PDF (6.0 MB) - GEA Group

PDF (6.0 MB) - GEA Group

PDF (6.0 MB) - GEA Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

�������<br />

���������������<br />

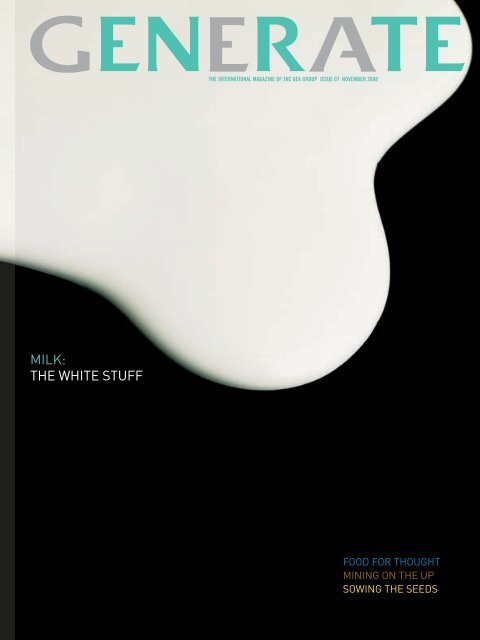

THE INTERNATIONAL MAGAZINE OF THE <strong>GEA</strong> GROUP ISSUE 07 NOVE<strong>MB</strong>ER 2008<br />

����������������<br />

����������������<br />

����������������

���������������������������������������<br />

������������������������������������������<br />

������������������������������������<br />

��������������������������<br />

��������������������������������������������<br />

���������������������������������������������<br />

������������������������������������������<br />

�����������������������������������������������<br />

���������������������������������������������<br />

����������������������������������������������<br />

���������������������������������������<br />

�������������������������������������������<br />

���������������������������������������������<br />

�����������<br />

�����������������������������������������<br />

���������������������������������������������<br />

���������������������������������������������<br />

���������������������������<br />

��������<br />

�����������������������������<br />

���������������������<br />

�������������<br />

����������������������<br />

�������������������������<br />

����������������<br />

�������������<br />

���������������������<br />

�����������������<br />

�������������������<br />

�������������������<br />

��������������<br />

������������������������������������<br />

������������������������������������������<br />

����������������������������������������<br />

����������������������������������������<br />

������������������������������������<br />

�����������������������������������������<br />

������������������������������������������<br />

��������������������������������<br />

�������������<br />

������������������������������������������<br />

�����������������������������������<br />

������������������������������������������<br />

����������������������������������������<br />

����������������������������������������<br />

�����������������������������������������<br />

���������������������������������������<br />

���������������������������������������������<br />

�������������������������������������������<br />

���������������������������������������<br />

��������������������������������������<br />

�������������������������������������<br />

�����������������������������������������<br />

����������������������������������<br />

������������������������������������<br />

��������������������������������������<br />

�����������������������������������������<br />

����������������������������������������<br />

���������������������������������������<br />

�����������������������������������������<br />

��������������������������������������<br />

���������������������������������������<br />

������������������������������������<br />

�����������������������������������������<br />

�������������������<br />

���������������������������������<br />

������������������������������������<br />

������������������������������������<br />

������������������������������������<br />

���������������������������������������<br />

���������������������������������������<br />

���������������������������������������<br />

��������������������������������������<br />

���������������������������������������<br />

����������������<br />

�����������������������������������������<br />

�����������������������������������������<br />

������������������������������������<br />

�����������������������������������������<br />

�������������������������������������<br />

�����������������������������������������<br />

�����������������������������������������<br />

���������������������������������������<br />

��������������������������������������������<br />

���������������������������������������<br />

��������������������������������������������<br />

���������������������������������������<br />

����������������������������������������<br />

�����������������������<br />

�����������������������������������������<br />

����������������������������������������<br />

�����������������������������������������<br />

�������������������������������������������<br />

������������������������������������������<br />

�����������������������<br />

�����������<br />

��������������������������������<br />

����������������������������<br />

������������������������������������������<br />

����������������������������������������������<br />

�������������<br />

�����������������<br />

�������������<br />

����������������

InnovatIon In actIon<br />

gea tablet process boosts<br />

pharma industry<br />

FooD FoR tHoUgHt<br />

food processing faces up to<br />

the future<br />

tHe stag RIses<br />

german liqueur takes on<br />

the world<br />

aRt In engIneeRIng<br />

FEATURE STORY<br />

Milk – something for everyone<br />

how the global dairy industry<br />

has kept pace with increasing<br />

demand for milk and its<br />

associated products<br />

HoW to Do It<br />

mining for copper<br />

Q&a<br />

protecting flora<br />

for eternity<br />

takIng stock<br />

paper industry leads<br />

recycling drive<br />

Last WoRD<br />

global news from gea<br />

DIggIng Deep<br />

satisfying the clamor<br />

for copper<br />

It’s sHoWtIme<br />

getting the best from<br />

exhibitions<br />

DaY In tHe LIFe<br />

gea westfaliasurge’s french<br />

connection<br />

GENERATE MAGAZINE ISSUE 07 1

2<br />

In the fast movIng and tIghtly<br />

controlled pharmaceutIcal Industry,<br />

the drIve Is always on to brIng more<br />

new products to the market and brIng<br />

them quIcker. an InnovatIve pIece of<br />

engIneerIng technology could play<br />

a key role In makIng thIs happen.

