Impedance methods for electrochemical sensors using nanomaterials

Impedance methods for electrochemical sensors using nanomaterials

Impedance methods for electrochemical sensors using nanomaterials

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Trends Trends in Analytical Chemistry, Vol. 27, No. 7, 2008<br />

<strong>Impedance</strong> <strong>methods</strong> <strong>for</strong><br />

<strong>electrochemical</strong> <strong>sensors</strong> <strong>using</strong><br />

<strong>nanomaterials</strong><br />

Ian I. Suni<br />

This article presents an overview of <strong>electrochemical</strong> <strong>sensors</strong> that employ<br />

<strong>nanomaterials</strong> and utilize <strong>electrochemical</strong> impedance spectroscopy <strong>for</strong><br />

analyte detection. The most widely utilized <strong>nanomaterials</strong> in impedance<br />

<strong>sensors</strong> are gold (Au) nanoparticles and carbon nanotubes (CNTs). Au nanoparticles<br />

have been employed in impedance <strong>sensors</strong> to <strong>for</strong>m electrodes from<br />

nanoparticle ensembles and to amplify impedance signals by <strong>for</strong>ming<br />

nanoparticle-biomolecule conjugates in the solution phase. CNTs have been<br />

employed <strong>for</strong> impedance <strong>sensors</strong> within composite electrodes and as nanoelectrode<br />

arrays. The advantages of <strong>nanomaterials</strong> in impedance <strong>sensors</strong><br />

include increased sensor surface area, electrical conductivity and connectivity,<br />

chemical accessibility and electrocatalysis.<br />

ª 2008 Elsevier Ltd. All rights reserved.<br />

Keywords: Analyte detection; Biosensor; Carbon nanotube; Electrochemical impedance<br />

spectroscopy; Electrochemical sensor; Gold nanoparticle; Immunosensor; <strong>Impedance</strong>;<br />

Nanoparticle; Nanomaterial<br />

Ian I. Suni*<br />

Department of Chemical and<br />

Biomolecular Engineering,<br />

Center <strong>for</strong> Advanced Materials<br />

Processing (CAMP), Clarkson<br />

University, Potsdam, NY<br />

13699-5705, USA<br />

* Tel.: +1 315 269 4471;<br />

E-mail: isuni@clarkson.edu<br />

1. Introduction<br />

1.1. Electrochemical impedance<br />

spectroscopy – background<br />

Electrochemical impedance spectroscopy<br />

(EIS) has long been employed <strong>for</strong> studying<br />

<strong>electrochemical</strong> systems [1], including<br />

those involved in corrosion, electrodeposition<br />

[2], batteries [3] and fuel cells [4].<br />

For impedance measurements, a small<br />

sinusoidal AC voltage probe (typically<br />

2–10 mV) is applied, and the current<br />

response is determined. The in-phase<br />

current response determines the real<br />

(resistive) component of the impedance,<br />

while the out-of-phase current response<br />

determines the imaginary (capacitive)<br />

component. The AC probe voltage should<br />

be small enough so that the system response<br />

is linear, allowing simple equivalent<br />

circuit analysis. <strong>Impedance</strong> <strong>methods</strong><br />

are quite powerful, in that they are capable<br />

of characterizing physicochemical<br />

processes of widely differing time constants,<br />

sampling electron transfer at high<br />

frequency and mass transfer at low frequency.<br />

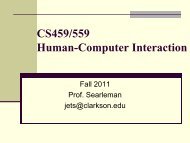

<strong>Impedance</strong> results are commonly fitted<br />

to equivalent circuits of resistors and<br />

capacitors, such as the Randles circuit<br />

shown in Fig. 1 [5], which is often used to<br />

interpret simple <strong>electrochemical</strong> systems.<br />

This equivalent circuit yields the Nyquist<br />

plot shown in Fig. 2, which provides visual<br />

insight into the system dynamics. In Figs.<br />

1 and 2, Rct is the charge-transfer resistance,<br />

which is inversely proportional to<br />

the rate of electron transfer; Cd is the<br />

double-layer capacitance; Rs is the solution-phase<br />

resistance; and, Zw is the<br />

Warburg impedance, which arises from<br />

mass-transfer limitations. If an analyte<br />

affects one or more of these equivalent<br />

circuit parameters and these parameters<br />

are not affected by interfering species, then<br />

impedance <strong>methods</strong> can be used <strong>for</strong> analyte<br />

detection. Rs arises primarily from the<br />

electrolyte resistance and is analytically<br />

useful mainly in conductivity <strong>sensors</strong>,<br />

which I will not discuss in this article. The<br />

Warburg impedance, which can be used to<br />

measure effective diffusion coefficients, is<br />

seldom useful <strong>for</strong> analytical applications.<br />

The equivalent circuit elements in Figs.<br />

1 and 2 that are most often useful <strong>for</strong><br />

analyte detection are Rct and Cd. The<br />

measured capacitance usually arises from<br />

the series combination of several elements,<br />

such as analyte binding (Canal) to a sensing<br />

layer (Csens) on an Au electrode (CAu). In this case, the measured capacitance is:<br />

1<br />

¼<br />

Cd<br />

1<br />

þ<br />

CAu<br />

1<br />

þ<br />

Csens<br />

1<br />

ð1Þ<br />

Canal<br />

<strong>for</strong> a sensing layer and analyte layer that<br />

are continuous. In many cases, the<br />

0165-9936/$ - see front matter ª 2008 Elsevier Ltd. All rights reserved. doi:10.1016/j.trac.2008.03.012 604

