You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

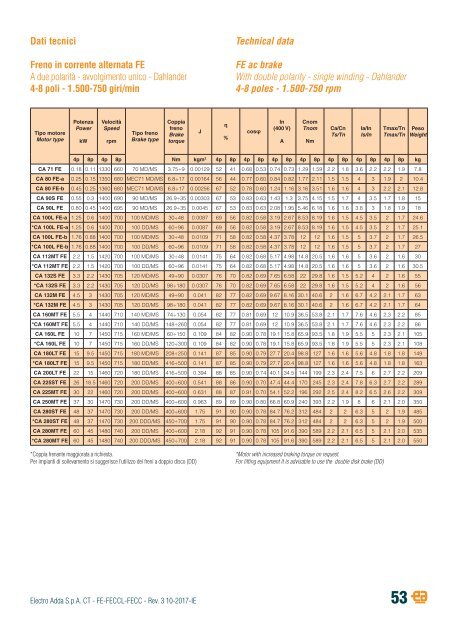

Dati tecnici<br />

Freno in corrente alternata <strong>FE</strong><br />

A due polarità - avvolgimento unico - Dahlander<br />

4-8 poli - 1.500-750 giri/min<br />

Technical data<br />

<strong>FE</strong> ac brake<br />

With double polarity - single winding - Dahlander<br />

4-8 poles - 1.500-750 rpm<br />

Tipo motore<br />

Motor type<br />

Potenza<br />

Power<br />

kW<br />

Velocità<br />

Speed<br />

rpm<br />

Tipo freno<br />

Brake type<br />

Coppia<br />

freno<br />

Brake<br />

torque<br />

J<br />

ƞ<br />

%<br />

cosφ<br />

In<br />

(400 V)<br />

A<br />

Cnom<br />

Tnom<br />

Nm<br />

Ca/Cn<br />

Ts/Tn<br />

Ia/In<br />

Is/In<br />

Tmax/Tn<br />

Tmax/Tn<br />

Peso<br />

Weight<br />

4p 8p 4p 8p Nm kgm 2 4p 8p 4p 8p 4p 8p 4p 8p 4p 8p 4p 8p 4p 8p kg<br />

CA 71 <strong>FE</strong> 0.18 0.11 1330 660 70 MD/MS 3.75÷9 0.00129 52 41 0.68 0.53 0.74 0.73 1.29 1.59 2.2 1.8 3.6 2.2 2.2 1.9 7.8<br />

CA 80 <strong>FE</strong>-a 0.25 0.15 1350 680 MEC71 MD/MS 6.8÷17 0.00164 56 44 0.77 0.60 0.84 0.82 1.77 2.11 1.5 1.5 4 3 1.9 2 <strong>10</strong>.4<br />

CA 80 <strong>FE</strong>-b 0.45 0.25 1360 680 MEC71 MD/MS 6.8÷17 0.00256 67 52 0.78 0.60 1.24 1.16 3.16 3.51 1.6 1.6 4 3 2.2 2.1 12.8<br />

CA 90S <strong>FE</strong> 0.55 0.3 1400 690 90 MD/MS 26.9÷35 0.00303 67 53 0.83 0.63 1.43 1.3 3.75 4.15 1.5 1.7 4 3.5 1.7 1.8 15<br />

CA 90L <strong>FE</strong> 0.80 0.45 1400 695 90 MD/MS 26.9÷35 0.0045 67 53 0.83 0.63 2.08 1.95 5.46 6.18 1.6 1.6 3.8 3 1.8 1.9 18<br />

CA <strong>10</strong>0L <strong>FE</strong>-a 1.25 0.6 1400 700 <strong>10</strong>0 MD/MS 30÷48 0.0087 69 56 0.82 0.58 3.19 2.67 8.53 8.19 1.6 1.5 4.5 3.5 2 1.7 24.6<br />

*CA <strong>10</strong>0L <strong>FE</strong>-a 1.25 0.6 1400 700 <strong>10</strong>0 DD/MS 60÷96 0.0087 69 56 0.82 0.58 3.19 2.67 8.53 8.19 1.6 1.5 4.5 3.5 2 1.7 25.1<br />

CA <strong>10</strong>0L <strong>FE</strong>-b 1.76 0.88 1400 700 <strong>10</strong>0 MD/MS 30÷48 0.0<strong>10</strong>9 71 58 0.82 0.58 4.37 3.78 12 12 1.6 1.5 5 3.7 2 1.7 26.5<br />

*CA <strong>10</strong>0L <strong>FE</strong>-b 1.76 0.88 1400 700 <strong>10</strong>0 DD/MS 60÷96 0.0<strong>10</strong>9 71 58 0.82 0.58 4.37 3.78 12 12 1.6 1.5 5 3.7 2 1.7 27<br />

CA 112MT <strong>FE</strong> 2.2 1.5 1420 700 <strong>10</strong>0 MD/MS 30÷48 0.0141 75 64 0.82 0.68 5.17 4.98 14.8 20.5 1.6 1.6 5 3.6 2 1.6 30<br />

*CA 112MT <strong>FE</strong> 2.2 1.5 1420 700 <strong>10</strong>0 DD/MS 60÷96 0.0141 75 64 0.82 0.68 5.17 4.98 14.8 20.5 1.6 1.6 5 3.6 2 1.6 30.5<br />

