l Buderus Die Steel 2714 ISO-B MOD - Buderus Edelstahl GmbH

l Buderus Die Steel 2714 ISO-B MOD - Buderus Edelstahl GmbH

l Buderus Die Steel 2714 ISO-B MOD - Buderus Edelstahl GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

l <strong>Buderus</strong> <strong>Die</strong> <strong>Steel</strong> <strong>2714</strong> <strong>ISO</strong>-B <strong>MOD</strong><br />

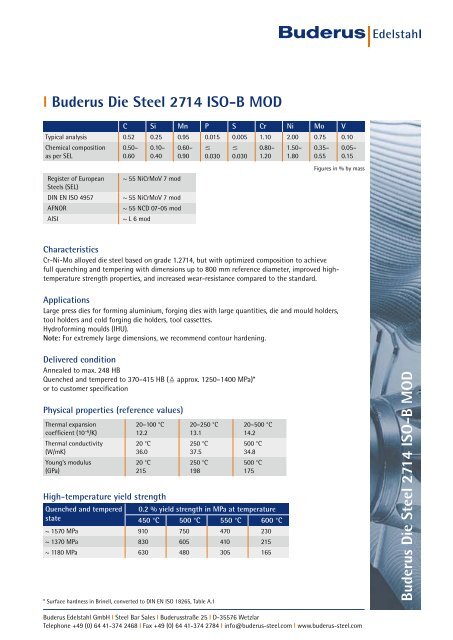

C Si Mn P S Cr Ni Mo V<br />

Typical analysis 0.52 0.25 0.95 0.015 0.005 1.10 2.00 0.75 0.10<br />

Chemical composition 0.50– 0.10– 0.60– � � 0.80– 1.50– 0.35– 0.05–<br />

as per SEL<br />

0.60 0.40 0.90 0.030 0.030 1.20 1.80 0.55 0.15<br />

Register of European<br />

<strong>Steel</strong>s (SEL)<br />

~ 55 NiCrMoV 7 mod<br />

DIN EN <strong>ISO</strong> 4957 ~ 55 NiCrMoV 7 mod<br />

AFNOR ~ 55 NCD 07-05 mod<br />

AISI ~ L 6 mod<br />

Figures in % by mass<br />

Characteristics<br />

Cr-Ni-Mo alloyed die steel based on grade 1.<strong>2714</strong>, but with optimized composition to achieve<br />

full quenching and tempering with dimensions up to 800 mm reference diameter, improved hightemperature<br />

strength properties, and increased wear-resistance compared to the standard.<br />

Applications<br />

Large press dies for forming aluminium, forging dies with large quantities, die and mould holders,<br />

tool holders and cold forging die holders, tool cassettes.<br />

Hydroforming moulds (IHU).<br />

Note: For extremely large dimensions, we recommend contour hardening.<br />

Delivered condition<br />

Annealed to max. 248 HB<br />

Quenched and tempered to 370–415 HB (� approx. 1250–1400 MPa)*<br />

or to customer specifi cation<br />

Physical properties (reference values)<br />

Thermal expansion<br />

coeffi cient (10 –6 /K)<br />

Thermal conductivity<br />

(W/mK)<br />

Young’s modulus<br />

(GPa)<br />

20–100 °C<br />

12.2<br />

20 °C<br />

36.0<br />

20 °C<br />

215<br />

20–250 °C<br />

13.1<br />

250 °C<br />

37.5<br />

250 °C<br />

198<br />

20–500 °C<br />

14.2<br />

500 °C<br />

34.8<br />

500 °C<br />

175<br />

High-temperature yield strength<br />

Quenched and tempered 0.2 % yield strength in MPa at temperature<br />

state<br />

450 °C 500 °C 550 °C 600 °C<br />

~ 1570 MPa 910 750 470 230<br />

~ 1370 MPa 830 605 410 215<br />

~ 1180 MPa 630 480 305 165<br />

* Surface hardness in Brinell, converted to DIN EN <strong>ISO</strong> 18265, Table A.1<br />

<strong>Buderus</strong> <strong>Edelstahl</strong> <strong>GmbH</strong> l <strong>Steel</strong> Bar Sales l <strong>Buderus</strong>straße 25 l D-35576 Wetzlar<br />

Telephone +49 (0) 64 41-374 2468 l Fax +49 (0) 64 41-374 2784 l info@buderus-steel.com l www.buderus-steel.com<br />

<strong>Buderus</strong> <strong>Die</strong> <strong>Steel</strong> <strong>2714</strong> <strong>ISO</strong>-B <strong>MOD</strong>

l <strong>2714</strong> <strong>ISO</strong>-B <strong>MOD</strong><br />

Heat treatment<br />

Stress relieving Temperature: Approx. 650 °C in the annealed state<br />

Duration: 1 hour per 50 mm wall thickness<br />

Cooling: Furnace<br />

Soft annealing Temperature: 700 °C<br />

Duration: 1 hour per 25 mm wall thickness<br />

Cooling: Furnace<br />

Hardening Temperature: 880 °C<br />

Duration: 1 minute per mm wall thickness<br />

Quenching hardness Max. 58 HRC in water/oil, protective atmosphere/oil, oil, hot bath or vacuum<br />

Tempering Temperature: See tempering curve<br />

Duration: 1 hour per 25 mm wall thickness<br />

Cooling: Air<br />

Working hardness 300–440 HB depending on application<br />

Note: pre-heating of the tools to 250–280 °C is recommended.<br />

Tempering curve<br />

Hardness in HRC<br />

60<br />

58<br />

56<br />

54<br />

52<br />

50<br />

48<br />

46<br />

44<br />

42<br />

40<br />

38<br />

36<br />

34<br />

32<br />

30<br />

0 100 200 300 400 500 600 700 800<br />

Tempering temperature in °C<br />

TTT curve (continuous)<br />

Temperature in °C<br />

1200<br />

1100<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

Average values on samples dia. 25 x 50 mm long<br />

hardened at 880 °C in oil<br />

HB converted from HRC<br />

743<br />

32<br />

50<br />

100<br />

P 25 91<br />

83<br />

85<br />

M<br />

Retained austenite >1 �10 �10<br />

68 7<br />

748 720 721 707 632 544 439 397 371 300 272<br />

HB<br />

(461)<br />

436<br />

413<br />

392<br />

373<br />

354<br />

337<br />

319<br />

303<br />

286<br />

0 1 10 10 2 10 3 10 4 10 5 10 6<br />

Seconds<br />

<strong>2714</strong> <strong>ISO</strong>-B <strong>MOD</strong><br />

M s<br />

<strong>2714</strong><br />

A + C<br />

B<br />

5<br />

Austenitising temperature: 880 °C<br />