Trends in Analytical Chemistry, Vol. 27, No. 7, 2008 Trends<br />

-Z imag<br />

R s<br />

R s<br />

decreasing w<br />

R ct<br />

R ct<br />

Z real<br />

C d<br />

Z w<br />

Figure 1. Randles equivalent circuit <strong>for</strong> a simple <strong>electrochemical</strong><br />

system.<br />

Slope=unity<br />

Figure 2. Nyquist plot arising from the Randles circuit shown in<br />

Fig. 1.<br />

capacitance at the Au electrode-sensing layer interface is<br />

large and can be neglected. The sensitivity is then<br />

determined by the relative capacitance of the analyte<br />

layer and the sensing layer. For each dielectric layer, the<br />

capacitance per unit area depends on the layer thickness<br />

(t) according to:<br />

C ed<br />

¼ ð2Þ<br />

A t<br />

where ed is the dielectric constant of the dielectric layer,<br />

so capacitance is most sensitive to binding of large<br />

analytes, such as proteins or cells.<br />

One difficulty with capacitive <strong>sensors</strong> is that their<br />

sensitivity depends on obtaining the proper thickness of<br />

the original sensing layer [6]. If the original sensing<br />

layer is too thin, then the underlying electrode surface<br />

may be partially exposed, allowing <strong>for</strong> non-specific<br />

interactions from interfering species. However, if the<br />

original sensing layer is too thick, then the AC impedance<br />

current that is detected is dramatically reduced, as<br />

is the change in capacitance upon analyte binding. Rct<br />

can also be quite sensitive to analyte binding, particularly<br />

<strong>for</strong> detection of large species, such as proteins or<br />

cells, which significantly impede electron transfer. For<br />

analyte binding (Ranal) to a sensing layer (Rsens) onan<br />

Au electrode (RAu), the measured resistance is:<br />

Rct ¼ RAu þ Rsens þ Ranal<br />

ð3Þ<br />

The resistance at the interface between the Au electrode<br />

and the sensing layer is typically negligible. Measurement<br />

of Rct requires the presence of redox-active species<br />

in the electrolyte. <strong>Impedance</strong> sensing is most useful <strong>for</strong><br />

large species that significantly perturb the sensing<br />

interface, although impedance detection of glucose was<br />

recently reported [7]. Many of the examples of impedance<br />

<strong>sensors</strong> that I discuss later in this article monitor<br />

Rct as a measure of analyte concentration.<br />

1.2. Electrochemical impedance spectroscopy – sensing<br />

applications<br />

For bio<strong>sensors</strong>, EIS has some important advantages over<br />

amperometry.<br />

For direct amperometric bio<strong>sensors</strong>, an oxidoreductase<br />

enzyme is immobilized at a conductive electrode, and<br />

electron transfer is detected during a biologically-mediated<br />

oxidation/reduction reaction. However, the active<br />

site must be both in close proximity to the electrode<br />

surface and easily accessible to the analyte solution. In<br />

many cases, electron transfer occurs far from the electrode<br />

surface, and electron-transfer rates drop exponentially<br />

with distance [8]. This problem can be reduced<br />

through the use of redox mediators, but detection then<br />

becomes limited by mediator mass transfer.<br />

Indirect amperometric bio<strong>sensors</strong> detect the product of<br />

a biologically-catalyzed reaction, often hydrogen peroxide.<br />

However, the analyte often contains additional<br />

species (e.g., ureate or ascorbate) that can also be <strong>electrochemical</strong>ly<br />

oxidized or reduced, so indirect amperometric<br />

bio<strong>sensors</strong> are not selective. One of the most<br />

significant advantages of impedance detection <strong>for</strong> biosensing<br />

is that antibody-antigen binding can be directly<br />

detected, allowing the development of immuno<strong>sensors</strong>.<br />

The main drawback of impedance <strong>methods</strong> <strong>for</strong> bio<strong>sensors</strong><br />

is the need <strong>for</strong> interfacial engineering to reduce<br />

non-specific adsorption. One well-studied method to<br />

minimize non-specific interactions is to embed the probe<br />

agent into a composite film that contains the biomolecule<br />

of interest interspersed with a protein-resistant<br />

species, such as molecules containing ethylene-glycol<br />

moieties. This approach has been widely touted by the<br />

research group of George Whitesides [9–11], and such<br />

reagents are now commercially available. The use of<br />

impedance <strong>methods</strong> <strong>for</strong> bio<strong>sensors</strong> has been recently<br />

reviewed [12], but not with a focus on the use of<br />

<strong>nanomaterials</strong>. Limits of detection (LODs) have been reported<br />

<strong>for</strong> impedance bio<strong>sensors</strong> in the nM–pM range in<br />

controlled laboratory conditions [13–17].<br />

It should be acknowledged that Au-nanoparticle<br />

conjugation to biomolecules has been employed in bio<strong>sensors</strong><br />

<strong>using</strong> several other <strong>electrochemical</strong> detection<br />

