Opportunity Issue 105

- Text

- Wwwglobalafricanetworkcom

- Economic

- Sector

- Operations

- Businesses

- Infrastructure

- Global

- Sustainable

- African

- Rand

- Mining

WATER DELIVERY What

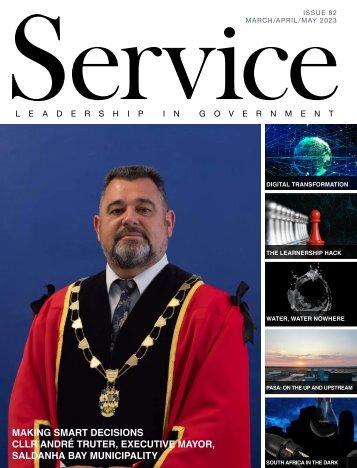

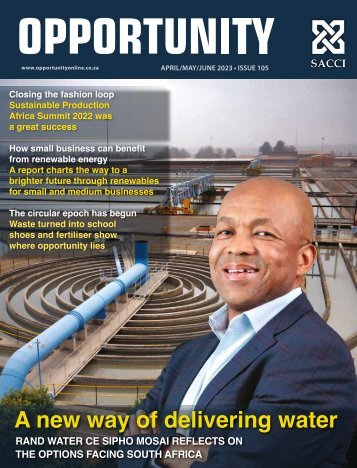

WATER DELIVERY What municipalities can do to promote efficient water delivery If municipalities can reduce water loss, water-demand volumes will return to levels where Rand Water’s purification systems can deliver. Rand Water also identifies here the major supply interruption factors hampering effective water purification and primary pumping. demand above the treatment capacity of Rand Water treatment then problems arise. National water consumption per capita per day is 233 litres-per-personper-day against an international standard of 173 litres. Some municipalities have water losses up to 40%. This is against the figure of just 6.5% for Rand Water. Reduction in water losses will reduce the water demand volume which, in turn, will result in the reduction in per capita consumption. Inlet pipe to flocculators at Zuikerbosch Purification Plant Rand Water has been part of the economic success story of the greater Johannesburg area almost from the time that gold was discovered. Unlike many cities which are located near water, it was gold that caused the city to be built. The first residents and the industries which developed in support of the gold-mining industry were a long way from water. The nearest water source is the Vaal River and several dams have been constructed along that water course to supply the large urban and peri-urban population that has grown up around Johannesburg. Rand Water has supplied those people – and farmers and other smallscale water users – reliably for a long time. The dams along the Integrated Vaal River System (IVRS) to supplement the Vaal Dam are the Woodstock and Sterkfontein Dams in KwaZulu-Natal and the Free State provinces, the Grootdraai Dam in Mpumalanga and the Katse and Mohale Dams in the Kingdom of Lesotho. Droughts are frequent feature of the South African climate, some lasting more than four years. South Africa is the 30th-driest country in the world. Climate change has added to the challenges faced by water authorities and so consumers must not be lulled into a false sense of security when dams are full. High consumption creates supply bottlenecks Municipalities can play a role in helping to reduce demand for water, thus reducing the pressure on water supply. The Annual Average Daily Demand (AADD) of 4 600Ml/d, is within the Rand Water treatment capacity of 5 000Ml/d. The AADD is derived from municipal estimates of annual demand. If consumption increases Interruption factors The major supply interruption factors for effective water purification and primary pumping are as follows: Absence of alternative power supply: Zuikerbosch is supplied by Eskom and is protected by an agreement not to be load-shed other than to save the grid. There are negotiations with Emfuleni for a similar agreement. Project execution postponements: Rand Water has streamlined compliance and procurement procedures that have delayed execution of capital projects, maintenance, procurement of spares and emergencies such as plant breakdowns. Old Infrastructure/Plant Capacity: Maximo is used for planned maintenance, repairs and refurbishments. Capex projects are executed on a five-year business plan cycle. A 600Ml/d plant will be commissioned early in 2024 to increase the capacity of the Zuikerbosch plant. Treating for safety Treatment of raw water must be done to the highest standards for safety reasons. Rand Water has two Water Treatment Plants (WTP) that are situated in Emfuleni Local Municipality (ELM). The plants are the Zuikerbosch Water Treatment Plant and the Vereeniging Water Treatment Plant (VWTP). Raw water is abstracted from the upper part of the Vaal River and pumped to the VWTP for purification. Raw water is also abstracted from the Vaal Dam and transferred to the ZWTP for purification purposes. The same process of purification is followed at the two plants. The raw water is transferred to the ZWTP through a canal. It is then processed through the screens to catch any visible dirt such as leaves, tree branches or any other undesirable objects that have the potential to obstruct the process. Turbidity is the measure of dirt contamination in water. When water is received from the Vaal Dam, it can have a turbidity of 60 Nephelometric Turbidity Unit (NTU), a low figure, or 160 NTU, a very high figure. The higher turbidity requires the use of more chemicals to ensure that the water is purified to meet the SANS 241 Standards. Rand Water purifies water to below 0.5 NTU against the South African National Standards (SANS) of 1 NTU. SANS is the South African Standard for measuring acceptable water 18 | www.opportunityonline.co.za

