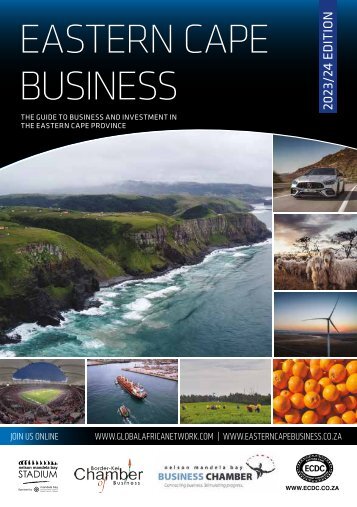

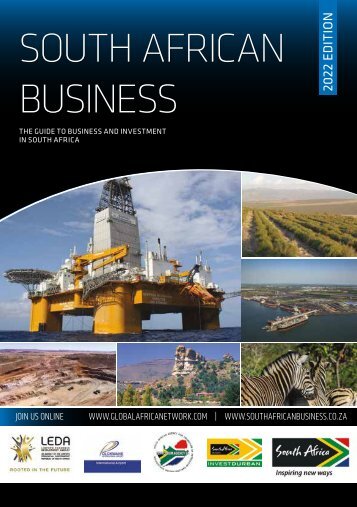

Eastern Cape Business 2017 edition

- Text

- Trade

- Maritime

- Development

- Province

- Investment

- Business

- Network

- Eastern

- Cape

- Municipality

- Sector

- Mandela

- Nelson

- Automotive

- Industrial

- Province

- African

OVERVIEW Manufacturing

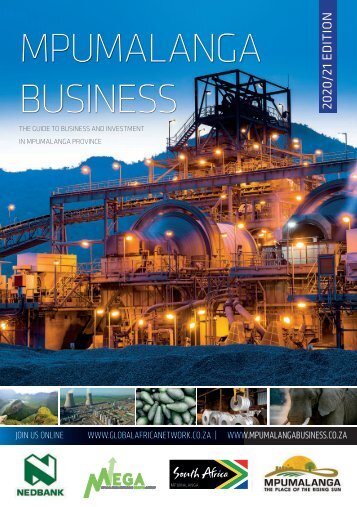

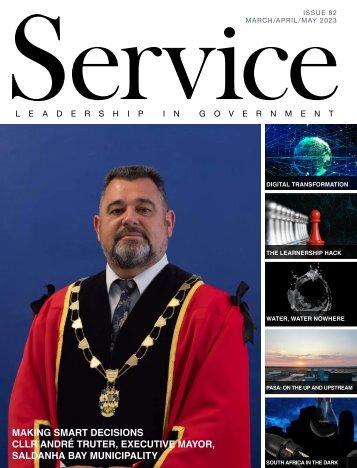

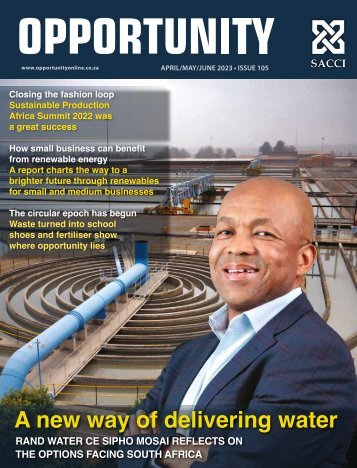

OVERVIEW Manufacturing From eye drops to dog food, the Eastern Cape has diverse manufacturing opportunities. SECTOR INSIGHT The Fagerhult Group from Sweden is a new investor. • BBF Safety Group is expanding production of shoes. • Aspen’s PE plant makes 25-million eye drops annually. Diversification has been the name of the manufacturing game in the Eastern Cape in recent years. The massive role played by the automotive industry and food and beverages as part of agri-processing (both covered in separate overviews) has not diminished, but with attractive incentives on offer in both of the province’s industrial development zones, the range of manufacturing capabilities is growing. Coega IDZ is home to Agni Steels SA and DCD Wind Towers and Electrawinds. East London’s IDZ has another company in the renewable energy sector, ILB Helios, who make solar panels. The provincial government is keen to support diversification, anxious that with the automotive sector supplying 30% of manufacturing employment and 32% of manufacturing gross value-added, the province’s economy might be vulnerable to fluctuations in demand for vehicles. The strategy is targeting sectors where the province already has a competitive advantage (as with wool and mohair), is labour intensive, will have a broad impact and has low barriers for SMME entry. Sectors targeted include: agri-processing and food; timber; tourism; construction; chemicals; energy and mariculture. One of South Africa’s most successful manufacturers is Port Elizabeth-based Aspen. The judges of the 2016 All Africa Business Leaders Awards agreed with this assessment when they named Aspen Group Chief Executive Stephen Saad as Entrepreneur of the Year. The company has 60 businesses in 50 countries and the Port Elizabeth and East London factories play an important role in producing excellent products in bulk. The Port Elizabeth site makes more than 12-billion oral solid dosage forms every year, in addition to more than 25-million units of Murine and Clear Eye eye drops being made for export to the US. The PE complex has four components, covering oral solid, liquid, steriles and niche high potency pharmaceutical products. Bodene, a subsidiary of Fresenius Kabi, makes intravenous medicine in Port Elizabeth. East London hosts Johnson & Johnson’s finance, operations and research and development divisions. EASTERN CAPE BUSINESS 2017 40