<strong>methods</strong>, predominantly anodic stripping voltammetry<br />

(ASV), anodic Au surface oxidation and quartz crystal<br />

http://www.elsevier.com/locate/trac 605

Trends Trends in Analytical Chemistry, Vol. 27, No. 7, 2008<br />

microbalance (QCM) [18,19]. However, impedance<br />

detection has some significant advantages over these<br />

<strong>methods</strong>. <strong>Impedance</strong> sensing does not require the voltage<br />

scanning needed <strong>for</strong> ASV and anodic oxidation,<br />

which is time consuming and may degrade the <strong>electrochemical</strong><br />

interface during wide potential sweeps. In<br />

addition, impedance <strong>methods</strong> are largely insensitive to<br />

environmental disturbance, which is often problematic<br />

<strong>for</strong> QCM <strong>sensors</strong>.<br />

2. Nanomaterials <strong>for</strong> sensing applications<br />

Nanomaterials are generally defined as involving the<br />

length scale from 1–100 nm; in other words, materials<br />

intermediate between the atomic and molecular scale<br />

and the bulk scale. The chemical, electronic, and optical<br />

properties of <strong>nanomaterials</strong> generally depend on both<br />

their dimensions and their morphology. Although a wide<br />

variety of <strong>nanomaterials</strong> <strong>for</strong> <strong>sensors</strong> have been reported<br />

in the literature, the most widely employed <strong>nanomaterials</strong><br />

are carbon nanotubes (CNTs) and Au nanoparticles,<br />

in part because of their commercial availability. In<br />

addition, both materials are considered to be biocompatible.<br />

2.1. Au nanoparticles<br />

Au nanoparticles are generally synthesized by chemical<br />

reduction of Au salts in aqueous-phase, organic-phase,<br />

or mixed-phase solutions [20]. The most difficult aspect<br />

of this synthesis is to control the reactivity of the Aunanoparticle<br />

surface during particle growth, since the<br />

surface energy is quite high. Controlled synthesis of Au<br />

nanoparticles requires the use of stabilizing agents, such<br />

as citrate or thiolated species, that bind to the particle<br />

surface to control growth and to prevent aggregation.<br />

Numerous <strong>methods</strong> have been reported <strong>for</strong> creation of<br />

biomolecule-Au-nanoparticle conjugates either during<br />

or after Au-nanoparticle synthesis [20]. Commercial reagents<br />

are now available <strong>for</strong> conjugation of biomolecules<br />

to Au nanoparticles of several different sizes. One of the<br />

primary reasons <strong>for</strong> the intensive research into biomolecule-Au-nanoparticle<br />

conjugates is that biomolecules in<br />

this environment are generally stable and retain their<br />

biological activity. Depending on the application, different<br />

Au-nanoparticle sizes may be optimal [21].<br />

2.2. Carbon nanotubes<br />

CNTs, which are allotropes of carbon from the fullerene<br />

structural family, can be conceived as sp 2 carbon atoms<br />

arranged in grapheme sheets that have been rolled up into<br />

hollow tubes. Multi-walled CNTs (MWCNTs) behave as<br />

conductors and have electrical conductivities greater than<br />

metals, suggesting their incorporation into sensing electrodes<br />

may be beneficial. However, depending on the tube<br />

diameter and chirality, single-walled CNTs (SWCNTs) can<br />

606 http://www.elsevier.com/locate/trac<br />

behave electronically as either metals or semiconductors<br />

[22], complicating their use in sensing electrodes. CNTsynthesis<br />

<strong>methods</strong> create a mixture that includes amorphous<br />

carbon, graphite particles and CNTs, so synthesis is<br />

typically followed by a difficult separation process.<br />

For <strong>electrochemical</strong> applications, CNTs are typically<br />

activated in strong acids, which opens the CNT ends and<br />

<strong>for</strong>ms oxygenated species, making the ends hydrophilic<br />

and increasing the aqueous solubility of CNTs [22]. The<br />

<strong>electrochemical</strong> behavior of CNTs varies considerably<br />

with the <strong>methods</strong> used <strong>for</strong> purification and preparation,<br />

including oxidation treatment [22]. For analytical<br />

applications, CNTs are most often used to modify other<br />

electrode materials, or as part of a composite electrode,<br />

in part due to difficulties in handling them.<br />

3. <strong>Impedance</strong> <strong>sensors</strong> <strong>using</strong> Au nanoparticles<br />

3.1. Au-nanoparticle substrates – impedance detection<br />

The most widely reported use of Au nanoparticles in<br />

impedance <strong>sensors</strong> involves their incorporation into an<br />

ensemble substrate onto which a protein, oligonucleotide,<br />

or other probe molecule is immobilized [23–34].<br />

Most studies involve construction of a sensing interface<br />

that contains one layer of Au nanoparticles on a conductive<br />

electrode, although, in a few cases, Au nanoparticles<br />

are incorporated into a ceramic sol gel or<br />

polymer film. The Au nanoparticles are sometimes made<br />

<strong>using</strong> colloidal techniques, and sometimes by electrodeposition.<br />

