Opportunity - Issue 94

- Text

- Logistics

- Nemesis

- Economic

- Prices

- Global

- Operations

- Procurement

- Railway

- Pandemic

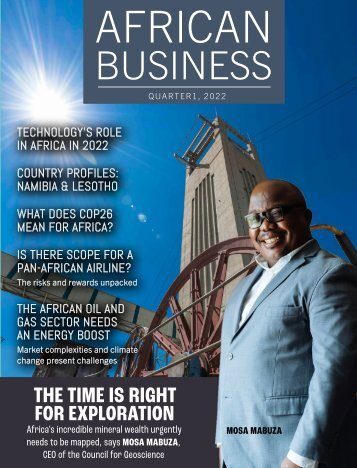

- African

SUPPLY CHAIN NEW ORDER

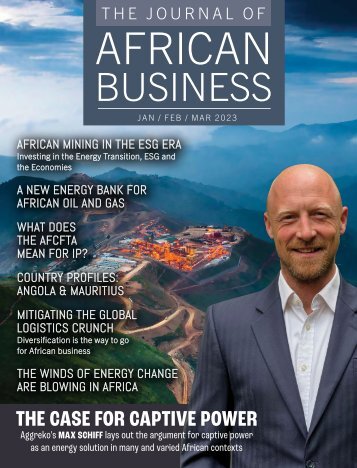

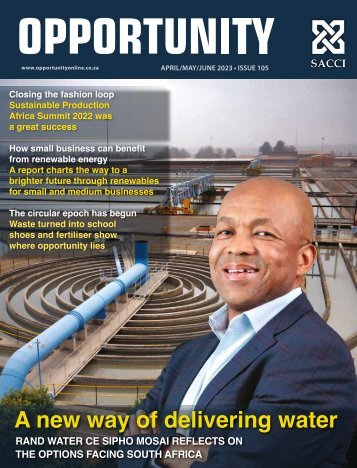

SUPPLY CHAIN NEW ORDER of magnitude COVID-19 TEST OF SUPPLY CHAIN RESILIENCE 2019 saw US companies actively adapting to what then felt like a major disruption – the US-China trade war. Specifically, US companies sharply reduced imports of manufactured goods from China. The shift was sizable, but there was still a sense that manufacturing imports might revert to old patterns once the trade war ends. Then everything changed. 2020 dawned with the disruption of a new order of magnitude: Covid-19. At time of writing, the full extent of the societal and economic trauma the coronavirus pandemic may cause is still unknown. But it will be historic. In multiple countries, social and economic activity is essentially frozen. Governments as dissimilar as the US, Russia and Italy are currently scrambling (and struggling) to construct a coherent and effective response. The outlook is daunting. The lessons we must learn from Covid-19 are as momentous as they are harsh. While the trade war triggered some notable tinkering, the massive operational disruption wrought by the coronavirus pandemic will compel companies to fundamentally rethink their sourcing strategies. DOMESTIC OUTLOOK Might such a strategic redistribution spur a dynamic resurgence of US domestic manufacturing? It seems unlikely. The limitations that held US manufacturing to flat growth in 2019, even as the trade war put Chinese manufacturing at a decided disadvantage, will continue to work against a US manufacturing revival. There is still a pronounced shortage of skilled manufacturing labour, and the long-promised productivity boom via automation has yet to be realised. Yes, companies will be more inclined to look at new sourcing options, but they will still want to place most of their eggs in costcompetitive baskets. The more likely outcome will be an accelerated scattering. Companies that began distributing their import supply risk in response to the stresses of the trade war will double down on that strategy in response to the much more severe disruptions caused by Covid-19. In that sense, the trade war may have been a blessing in disguise. Unanticipated shifts in US trade policy and the resulting retaliatory exchange with China prompted companies that had long relied on Chinese suppliers to start rethinking old assumptions about where and how to source. More broadly, by confronting US companies with costly disruptions that were largely beyond their control, the trade war triggered at least a partial awakening to the intrinsic vulnerabilities of modern global supply chains. Events in 2020 cast the trade war as a mere precursor to the far greater economic and operational disruptions being wrought by the coronavirus. What we are experiencing now demands a more profound reckoning. Covid-19 should cause companies to fundamentally rethink the criteria they use to shape their supply chains. COST, RISK AND RESILIENCE Three decades ago, many US producers began manufacturing and sourcing in China for one reason: cost. The US-China trade war brought a second dimension more fully into the equation – risk – as tariffs and the threat of disrupted China imports prompted companies to weigh surety of supply more fully alongside costs. Covid-19 brings the third dimension more fully into the mix, and arguably to the fore – resilience. ___ __ Recent events illustrate, with distressing clarity, that events frequently unfold in ways that were impossible for anyone to foresee, shattering the assumptions that shaped supply chain strategies. 28 | www.opportunityonline.co.za