harmaceutical manufacturing is complex,<br />

tightly controlled and highly regulated.<br />

and it has to be because, with people’s<br />

health at stake, there can be no margin<br />

for error.<br />

like many other manufacturing industries,<br />

drug companies are under increasing<br />

pressure to make more faster, while<br />

reducing costs and maintaining high quality<br />

standards. according to the us food and<br />

drug administration’s process analytical<br />

technology (pat) guidelines for 2004,<br />

pharmaceutical manufacturers could<br />

achieve all these goals by shifting to<br />

continuous processing.<br />

currently, ingredients for medicines tend<br />

to be produced in batches. batch processes<br />

are very often inefficient and cannot manage<br />

the variability of the incoming material<br />

characteristics in a proper way. therefore,<br />

batch processes often result in reduced<br />

reliability and poor yields. a statistically<br />

disputable sampling step, after every batch,<br />

decides whether the product of that batch<br />

can be released to the next production step.<br />

Making medicines<br />

batch processing has been a feature of<br />

making medicines since the very early days.<br />

drugs were made as and when required,<br />

first by extracting the active ingredients from<br />

plants by soaking them in water or alcohol to<br />

create a potion for the patient to drink. later,<br />

medicinal plants were dried and ground into<br />

powders. but the problem was how to make<br />

sure patients received an accurate dose<br />

of medication.<br />

the invention of tablets provided the solution.<br />

before industrialization in the 19th century,<br />

tablets were handmade by pharmacists. with<br />

the introduction of the pill machine – a brass<br />

plate with grooves – greater accuracy was<br />

assured.<br />

PIll gaIns<br />

ConsiGma is a small unit that<br />

can easily be installed in existing<br />

production rooms, avoiding the need<br />

for expensive building alterations. It<br />

has environmental advantages, too.<br />

Running the machines continuously<br />

uses energy more efficiently over a<br />

longer period.<br />

fast-forward to the 21st century and the<br />

difference in tablet-making couldn’t be<br />

more marked. drug manufacture is carried<br />

out on a massive scale, using sophisticated<br />

processes. a typical tablet press can produce<br />

from 250,000 to more than one million tablets<br />

an hour.<br />

nevertheless, as wim van der goten,<br />

sales director of gea collette, points out:<br />

“the production methods for solid dosage<br />

forms are rather conservative compared to<br />

other industries, like food and chemicals,<br />

where continuous processing has been<br />

the standard for many years now. but<br />

continuous processing can only be successful<br />

with the development of better production<br />

techniques to provide consistent quality and<br />

measurement tools that allow for full control<br />

of production quality, at every instant”.<br />

Quality innovation<br />

with this in mind, a team at gea collette<br />

developed an innovative way of manufacturing<br />

granules for tablet production – consigma.<br />

this is a continuous high shear granulation<br />

and drying system which embraces the six<br />

sigma manufacturing quality standard*. it<br />

incorporates quality control at every instant<br />

inside the process and ensures that the<br />

outcome is 100 per cent within specification.<br />

it offers major advantages says van der<br />

goten: “for example, a 300 kg batch process<br />

can only be controlled once, on end quality,<br />

while, with consigma, the batch is<br />

controlled 6,000 times in-line.”<br />

the project won the gea innovation award<br />

2008, presented at the company’s global<br />

management meeting in beijing. an appropriate<br />

location given that the chinese capital<br />

has been the focus of record-breaking<br />

excellence with the olympic games. in this<br />

case, ultimately, the pharmaceutical industry<br />

and patients could turn out to be the real<br />

winners.<br />

one machine can operate successfully on<br />

any quantity from small 500g r&d batches<br />

to full-scale production. there is no process<br />

scale-up, which drastically cuts development<br />

time and cost so that new medicines can be<br />

made available to patients much faster.<br />

the granules produced can be compressed<br />

better which makes the tablet presses run<br />

more efficiently.<br />

since consigma was launched in april<br />

2008, several companies have invested in<br />

the technology, including two of the top ten<br />

pharmaceutical manufacturers, one of<br />

which is using it for production of a blockbuster<br />

drug.<br />

the development of consigma began three<br />

years ago and pharmaceutical companies<br />

were involved from the outset as they helped<br />

determine the specifications for the new<br />

system. a multi-disciplinary team of process<br />

engineers, technologists, software and<br />

service engineers from gea collette worked<br />

on the project, assisted by r&d staff from<br />

gea pharma systems.<br />

and the continuous processing revolution<br />

doesn’t stop there. gea pharma systems has<br />

developed a continuous blender, while gea<br />

courtoy has developed an advanced on-line<br />

pat for its tablet presses.<br />

* six sigma is a disciplined, data-driven process and<br />

methodology for developing products. it focuses on<br />

improving processes and eliminating defects.<br />

GENERATE MAGAZINE ISSUE 07 3

4<br />

Ore<br />

copper is a naturally occurring mineral but<br />

is found most commonly in ore (rocks) such<br />

as chalcopyrite, bornite and malachite. The<br />

process starts with digging the ore from the<br />

ground in open pit mines across the world,<br />

mainly in north and South america.<br />

cruSHing<br />

The ore is taken in 300-tonne trucks to the<br />

crushing plant, where it is dumped into a<br />

primary crusher. The resulting discharge is<br />

then fed into two secondary crushers and<br />

broken down into coarse (oxide) ore and fine<br />

(sulfide) ore. Oxide ore (see 3a & 4a) and<br />

sulfide ore (see 3B and 4B) are turned into pure<br />

copper cathodes in two different ways.<br />

Mining copper<br />

The global mining market for<br />

minerals like copper, nickel<br />

and zinc has seen a boom in<br />

recent years due to increased<br />

demand for metallic and energy<br />

raw materials, particularly<br />

from China. With the world<br />

clamoring for pure copper,<br />

here’s a quick guide to the<br />

production process.<br />

Heap leacHing<br />

Oxide ore is transported to a heap leach<br />

pad, into which a series of pipes and hoses add<br />

diluted sulfuric acid. The dissolved copper flows<br />

to a pond. This can take several months.<br />

cOncenTraTing<br />

The sulfide ore is concentrated into a slurry<br />

that is 15 per cent copper and the waste is<br />

removed and recycled to produce a grey copper<br />

concentrate powder.

SOlvenT exTracTiOn/elecTrOwinning<br />

The leach solution containing the dissolved<br />

copper passes to the Solvent extraction (Sx)<br />

plant. as its name suggests, this part of the<br />

process concentrates and purifies the dissolved<br />

copper by adding a chemical reagent to the<br />

Sx tanks, which binds with and extracts the<br />

copper. The copper is then transferred to an<br />

electrowinning plant where a current is passed<br />

from an inert anode through the liquid leach<br />

solution so that the metal is extracted and<br />

deposited in an electroplating process onto<br />

the cathode. The result is high-grade<br />

copper cathodes.<br />

SMelTing/elecTrOlyTic refining<br />

The sulfide ore then goes through several<br />

melting stages to purify the copper. The sheets<br />

of pure copper are electrolytically refined<br />

in an electrolyte bath. copper ions migrate<br />

electrolytically from the anodes to starter<br />

sheets made from copper foil where they plate<br />

themselves on the cathodes, leaving similarly<br />

high-grade cathodes.<br />

<strong>GEA</strong> And thE mininG industry<br />

Separation is a key part of the mining production process so it’s no<br />

surprise that one of the leaders in the field, <strong>GEA</strong> Westfalia Separator<br />

has a presence in this growing market. It’s <strong>GEA</strong> Westfalia Separator<br />

Process business provides the mining industry with a range of<br />

products. Leading the way are separators and decanters that enable<br />

mining companies to guarantee continuous efficiency during the<br />

extraction process.<br />

Over the years, liquid extraction with acid has become the standard<br />

method for recovering metals like copper, nickel and zinc. However,<br />

crud (a layer of emulsion formed of aqueous and organic compounds,<br />

air and solids) is formed during the extraction process. Crud can<br />

have a negative impact on the extraction process and needs to be<br />

continuously removed, which is where <strong>GEA</strong> Westfalia’s separation<br />

technology comes in. A three-phase decanter process separates the<br />

emulsion into solids, water and solvent. The solids and water are<br />

disposed of and the solvent is recycled. Crud is continuously removed<br />

and the solvent recycled back to the extraction stage. <strong>GEA</strong> Westfalia<br />

has actually gone one stage better with its PLS (Pure Liquid Solution)<br />

clarification process that prevents crud forming by removing insoluble<br />

particles with nozzle-type separators. In addition, <strong>GEA</strong> Westfalia<br />

supplies a range of decanters and project management expertise for<br />

the mining industry.<br />

cOpper caTHOdeS<br />

The copper cathodes (99.9 per cent purity) are<br />

transported to mills or foundries, from where<br />

they are manufactured into finished products<br />

for use in the electrical engineering industry<br />

for wiring, as well as plumbing, roofing and the<br />

power, transport and communication industries.<br />

GENERATE MAGAZINE ISSUE 07<br />

5

oveR tHe past 10,000 YeaRs, bILLIons oF tonnes oF<br />

coppeR Have been extRacteD FRom tHe eaRtH anD tHe<br />

coppeR DeveLopment assocIatIon estImates tHat a<br />

LaRge peRcentage oF tHat Is stILL beIng UseD toDaY.<br />

geneRate Looks at HoW tHe WoRLD’s most RecYcLeD<br />

metaL contInUes to make a vItaL contRIbUtIon to<br />

eveRYDaY LIFe.<br />

6<br />

safE voyagE<br />

Christopher Columbus’ ships were among the<br />

first to have hulls sheathed with copper plate to<br />

protect the wood against barnacles and algae.<br />

sIzE mattErs<br />

The world’s largest statue is the 152-meter high<br />

copper Buddha on the Jiuhua Mountain in central<br />

China. It is more than three times taller than New<br />

York’s statue of Liberty and weighs 1,000 tonnes.<br />

id you know that the copper in your<br />

home, cookware, your car and even the<br />

coins in your pocket could date back to<br />

the egyptian pharaohs?<br />

this surprising claim from the copper<br />

development association is not nearly as<br />

far-fetched as it seems. the fact is that<br />

copper and its alloys, such as bronze and<br />

brass, can be melted down and re-used over<br />

and over again.<br />

copper has the world’s highest recycling<br />

rate for engineering metals. statistics from<br />

the international copper study group (icsg)<br />

show that, in 2005, 34 per cent of world<br />

copper consumption was recycled. the us<br />

alone recycles almost as much copper as<br />

it mines.<br />

this is just as well. demand for copper is<br />

soaring, particularly from china and india –<br />

in asia between 1960 and 2006 it rose from<br />

455,000 tonnes to eight million tonnes.<br />

in July this year the icsg predicted that<br />

copper mine output will rise by 5.2 per<br />

cent a year between 2008 and 2012, with<br />

annual production of 23 million tonnes,<br />

29 per cent higher than in 2007.<br />

more than 60 per cent of the world’s<br />

copper resources are found in chile,<br />

where gea westfalia separator<br />

process is the country’s leading<br />

supplier of centrifugal equipment<br />

for the copper mining sector.<br />

What’s In a namE?<br />

Copper was named after the Mediterranean<br />

island of Cyprus where it was mined<br />

extensively in Roman times. Cyprium or ‘metal<br />

of Cyprus’ was later shortened to cuprium,<br />

which became the Latin word for copper.