The Au nanoparticles can be conjugated with<br />

probe reagents (antibodies or ssDNA) either be<strong>for</strong>e or<br />

after the Au-nanoparticle ensemble is <strong>for</strong>med.<br />

The advantages of sensing interfaces that contain Aunanoparticle<br />

networks, compared to sensing interfaces<br />

based on flat Au surfaces, include the increased surface<br />

area <strong>for</strong> sensing, improved electrical connectivity<br />

through the Au-nanoparticle network, and chemical<br />

accessibility to the analyte through these networks. The<br />

advantages, compared to non-Au surfaces, also include<br />

electrocatalysis.<br />

One potentially powerful method <strong>for</strong> <strong>using</strong> Au nanoparticles<br />

to enhance impedance detection in bio<strong>sensors</strong><br />

involves the construction of three-dimensional networks<br />

with Au nanoparticles dispersed throughout the sensing<br />

interface. This can be accomplished through repeated<br />

use of a bifunctional reagent, such as cysteineamine or<br />

4-aminothiophenol, where the thiol group can bind to a<br />

biomolecule and the amine group can bind to Au<br />

nanoparticles, <strong>for</strong> layer-by-layer <strong>for</strong>mation of an Aunanoparticle<br />

network. <strong>Impedance</strong> detection of human<br />

immunoglobulin (hIgG) <strong>using</strong> such a three-dimensional<br />

Au-nanoparticle network was recently reported <strong>using</strong> 6nm<br />

diameter Au nanoparticles and cysteamine as the<br />

bifunctional reagent [23]. Fig. 3 shows the sensorpreparation<br />

process.

Trends in Analytical Chemistry, Vol. 27, No. 7, 2008 Trends<br />

Figure 3. Au-nanoparticle-multilayer preparation onto an Au electrode (a), and the immobilization of antibody and the interaction of antigen and<br />

biotin-conjugated antibody (b) (from [23]).<br />

These authors also studied the nature of the sensing<br />

interface as a function of the number of Au-nanoparticle<br />

layers <strong>using</strong> both cyclic voltammetry and EIS. As the<br />

number of Au-nanoparticle layers increased, the<br />

FeðCNÞ<br />

3 =4<br />

6<br />

oxidation/reduction peak height increased<br />

and the peak separation decreased, demonstrating increased<br />

reversibility. Similarly, Rct decreased continuously<br />

as the number of Au-nanoparticle layers increased.<br />

Following electrostatic binding of goat anti-human<br />

IgG antibody, the sensing interface was able to detect the<br />

presence of hIgG, with Rct increasing with an increase in<br />

human-IgG concentration. Amplification of the impedance<br />

signal was accomplished by further binding biotinconjugated<br />

goat anti-human IgG, resulting in a detection<br />

range of 5–400 lg/L. The LOD was then estimated to be<br />

0.5 lg/L [23]. In this study, antibody was immobilized<br />

only on the outer layer of Au nanoparticles to ensure<br />

chemical accessibility of the analyte, a protein. For<br />

small-molecule analytes that can be detected by impedance<br />

<strong>methods</strong>, such multilayer Au-nanoparticle net-<br />

works may be invaluable <strong>for</strong> sensing. They could allow<br />

dramatic increases in the electrode surface area without<br />

introducing mass-transfer limitation.<br />

<strong>Impedance</strong> detection of carcinoembryonic antigen<br />

(CEA), a glycoprotein involved in cell adhesion produced<br />

only during fetal development, was recently reported<br />

[31]. The CEA antibody was first bound through its<br />

surface amino groups to glutathione-modified Au<br />

nanoparticles of diameter 15 ± 1.5 nm by amide-bond<br />

<strong>for</strong>mation <strong>using</strong> N-(3-dimethylaminopropyl)-N 0 -ethylcarbodiimide<br />

hydrochloride (EDC) and N-hydroxysulfylsuccinimide<br />

sodium salt (NHSS). The sensing interface<br />

was then <strong>for</strong>med by co-polymerizing a mixture of<br />

o-aminophenol and the Au-nanoparticle-conjugated<br />

CEA antibodies. An interesting feature of their study was<br />

the direct comparison between the antibody-containing<br />

sensing interface, with and without Au-nanoparticle<br />

conjugation. They reported that Rct increased by only<br />

0.59 · 10 5 X (35%) <strong>for</strong> the sensing interface without<br />

Au nanoparticles, but by 6.3 · 10 5 X (7%) with Au<br />

http://www.elsevier.com/locate/trac 607

Trends Trends in Analytical Chemistry, Vol. 27, No. 7, 2008<br />

nanoparticles [31]. The authors tested their sensing<br />

interface in both model lysozyme solutions and serum<br />

samples and reported no false positives arising from<br />

non-specific interactions. They estimated an LOD <strong>for</strong> CEA<br />

of 0.1 ng/mL.<br />

<strong>Impedance</strong> detection was recently demonstrated <strong>for</strong> an<br />

intriguing application, detection of the IgE antibody to a<br />

protein allergen from dust mites [29,30]. Au nanoparticles<br />

were deposited onto a glassy-carbon electrode<br />

(GCE) either by electrodeposition, or by immersion in<br />

(3-mercaptopropyl)trimethoxysilane (MPTS), followed<br />

by immersion in a colloid solution containing 16-nm<br />

diameter Au nanoparticles. For Au electrodeposition,<br />

30 s of deposition from 0.1% HAuCl4 produced Au<br />

nanoparticles of average diameter 40 ± 8 nm. The Aunanoparticle-modified<br />

GCE was then immersed in recombinant<br />

dust-mite allergen Der f2 to <strong>for</strong>m a protein<br />

film, and this interface was employed <strong>for</strong> impedance<br />

detection of the murine monoclonal antibody to Der F2<br />

over the range 2–300 lg/ml. At relatively low antibody<br />

concentrations, Rct increased continuously with antibody<br />

concentration. At higher antibody concentrations,<br />

Rct became relatively insensitive to changes in antibody<br />

concentration, probably due to surface saturation. This<br />

type of impedance sensor might be employed <strong>for</strong> allergy<br />

screening of patients, where allergen-specific IgE is detected<br />

<strong>for</strong> a wide range of allergens.<br />

In addition to <strong>using</strong> antibodies as probe reagents,<br />

impedance <strong>sensors</strong> have been demonstrated <strong>using</strong> DNA<br />