quality for consumption. The 0.5 NTU is a stricter standard used by the World Health Organization (WHO). The treatment process consists of seven stages, namely: coagulation, flocculation, sedimentation, carbonation, filtration, chlorination and pumping. Coagulation is the mixing of water with crushed lime to produce liquid lime. This is done to destroy bacteria and/or algae to stabilise water. The flocculator mixes water and milk of lime at high energy so that solids form clusters or flocs. In this process the particles attract each other to form visible flocs floating on top of the water. The flocculator has a spiral shape so that it can circulate water first at high energy, gradually slowing down as the spiral flocculator widens in diameter and the flocs formulated sink to the floor when entering the sedimentation tank. Sludge is formed when the sedimentation tank draws the flocs down to settle at the bottom of the tank. The clean water still on top of the tank drains through the launders into the flume so that it flows to the carbonation bay. The bridges on the sedimentation tank drain the sludge from the bottom of the sedimentation tank which is eventually pumped to the drying beds in the Panfontein sludge plant. The clean water is then gravitated through carbonation bays to the Filter House. At the carbonation bay, carbon dioxide (CO2) is added to water from the sedimentation tank to reduce pH to 8.6 for safe drinking water. The next stage from is the filtration process. At the Filter House water is passed through fine sand in a slow process that can take two hours. The process of filtration is designed to capture small living organisms. The filter house is kept dark to prevent the growth of algae. At this stage the turbidity is at 0.5 NTU or below. The Chlorine House hosts the next stage. The chlorine cylinders containing liquid chlorine and gas chlorine at the top of the cylinder are used for disinfection. This stage is designed to kill germs that may be invisible and may have escaped the purification process. Pumping of potable water in the Engine Rooms signals the final process. Water is pumped to an elevation of 380m to reach Rand Water’s four booster stations. These are the Eikenhof, Zwartkopjes, Palmiet and Mapleton Pumping Stations. The Filter House at Zuikerbosch Water quality is measured by monitoring water quality determinants. Over and above the online monitoring system, two-hourly samples are taken 24 hours a day to monitor the accuracy of the online instruments calibration. Each Rand Water site has its own site laboratories and is in charge of the online monitoring system. The sites monitor mainly four elements, that is: Turbidly, Chlorine, Calcium Carbonate Precipitation Potential (CCPP) and pH. A laboratory within the Scientific Services Division, which is independent from Operations, monitors various water quality determinants to cross check data from Operations and monitor water quality at the tap. This demanding purification processes is conducted to make sure that Rand Water supplies its customers with drinking water of worldclass quality. Conclusion Rand Water does not receive any subsidy from national government. Funding is derived purely by the water it sells. The client base is primarily municipalities and it is at that level that water losses can be reduced. Through sensible measures, cooperation and awareness, a situation can be reached where reasonable water tariffs are charged across the board. This will create satisfied customers and consumers and contribute to water security for South Africa. ABOUT RAND WATER Africa’s biggest bulk water utility meets and exceeds exacting standards. Rand Water provides bulk potable water to more than 11-million people in the South African provinces of Gauteng, Mpumalanga, the Free State and North West – an area that stretches over 18 000km2. Rand Water customers include metropolitan municipalities, local municipalities, mines and large industries. Rand Water has a global reputation for providing water of high quality that ranks among the best in the world and consistently meets and exceeded national standards and international guidelines on water quality. The strategic objectives of Rand Water include achieving growth, operational integrity and a culture of high-performance. Rand Water uses best-fit technology and positively engages with its stakeholder base to maintain financial health and sustainability. Rand Water contacts: Head Office Physical address: 522 Impala Road, Glenvista 2058 Postal address: PO Box 1127, Johannesburg 2000, South Africa Tel: +27 11 682 0911 | Customer Service Centre: 0860 10 10 60 Email: customerservice@randwater.co.za | Website: www.randwater.co.za I N T E G R A T E D ANNUAL REPORT www.opportunityonline.co.za | 19