A versatile metal<br />

surprisingly, although copper has been used<br />

for 10,000 years, more than 95 per cent of<br />

the copper mined in that time was extracted<br />

after 1900. copper is truly a metal for the<br />

modern world.<br />

because copper doesn’t corrode and has<br />

heat and electricity conducting properties<br />

that are second to none, it is the metal<br />

of choice for a vast range of domestic<br />

and industrial applications. it’s also very<br />

attractive, making it ideal for musical<br />

instruments, decorative features on<br />

buildings and statues – the statue of<br />

liberty, for instance, is made from copper.<br />

here are just a few of copper’s many<br />

uses: wiring in buildings, power cables,<br />

electronics, telephone lines, plumbing,<br />

gas pipes, cookware, the magnetrons in<br />

microwave ovens and even the spray for<br />

killing mildew on garden plants. the average<br />

car has approximately two kilometers of<br />

copper cables and the metal is also used for<br />

the radiator, brakes and bearings. it’s also<br />

being used in new aircraft models and highspeed<br />

trains have between two and four<br />

tonnes of copper – twice as much as their<br />

traditional counterparts.<br />

copper doesn’t react with water, which<br />

is why you’ll find fittings made from<br />

copper nickel alloy on offshore oil and gas<br />

platforms, desalination plants and ships.<br />

Good health<br />

although copper is toxic in large doses, the<br />

world health organization’s international<br />

program on chemical safety reported in<br />

1996 that “there is greater risk of health<br />

effects from deficiency of copper intake than<br />

from excess of copper intake.”<br />

the fact is that people need copper.<br />

enzymes critical for bone growth and<br />

strength, maintaining the immune system<br />

and a healthy heart, the development of<br />

red and white blood cells, transporting and<br />

absorbing iron, brain development and for<br />

protecting against tissue damage are all<br />

dependent on copper. a lack of copper in<br />

the system puts the body at increased<br />

risk of developing high cholesterol and<br />

heart disease.<br />

copper-containing foods include beef,<br />

fish, oysters, chocolate, avocado and<br />

various vegetables, nuts and fruit. many<br />

people who suffer from arthritis and other<br />

joint conditions find it helpful to wear a<br />

bracelet made from copper which the skin<br />

gradually absorbs.<br />

another plus is that copper is biostatic,<br />

which means bacteria can’t grow on it.<br />

this makes it an ideal metal to have around<br />

hospitals for door handles, push panels and<br />

other surfaces to prevent the transfer of<br />

disease. medically, a complex of radioactive<br />

copper is used in imaging and also in<br />

radiation treatment for cancer.<br />

Future proof<br />

the use of copper has increased in<br />

line with technological developments<br />

and continues to be an essential<br />

component of innovation.<br />

microprocessors can operate<br />

faster and use less energy<br />

thanks to copper conductors<br />

in silicon chips.<br />

it’s worth remembering that high speed data<br />

transmission, including the internet, was<br />

achieved via existing copper telephone wires<br />

and you’ll find copper in mobile telephones,<br />

too.<br />

copper now has a role in environmentallyfriendly<br />

alternatives to oil and gas for heating<br />

homes. as the number one conductor of<br />

heat, it’s in demand for direct exchange<br />

geothermal heating systems. this is where<br />

heat stored in the ground is transferred by<br />

copper tubing into the home.<br />

with its continued versatility and huge<br />

worldwide demand to satisfy, copper’s<br />

future is assured – today’s copper could<br />

be recycled for tomorrow’s cutting-edge<br />

technology.<br />

GENERATE MAGAZINE ISSUE 07 7

©alimentarium<br />

8<br />

tHeRe can neveR Have<br />

been a tIme WHen FooD<br />

Was not pRocesseD In<br />

some WaY. sInce ancIent<br />

man DIscoveReD tHat meat<br />

LasteD LongeR IF DRIeD<br />

In tHe sUn oR tasteD<br />

betteR IF cookeD, FooD<br />

pRocessIng Has been a<br />

vItaL paRt oF oUR LIves.<br />

Packaging of soup<br />

at the Maggi factory<br />

about 1900.

