineer: Richard Alben (Dept. of Mechanical, Aerospace & Nuclear Eng.)<br />

Aerospace Engineering & Flow Controls<br />

Flow control is any mechanism or process through which the<br />

flow is caused to behave differently than it normally would.<br />

In internal flows, flow control is used to delay separation and<br />

reduce head losses. <strong>The</strong>re are passive mechanisms like<br />

turbulators, vortex generators or surface roughness, which<br />

are used to promote turbulent flow and delay separation,<br />

and there are active mechanisms such as unsteady blowing,<br />

oscillating ribbon or flap, and internal and external acoustic<br />

excitations. <strong>The</strong> objective of this project was to design and<br />

build a hybrid “fail-safe” actuator, comprised of a changeable<br />

actuated micro-vane with a synthetic jet for Professor<br />

Amitay’s transonic inlet duct facility. One fixed synthetic jet<br />

geometry will be combined with two interchangeable microvane<br />

geometries (rectangular and triangular). <strong>The</strong> team has<br />

designed and built test hardware in the wind tunnel to verify<br />

and quantify mechanical performance, including accuracy<br />

and repeatability of positioning. <strong>The</strong>y also achieved<br />

satisfactory aerodynamic fit and finish, practical assembly,<br />

and leak tight operation.<br />

Hybrid Flow Control Actuators<br />

Micro-Vane Assembly<br />

Accomplishments: <strong>Design</strong>ed and modeled a demonstration module of a micro-vane<br />

sub-assembly consisting of linear motors, sensory devices, and vane locators.<br />

Developed electrical circuitry to control vane actuation. Manufactured prototype<br />

completed to demonstrate actuation and to evaluate conceptual requirements.<br />

Screw drive position actuator contains two<br />

micro-vane components to demonstrate<br />

actuations accurately. Micro-vane<br />

locators can be switch for<br />

positioning.<br />

Students working together in the shop.<br />

Semester Objective: <strong>Design</strong> and<br />

fabricate a “fail safe” hybrid<br />

actuator prototype with<br />

actuating micro-vanes. <strong>The</strong><br />

assembly should allow for<br />

micro-vane positioning by<br />

swapping vane locators. It<br />

should also allow for switching<br />

interchangeable synthetic jets<br />

Assembly – Right View<br />

and steady jets modules.<br />

Electrical Sensors<br />

Micro vane actuation is controlled by a<br />

Hall effect sensor. Electrical currents are<br />

measured through magnetic fields to<br />

calculate vane positioning.<br />

2010 Project Portfolio 19

20 <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> at <strong>Rensselaer</strong><br />

SAIC consulting with the students<br />

on the progress of their project.

Computer Science & Communications<br />

SAIC is a FORTUNE 500 ® scientific, engineering and<br />

technology applications company that uses its deep domain<br />

knowledge to solve problems of vital importance to the<br />

nation and the world, in national security, energy and the<br />

environment, critical infrastructure, and health.<br />

Modern tools, such as email, IM, and Twitter, are supposed<br />

to improve workers’ connectivity and productivity. Yet, Basex<br />

reported that interruptions alone cost companies in the U.S.<br />

$650 billion per year.<br />

Many organizations need a means to better manage<br />

electrically communicated information.<br />

<strong>The</strong> SAIC IT group challenged the RPI students to come<br />

up with a solutions for engineers, particularly those who<br />

participate in multiple engineering projects, to manage their<br />

project related communication.<br />

<strong>The</strong> SAIC team after presenting their power-point presentation.<br />

2010 Project Portfolio 21

22 <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> at <strong>Rensselaer</strong><br />

Seniors find reaching for groceries and pushing a heavy cart<br />

more challenging than it needs to be.

Improving <strong>The</strong> Lives Of <strong>The</strong> Elderly<br />

Senior Friendly Shopping Cart<br />

Matt Forget (CSYS/ELEC), Matt Guilfoy (CSYS/ELEC), Adam Pasquale (ELEC), Brian Calderon (ELEC), Jim Smith (EPOW),<br />

Jim McKenna (MECH), Jeff Caldwell (MECL), Rob Garstka (MECL, Tommy Cheng (MECL)<br />

