Mustang EVO (TGW Systems) - wikiMHEDA

Mustang EVO (TGW Systems) - wikiMHEDA

Mustang EVO (TGW Systems) - wikiMHEDA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MUSTANG <strong>EVO</strong><br />

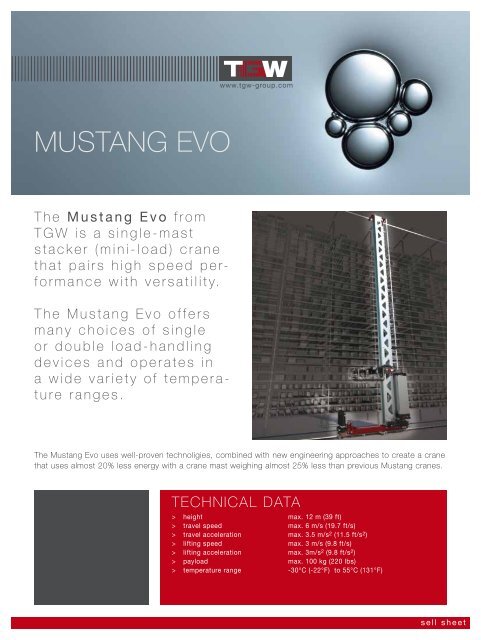

T h e M u s t a n g E v o f r o m<br />

T G W i s a s i n g l e - m a s t<br />

s t a c k e r ( m i n i - l o a d ) c r a n e<br />

t h a t p a i r s h i g h s p e e d p e rf<br />

o r m a n c e w i t h v e r s a t i l i t y.<br />

T h e M u s t a n g E v o o f f e r s<br />

m a n y c h o i c e s o f s i n g l e<br />

o r d o u b l e l o a d - h a n d l i n g<br />

d e v i c e s a n d o p e r a t e s i n<br />

a w i d e v a r i e t y o f t e m p e r a -<br />

t u r e r a n g e s .<br />

www.tgw-group.com<br />

The <strong>Mustang</strong> Evo uses well-proven technoligies, combined with new engineering approaches to create a crane<br />

that uses almost 20% less energy with a crane mast weighing almost 25% less than previous <strong>Mustang</strong> cranes.<br />

TECHNICAL DATA<br />

> height max. 12 m (39 ft)<br />

> travel speed max. 6 m/s (19.7 ft/s)<br />

> travel acceleration max. 3.5 m/s 2 (11.5 ft/s 2)<br />

> lifting speed max. 3 m/s (9.8 ft/s)<br />

> lifting acceleration max. 3m/s 2 (9.8 ft/s 2)<br />

> payload max. 100 kg (220 lbs)<br />

> temperature range -30°C (-22°F) to 55°C (131°F)<br />

s e l l s h e e t

BENEFITS<br />

> highest throughput rates<br />

> Low approach distances<br />

> Flexible application for totes, trays or cartons<br />

> Maximum energy efficiency<br />

> Ease of maintenance<br />

> Even distribution of loads to running wheels<br />

> Reduced wear of guide wheels<br />

> Standard aS/RS components<br />

<strong>TGW</strong> is the leading manufacturer of integrated material<br />

handling solutions and automated material handling equipment.<br />

<strong>TGW</strong>’s expertise is in the planning, design, implementation, and lifetime service of integrated logistics solutions to<br />

help a company’s supply chain. Solution offerings include:<br />

• Carton, tote and unit load conveyor & sortation systems<br />

• Automated Storage and Retrieval <strong>Systems</strong> (AS/RS) for case, tote, carton and pallet loads<br />

• Warehouse Control (WCS) and Warehouse Management (WMS) <strong>Systems</strong><br />

<strong>TGW</strong> is a global company with manufacturing facilities in the United States and Austria, and local offices in<br />

Germany, the United States, Spain, Italy, the United Kingdom, Poland, France, and Sweden. The company<br />

employs more than 1,100 people worldwide and has annual sales of over $300 million.<br />

<strong>TGW</strong> SySTEMS inC., 6870 Grand Haven Road, Spring Lake, MI 49456-9652 USA, Phone +1.231.798.4547<br />

E-mail: usinfo@tgw-group.com, www.tgw-group.com<br />

<strong>TGW</strong> MEChaniCS GMbh, A-4600 Wels, Collmannstraße 2, T+43.(0)7242.486-0, F+43.(0)7242.486-31<br />

E-mail: mechanics@ tgw-group.com, www.tgw-group.com<br />

© T G W, 2 0 1 1 . Ve r s i o n 2 / 2 0 1 1<br />

FEATURES<br />

> high speeds and acceleration<br />

> Fast positioning<br />

> State-of-the-art lightweight design<br />

> highest stiffness of mast and chassis frame<br />

> Drive unit positioned at the front end of the chassis<br />

> improved center of gravity<br />

> Weight-optimized positioning of control cabinet<br />

s e l l s h e e t