ost early food processing techniques<br />

concerned preservation. sun drying,<br />

salting, fermentation, pickling and the<br />

preparation of conserves (jams and jellies)<br />

were all motivated by a desire to extend the<br />

shelf lives of otherwise perishable foods.<br />

these foods were largely used by those who<br />

did not have access to a regular supply of<br />

fresh provisions – sailors and soldiers mainly<br />

– who for centuries owed their survival to<br />

preserved foods.<br />

many of the advances in food processing, as<br />

with most technology, have been born out of<br />

conflict. french soldiers in the napoleonic<br />

wars were the first to try out food preserved<br />

in cans, ironically a process invented by<br />

an englishman, peter durand in 1810.<br />

subsequent wars increased the popularity<br />

of canning, especially during the first world<br />

war where cans were uniquely able to survive<br />

the ravages of trench warfare. even today,<br />

preservation techniques such as freezedrying<br />

and vacuum packing owe much of<br />

their success to the need to provide armies<br />

with daily rations, and to space exploration.<br />

Convenience food<br />

as society has developed, the motivation<br />

for food processing has changed. now it’s<br />

no longer sufficient simply to slow down<br />

the process of decomposition, now people<br />

want convenience, novelty and excitement<br />

from their food. it’s much easier to choose a<br />

packet of your favorite fries from the freezer<br />

than to make your own, even if you would<br />

know how and had the time. the modern<br />

kitchen in the developed world is packed full<br />

of processed food – even staple items such as<br />

bread, butter and cheese.<br />

its very success has led food processors<br />

on to the next stage of development for<br />

the industry. beyond preservation, more<br />

than convenience, novelty and excitement,<br />

the modern consumer now demands<br />

taste and nutritional excellence as well.<br />

food processing can lower the nutritional<br />

value of foods. processed foods tend to<br />

include additives, such as flavorings and<br />

texture enhancing agents, which may have<br />

no nutritive value or even be unhealthy.<br />

processed foods also tend to have more<br />

calories.<br />

so the challenge now for food processors<br />

is to produce exciting, novel foods that<br />

are healthy, packed with vitamins, fiber<br />

and minerals, contain the minimum of fat,<br />

preservatives and artificial colorings, have<br />

a long shelf life, and taste great, too. as<br />

if that’s not difficult enough, modern food<br />

processing factories need to operate under<br />

extremely hygienic or even aseptic conditions<br />

and use the minimum of energy and natural<br />

resources. no easy job.<br />

throughout the last century gea companies<br />

have played their part in providing the<br />

equipment food and drink processing<br />

companies need. gea niro for the spray<br />

drying of powders to make products such<br />

as baby foods, soups and instant coffee; and<br />

for freeze-drying equipment to preserve<br />

the natural flavor and nutritional value of<br />

fruits and vegetables. gea procomac for<br />

aseptic bottling lines with minimal power<br />

consumption; gea westfalia separator has<br />

the technology to extract bacteria from<br />

milk through centrifugal separation before<br />

bottling, thereby significantly extending its<br />

shelf life without affecting its taste; gea<br />

wiegand for evaporation technology, gea<br />

grasso for refrigeration; gea niro soavi for<br />

homogenizers that create our smooth, easyspread<br />

dairy products; and gea tuchenhagen<br />

to link everything together to create<br />

innovative, efficient systems. all of these are<br />

just examples of how gea companies serve<br />

this continuously growing market.<br />

Global growth<br />

as global development, particularly in china<br />

and india, gathers pace, so the demand for<br />

processed food grows, too. according to<br />

the indian food and beverages forecast<br />

published by the bahrat book bureau,<br />

between now and 2011 higher incomes in<br />

india will encourage more indians to shop in<br />

supermarkets; and changing lifestyles should<br />

lead to rapid demand for value-added milkbased<br />

products such as processed cheese,<br />

butter and ice cream.<br />

coffee consumption, too, is expected to grow<br />

by ten per cent a year. the chinese, as the<br />

country’s 1.3 billion people become richer,<br />

are demanding higher-quality products, more<br />

processed food, more meat and more dairy<br />

products. they are also becoming much more<br />

discerning consumers, potentially causing<br />

shortages and higher prices elsewhere in the<br />

world, but certainly creating opportunities for<br />

those companies involved in food production.<br />

the opportunities for food producers are<br />

immense and are likely to continue as<br />

from kItchEn to factory<br />

The history of industrial food processing is the<br />

subject of a special exhibition at the Alimentarium<br />

Food Museum at Vevey on the shores of Lake<br />

Geneva in Switzerland.<br />

Called ‘De La Cuisine A L’Usine’ the exhibition<br />

showcases four landmark products – powdered<br />

soup, condensed milk, milk chocolate and coffee<br />

substitute – and their development at the<br />

beginning of the 20th century. It runs until the end<br />

of January 2009.<br />

The Alimentarium Food Museum, which opened<br />

in 1985, has a range of permanent displays<br />

and activities, including the history of cooking<br />

techniques, nutrition and demonstrations from<br />

professional chefs.<br />

an IntErEstIng fact<br />

The can opener was not invented until 30 years<br />

after the can. Napoleon’s soldiers were required<br />

to open their canned meals using bayonets or by<br />

hitting them with rocks.<br />

GENERATE MAGAZINE ISSUE 07<br />

©alimentarium<br />

long as the raw materials remain plentiful.<br />

opportunities for equipment suppliers also<br />

seem boundless. yet strong competition will<br />

always ensure that only excellence, in both<br />

product and service, is rewarded.<br />

9

milk is widely regarded as nature’s<br />

miracle food – and it’s easy to see<br />

why. apart from being packed full<br />

of essential protein, vitamins and<br />

minerals, it is arguably the most<br />

versatile food on the planet.<br />

Julie Mitchell looks at a global<br />

phenomenon that shows no signs<br />

of slowing.<br />

photography: will thom<br />

styling: sabrina Jard

othing cappuccino coffee, an indulgent<br />

cake oozing with cream, a cool glass of<br />

milkshake on a summer’s day, butter<br />

melting tantalizingly on hot toast, a crusty<br />

bread roll crammed with delicious, nuttyflavored<br />

cheddar cheese. there’s no doubt<br />

that dairy products regularly feature in<br />

the daily diet in most parts of the world.<br />

the uses of milk are legion. as a drink,<br />

flavored with fruit or chocolate or added<br />

to hot drinks. you can process it into a<br />

variety of milk types. skim the cream off<br />

the top for myriad culinary uses or churn<br />

it into butter. curdle milk and you get<br />

cheese – the varieties run into thousands.<br />

whey, the by-product of cheese-making,<br />

which used to be discarded as waste, is<br />

today a valuable raw ingredient for the<br />

food industry. and even when milk turns<br />

sour you can still enjoy it as yogurt.<br />

such is the cultural impact of dairy products<br />

that they have inspired many well-known<br />

phrases. people in the us refer to an<br />

important person as ‘a big cheese’, while<br />

the french expression ‘en faire tout un<br />

fromage’ means to make a big deal of<br />

something. similarly, ‘to milk’ is associated<br />

with making the most of a situation, for<br />

example, “he milked it for all it was worth”.<br />

12<br />

the uses of milk are legion: skim<br />

the cream off the top for myriad<br />

culinary uses or churn it into butter.<br />

curdle milk and you get cheese –<br />

the varieties run into thousands.<br />

how Milking developed<br />

there’s no conclusive evidence to pinpoint<br />

when humans started to drink milk<br />

from animals, although it is generally<br />

accepted to date from when man learned<br />

to domesticate goats and sheep in the<br />

middle east around 8000 bc. it’s also<br />

known that people were herding cattle<br />

in parts of turkey as early as 7000 bc.<br />

the ancient egyptians enjoyed dairy<br />

products. murals on some of their tombs<br />

show cheese being made. and there was<br />

also a cosmetic value – cleopatra famously<br />

bathed in ass’s milk to improve her skin. the<br />

greeks, too, were into cheese. one of their<br />

most famous sons, homer, immortalized<br />

it in his epic poem, the odyssey, where<br />

he describes the cyclops making cheese<br />

from sheep and goat’s milk. but it were the<br />

romans who are credited with establishing<br />

uniform cheese-making techniques in<br />