Project Overview<br />

Our main objective was to lessen the strains<br />

that a shopping experience places on a senior<br />

citizen by designing, building, testing, and refining<br />

prototype systems. Our customers (retail<br />

stores) need the cart and its subsystems to be<br />

cost effective and to improve the shopping experience<br />

enough for senior citizens that it influences<br />

their store choice.<br />

New Basket Shape and Size<br />

To help increase mobility we created a<br />

shorter cart. This helps the ease of turning<br />

the cart. We also added a platform to rest<br />

hand baskets, a shallower main basket for<br />

easier reaching, and a slide out basket on<br />

the bottom for bigger items.<br />

Different Wheels<br />

Using rear wheels with a larger diameter we<br />

found we could reduce the average force on<br />

the user by up to 95%. This also gives us a<br />

smoother and more enjoyable ride.<br />

Storage Box<br />

Many seniors wanted a safer place to put<br />

their bags or personal items. We decided to<br />

design a box to attach to the rear of the<br />

cart that can close protecting their items<br />

In 2000 there were 18.4 million people ages 65 to 74 years<br />

old, representing 53 percent of the older poplulation in the<br />

US.<br />

According to the US Census Bureau, those 85 years and<br />

over showed the highest percentage increase in population.<br />

<strong>The</strong> mission of Albany Guardian Society is to improve the<br />

quality of life for seniors in the Capital District, of New York<br />

State.<br />

<strong>The</strong> team designed, built, tested and refined a prototype<br />

shopping cart that improves the shopping experience for<br />

senior citizens.<br />

Subsystem Decisions<br />

In order to determine what areas to focus<br />

on we surveyed many seniors and see<br />

what they wanted. <strong>The</strong>n we took these<br />

items, rated them by priority and difficulty,<br />

and created our subsystems. We decided to<br />

change the size of the carts, increase the<br />

mobility, the ergonomics, and general helpfulness<br />

of the cart. Our Decision Matrix is<br />

on the right.<br />

Unique Handle Bar<br />

We found that an ergonomically designed<br />

handle bar would address common arthritic<br />

problems in seniors and mimic the feel of a<br />

walker to allow seniors to feel more comfortable<br />

moving around with the cart.<br />

Barcode Scanner<br />

. We wanted to help Seniors with vision<br />

problems read labels in the store. We experimented<br />

with a barcode scanner to help<br />

assist this.<br />

Subsystem Priority D fficulty Weight Score<br />

Cart Size 9.50 2.88 4 13.19<br />

Mobi ity 8.00 5.88 5 6.80<br />

Storage for Personal Property 4.63 2.50 3 5.56<br />

Reading <strong>Lab</strong>les 6.88 5.63 3 3.67<br />

Outside Mob lity 5.25 7.88 3 2.00<br />

Time Keeping 4.75 2.50 1 1.90<br />

Difficulity Finding Items 5. 8 6.00 2 1.79<br />

arge Gap in Child Area 5.13 2.88 1 1.78<br />

ong Walking Distances 5.50 4.75 1 1.16<br />

Carts Confusing 4.63 8.75 2 1.06<br />

Seperating Carts 5.25 5.88 1 0.89<br />

Multiple People Shopping 3. 8 4.25 1 0.80<br />

Falling Over 4.13 6.25 1 0.66<br />

Reaching High and Low Items 5.13 8. 8 1 0.61<br />

Waiting For Check Out 3. 8 6.63 1 0.51<br />

Transportation to and From<br />

Store 3.50 7.75 1 0.45<br />

Drive System<br />

We experimented with force sensors and<br />

electric motors to help assist seniors move<br />

their carts around their place of business.<br />

Braking System<br />

A braking system in the cart will provide<br />

security and safety for the senior. Having a<br />

cart that will not roll away and hit another<br />

person or a vehicle is a great plus. After preliminary<br />

testing, mechanical braking was<br />

preferred.<br />

Project Engineer: Casey Goodwin (<strong>The</strong> <strong>Design</strong> <strong>Lab</strong>), Chief Engineer: Junichi Kanai (Electrical, Computer, & Systems Engineering Dept.)<br />

Rick Iannello of Albany Guardian Society discussing the project with<br />

Linda Schadler, Associate Dean of Academic Affairs<br />

ALBANY GURADIAN SOCIETY<br />

A L B A N Y N E W Y O R K<br />

2010 Project Portfolio 23

24 <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> at <strong>Rensselaer</strong><br />

Students examining biometric circuitry built by the team.<br />

Photo credit: <strong>Rensselaer</strong> / Barry Stein

Biometrics<br />

Team: Jesse Herrmann1 , Jus4n Toth1 , Rob Margolies1 , Sean Fleury2 , Kevin SwiB2 , Shannon Johnson3 , Hannah Piontek3 , Benjamin Scheiner3 1Electrical, Computers and Systems Engineering, 2 Biomedical Engineering, 3 Materials Science & Engineering<br />

