Dossier MO ARIANA FR-UK - SR Industrial Ltd

Dossier MO ARIANA FR-UK - SR Industrial Ltd

Dossier MO ARIANA FR-UK - SR Industrial Ltd

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3<br />

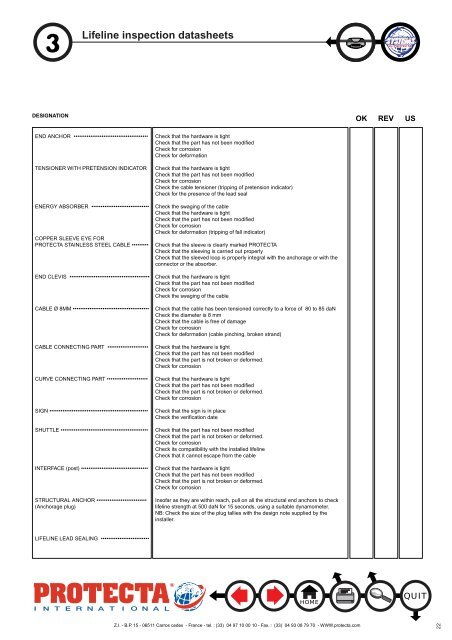

DESIGNATION<br />

Lifeline inspection datasheets<br />

END ANCHOR ••••••••••••••••••••••••••••••••••••••••<br />

TENSIONER WITH PRETENSION INDICATOR<br />

ENERGY ABSORBER •••••••••••••••••••••••••••••••<br />

COPPER SLEEVE EYE FOR<br />

PROTECTA STAINLESS STEEL CABLE •••••••••<br />

END CLEVIS •••••••••••••••••••••••••••••••••••••••••••<br />

CABLE Ø 8MM •••••••••••••••••••••••••••••••••••••••••<br />

CABLE CONNECTING PART ••••••••••••••••••••••<br />

CURVE CONNECTING PART ••••••••••••••••••••••<br />

SIGN •••••••••••••••••••••••••••••••••••••••••••••••••••••<br />

SHUTTLE •••••••••••••••••••••••••••••••••••••••••••••••<br />

INTERFACE (post) ••••••••••••••••••••••••••••••••••••<br />

STRUCTURAL ANCHOR •••••••••••••••••••••••••••<br />

(Anchorage plug)<br />

LIFELINE LEAD SEALING ••••••••••••••••••••••••••<br />

Check that the hardware is tight<br />

Check that the part has not been modified<br />

Check for corrosion<br />

Check for deformation<br />

Check that the hardware is tight<br />

Check that the part has not been modified<br />

Check for corrosion<br />

Check the cable tensioner (tripping of pretension indicator)<br />

Check for the presence of the lead seal<br />

Check the swaging of the cable<br />

Check that the hardware is tight<br />

Check that the part has not been modified<br />

Check for corrosion<br />

Check for deformation (tripping of fall indicator)<br />

Check that the sleeve is clearly marked PROTECTA<br />

Check that the sleeving is carried out properly<br />

Check that the sleeved loop is properly integral with the anchorage or with the<br />

connector or the absorber.<br />

Check that the hardware is tight<br />

Check that the part has not been modified<br />

Check for corrosion<br />

Check the swaging of the cable<br />

Check that the cable has been tensioned correctly to a force of 80 to 85 daN<br />

Check the diameter is 8 mm<br />

Check that the cable is free of damage<br />

Check for corrosion<br />

Check for deformation (cable pinching, broken strand)<br />

Check that the hardware is tight<br />

Check that the part has not been modified<br />

Check that the part is not broken or deformed.<br />

Check for corrosion<br />

Check that the hardware is tight<br />

Check that the part has not been modified<br />

Check that the part is not broken or deformed.<br />

Check for corrosion<br />

Check that the sign is in place<br />

Check the verification date<br />

Check that the part has not been modified<br />

Check that the part is not broken or deformed.<br />

Check for corrosion<br />

Check its compatibility with the installed lifeline<br />

Check that it cannot escape from the cable<br />

Check that the hardware is tight<br />

Check that the part has not been modified<br />

Check that the part is not broken or deformed.<br />

Check for corrosion<br />

Insofar as they are within reach, pull on all the structural end anchors to check<br />

lifeline strength at 500 daN for 15 seconds, using a suitable dynamometer.<br />

NB: Check the size of the plug tallies with the design note supplied by the<br />

installer.<br />

HOME<br />

Z.I. - B.P. 15 - 06511 Carros cedex - France - tel. : (33) 04 97 10 00 10 - Fax. : (33) 04 93 08 79 70 - WWW.protecta.com<br />

OK REV US<br />

QUIT<br />

22