europe. they also introduced them to<br />

other parts of their empire where cheesemaking<br />

had previously been unknown.<br />

eventually, dairy products were on the menu<br />

throughout europe as well as parts of asia<br />

and africa. then, during the age of discovery<br />

in the 15th-17th centuries, europeans<br />

spread the word to the far-flung corners of<br />

the globe when they took domestic cows<br />

and dairy production to their colonies.<br />

today, more people drink milk from cows<br />

than from any other animal. according to the<br />

international dairy federation’s world dairy<br />

situation 2007¹ cow milk represents 84 per<br />

cent of world output – 551 million tonnes in<br />

2007. interestingly, the report also reveals<br />

that, in india and pakistan, buffalo milk<br />

production is growing faster than cow milk<br />

production. sheep and goat milk production<br />

is estimated at 21 million tonnes worldwide.<br />

other animal milk sources include camels,<br />

yaks, reindeer and horses. people in central<br />

asia are partial to drinking fermented mare’s<br />

milk, which they call kumis, while in sweden<br />

and russia there are moose dairies.<br />

because milking is a labor intensive process<br />

– between three and five minutes per cow –<br />

up until relatively recently dairy production<br />

could only be achieved on a small scale.<br />

milking had to be done by hand – the farmer<br />

or milkmaid sitting beside the animal with a<br />

bucket. but when electricity was discovered<br />

in the mid-19th century the race was on to<br />

transform milking from an art to a science.<br />

after 50 years of trial and error the<br />

first pulsator was introduced in 1895,<br />

paving the way for the modern pulsator<br />

machines. another key development<br />

around this time was the milk pipeline,<br />

which replaced the cumbersome task of<br />

carrying pails of milk to collection tanks.<br />

but the real breakthrough came in 1929 when<br />

the first rotary milking parlor was installed on<br />

the walker-gordon dairy farm in plainsboro,<br />

new Jersey in the us. called the ‘rotolactor’,<br />

it could milk 50 cows at a time. it remained in<br />

use until the 1960s when it was superseded<br />

by more sophisticated rotary milking parlors.<br />

advances in milking technology, not least<br />

rotary parlors capable of milking more than<br />

100 cows an hour, have enabled dairy farms<br />

throughout the western world to become<br />

huge corporations with thousands of cows.<br />

and the trend is spreading to new markets<br />

such as china, iran, pakistan and turkey.<br />

during the 20th century mechanization, food<br />

processing technology and refrigeration<br />

have made a huge variety of dairy products<br />

readily available around the world.<br />

1/2 bulletin of the idf n°423/2007 – the world dairy<br />

situation 2007, international dairy federation,<br />

diamant building – 80, boulevard auguste reyers,<br />

1030 brussels – belgium, www.fil-idf.org

Estimated volume of cow milk delivered<br />

to processing facilities in 2007.<br />

PastEurIzEd by heating it to<br />

74°C for 15-20 seconds<br />

WholE mIlk has a fat content<br />

of 3.5 to four per cent.<br />

sEmI-skImmEd milk has a lower<br />

fat content, 1.5 to 1.7 per cent,<br />

while skimmed milk is virtually<br />

fat free<br />

uht (ultra heat treated) milk is<br />

heated to at least 135°C and<br />

packaged in sterile containers.<br />

EvaPoratEd mIlk is heated at<br />

temperatures between 60°– 65°C<br />

then sterilized in sealed cans for<br />

ten minutes<br />

mIlk PoWdEr<br />

Milk is heat-treated and preconcentrated,<br />

then homogenized<br />

and fed into a spray dryer where the<br />

water is removed.<br />

saFe to DRInk<br />

the milk collection revolution has gone<br />

hand-in-hand with advances in food<br />

production. today “the share of milk<br />

production which is delivered to dairies for<br />

processing is growing faster than in previous<br />

years,” says the World Dairy situation 2007<br />

bulletin². “an estimated volume of 371<br />

million tonnes of cow milk was delivered<br />

to processing facilities, which is 65 million<br />

tonnes more than ten years ago.”<br />

milk is first pasteurized by heating it to<br />

74°c for 15-20 seconds to kill potentially<br />

harmful bacteria, without damaging the<br />

nutritional value or taste, then rapidly cooled<br />

and refrigerated to preserve its shelf life.<br />

Whole milk, which has a fat content of 3.5-4<br />

per cent, is usually homogenized to spread<br />

the fat evenly through the milk and prevent<br />

cream forming on the top. semi-skimmed<br />

milk has a lower fat content, 1.5 – 1.7 per<br />

cent, while skimmed milk is virtually fat<br />

free. Unfortunately, reducing the fat content<br />

lowers the levels of vitamin a and D but, on<br />

the positive side, reduced fat milks contain<br />

slightly more calcium by volume.<br />

Ultra heat treated (UHt) milk is heated<br />

to at least 135°c and packaged in sterile<br />

containers. as a result it can be stored<br />

for several months and, until it’s opened,<br />

doesn’t need to be kept in the refrigerator.<br />

sterilized milk, which goes through a<br />

more severe heat treatment, will last even<br />

longer but has a lower nutritional value<br />

and the taste is affected. other durable<br />

liquid varieties are evaporated milk, heated<br />

at temperatures between 60°–65°c then<br />

sterilized in sealed cans for ten minutes,<br />

and condensed milk from which most of the<br />

water has been removed and sugar added.<br />

the longest-lasting format is milk powder.<br />

milk is heat treated and pre-concentrated,<br />

then homogenized and fed into a spray<br />

dryer where the water is removed. With the<br />

exception of some vitamins, whole milk and<br />

skimmed milk powders retain the nutritional<br />

value of their liquid forms. milk powders<br />

can be reconstituted with water and then<br />

treated the same way as fresh milk. they<br />

are used extensively in food manufacturing,<br />

particularly in cakes, biscuits and sweets and<br />

also form the basis for baby milk formula.<br />

><br />

GENERATE MAGAZINE ISSUE 07 13

Estimated value of worldwide<br />

dairy products market by 2010.<br />

a gRoWIng maRket<br />

by 2010 the worldwide dairy products<br />

market is predicted to be worth more<br />

than usd 305 billion, according to a<br />

report published this year by global<br />

industry analysts (gia). several factors<br />

are expected to fuel this growth, including<br />

more emphasis on value-added products,<br />

changing eating habits, increasing<br />

demand for organic products, packaging<br />

innovations and marketing of niche brands.<br />

gia found that europe, the us and the<br />

asia pacific region now account for more<br />

than 70 per cent of the dairy market but<br />

that, by 2010, asia pacific will be the<br />

fastest growing regional market. this is<br />

attributed to changing dietary aspirations<br />

in line with new-found wealth. the report<br />

14<br />

usa<br />

BIggEst mIlk ProducErs<br />

grEatEst dEmand<br />

futurE ExPandIng markEts<br />

usa<br />

europe, the us and asia<br />

pacific account for more<br />

than 70 per cent of the<br />

dairy market but by 2010 asia<br />

pacific will be the fastest<br />

growing regional market<br />

latIn<br />

amErIca<br />

also argues that yogurt will be the most<br />

profitable sector, particularly in china.<br />

higher demand for dairy products is<br />

expected to come from latin america and<br />

the caribbean, while western europe will<br />

continue to lead the dairy consumption<br />

league table – it currently accounts for<br />

42 per cent of the global market.<br />

the biggest milk producer by far is the us,<br />

followed by india and russia. as mentioned,<br />

most farms in the developed world are run<br />

to industrial capacity. but, thanks to the<br />

latest processing technology, countries like<br />

pakistan are being encouraged to develop<br />

their dairy industries for the export market.<br />

pakistan is actually the world’s fourth<br />

largest milk producer but, interestingly, its<br />

livestock is widely distributed among rural<br />

households. new state-of-the-art processing<br />

plants, like nestle’s at kabirwala, have the<br />

capacity to process up to three million liters<br />

of milk per day to international standards.<br />

><br />

WEstErn<br />

EuroPE<br />

PakIstan<br />

IndIa<br />

russIa<br />

asIa<br />

PacIfIc<br />

asIa<br />

PacIfIc<br />

mIlkIng succEss<br />

Movie star Sir Sean Connery began his working life as<br />

a milkman at the Corstorphine Dairy in Scotland before<br />

turning to acting.<br />

chEEsE off thE mEnu for mIcE<br />

In 2006 researchers at Manchester Metropolitan<br />

University in the UK made an amazing discovery that<br />

debunks the long-held belief that mice like cheese. Their<br />

study showed that mice are attracted to sweet, sugary<br />

foods, preferring to tuck in to fruit and grains rather<br />

than the Cheddar on the mousetrap.