or oligonucleotides bound to Au-nanoparticle arrays to<br />

detect complementary target molecules [26,34]. In<br />

addition, the incorporation of CdS nanoparticles conjugated<br />

to ssDNA into the sensing interface of an impedance<br />

sensor has been reported [35]. One group reports<br />

<strong>for</strong>ming a sensing interface by binding thiol-derivatized<br />

oligonucleotides onto Au surfaces modified by Au electrodeposition,<br />

followed by impedance detection of two<br />

minor DNA groove-binding agents, mythramycin and<br />

netropsin, and a DNA intercalator, nogalamycin [26].<br />

The advantage of <strong>using</strong> Au electrodeposition to modify<br />

the Au substrate is that the effects of surface roughness,<br />

which is related to the Au-nanoparticle size, can be<br />

studied quantitatively by measuring the surface area by<br />

voltammetric reduction of Au oxide. Substrates were<br />

prepared with a total surface area up to 90% greater<br />

than that of the original flat Au substrate. The greatest<br />

sensitivity was observed <strong>for</strong> an Au-electrodeposition<br />

process that produced Au nanoparticles in the 20–80nm<br />

range. The authors estimated that this allowed a<br />

reduction in the LOD by a factor of 20–40x, down to<br />

5 nM <strong>for</strong> nogalamycin [26].<br />

Au nanoparticles and carbon nanofibers have also<br />

been reported to be useful in composite substrates <strong>for</strong><br />

impedance sensing of cells [36,37]. In these studies<br />

<strong>using</strong> EIS, the binding of K562 leukemia cells was<br />

monitored as an increase in Rct. These authors reported<br />

608 http://www.elsevier.com/locate/trac<br />

that incorporating Au nanoparticles increased the sensitivity<br />

to cell binding, which was attributed to increased<br />

electrode-surface area. Au nanoparticles were first synthesized<br />

<strong>using</strong> chitosan as a combined reducing and<br />

stabilizing agent, then reacted with ammonia to create a<br />

sol-gel film atop a GCE with embedded Au nanoparticles<br />

of 12-nm diameter. Adhesion of K562 leukemia cells<br />

was then monitored in situ by EIS. Cell adhesion could be<br />

detected only by the combination of chitosan and Au<br />

nanoparticles atop a GCE. R ct was reported to correlate<br />

to the logarithm of the cell concentration over the range<br />

10 4 –10 8 cells/mL with an LOD of 8.7 · 10 2 cells/mL.<br />

3.2. Au-nanoparticle conjugation in solution<br />

Several recent studies described different strategies <strong>for</strong><br />

the use of Au nanoparticles <strong>for</strong> impedance sensing that<br />

involved Au-nanoparticle conjugation in the solution<br />

phase rather than prior modification of the sensing<br />

interface.<br />

In one approach, impedance sensing included an extra<br />

step of analyte conjugation to 10-nm diameter Au<br />

nanoparticles, with signal amplification occurring only<br />

when the Au nanoparticles become embedded in the<br />

sensing interface [38]. This approach was demonstrated<br />

<strong>using</strong> the model system fluorescein/anti-fluorescein,<br />

with fluorescein bound to the flat Au substrate <strong>using</strong><br />

EDC/NHSS linker chemistry. The analyte (goat antifluorescein)<br />

was conjugated to Au nanoparticles in<br />

solution prior to detection. A change in the impedance at<br />

the sensing interface was observed only when the antibody<br />

was conjugated to Au nanoparticles, but not <strong>for</strong> the<br />

bare antibody [38]. Signal amplification was significantly<br />

higher with a redox probe (impedance detection)<br />

than without a redox probe (capacitance detection). This<br />

is believed to reflect the substantial electrochemistry that<br />

can occur on the Au nanoparticles embedded within the<br />

sensing interface, which is otherwise essentially a polymer<br />

film. As a result, Rct is substantially reduced upon<br />

analyte binding, which embeds Au nanoparticles within<br />

the sensing interface.<br />

A similar detection scheme was recently reported to<br />

detect DNA hybridization, with the target ssDNA conjugated<br />

to 5-nm diameter CdS nanoparticles [39]. Probe<br />

ssDNA was immobilized onto an Au electrode <strong>using</strong> selfassembly<br />

chemistry and amide-bond <strong>for</strong>mation with<br />

EDC/NHSS coupling. CdS nanoparticles were prepared<br />

by precipitation from CdCl2 and Na2S <strong>using</strong> mercaptoacetic<br />

acid as a stabilizer, then conjugated to the<br />

complementary ssDNA. The authors reported that conjugation<br />

to CdS nanoparticles increased the sensitivity by<br />

about two orders of magnitude. Interestingly, unlike the<br />

results observed with Au-nanoparticle conjugation [38],<br />

here analyte binding was accompanied by a dramatic<br />

increase in Rct [39]. The difference between these two<br />

studies can be explained by the different rates of electron<br />

transfer on Au and CdS, and by the different sensing

Trends in Analytical Chemistry, Vol. 27, No. 7, 2008 Trends<br />

interfaces. For CdS-nanoparticle conjugation, the interfacial<br />

R ct prior to analyte detection was about two orders<br />

of magnitude lower than that in the study with Aunanoparticle<br />

conjugation. For this less well-passivated<br />

sensing interface, the dominant effect upon binding of<br />

ssDNA-CdS is obscuration of the underlying conductive<br />

electrode, rather than enhanced rates of electron transfer<br />

due to embedding of CdS nanoparticles. However, when<br />

Au nanoparticles are embedded into a sensing interface<br />

that is completely polymer coated, the dominant effect is<br />

the improved rates of electron transfer on the Au<br />

nanoparticles.<br />

In bio<strong>sensors</strong>, the use of <strong>nanomaterials</strong> has been<br />