SUPPLY CHAIN www.kearney.com The current crisis is exposing vulnerabilities that cannot be addressed with short-term fixes and minor tinkering. Many companies quickly ran out of any inventory they were able to stockpile ahead of the Covid-19 outbreak. Some with heavy dependence on China found they had few alternatives that could help see them through the drought. We have subsequently learned that the disruption of supply from core manufacturing regions of China was just the beginning of the havoc to be wrought by the coronavirus. Recent events illustrate, with distressing clarity, that events frequently unfold in ways that were impossible for anyone to foresee, shattering the assumptions that shaped supply chain strategies. The answer? Companies need to place more value on resilience by building supply chains that can nimbly sense and pivot in response to unexpected demands and disruptions. This is the key to operating profitably in the face of ongoing disruptions. ___ __ ___ __ _ _ The current crisis is exposing vulnerabilities that cannot be addressed with short-term fixes and minor tinkering ___ __ ___ __ _ _ Many supply chain leaders have transitioned from the uncertainty by adopting new ways of working to stabilise their business. Now it’s time to begin thinking strategically about how to position operational networks for life beyond the pandemic by designing a supply chain that is both resilient and agile, can withstand risks to both demand and supply, and can quickly respond to shocks. The first step is to conduct a rigorous review of the impact Covid-19 is having on demand and the corresponding performance of the supply chain. This will require drilling down to the specifics of how the pandemic has already affected demand and how demand might change in the future. To build a framework for a post-pandemic review, considering these impacts of the coronavirus outbreak is a good start: • Demand has shifted The demand for many products saw a rapid increase; others saw a rapid decline. Some are no longer a priority and may be gone for good. • Customer behaviours have changed Internet purchasing is skyrocketing in some industries, and brick-and-mortar retail may never be the same. • There are new customers People have reprioritised their wants versus their needs, and it has affected what they buy and who they buy it from. • Portfolios are back to the drawing board Certain stock keeping units (SKUs) are no longer important, and in other cases, product needs in a post-Covid world are being rapidly redesigned. Similarly, the impacts on supply will also require a post-pandemic review: • Supply chains were disrupted during the pandemic The Covid-19 outbreak caused major shifts – from transitioning supply planners so they can work from home and finding alternative sources for suppliers that are under lockdown to keeping employees safe and manufacturing capacity available. • Some supply areas performed well, others struggled New best practices were learned and will be capitalised on, and risky practices will be eliminated. • Structural elements exacerbated supply issues Global supply chains will be questioned as geographies experienced the pandemic in phases and suppliers, manufacturers and distributors were cut off from one another. • Technology is essential Responding during a crisis requires real-time data about where materials and products are as well as the status, location and health of employees in plants and warehouses. It also requires control towers that can orchestrate operations from end to end. Historically, operations strategy focused on balancing cost reduction and investments to improve availability performance and lead times. The business risk was important, but it was typically addressed with relatively simple approaches, such as maintaining safety stock at distribution centres or establishing one-off secondary supplier relationships. Responding to a global crisis was rarely part of the picture. As the world advances towards recovery, a supply chain strategy will need to evolve to incorporate the lessons learned during this pandemic. That means moving away from a narrow focus on cost and availability to a more comprehensive perspective that incorporates risk and resilience factors. Supply chain organisations that are designed to manage the right risks in the right way will ultimately beat out the competition when the next crisis inevitably strikes. ___ __ Now it’s time to begin thinking strategically about how to position operational networks for life beyond the pandemic by designing a supply chain that is both resilient and agile, can withstand risks to both demand and supply, and can quickly respond to shocks. www.opportunityonline.co.za | 29

- Page 1 and 2: Quarterly journal for business and

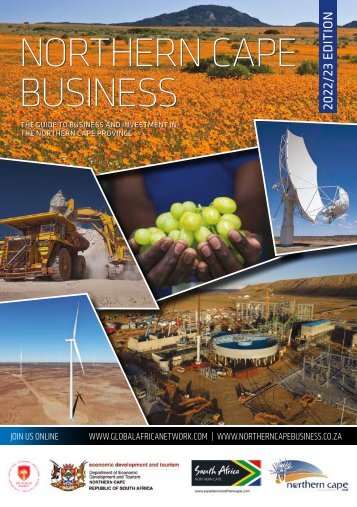

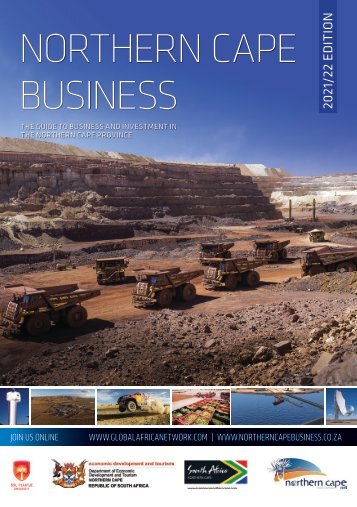

- Page 3 and 4: Operating from Kimberley in the Nor

- Page 5 and 6: ontents ISSUE 94 | AUGUST-OCTOBER 2

- Page 7 and 8: FOREWORD African population, but is

- Page 9 and 10: PIC: spotongmag.co.za R1-BILLION FO

- Page 11 and 12: ENERGY where oil prices are volatil

- Page 13 and 14: ENERGY MATERIAL BREACH OF REPRESENT

- Page 15 and 16: INTERVIEW company to do alone. In t

- Page 17 and 18: of Legal, Business, Finance and Ent

- Page 19 and 20: TRANSPORT TECHNOLOGY: transforming

- Page 21 and 22: SeaRail is a logistics company that

- Page 24 and 25: TOGETHER WE CAN PROFILE Tshepo Kgar

- Page 26 and 27: TECHNOLOGY Are you missing out on t

- Page 28 and 29: PROCUREMENT Becoming risk-savvy POS

- Page 32 and 33: E-COMMERCE ovid-19 nd its impact on

- Page 34 and 35: E-COMMERCE Reliability and control

- Page 36: Smart logistics Fiercely precise FL

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...