the unique teXture and flavor of the different<br />

cheeses depends on the milk used – usually from<br />

cows, buffalo, goats or sheep – the animal’s diet,<br />

the curdling technique, butterfat content,<br />

processing and length of aging.<br />

crEam and ButtEr<br />

Without homogenization the fat content of milk will,<br />

when left to stand, rise to the surface and float on<br />

the top. Before mechanization this cream would<br />

simply be skimmed from the surface. Today, the<br />

process is speeded up using centrifugal separators.<br />

There are several grades of cream available<br />

– the higher the fat content, the thicker the<br />

cream. Thick cream, known as double cream in<br />

the UK and heavy cream in the US, is favored<br />

for cooking as it is less likely to separate<br />

when heated than the lower fat type.<br />

Cream is a key ingredient for many cakes and<br />

desserts, not least ice cream, as well as sauces<br />

both sweet and savory. It can also be fermented<br />

with bacterial cultures to create sour cream<br />

and crème fraîche. Central and Eastern Europe<br />

have a similar product called smetana.<br />

Churning cream produces butter, another worldwide<br />

dairy staple. Butter can be salted or unsalted and<br />

the color varies according to the breed of cow and<br />

its diet. Clarified butter, made by separating the<br />

milk solids and water from the butterfat through<br />

gentle heating, is favored for frying because it can<br />

be heated to higher temperatures than ordinary<br />

butter. India has its own version, known as ghee,<br />

which is a regular ingredient in recipes. Moroccan<br />

smen is clarified butter mixed with spices.<br />

Tibetan households have butter made from<br />

yak milk. Tsampa, the national dish, consists<br />

of barley flour mixed with yak butter. Another<br />

favorite is tea with rancid yak butter and salt.<br />

chEEsE<br />

US television host Clifton Fadiman summed up<br />

the feeling of cheese-lovers everywhere when he<br />

described cheese as, “milk’s great leap towards<br />

immortality”. No other food has quite captured<br />

the imagination, or the palate, like cheese.<br />

There are literally thousands of cheeses from the<br />

familiar Cheddar, Brie, Gouda, Emmental and<br />

Gorgonzola to the less well-known Kadchgall<br />

from Afghanistan and Daralagjazsky from<br />

Russia. Many cheeses are allowed to develop<br />

molds which create distinctive blue veins, or<br />

have colorings and flavorings added, for example<br />

Wensleydale with cranberries or the fiery Afuega<br />

‘I Pitu with chilies. And for the brave there is<br />

Casu Marzu from Sardinia with live maggots.<br />

The method of making cheese is basically the same,<br />

whatever the type. Rennet, a starter bacteria, or acid<br />

such as vinegar, are added to the milk to curdle it<br />

so that the solid curds are separated from the liquid<br />

whey. The curd is then pressed into a mold and the<br />

whey is usually transformed into a powder for use in<br />

the food, animal feed and pharmaceutical industries.<br />

The unique texture and flavor of the different cheeses<br />

depends on the milk used – usually from cows,<br />

buffalo, goats or sheep – the animal’s diet, the<br />

curdling technique, butterfat content, processing<br />

and length of aging. Some cheeses are heated to<br />

between 35° and 55°C to remove more moisture,<br />

giving them a harder texture, while others are made<br />

by washing the curd in warm water to create a milder<br />

flavor. There is also a range of cheeses, such as<br />

cottage cheese or Romanian Cas, which require little<br />

yogurt and fromagE fraIs<br />

For centuries, people living in the Balkans,<br />

Turkey, Asia and the Middle East have sworn by<br />

the restorative powers of yogurt. It was generally<br />

believed that yogurt helped to prolong life and cure<br />

gastrointestinal conditions. Although yogurt is a<br />

Turkish word it’s not certain who actually invented it.<br />

However, yogurt is probably the oldest method<br />

of preserving milk. It is made by adding specific<br />

bacteria to milk and fermenting it under<br />

controlled temperatures. The bacteria eat the<br />

lactose (milk sugar) and release lactic acid<br />

which thickens the milk protein while preventing<br />

harmful bacteria getting into the product.<br />

Yogurt is available in whole, reduced fat and non-fat<br />

varieties, either in its natural sour state or sweetened<br />

and mixed with fruits, nuts and syrup. Some types,<br />

such as Greek yogurt, are strained through a cloth or<br />

paper filter to give a thicker consistency. Across the<br />

Middle East, Central Asia and India yogurt is popular<br />

as the basis for drinks, such as kefir and lassi.<br />

Another dairy product which resembles yogurt is<br />

fromage frais. It is actually made from curdled<br />

milk, like cheese, except that curds are stirred<br />

to prevent them from solidifying. Pure fromage<br />

frais is fat free but there are versions with cream<br />

added. It can be enjoyed the same way as yogurt<br />

or added to desserts and savory dishes.<br />

GENERATE MAGAZINE ISSUE 07 15

What’s good aBout a glass?<br />

vitamin B12 = red blood cells<br />

calcium = strong bones and teeth<br />

16<br />

carbohydrates = energy<br />

magnesium = muscle function<br />

Phosphorus = release energy<br />

Potassium = nerve function<br />

Protein = growth and repair<br />

riboflavin = healthy skin<br />

zinc = immune system<br />

DaIRY anD HeaLtH<br />

are dairy products good for you? for<br />

milkmaids it would seem that the answer<br />

is yes. historically, milkmaids, who<br />

milked the cows and prepared cream,<br />

butter and cheese, have been presented<br />

as fair, fecund and in fine health.<br />

perhaps easy access to dairy products<br />

meant they were getting enough to eat at<br />

a time when many working people were<br />

malnourished. their skin was certainly in<br />

better condition: working with dairy cattle<br />

exposed them to cowpox, a less serious<br />

form of the human version, smallpox.<br />

contracting cowpox made them immune<br />

to smallpox, which meant milkmaids did<br />

not have the pockmarked complexion<br />

common to smallpox survivors.<br />

in the 19th century kumis, made from<br />

mare’s milk, was considered to be a panacea<br />

for all ills, so much so that kumis resorts<br />

sprang up in the south east of russia.<br />

even now the antioxidant content of mare’s<br />

milk makes it much sought after in the<br />

cosmetics industry for use in skin creams.<br />

in today’s health-conscious, diet-obsessed<br />

world the jury is still out on how good or<br />

bad dairy products are for human health.<br />

certainly dairy products, especially the full<br />

fat varieties, can be fattening and doctors<br />

recommend that people with high cholesterol<br />

or heart conditions should avoid them.<br />

also some people lose the ability to digest<br />

lactose, becoming lactose intolerant.<br />

on the plus side a glass of milk contains:<br />

vitamin b12 for red blood cells, calcium for<br />

strong bones and teeth, carbohydrates for<br />

energy, magnesium for muscle function,<br />

phosphorus to release energy, potassium<br />

for nerve function, protein for growth<br />

and repair, riboflavin for healthy skin and<br />

zinc to protect the immune system.<br />

numerous studies have been carried out into<br />

the effects of regular milk consumption. it’s<br />

been suggested that drinking low fat milk<br />

reduces the risk of hypertension, coronary<br />

heart disease, colorectal cancer and obesity.<br />

in recent years there’s been an upsurge<br />

in demand for probiotic milk drinks and<br />

yogurts from health-conscious consumers.<br />

probiotics contain bacteria that can<br />

counteract harmful bacteria in the intestines.<br />

tRenDs In tHe DaIRY InDUstRY<br />

because fresh milk has a relatively short<br />

shelf life it used to be delivered directly<br />

to households. the milkman and his daily<br />

round are still alive and well in the uk<br />

and in rural india it’s delivered in a metal<br />

container attached to a bicycle. but, in<br />

many countries, modern food distribution,<br />

refrigeration and lifestyles have taken away<br />

the need for home delivery and now most<br />

people buy their milk from the shops.<br />

over the years the packaging has changed<br />

from the glass bottle to the wax-coated paper<br />

carton and the plastic container. now, with<br />

the environmental lobby seeking to cut down<br />

on plastic, the next stage of the packing<br />

evolution looks set to be recyclable bags.<br />

a major growth area for dairy is flavored<br />

milk as concerns about wellbeing and<br />

obesity prompt consumers to ditch<br />

carbonated sugary drinks in favor of<br />

healthier options. chocolate, strawberry<br />

and banana are the most popular.<br />

goat’s milk is also experiencing a<br />

renaissance. in europe the market is<br />

increasing by ten per cent a year, prompting<br />

farmers to increase herd sizes.<br />

like other food producers dairy farmers are<br />

feeling the effects of increased animal feed<br />

and fuel costs, which are driving up prices.<br />

but the long-term outlook is healthy: with<br />

the enhanced demand for new products<br />

such as milk-based drinks, probiotics and<br />

niche cheeses, the world’s appetite for dairy<br />

products shows no signs of abating.<br />

PErfEct snack<br />

Log on to www.cheddarometer.com to find the recipe<br />

for the perfect cheese sandwich. The site contains<br />

a mathematical formula devised by scientists at<br />

Bristol University in the UK, which calculates the ideal<br />

thickness of the bread and cheese, plus the required<br />

amount of salad, mayonnaise or pickle.<br />

cokE not ‘thE rEal thIng’ In oz<br />

More flavored milk is drunk in South Australia than<br />

anywhere else in the world. Farmers Union Iced Coffee,<br />

a coffee-milk-mix drink, is a far bigger hit there than<br />

coke.