envisioned to create successive amplification steps [40].<br />

This type of approach was recently demonstrated with a<br />

different type of solution-phase Au-nanoparticle conjugation,<br />

utilizing a strategy that might be termed an<br />

impedance-sandwich assay [41]. In this approach, antiprotein<br />

A IgG was bound to an Au-electrode surface, and<br />

then exposed to protein A of varying concentrations.<br />

Following protein A binding, the sensing interface was<br />

exposed to a solution containing IgG antibodies conjugated<br />

to 13-nm diameter Au nanoparticles. Without this<br />

amplification step, the LOD of protein A was reported to<br />

be 1.0 ng/mL, and the LOD was reduced by one order of<br />

magnitude by the amplification step. The authors reported<br />

that their sensitivity was about 100x better than<br />

that obtained with conventional ELISAs. One advantage<br />

of this approach is that the protein-antibody conjugate<br />

can be prepared in advance and stored <strong>for</strong> about one<br />

month without loss of activity.<br />

Another group recently reported the use of solutionphase<br />

Au-nanoparticle conjugation <strong>for</strong> amplifying the<br />

signal from an impedance biosensor. The sensing interface<br />

was an Au electrode onto which Au nanoparticles<br />

were attached <strong>using</strong> 1,6-hexanedithiol, followed by<br />

immobilization of rabbit anti-IgG [28]. After binding the<br />

hIgG analyte, and blocking non-reacted surface sites<br />

with bovine serum albumin (BSA), the impedance signal<br />

was amplified by binding Au-colloid-labeled goat antihIgG<br />

that was synthesized in advance [28]. This approach<br />

(Fig. 4) was motivated by the relatively small<br />

impedance change sometimes observed upon antigen<br />

recognition by a surface-immobilized antibody. Without<br />

amplification, the impedance change upon binding of<br />

hIgG was about 100 X-cm 2 , whereas, with amplification,<br />

the impedance change was several thousand<br />

X-cm 2 . The authors reported an LOD <strong>for</strong> human IgG of<br />

4.1 ng/L and a linear concentration range of about<br />

15–330 ng/L.<br />

Figure 4. The process of immobilization of rabbit anti-hIgG antibody onto an Au electrode, followed by analyte binding and amplification by the<br />

Au-nanoparticle-labeled antibody (from [28]).<br />

http://www.elsevier.com/locate/trac 609

Trends Trends in Analytical Chemistry, Vol. 27, No. 7, 2008<br />

4. <strong>Impedance</strong> <strong>sensors</strong> <strong>using</strong> carbon nanotubes<br />

4.1. Carbon-nanotube substrates – impedance detection<br />

The most detailed studies of impedance <strong>sensors</strong> that<br />

employ CNTs do not employ SWCNTs or MWCNTs, but<br />

instead employ electrodes constructed from CNT towers<br />

grown by chemical-vapor deposition (CVD) [42–44].<br />

Starting with bare Si wafers, Al was deposited by electron-beam<br />

evaporation and then oxidized, followed by<br />

deposition of a Fe-catalyst film through a shadow mask.<br />

CNT towers several mm thick were then grown by CVD<br />

at 750°C from a mixture of ethylene, water, and<br />

hydrogen. The CNT tower was peeled from the Si substrate,<br />

cast in epoxy, and polished to reveal the underlying<br />

CNTs. The average CNT diameter is 20 nm, the<br />

average spacing is about 200 nm, and the aspect ratio is<br />

approximately 2 · 10 5 . A significant advantage of this<br />

method <strong>for</strong> creating an <strong>electrochemical</strong>-sensing interface<br />

is that purification of the CNTs is not needed.<br />

The <strong>electrochemical</strong> characteristics of these CNTtower<br />

electrodes have been most fully characterized by<br />

voltammetry. Voltammetry of CNT towers in both<br />

3 =4<br />

FeðCNÞ6 and RuðNH3Þ 3þ<br />

6 show a sigmoidal shape,<br />

without clear current peaks, at scan rates of up to<br />

100 mV/s, and show current peaks <strong>for</strong> scan rates of<br />

500 mV/s and above [42,43]. These results are similar<br />

to results <strong>for</strong> MWCNT arrays that exhibit sigmoidal<br />

voltammograms <strong>for</strong> large nanotube spacing, where the<br />

diffusion fields from individual nanotubes do not fully<br />

overlap, and peak-shaped voltammograms <strong>for</strong> small<br />

nanotube spacing, where diffusion fields overlap [45,46].<br />

As has been widely reported <strong>for</strong> micro-electrodes [47],<br />

arrays of nanotube electrodes have enhanced diffusion<br />

rates relative to macroscopic electrodes, and reduced<br />

capacitance per unit area, which can significantly improve<br />

their sensitivity. Given the high electron-transfer<br />

rates observed, CNT towers might be useful <strong>for</strong> characterizing<br />