CA 132S <strong>FE</strong> 3.3 2.2 1430 705 120 MD/MS 49÷90 0.0307 76 70 0.82 0.69 7.65 6.58 22 29.8 1.6 1.5 5.2 4 2 1.6 55<br />

*CA 132S <strong>FE</strong> 3.3 2.2 1430 705 120 DD/MS 98÷180 0.0307 76 70 0.82 0.69 7.65 6.58 22 29.8 1.6 1.5 5.2 4 2 1.6 56<br />

CA 132M <strong>FE</strong> 4.5 3 1430 705 120 MD/MS 49÷90 0.041 82 77 0.82 0.69 9.67 8.16 30.1 40.6 2 1.6 6.7 4.2 2.1 1.7 63<br />

*CA 132M <strong>FE</strong> 4.5 3 1430 705 120 DD/MS 98÷180 0.041 82 77 0.82 0.69 9.67 8.16 30.1 40.6 2 1.6 6.7 4.2 2.1 1.7 64<br />

CA 160MT <strong>FE</strong> 5.5 4 1440 7<strong>10</strong> 140 MD/MS 74÷130 0.054 82 77 0.81 0.69 12 <strong>10</strong>.9 36.5 53.8 2.1 1.7 7.6 4.6 2.3 2.2 85<br />

*CA 160MT <strong>FE</strong> 5.5 4 1440 7<strong>10</strong> 140 DD/MS 148÷260 0.054 82 77 0.81 0.69 12 <strong>10</strong>.9 36.5 53.8 2.1 1.7 7.6 4.6 2.3 2.2 86<br />

CA 160L <strong>FE</strong> <strong>10</strong> 7 1450 715 160 MD/MS 60÷150 0.<strong>10</strong>9 84 82 0.90 0.78 19.1 15.8 65.9 93.5 1.8 1.9 5.5 5 2.3 2.1 <strong>10</strong>5<br />

*CA 160L <strong>FE</strong> <strong>10</strong> 7 1450 715 160 DD/MS 120÷300 0.<strong>10</strong>9 84 82 0.90 0.78 19.1 15.8 65.9 93.5 1.8 1.9 5.5 5 2.3 2.1 <strong>10</strong>8<br />

CA 180LT <strong>FE</strong> 15 9.5 1450 715 180 MD/MS 208÷250 0.141 87 85 0.90 0.79 27.7 20.4 98.8 127 1.6 1.6 5.6 4.8 1.8 1.8 149<br />

*CA 180LT <strong>FE</strong> 15 9.5 1450 715 180 DD/MS 416÷500 0.141 87 85 0.90 0.79 27.7 20.4 98.8 127 1.6 1.6 5.6 4.8 1.8 1.8 163<br />

CA 200LT <strong>FE</strong> 22 15 1460 720 180 DD/MS 416÷500 0.394 88 85 0.90 0.74 40.1 34.5 144 199 2.3 2.4 7.5 6 2.7 2.2 209<br />

CA 225ST <strong>FE</strong> 26 18.5 1460 720 200 DD/MS 400÷600 0.541 88 86 0.90 0.70 47.4 44.4 170 245 2.3 2.4 7.8 6.3 2.7 2.2 289<br />

CA 225MT <strong>FE</strong> 30 22 1460 720 200 DD/MS 400÷600 0.631 88 87 0.91 0.70 54.1 52.2 196 292 2.5 2.4 8.2 6.5 2.6 2.2 309<br />

CA 250MT <strong>FE</strong> 37 30 1470 730 200 DD/MS 400÷600 0.963 89 89 0.90 0.80 66.8 60.9 240 393 2.2 1.9 8 6 2.1 2.0 350<br />

CA 280ST <strong>FE</strong> 48 37 1470 730 200 DD/MS 400÷600 1.75 91 90 0.90 0.78 84.7 76.2 312 484 2 2 6.3 5 2 1.9 485<br />

*CA 280ST <strong>FE</strong> 48 37 1470 730 200 DDD/MS 450÷700 1.75 91 90 0.90 0.78 84.7 76.2 312 484 2 2 6.3 5 2 1.9 500<br />

CA 280MT <strong>FE</strong> 60 45 1480 740 200 DD/MS 400÷600 2.18 92 91 0.90 0.78 <strong>10</strong>5 91.6 390 589 2.2 2.1 6.5 5 2.1 2.0 535<br />

*CA 280MT <strong>FE</strong> 60 45 1480 740 200 DDD/MS 450÷700 2.18 92 91 0.90 0.78 <strong>10</strong>5 91.6 390 589 2.2 2.1 6.5 5 2.1 2.0 550<br />

*Coppia frenante maggiorata a richiesta.<br />

Per impianti di sollevamento si suggerisce l’utilizzo dei freni a doppio disco (DD)<br />

*Motor with increased braking torque on request.<br />

For lifting equipment it is advisable to use the double disk brake (DD)<br />

Electro Adda S.p.A. CT - <strong>FE</strong>-<strong>FE</strong>CCL-<strong>FE</strong>CC - Rev. 3 <strong>10</strong>-<strong>2017</strong>-<strong>IE</strong><br />

53