Objec&ve:<br />

To create an easy to use, affordable biometric measuring system that<br />

integrates mul4ple exis4ng sensors into a single noninvasive unit.<br />

Benefits:<br />

Increases availability of physiological self-‐knowledge to all consumers.<br />

Removes price/knowledge restric4ons for physiological self-‐awareness.<br />

New approach to public health, connec4vity, and device marke4ng.<br />

Plan:<br />

Iden4fy Target Market<br />

Conceptualize <strong>Design</strong><br />

Build and Integrate Subsystems<br />

System Tes4ng and Data Collec4on<br />

Biometric Subsystem Outline<br />

Real-Time Vital Statistic Processing<br />

Technical Results:<br />

Successfully completed major subsystems:<br />

Luminary Microcontroller<br />

System Wiring<br />

Accomplishments:<br />

Successfully built Microcontroller,<br />

Sensor, Power and Packaging systems.<br />

Integrated into cohesive device that<br />

recorded user’s biometric informa4on.<br />

Laid framework for future modular systems,<br />

adaptable to variety of markets.<br />

Chief Engineer: Dr. Partha DuLa (ECSE); Project Engineer: Mr. Casey Goodwin (<strong>Design</strong> <strong>Lab</strong>)<br />

<strong>The</strong> purpose of the Biometrics project was to design and<br />

deliver a non-invasive sensor system aimed toward the<br />

extraction and acquisition of data regarding the indicators of<br />

physical activity in the human body. Vital statistic processing<br />

was calculated as a function of output from various physical<br />

sensors integrated into a complete upper body article<br />

designed for convenience of motion. All data handling was<br />

managed by a Luminary microcontroller held in a pocket sewn<br />

into a pressure sleeve worn over the clothing and wirelessly<br />

networked to an Android based cell phone. <strong>The</strong> gauged<br />

vitals were then streamed to the phone over a Bluetooth link<br />

and output to the screen through a pre-installed application,<br />

providing a dynamic mechanism to display real-time vital<br />

statistics to the user so as to encourage both well-being<br />

and performance. <strong>The</strong> ultimate goal of this project was to<br />

make physiological self-knowledge easily accessible to all<br />

consumers, regardless of prior training and level of expertise<br />

through the communication of physiological process<br />

parameters in a logical, easily understandable manner.<br />

Students assembling biometric monitoring circuitry.<br />

BaLery and Voltage Convertor<br />

Heart Rate (Beats/Min)<br />

60<br />

150<br />

140<br />

130<br />

120<br />

110<br />

00<br />

90<br />

80<br />

70<br />

60<br />

Heart Rate<br />

Sample Heart Rate Data<br />

1 26 51 76 101 126 151 176 201 226 251 276<br />

Sample Number<br />

2010 Project Portfolio 25

26 <strong>The</strong> <strong>Design</strong> <strong>Lab</strong> at <strong>Rensselaer</strong><br />

Students discussing the sustainability rating of vaccum<br />

cleaner parts with their instructor Jeff Morris.<br />

Photo credit: <strong>Rensselaer</strong> / Barry Stein

<strong>Design</strong> for Sustainability<br />

Kate Biagio4 (MGTE), John Cannarella (MECL), Pete Cassellini (MGTE), Andy Dubickas (MGTE), Maggie Exton (MS&E),<br />

Michelle Pelersi (MS&E), Chasidy Perrin (ELEC), Saadia Safir (MECL)<br />

Purpose<br />

To provide product designers with a tool to use a guide during the design process that<br />

accurately assesses a product’s overall sustainability<br />

Previous Work: Fall 2009 Metric<br />

Semester ObjecAves<br />

• Revise and validate previous model<br />

• Complete reverse engineering case studies<br />

• Develop a customer-‐friendly way of displaying<br />

model results on products<br />

• Research ways of developing an absolute<br />

model that can adapt with Pme (measured in<br />

dollars, stars, etc.)<br />

Rating Engineered Parts For Sustainability<br />

“Sustainable development” can be defined as the<br />

development that meets the needs of the present without<br />

compromising the ability of future generations to meet<br />

their own needs [World Commission, 1987]. A sustainable<br />

product has a designed life cycle for the purposes of<br />

furthering its functional life or reclaiming its value for future<br />

products, so that minimal waste is generated.<strong>The</strong> current<br />

challenge for design methodologies is the assessment<br />

of measurable design parameters/metrics/attributes,<br />

where the designer has empirically obtained, or a priori<br />

knowledge of the quantities of these metrics.<strong>The</strong> current<br />