rapid redox processes [42].<br />

CNT-tower electrodes have been employed <strong>for</strong><br />

impedance detection of both mouse IgG and prostatecancer<br />

cells [43,44]. Prior to immobilization of antimouse<br />

IgG, the open end of the CNTs were oxidized in<br />

strong acid or <strong>electrochemical</strong>ly to <strong>for</strong>m active carboxylate<br />

groups [43]. This allowed the use of standard EDC/<br />

NHSS coupling chemistry <strong>for</strong> amide-bond <strong>for</strong>mation to<br />

anti-mouse IgG. Both antibody immobilization and analyte<br />

binding were monitored by the extent to which they<br />

increased Rct, providing a non-linear calibration curve.<br />

The LOD <strong>for</strong> mouse IgG was reported as 200 ng/mL, with<br />

a dynamic range of up to 100 lg/mL. Preliminary results<br />

<strong>for</strong> impedance detection of prostrate-cancer cells involved<br />

somewhat more complex electrode preparation, including<br />

Au electrodeposition onto the CNT-tower electrode [44].<br />

As <strong>for</strong> protein detection, cell binding is detected as an<br />

increase in Rct.<br />

610 http://www.elsevier.com/locate/trac<br />

CNTs have also been incorporated into composite<br />

electrodes used <strong>for</strong> impedance detection of DNA hybridization<br />

[48,49]. In these studies, MWCNTs were copolymerized<br />

with polypyrrole atop a GCE. EDC/NHSS<br />

linker chemistry was used to <strong>for</strong>m an amide bond and<br />

immobilize ssDNA. The complementary oligonucleotide<br />

could be detected by the accompanying change in Rct,<br />

both with [48] and without [49] subsequent metallization.<br />

DNA metallization is a widely-studied technique,<br />

whereby metal ions that bind to the center of the DNA<br />

double helix greatly increase the conductivity of the<br />

sensing interface, and that could be detected as a<br />

reduction in Rct [48].<br />

However, DNA hybridization without metallization<br />

could be detected as an increase in Rct [49]. CNTs were<br />

incorporated within the sensing interface due to their<br />

high conductivity and their effect of increasing the active<br />

surface area.<br />

5. Future outlook<br />

EIS has been widely used to study a variety of other<br />

<strong>electrochemical</strong> systems, including corrosion, electrodeposition,<br />

batteries and fuel cells. However, only<br />

recently have impedance <strong>methods</strong> been applied in the<br />

field of bio<strong>sensors</strong>. Given their ability to sense R ct and C d,<br />

application should be possible <strong>for</strong> several different types<br />

of sensing schemes, with numerous recognition agents.<br />

Electrochemical impedance <strong>sensors</strong> are particularly<br />

promising <strong>for</strong> portable and implantable applications.<br />

Commercialization will depend on improvements in<br />

several different areas, including minimization of the<br />

effects of non-specific adsorption.<br />

References<br />

[1] A. Lasia, Electrochemical impedance spectroscopy and its applications,<br />

in: B.E. Conway, J. OÕM. Bockris, R. White (Editors),<br />

Modern Aspects of Electrochemistry, vol. 32, Plenum Press, New<br />

York, USA, 1999, p. 143.<br />

[2] R. Wiart, Electrochim. Acta 35 (1990) 1587.<br />

[3] F. Huet, J. Power Sources 70 (1998) 59.<br />

[4] C.Y. Yuh, J.R. Selman, AIChE J. 34 (2004) 1949.<br />

[5] J.E.B. Randles, Discuss. Faraday Soc. 1 (1947) 11.<br />

[6] S.Q. Hu, Z.Y. Wu, Y.M. Zhou, Z.X. Cao, G.L. Shen, R.Q. Yu, Anal.<br />

Chim. Acta 458 (2002) 297.<br />

[7] J. Wang, K.A. Carmon, L.A. Luck, I.I. Suni, Electrochem. Solidstate<br />

Lett. 8 (2005) H61.<br />

[8] F.A. Armstrong, G.S. Wilson, Electrochim. Acta 45 (2000) 2623.<br />

[9] J. Lahiri, L. Isaacs, J. Tien, G.M. Whitesides, Anal. Chem. 71<br />

(1999) 777.<br />

[10] E. Ostuni, R.G. Chapman, R.E. Holmlin, S. Takayama, G.M.<br />

Whitesides, Langmuir 17 (2001) 5605.<br />

[11] X. Qian, S.J. Metallo, I.S. Choi, H. Wu, M.N. Liang, G.M.<br />

Whitesides, Anal. Chem. 74 (2002) 1805.<br />

[12] E. Katz, I. Willner, Electroanalysis (N.Y.) 15 (2003) 913.<br />

[13] C. Berggren, G. Johansson, Anal. Chem. 69 (1997) 3651.