Milking and processing excellence<br />

The globalization of the dairy industry could not have<br />

been achieved without milking machines, cutting-edge<br />

processing technology and refrigeration. And new<br />

developments in all these areas will continue to play a<br />

critical role in helping farmers and dairy companies to<br />

meet the challenges of the future.<br />

One of the leaders in this field is the <strong>GEA</strong> <strong>Group</strong>, which<br />

has a long and impressive history of supplying innovation<br />

and engineering know-how throughout the dairy chain.<br />

Given that <strong>GEA</strong> technology is involved in approximately<br />

one quarter of all milk produced worldwide it’s highly<br />

likely that the dairy products in your refrigerator will<br />

have had some contact with the company’s milking or<br />

processing equipment.<br />

Since 1926 WestfaliaSurge – part of <strong>GEA</strong> Farm<br />

Technologies – has been setting the trends in milk<br />

collection technology, with a comprehensive range of<br />

equipment for all stages of the milking process. In<br />

particular, the market-leading WestfaliaSurge AutoRotor<br />

can milk more than 100 cows an hour. And now the<br />

company has now taken the milking revolution further<br />

again with the T!TAN milking robot, which enables cows<br />

to be milked when they choose and is suitable for farms<br />

of virtually all typical sizes.<br />

<strong>GEA</strong>’s Process Engineering Division supplies everything<br />

from stand-alone installations to complete plants for<br />

processing dairy products including milk and whey<br />

powders. The division supplies turnkey plants for some<br />

of the world’s biggest dairy operations. <strong>GEA</strong> Process<br />

Engineering company Ahlborn was founded in 1856 and<br />

became part of the <strong>GEA</strong> <strong>Group</strong> in 1979. Today, it is part<br />

