Impact of small scale fermentation technology on food safety in ...

Impact of small scale fermentation technology on food safety in ...

Impact of small scale fermentation technology on food safety in ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

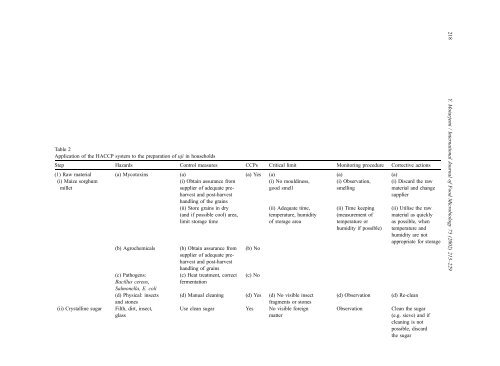

Table 2<br />

Applicati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the HACCP system to the preparati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> uji <strong>in</strong> households<br />

Step Hazards C<strong>on</strong>trol measures CCPs Critical limit M<strong>on</strong>itor<strong>in</strong>g procedure Corrective acti<strong>on</strong>s<br />

(1) Raw material (a) Mycotox<strong>in</strong>s (a) (a) Yes (a) (a) (a)<br />

(i) Maize sorghum<br />

millet<br />

(c) Pathogens:<br />

Bacillus cereus,<br />

Salm<strong>on</strong>ella, E. coli<br />

(d) Physical: <strong>in</strong>sects<br />

and st<strong>on</strong>es<br />

(ii) Crystall<strong>in</strong>e sugar Filth, dirt, <strong>in</strong>sect,<br />

glass<br />

(i) Obta<strong>in</strong> assurance from<br />

supplier <str<strong>on</strong>g>of</str<strong>on</strong>g> adequate preharvest<br />

and post-harvest<br />

handl<strong>in</strong>g <str<strong>on</strong>g>of</str<strong>on</strong>g> the gra<strong>in</strong>s<br />

(ii) Store gra<strong>in</strong>s <strong>in</strong> dry<br />

(and if possible cool) area,<br />

limit storage time<br />

(b) Agrochemicals (b) Obta<strong>in</strong> assurance from<br />

supplier <str<strong>on</strong>g>of</str<strong>on</strong>g> adequate preharvest<br />

and post-harvest<br />

handl<strong>in</strong>g <str<strong>on</strong>g>of</str<strong>on</strong>g> gra<strong>in</strong>s<br />

(c) Heat treatment, correct<br />

<str<strong>on</strong>g>fermentati<strong>on</strong></str<strong>on</strong>g><br />

(b) No<br />

(c) No<br />

(i) No mould<strong>in</strong>ess,<br />

good smell<br />

(ii) Adequate time,<br />

temperature, humidity<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> storage area<br />

(d) Manual clean<strong>in</strong>g (d) Yes (d) No visible <strong>in</strong>sect<br />

fragments or st<strong>on</strong>es<br />

Use clean sugar Yes No visible foreign<br />

matter<br />

(i) Observati<strong>on</strong>,<br />

smell<strong>in</strong>g<br />

(ii) Time keep<strong>in</strong>g<br />

(measurement <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

temperature or<br />

humidity if possible)<br />

(i) Discard the raw<br />

material and change<br />

supplier<br />

(ii) Utilise the raw<br />

material as quickly<br />

as possible, when<br />

temperature and<br />

humidity are not<br />

appropriate for storage<br />

(d) Observati<strong>on</strong> (d) Re-clean<br />

Observati<strong>on</strong> Clean the sugar<br />

(e.g. sieve) and if<br />

clean<strong>in</strong>g is not<br />

possible, discard<br />

the sugar<br />

218<br />

Y. Motarjemi / Internati<strong>on</strong>al Journal <str<strong>on</strong>g>of</str<strong>on</strong>g> Food Microbiology 75 (2002) 213–229