OVERVIEW Swedish concern Fagerhult Group has entered the South African market via an acquisition of the factory of Port Elizabeth’s Lighting Innovations, and the two subsidiary companies Arrow Lighting and Beacon Lighting. Aberdare Cables and Everyready Batteries are examples of companies in the medium-toheavy sector. East London has two First National Battery manufacturing sites. Montego Pet Nutrition is Graaff-Reinet’s biggest private employer, with more than 200 staff members working in the Karoo town’s factory. Established in 2000, the company now makes about 200 tons of product daily and supplies more than 1 000 retail outlets across South Africa. Considerable potential exists to create more value from the excellent wool, leather and mohair that the province’s livestock produce. The production and working with merino wool and mohair fibres are skills that have been handed down from generation to generation. A fibre processing plant to spin wool and mohair fibre into yarn is planned, as is a textile mill to focus on cotton, poly-cotton and acrylic fabric. The latter is planned for the IDZ in East London, which is already home to Da Gama Textiles, whose factory has the capacity to produce 45-million square metres of fabric per annum. Da Gama makes the popular and distinctive shweshwe fabric, using its own unique printing process which makes it very difficult for fakers to copy. The BBF Safety Group invested R16-million in a new machine at its Port Elizabeth plant in 2016 which will take shoe production up to 5 000 pairs per day. The injection moulding machine can inject a moulded sole to the shoe upper every 15 seconds. The BBF Group was formed from a merger of several South African companies, to allow them to specialise and to compete with cheap foreign imports. The companies were Bagshaw Footwear, Beier Safety Footwear, Bronx Safety, United Frams and Wayne. The plastics industry is a key supporter of the automotive industry but it is not limited to vehicle applications: moulding, packaging and the construction industries are other important sub-sectors. GenTech, which operates out of Neave township, specialises in polyurethane elastomer components and sells to the automotive, tyre, textile and food industries and Maizey Plastics are suppliers of semi-finished thermoplastic materials. Incentives The Department of Trade and Industry (dti) offers a Competitiveness Enhancement Programme aimed at medium-sized manufacturers. It includes a cost-sharing grant of between 30% and 50% for investments up to R50-million and up to 80% if a group of smaller companies want to collaborate on matters such as advertising. The dti also oversees: • Critical Infrastructure Programme. • Research and Development Tax Incentive Programme. • Cash for new or upgraded production facilities. • The Foreign Investment Grant repays foreign investors for the cost of transporting new machinery and equipment to South Africa. • Companies are assisted in creating prototypes arising from their own research. • Clothing and Textile Competitiveness Programme is a cost-sharing grant. ONLINE RESOURCES Border-Kei Chamber of Business: www.bkcob.co.za Coega Development Corporation: www.coega.co.za Department of Economic Development, Environmental Affairs and Tourism: www.dedea.gov.za East London Industrial Development Zone: www.elidz.co.za Manufacturing Circle: wwww.manufacturingcircle.co.za National Agricultural Marketing Council: www.namc.co.za National Association of Pharmaceutical Manufacturers: www.napm.co.za South African Bureau of Standards: www.sabs.ca.za 41 EASTERN CAPE BUSINESS 2017

