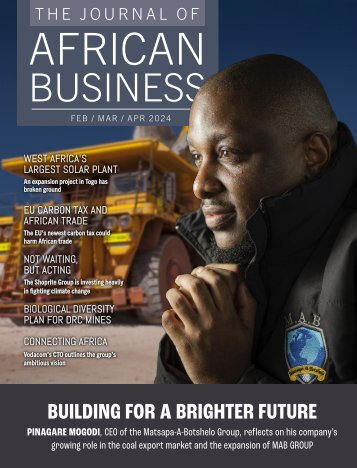

Opportunity Issue 105

- Text

- Wwwglobalafricanetworkcom

- Economic

- Sector

- Operations

- Businesses

- Infrastructure

- Global

- Sustainable

- African

- Rand

- Mining

STEAM GENERATION

STEAM GENERATION Blending imagination and creativity for six decades Piping technology Pipe supports Plant erection services Explosive welding 7912 Steinmuller - Engineering News Boilers Feature - Advert 210x275mm Steinmüller Africa started in South Africa in 1962 working on the power stations Grootvlei and Hendrina, before moving on to the other baseload stations of Kriel, Duvha, Tutuka and Majuba as they were constructed. More recently, Steinmüller Africa has been a subcontractor to Hitachi for the fabrication of the Medupi and Kusile boilers, which are supercritical boilers that operate at main steam conditions of 240 bar at 560°C, with reheat temperatures up to 570°C. Bolofo notes of this specialised work, “This requires Level 1 high-pressure pipework, which is an area of expertise for us.” When various other power stations such as Camden, Grootvlei and Komati were either mothballed or returned to service, Steinmuller Africa was again called on to provide the expertise for these complex tasks. Steam generation is also at the heart of Steinmüller Africa’s operations in other sectors, such as pulp and paper, sugar milling and processing or in the generation or reticulation of steam in petrochemical plants and fuel refineries. From doing all the fabrication and following up with the installation and commissioning of boilers, the company has progressed to become a key service provider for ongoing plant maintenance. Speaking of the company’s facilities in Pretoria North, Bolofo says, “Our fabrication equipment there is world class.” This includes steam headers and the Cojafex Induction Bending Machine for pipe spools, both of which are unique to the African continent. Some of the specifications of the Pretoria facility are: • 50 000m² under-roof fabrication workshops, 50-ton lifting capacity • some bays are 35m wide and 700m long • pressure component production capacity of one-million hours per year Steinmüller Africa Director, Moso Bolofo Steinmüller Africa is a leading company in steam generation which has been offering its expert services in and beyond South Africa for six decades. Moso Bolofo, Steinmüller Africa Director, is proud of the company’s legacy which is built on high levels of training and precision in execution and which aims to combine first-class engineering with imagination and creativity. Steinmüller Africa offers comprehensive expertise in welding and environmental technology, manufacturing, maintenance, lifetime extension plans and project management. In addition, the company provides a wide range of cranes, lifting gear, welding equipment and mobile offices for site establishment. All of these services and areas of specialisation have evolved around the core industrial focus, steam generation. Piping Division excellence Says Bofolo, “Steinmüller Africa’s Piping Division in Pretoria is a true onestop shop for all induction bending requirements. It offers induction bending of pipes 48-850mm in diameter and a maximum wall thickness of 120mm with a maximum radius of 4 600mm. “The team also provides shop fabrication after bending, which entails heat treatment, pipe end preparation, spool fabrication, surface preparation and packing. Advantages of the bending facilities are high accuracy of shape, custom-made individual bends and less butt-welds using complex bends. Based on the requirements and application of the material, it might be crucial to heat-treat induction bends. Steinmüller Africa has furnaces with accurate temperature up to 1 200⁰C. We also specialise in electrical post-weld heat treatment, which is crucial to the quality and integrity of welding on high-pressure parts and pipelines. “Steinmüller Africa’s history proves the claim of being an end-to-end service provider, that really does look at the whole lifecycle of a plant, from conceptual design, manufacture and installation and, thereafter, to the maintenance and all the way through the service life until de-commissioning.” 42 | www.opportunityonline.co.za

60 60 CELEBRATING CELEBRATING CELEBRATING YEARS YEARS YEARS of Outstanding Customer Service and of Outstanding Making Steam Customer Generation Service Work and Making Steam Generation Work We have come a long way, We have come a long way, 6 decades and counting! 6 decades and counting!

