estudio y caracterización de un plasma de microondas a presión ...

estudio y caracterización de un plasma de microondas a presión ...

estudio y caracterización de un plasma de microondas a presión ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

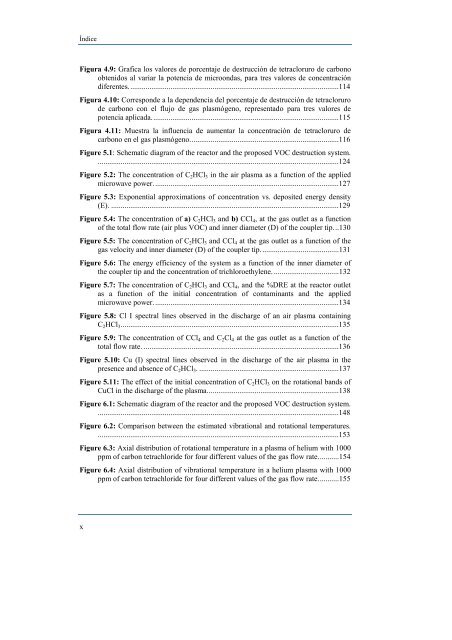

Índice<br />

Figura 4.9: Grafica los valores <strong>de</strong> porcentaje <strong>de</strong> <strong>de</strong>strucción <strong>de</strong> tetracloruro <strong>de</strong> carbono<br />

obtenidos al variar la potencia <strong>de</strong> <strong>microondas</strong>, para tres valores <strong>de</strong> concentración<br />

diferentes. ............................................................................................................. 114<br />

Figura 4.10: Correspon<strong>de</strong> a la <strong>de</strong>pen<strong>de</strong>ncia <strong>de</strong>l porcentaje <strong>de</strong> <strong>de</strong>strucción <strong>de</strong> tetracloruro<br />

<strong>de</strong> carbono con el flujo <strong>de</strong> gas plasmógeno, representado para tres valores <strong>de</strong><br />

potencia aplicada. ................................................................................................. 115<br />

Figura 4.11: Muestra la influencia <strong>de</strong> aumentar la concentración <strong>de</strong> tetracloruro <strong>de</strong><br />

carbono en el gas plasmógeno. ............................................................................. 116<br />

Figure 5.1: Schematic diagram of the reactor and the proposed VOC <strong>de</strong>struction system.<br />

.............................................................................................................................. 124<br />

Figure 5.2: The concentration of C2HCl3 in the air <strong>plasma</strong> as a f<strong>un</strong>ction of the applied<br />

microwave power. ................................................................................................ 127<br />

Figure 5.3: Exponential approximations of concentration vs. <strong>de</strong>posited energy <strong>de</strong>nsity<br />

(E). ....................................................................................................................... 129<br />

Figure 5.4: The concentration of a) C2HCl3 and b) CCl4, at the gas outlet as a f<strong>un</strong>ction<br />

of the total flow rate (air plus VOC) and inner diameter (D) of the coupler tip. .. 130<br />

Figure 5.5: The concentration of C2HCl3 and CCl4 at the gas outlet as a f<strong>un</strong>ction of the<br />

gas velocity and inner diameter (D) of the coupler tip. ........................................ 131<br />

Figure 5.6: The energy efficiency of the system as a f<strong>un</strong>ction of the inner diameter of<br />

the coupler tip and the concentration of trichloroethylene. .................................. 132<br />

Figure 5.7: The concentration of C2HCl3 and CCl4, and the %DRE at the reactor outlet<br />

as a f<strong>un</strong>ction of the initial concentration of contaminants and the applied<br />

microwave power. ................................................................................................ 134<br />

Figure 5.8: Cl I spectral lines observed in the discharge of an air <strong>plasma</strong> containing<br />

C2HCl3. ................................................................................................................. 135<br />

Figure 5.9: The concentration of CCl4 and C2Cl4 at the gas outlet as a f<strong>un</strong>ction of the<br />

total flow rate. ...................................................................................................... 136<br />

Figure 5.10: Cu (I) spectral lines observed in the discharge of the air <strong>plasma</strong> in the<br />

presence and absence of C2HCl3. ......................................................................... 137<br />

Figure 5.11: The effect of the initial concentration of C2HCl3 on the rotational bands of<br />

CuCl in the discharge of the <strong>plasma</strong>. .................................................................... 138<br />

Figure 6.1: Schematic diagram of the reactor and the proposed VOC <strong>de</strong>struction system.<br />

.............................................................................................................................. 148<br />

Figure 6.2: Comparison between the estimated vibrational and rotational temperatures.<br />

.............................................................................................................................. 153<br />

Figure 6.3: Axial distribution of rotational temperature in a <strong>plasma</strong> of helium with 1000<br />

ppm of carbon tetrachlori<strong>de</strong> for four different values of the gas flow rate. .......... 154<br />

Figure 6.4: Axial distribution of vibrational temperature in a helium <strong>plasma</strong> with 1000<br />

ppm of carbon tetrachlori<strong>de</strong> for four different values of the gas flow rate. .......... 155<br />

x