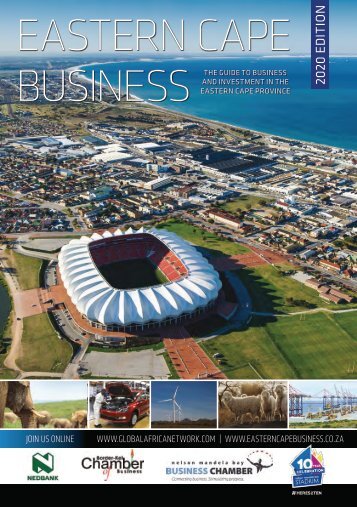

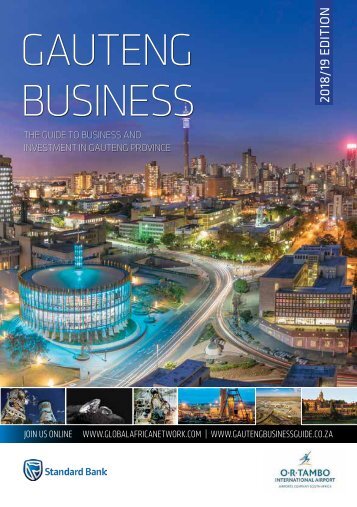

- Page 1 and 2: EASTERN CAPE BUSINESS THE GUIDE TO

- Page 3 and 4: Amatola t:HhAAU:(d wde,,1,, k / ..

- Page 5 and 6: UIF SAVING JOBS THROUGH SOCIALLY RE

- Page 7 and 8: CREDITS Publisher: Chris Whales Pub

- Page 9 and 10: MESSAGE competitive labour costs an

- Page 11 and 12: SPECIAL FEATURE The Umzimvubu Multi

- Page 13 and 14: SPECIAL FEATURE Chris Hani District

- Page 15 and 16: SPECIAL FEATURE from the east offlo

- Page 17 and 18: SPECIAL FEATURE renewable energy an

- Page 20 and 21: PROFILE The Nelson Mandela Bay Busi

- Page 22 and 23: PROFILE Border-Kei Chamber of Busin

- Page 24 and 25: Skills development Skills training

- Page 26 and 27: ADVERTORIAL Nedbank’s new brand p

- Page 28 and 29: ADVERTORIAL Expertise in small busi

- Page 30 and 31: The Masisizane Fund was established

- Page 33 and 34: KEY SECTORS Overview of the main ec

- Page 35 and 36: OVERVIEW the east. Improving the ag

- Page 37 and 38: OVERVIEW population, as South Afric

- Page 39 and 40: Aquaculture Fish from the Karoo wil

- Page 41: OVERVIEW strategy. RED hubs will su

- Page 45 and 46: OVERVIEW in East London. Mercedes-B

- Page 47 and 48: OVERVIEW Renewable energy If the po

- Page 49 and 50: OVERVIEW delivered water from the O

- Page 51 and 52: FOCUS Sanitation to fast-track the

- Page 53 and 54: OVERVIEW environment, but it is now

- Page 55 and 56: OVERVIEW now operates in 32 countri

- Page 57 and 58: OVERVIEW means the company can move

- Page 59 and 60: OVERVIEW cial tourism body’s info

- Page 62 and 63: LISTING Eastern Cape Provincial Gov

- Page 64 and 65: Raymond Mhlaba Local Municipality T

- Page 66 and 67: INDEX INDEX Amatola Water .........

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...