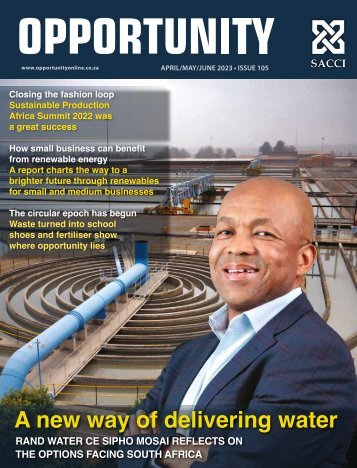

- Page 1 and 2: www.opportunityonline.co.za APRIL/M

- Page 3 and 4: Sociedade Industrial e Comercial, L

- Page 5 and 6: SD-WAN TECHNOLOGY _________________

- Page 7 and 8: EXECUTIVE EDUCATION 2023 Future Fit

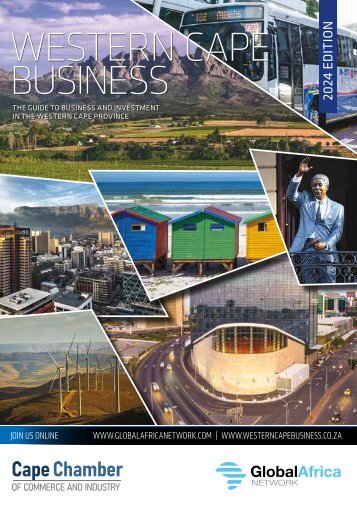

- Page 9 and 10: The picturesque Table Mountain and

- Page 11 and 12: This product is not intented to dig

- Page 13 and 14: industry-related documentation. CCW

- Page 15 and 16: SACCI MEMBER PROFILE Unleashing the

- Page 17 and 18: WATER DELIVERY Sedimentation tanks

- Page 19 and 20: UTILITY FINANCES I N T E G R A T E

- Page 21 and 22: quality for consumption. The 0.5 NT

- Page 23 and 24: SUSTAINABLE FASHION Caroline Nelson

- Page 25 and 26: Bringing the land to life again H&M

- Page 27 and 28: Access Bank South Africa wins major

- Page 29 and 30: BUSINESS BANKING Commercial Banking

- Page 31 and 32: Beverages South Africa Since incept

- Page 33 and 34: yarns@samil.co.za | sales@samil.co.

- Page 35 and 36: CIRCULAR ECONOMY SOLUTIONS have the

- Page 38 and 39: FOOTWEAR Bata South Africa taking s

- Page 40 and 41: SUSTAINABLE MINING Operationalising

- Page 42 and 43: MINING INDABA REVIEW President Cyri

- Page 46 and 47: SMALL BUSINESS AND RENEWABLES How s

- Page 48 and 49: EXPLORATION FOR DEVELOPMENT Helium

- Page 50 and 51: RAIL FREIGHT Transnet digitises fre

- Page 52 and 53: SMART MOBILITY Smart Mobility solut

- Page 54: SHIPPING Online platform offers sea

- Page 57 and 58: BUSINESS TRAVEL _________________ T

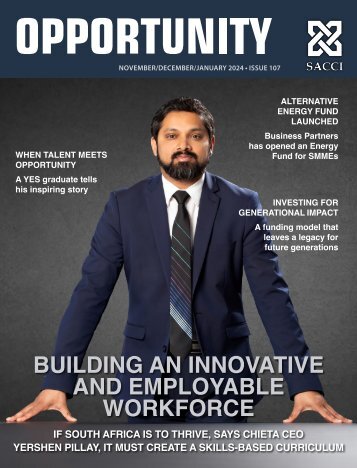

- Page 59 and 60: EMPLOYABLE SKILLS If the idea of be

- Page 61 and 62: SMME TRENDS Social commerce will op

- Page 64: strive to thrive Towards a Brighter

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...