Trends in Analytical Chemistry, Vol. 27, No. 7, 2008 Trends<br />

[14] V.M. Mirsky, M. Riepl, O.S. Wolfbeis, Biosens. Bioelectron. 12<br />

(1997) 977.<br />

[15] M. Zayats, O.A. Raitman, V.I. Chegel, A.B. Kharitonov, I. Willner,<br />

Anal. Chem. 74 (2002) 4763.<br />

[16] F. Lucarelli, G. Marrazza, M. Mascini, Biosens. Bioelectron. 20<br />

(2005) 2001.<br />

[17] H. Cai, T.M.H. Lee, I.M. Hsing, Sens. Actuators, B 114 (2006)<br />

433.<br />

[18] J. Wang, Anal. Chim. Acta 500 (2003) 247.<br />

[19] W. Fritzsche, T.A. Tatton, Nanotechnology 14 (2003) R63.<br />

[20] S. Guo, E. Wang, Anal. Chim. Acta 598 (2007) 181.<br />

[21] J.F. Hainfield, R.D. Powell, J. Histochem. Cytochem. 48 (2000)<br />

471.<br />

[22] J.J. Gooding, Electrochim. Acta 50 (2005) 3049.<br />

[23] M. Wang, L. Wang, H. Yuan, X. Ji, C. Sun, L. Ma, Y. Bai, T. Li, J.<br />

Li, Electroanalysis (N.Y.) 16 (2004) 757.<br />

[24] M. Wang, L. Wang, G. Wang, X. Ji, Y. Bai, T. Li, S. Gong, J. Li,<br />

Biosens. Bioelectron. 19 (2004) 575.<br />

[25] D. Tang, R. Yuan, Y. Chai, J. Dai, X. Zhong, Y. Liu, Bioelectrochemistry<br />

65 (2004) 15.<br />

[26] C.Z. Li, J.H.T. Luong, Anal. Chem. 77 (2005) 478.<br />

[27] Z.S. Wu, J.S. Li, M.H. Luo, G.L. Shen, R.Q. Yu, Anal. Chim. Acta<br />

528 (2005) 235.<br />

[28] H. Chen, J.H. Jiang, Y. Huang, T. Deng, J.S. Li, G.L. Shen, R.Q. Yu,<br />

Sens. Actuators, B 117 (2006) 211.<br />

[29] H. Huang, Z. Liu, X. Yang, Anal. Biochem. 356 (2006) 208.<br />

[30] H. Huang, P. Ran, Z. Liu, Bioelectrochemistry 70 (2007) 257.<br />

[31] H. Tang, J. Chen, L. Nie, Y. Kuang, S. Yao, Biosens. Bioelectron.<br />

22 (2007) 1061.<br />

[32] I. Szymanska, H. Radecka, J. Radecki, R. Kaliszan, Biosens.<br />

Bioelectron. 22 (2007) 1955.<br />

[33] S. Zhang, F. Huang, B. Liu, J. Ding, X. Xu, J. Kong, Talanta 71<br />

(2007) 874.<br />

[34] J. Yang, T. Yang, Y. Feng, K. Jiao, Anal. Biochem. 365 (2007) 24.<br />

[35] H. Peng, C. Soeller, M.B. Camnell, G.A. Bowmaker, R.P. Cooney, J.<br />

Travas-Sejdic, Biosens. Bioelectron. 21 (2006) 1727.<br />

[36] C. Hao, L. Ding, X. Zhang, H. Ju, Anal. Chem. 79 (2007) 4442.<br />

[37] L. Ding, C. Hao, Y. Xue, H. Ju, Biomacromolecules 8 (2007) 1341.<br />

[38] J. Wang, J.A. Proffitt, M.J. Pugia, I.I. Suni, Anal. Chem. 78 (2006)<br />

1769.<br />

[39] Y. Xu, H. Cai, P.G. He, Y.Z. Fang, Electroanalysis (N.Y.) 16 (2004)<br />

150.<br />

[40] J. Wang, Small 1 (2005) 1036.<br />

[41] M. Li, Y.C. Lin, K.C. Su, Y.T. Wang, T.C. Chang, H.P. Lin, Sens.<br />

Actuators, B 117 (2006) 451.<br />

[42] Y.H. Yun, V.N. Shanov, M.J. Shulz, Z. Dong, A. Jazieh, W.R.<br />

Heineman, H.B. Halsall, D.K.Y. Wong, A. Bunge, Y. Tu, S.<br />

Subramanian, Sens. Actuators, B 120 (2006) 298.<br />

[43] Y.H. Yun, A. Bunge, W.R. Heineman, H.B. Halsall, V.N. Shanov,<br />

Z. Dong, S. Pixley, M. Behbehani, A. Jazieh, D.K.Y. Wong, A.<br />

Bhattacharya, M.J. Shulz, Sens. Actuators, B 123 (2007) 177.<br />

[44] Y.H. Yun, Z. Dong, V.N. Shanov, M.J. Shulz, Nanotechnology 18<br />

(2007) 465505.<br />

[45] J. Li, H.T. Ng, A. Cassell, W. Fan, H. Chen, Q. Ye, J. Koehne, J.<br />

Han, M. Meyyapan, Nano Lett. 3 (2003) 597.<br />

[46] J. Koehne, J. Li, A.M. Cassell, H. Chen, Q. Ye, H.T. Ng, J. Han, M.<br />

Meyyapan, J. Mater. Chem. 14 (2004) 676.<br />

[47] A.M. Bond, Analyst (Cambridge, U.K.) 119 (1994) 1R.<br />

[48] Y. Xu, Y. Jiang, H. Cai, P.G. He, Y.Z. Fang, Anal. Chim. Acta 516<br />

(2004) 19.<br />

[49] Y. Xu, X. Ye, L. Yang, P.G. He, Y.Z. Fang, Electroanalysis (N.Y.)<br />

18 (2006) 1471.<br />

http://www.elsevier.com/locate/trac 611