Hazardous Waste Disposal with Thermal Oxidation - John Zink ...

Hazardous Waste Disposal with Thermal Oxidation - John Zink ...

Hazardous Waste Disposal with Thermal Oxidation - John Zink ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

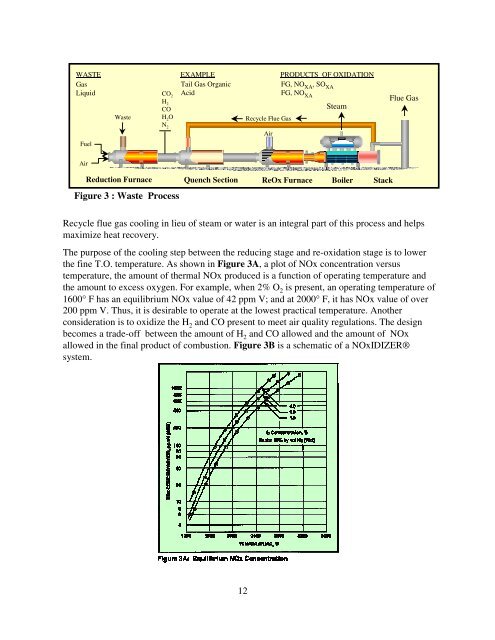

WASTE EXAMPLE PRODUCTS OF OXIDATION<br />

Gas<br />

Liquid<br />

Fuel<br />

Air<br />

<strong>Waste</strong><br />

CO 2<br />

H 2<br />

CO<br />

H 2O<br />

N 2<br />

Figure 3 : <strong>Waste</strong> Process<br />

Tail Gas Organic<br />

Acid<br />

Reduction Furnace Quench Section<br />

Recycle flue gas cooling in lieu of steam or water is an integral part of this process and helps<br />

maximize heat recovery.<br />

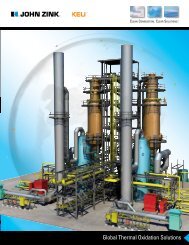

The purpose of the cooling step between the reducing stage and re-oxidation stage is to lower<br />

the fine T.O. temperature. As shown in Figure 3A, a plot of NOx concentration versus<br />

temperature, the amount of thermal NOx produced is a function of operating temperature and<br />

the amount to excess oxygen. For example, when 2% O 2 is present, an operating temperature of<br />

1600° F has an equilibrium NOx value of 42 ppm V; and at 2000° F, it has NOx value of over<br />

200 ppm V. Thus, it is desirable to operate at the lowest practical temperature. Another<br />

consideration is to oxidize the H 2 and CO present to meet air quality regulations. The design<br />

becomes a trade-off between the amount of H 2 and CO allowed and the amount of NOx<br />

allowed in the final product of combustion. Figure 3B is a schematic of a NOxIDIZER®<br />

system.<br />

12<br />

Recycle Flue Gas<br />

Air<br />

FG, NO XA ,SO XA<br />

FG, NO XA<br />

ReOx Furnace<br />

Steam<br />

Boiler<br />

Stack<br />

Flue Gas