- Page 1 and 2: www.opportunityonline.co.za APRIL/M

- Page 3 and 4: Sociedade Industrial e Comercial, L

- Page 5 and 6: SD-WAN TECHNOLOGY _________________

- Page 7 and 8: EXECUTIVE EDUCATION 2023 Future Fit

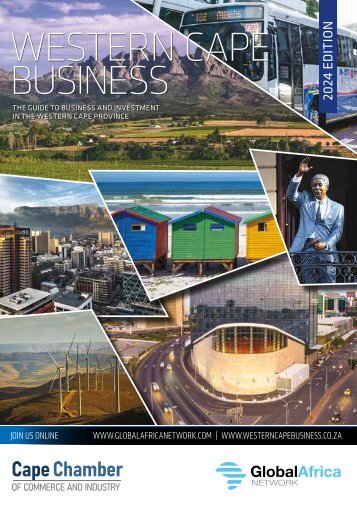

- Page 9 and 10: The picturesque Table Mountain and

- Page 11 and 12: This product is not intented to dig

- Page 13 and 14: industry-related documentation. CCW

- Page 15 and 16: SACCI MEMBER PROFILE Unleashing the

- Page 17 and 18: WATER DELIVERY Sedimentation tanks

- Page 19: UTILITY FINANCES I N T E G R A T E

- Page 23 and 24: SUSTAINABLE FASHION Caroline Nelson

- Page 25 and 26: Bringing the land to life again H&M

- Page 27 and 28: Access Bank South Africa wins major

- Page 29 and 30: BUSINESS BANKING Commercial Banking

- Page 31 and 32: Beverages South Africa Since incept

- Page 33 and 34: yarns@samil.co.za | sales@samil.co.

- Page 35 and 36: CIRCULAR ECONOMY SOLUTIONS have the

- Page 38 and 39: FOOTWEAR Bata South Africa taking s

- Page 40 and 41: SUSTAINABLE MINING Operationalising

- Page 42 and 43: MINING INDABA REVIEW President Cyri

- Page 44 and 45: STEAM GENERATION Blending imaginati

- Page 46 and 47: SMALL BUSINESS AND RENEWABLES How s

- Page 48 and 49: EXPLORATION FOR DEVELOPMENT Helium

- Page 50 and 51: RAIL FREIGHT Transnet digitises fre

- Page 52 and 53: SMART MOBILITY Smart Mobility solut

- Page 54: SHIPPING Online platform offers sea

- Page 57 and 58: BUSINESS TRAVEL _________________ T

- Page 59 and 60: EMPLOYABLE SKILLS If the idea of be

- Page 61 and 62: SMME TRENDS Social commerce will op

- Page 64: strive to thrive Towards a Brighter

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...