of the newly named <strong>GEA</strong> TDS GmbH company, which also<br />

includes Tuchenhagen Dairy Systems, a leader in the<br />

dairy, fruit juice and food processing industries.<br />

The companies of the <strong>GEA</strong> Process Equipment division<br />

support adherence to strict hygiene regulations for<br />

companies from the brewing, beverages, dairy and<br />

foodstuff industries, as well as the pharmaceutical,<br />

biotechnology, cosmetics and health care industries<br />

with a range of homogenizers, valves and plate heat<br />

exchangers. The diverse processes for handling liquid<br />

foodstuffs require many heating up and cooling steps.<br />

<strong>GEA</strong> Ecoflex plate heat exchangers meet these demands<br />

with a wide range of plates for all applications. A high<br />

level of productivity, cost-efficient operations and reliable<br />

product consistency characterize process components<br />

from <strong>GEA</strong> Tuchenhagen. Process valves, valve blocks,<br />

in-line measurement and control equipment, cleaning<br />

devices, CIP units and pumps manufactured by the<br />

company from Büchen, Germany, meet the demanding<br />

hygienic and sterile requirements of these industries.<br />

High pressure homogenization is essential for improving<br />

the stability and shelf life of dairy products. <strong>GEA</strong> Niro<br />

Soavi offers a full range of homogenizers and pumps<br />

covering all dairy industry requirements, from pilot<br />

to large scale fully automated units. Compared to<br />

conventional homogenizing valves, the company’s<br />

patented NanoValve achieves optimal performance<br />

at low pressure and is ideal for processing milk, cream,<br />

yogurt, cheese, baby food, ice cream, whey and butter.<br />

The company <strong>GEA</strong> Niro offers pilot plants for test<br />

processing and manufacturing product samples. And its<br />

Test Center for Food and Chemical Products in Denmark<br />

offers a world-leading resource for food and chemical<br />

companies to try out a range of extraction, evaporation<br />

and drying technologies.<br />

Separation equipment is central to the processing system<br />

within modern dairies. This is also a field in which <strong>GEA</strong><br />

– with its company <strong>GEA</strong> Westfalia Separator Process –<br />

excels. The centrifugal separators remove bacteria and<br />

they are crucial to a wide variety of dairy processes.<br />

Applications range from single-stage/two-stage bacterial<br />

clarification to the special bacterial clarification used<br />

for drinking milk as well as the variable bacterial<br />

clarification of cheese milk, treating concentrated whey<br />

and pre-treatment of milk powder. Westfalia is the<br />

market leader in centrifugal separators for fresh cheese.<br />

The FAGE dairy, the largest operation of its kind in Greece,<br />

chose machines from <strong>GEA</strong> Westfalia Separator Process<br />

for its main plant in Athens as well as for a new dairy in<br />

the US.<br />

Another innovation from Westfalia’s Dairy Technology<br />

Business Unit is PROCOOL – which enables dairies<br />

to switch from cold to warm milk separation, using<br />

the same machine, providing more flexibility and<br />

cheaper running costs. Westfalia also produces turnkey<br />

process lines for the variety of soft cheese products<br />

that have been developed in the trend towards more<br />

health-conscious diets (including cream cheese, quark,<br />

Thermoquark and Baker’s Cheese). There is a high level<br />

of automation in the process lines. In addition Westfalia<br />

supplies all elements of the process lines for the butter<br />

industry, including the buttermilking machine, tanks,<br />

pasteurization unit and associated pipework.<br />

Like most fresh foods, dairy products need to be kept<br />

cold. <strong>GEA</strong> Refrigeration is one of the world’s leaders in<br />

industrial refrigeration. The division provides stateof-the-art<br />

refrigeration technology, which can be used<br />

during the whole process, from the delivery of the fresh<br />

milk to the factory through all stages of production and<br />

storage.<br />

Finally, clean air at the right temperature is essential to<br />

providing the hygienic conditions needed for processing<br />

and storing dairy products. Leading air treatment experts<br />

of the <strong>GEA</strong> Air Treatment Division broke new ground<br />

by providing a climate control system at the Müritz-<br />

Milch cheese dairy in Waren, Germany, based on the<br />

dehumidifiers normally used for indoor swimming pools.<br />

To counteract the effects of the salty air from the brine<br />

bath – central to the cheese-making process – <strong>GEA</strong><br />

Happel Klimatechnik supplied equipment made from<br />

corrosion-resistant steel.<br />

GENERATE MAGAZINE ISSUE 07 17

18<br />

millennium seed bank<br />

laboratory manager<br />

keith manger gave<br />

geneRAte a guided tour<br />

through the most<br />

bio-diverse building<br />

on earth.<br />

photography: James bell

GENERATE MAGAZINE ISSUE 07<br />

19

An underground vault in<br />

the heart of the Sussex<br />

countryside in the south<br />

of England contains an<br />

international safety deposit<br />

box. It doesn’t hold money<br />

or gold but something<br />

far more valuable to the<br />

survival of the planet –<br />

seeds. The Millennium<br />

Seed Bank Project is the<br />

most ambitious worldwide<br />

conservation project<br />

ever. And, by the end of<br />

the decade, will have<br />

safeguarded 30,000 wild<br />

plant species – ten per cent<br />

of the world’s flora.<br />

20<br />

Q. why was the millennium seed bank<br />

established?<br />

A. It started in the 1960s when the royal<br />

botanic gardens, kew, in london, and<br />

other botanic gardens wanted to store<br />

and exchange seeds from plant species<br />

of particular horticultural interest. kew<br />

decided to expand the criteria to wild plants<br />

generally and particularly those facing<br />

extinction and those that are economically<br />

important in developing countries. In 1995<br />

we were granted eur 37.9 million from<br />

the millennium commission to support the<br />

development of a millennium seed bank<br />

(msb). with matching donations from a<br />

variety of organizations the project was<br />

able to move to purpose-built premises in<br />

august 2000.<br />

since then, the team has grown from 15<br />

to almost 70 people. they include expert<br />

botanists who collect the seeds plus<br />

technical staff responsible for cleaning<br />

and storing the seeds and also for testing<br />

their viability.<br />

the msb has formal partnerships with<br />

australia, botswana, burkina faso, chile,<br />

china, egypt, Jordan, kenya, lebanon,<br />

madagascar, malawi, mali, mexico, namibia,<br />

saudi arabia, south africa, tanzania and the<br />

us. we also collaborate with organizations<br />

from more than 50 countries, creating a<br />

global seed conservation network helping to<br />

deliver the aspirations of the convention on<br />

biological diversity and the global strategy<br />

for plant conservation.<br />

Q. how many seeds does the msb hold and<br />

from how many different species?<br />

A. we have the world’s largest wild plant<br />

seed bank, currently safeguarding more than<br />

1.2 billion seeds from 24,000 plant species.<br />

they come from all continents, including the<br />

only two species found in antarctica. virtually<br />

all of the uk’s flora is represented – making<br />

the uk the first country to conserve its entire<br />

flora in a seed bank.<br />

by 2009 we will have succeeded in our<br />

ambitious target of collecting seeds from<br />

ten per cent of the world’s plant species. we<br />

have concentrated on endangered, endemic<br />

(geographically specific) and economically<br />

important species. over the next ten years<br />

we are hoping to expand to 25 per cent of the<br />

world’s flora.<br />

Q. how are the seeds collected?<br />

A. expert teams collect the seeds when<br />

the plants are ready to release them. the<br />

collectors never take more than 20 per cent<br />

of the available seed on a given day so as<br />

not to compromise the growing population.<br />

they collect randomly to obtain a good<br />

representation of the genes.<br />

the majority of our seeds come via our<br />

formal international partners. where<br />

possible half of the seeds will be stored in<br />

suitable seed banks in the country of origin<br />

and the rest are sent by courier for safe<br />

long-term storage at the msb.<br />

for each species, we also collect location<br />

data using gps (global positioning system)<br />

co-ordinates, habitat information and photos.<br />

this is proving invaluable for monitoring wild<br />

plant populations, particularly in relation to<br />

climate change.<br />

Q. what conditions are required to<br />

conserve seeds?<br />

A. seeds need to be kept cold and dry. on<br />

arrival each batch is dried in a mechanical<br />

drying room at 15°c with 15 per cent<br />

relative humidity. the seeds are then<br />

cleaned and x-rayed to ensure their quality<br />

before being placed in hermetically sealed<br />

glass containers and stored in one of our<br />

underground cold rooms at -20°c.<br />

a computerized building management<br />

system accurately controls the temperature<br />

and humidity in the dry rooms, cold rooms,<br />

glasshouses, incubators and other critical<br />

areas. the cold rooms are served by a

scrolling compressor pack system which not<br />

only achieves optimum temperature control<br />

but is also extremely energy efficient. the<br />

system is water cooled and the waste hot<br />

water is recovered for domestic use. all<br />

critical areas of the building have inbuilt<br />

alarms and emergency systems including<br />

automatic generator back-up and round the<br />

clock security.<br />

Q. How long can the seeds survive<br />

in storage?<br />

A. Hundreds and, potentially, thousands of<br />

years. Recently, we were asked if we could<br />

test some seeds that had been discovered<br />

in a leather purse in the national archive<br />

at kew. the seeds had been collected in<br />

south africa by a Dutch merchant in 1803<br />

and had since been stored in less than ideal<br />

conditions. many of the seeds were dead<br />

but we managed to successfully germinate<br />

and grow seeds of a Leucospermum and<br />

an acacia. We are now waiting for them to<br />

flower so they can be formally identified. but<br />

this proves that many seeds can indeed be<br />

stored for centuries.<br />

every ten years we germinate a sample<br />

from each seed collection by growing them<br />

on agar, to check that they are still alive.<br />

many wild plants have evolved dormancy<br />

mechanisms so that seeds only germinate at<br />

a precise time in nature. consequently, we<br />

frequently have to apply special treatments<br />

to encourage the seeds to grow.<br />

although 91 per cent of seeds can be stored<br />

in cold rooms, the remaining nine per cent,<br />

which tend to have large, fleshy seeds,<br />

are desiccation intolerant or recalcitrant.<br />

this means they have to be kept moist and<br />

can only be stored short term or via cryopreservation<br />

and tissue culture techniques.<br />

Q. How and when will the seeds be released?<br />

A. Up to now we have been focusing on<br />

reaching our main target of collecting 24,000<br />

species, particularly endangered, endemic<br />

and economically important plants. but<br />

increasingly msb collections are being<br />

used in restoration, sustainable use and<br />

re-introduction projects around the world.<br />

However, the distribution of seed from the<br />

msb to third parties is governed by the<br />

terms and conditions of the access and<br />

benefit agreements that we have with our<br />

international partners. In most cases it is<br />

our partners who make most use of the<br />

collections and we provide an insurance<br />

policy by looking after the duplicate<br />

collection at the msb.<br />

an important tenet of the convention on<br />

biological Diversity is that benefits arising<br />

from genetic resources are shared fairly<br />

and equitably with the country of origin.<br />

Q. Has the msb helped to improve<br />

knowledge of plants and aid research?<br />

A. the msb works with other departments<br />

at kew including the Jodrell laboratory<br />

and Herbarium to better understand the<br />

chemical traits and taxonomy of plants. all<br />

aspects of the work of the msb produce<br />

data that helps to improve the knowledge of<br />

plants and their conservation. much of this<br />

knowledge is freely available via our website.<br />

members of our team share their skills<br />

and experience with our partners, including<br />

training. We make our laboratories available<br />

to research scientists from partner<br />

organizations.<br />

We involve schools with our work. For<br />

example, through a nationwide project Uk<br />

schools have been carrying out experiments<br />

on the longevity of seeds of Uk species. this<br />

is helping us to better predict the storage life<br />

and hence management of our collections.<br />

also we have developed a ‘mini seed bank’<br />

kit which is available for schools and<br />

members of the public to collect and store<br />

seeds using the principles of seed banking.<br />

Q. How many species have been saved from<br />

extinction as a result of the work that you do?<br />

A. there are many examples of endangered<br />

plants having their seeds safely stored<br />

with subsequent reintroduction into their<br />

natural environment. We’ve recently been<br />

involved with a project in south africa where<br />

a species called cylindrophyllum Hallii<br />

thought to be extinct was re-discovered by<br />

our partners. We have successfully stored<br />

the seed and have been able to grow plants<br />

in our glasshouse for increasing the size of<br />

seed collection and for reintroduction in<br />

the wild.<br />

sEEd sElEctIon<br />

coco-dE-mEr<br />

(Lodoicea maldivica)<br />

The world’s largest seed,<br />

from the Seychelles.<br />

Banksia cone<br />

(Proteaceae)<br />

From Australia.<br />

conE of thE sugar PInE<br />

(Pinus lambertiana)<br />

The longest cone in the<br />

world, from the USA.<br />

lEgumE sEEd casE<br />

(Berlinia grandiflora)<br />

A large legume tree from<br />

Burkina Faso, West Africa.<br />

BaoBaB fruit<br />

(Adansonia digitata)<br />

The fruit of the upside down tree,<br />

found throughout Africa.<br />

vIsIt thE msB<br />

The MSB is housed in the Wellcome Trust Millennium<br />

Building adjacent to Wakehurst Place in West Sussex.<br />

Owned by the National Trust, Wakehurst Place is<br />

managed by the Royal Botanic Gardens, Kew.<br />

One of the aims of the MSB Project is to educate<br />

and involve the general public, which is why 70 per<br />

cent of the laboratories are on view. Visitors can<br />

watch the seeds being researched and processed<br />

and see a virtual tour of the seed vault.<br />

more information is available from<br />

www.kew.org/msbp or http://data.kew.org/sid/<br />

thE rIght tEmPEraturE<br />

<strong>GEA</strong> Refrigeration is a world leader in industrial<br />

refrigeration equipment, systems and services. It<br />

offers customized solutions for the food, brewery,<br />

drinks, marine, chemical, pharmaceutical, and<br />

logistics industries. The company’s ammoniaoperated,<br />

high-performance and energy-efficient<br />

heat pumps are proving useful in commercial<br />

greenhouses – ensuring the right temperature<br />

without harming the environment.<br />

Increasingly, <strong>GEA</strong> Refrigeration is playing an<br />

important role in the ornamental plant sector where<br />

cool temperatures and conditioned relative humidity<br />

are required.<br />

GENERATE MAGAZINE ISSUE 07 21

22<br />

Books, cARs, coMputeRs, dRink, food,<br />

fuRnituRe, tRAvel, toys – whAteveR<br />

you’Re Buying oR selling, A tRAde<br />

show is the plAce to see And Be seen.

very year millions of people flock to<br />

many thousands of trade fairs and<br />

exhibitions held around the world.<br />

For visitors and exhibitors alike, these<br />

events are the perfect showcase for<br />

the latest products and services.<br />

companies can test new markets, make<br />