International Operating Engineer - Summer 2015

Education & Training

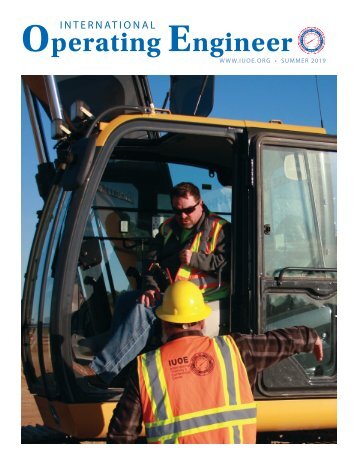

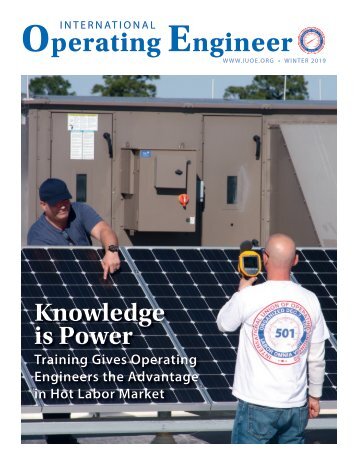

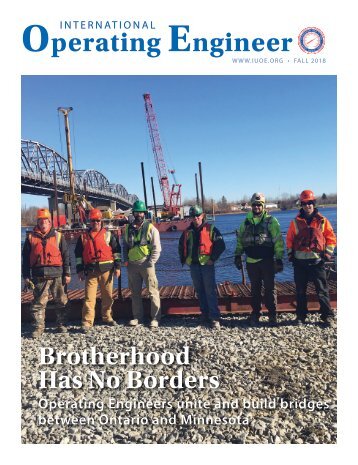

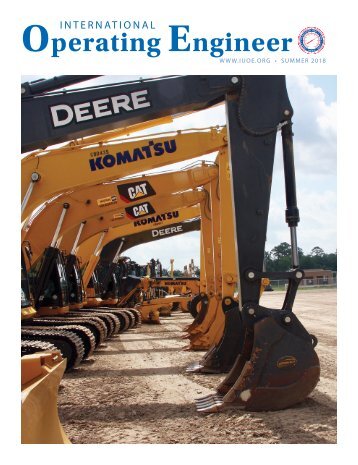

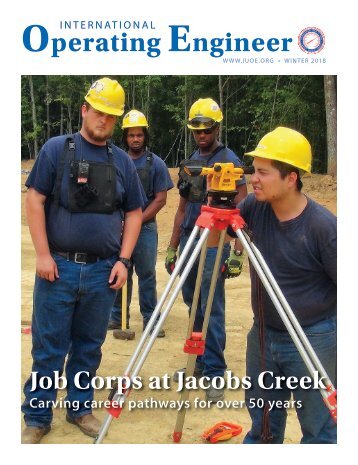

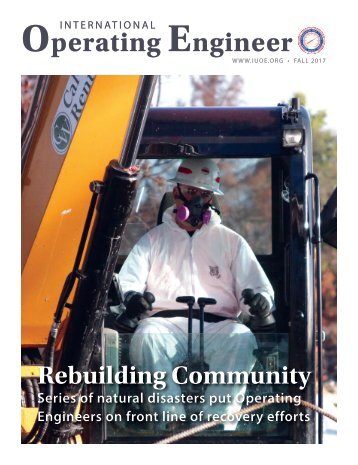

Education & Training Boom Time Great training opens up great opportunities FIFTY MILES NORTHEAST of Edmonton, Alberta, a team of side boom operators moves hundreds of feet of pipe. Working in tandem, they keep a keen eye on each other and their surroundings, skillfully maneuvering their machines below an overhead power line to lay the pipe in place. Sounds like a typical day working pipeline. But this is definitely different. You wouldn’t know it watching them work, but three weeks ago, none of the people in the seats had operated a side boom before. These operators are the latest graduates of the Side Boom Year 1 course presented by IUOE Local 955 Alberta’s Training Trust Fund. The course runs in springtime each year, when the thawing ground restricts movement of heavy equipment. During this brief pipeline breakup window, Local 955’s Training Center is dedicated exclusively to the side boom course for three weeks. Students spend 10-hour days at the Center, which is comprised of a 3,000-square-foot, modern classroom facility on 160 acres of land. One or two hours per day are spent in the classroom, and the rest of the time is spent working on and in the machine. The course covers subject matter and processes including: Occupational Health and Safety regulations, characteristics of the machine, machine systems, basic operations, multiple control manipulation, construction rigging, hoisting signals, and performing lifts. The quality of union equipment training is unmatched in the industry. The key to our students’ success is the low student-to-instructor—and student-to-machine—ratio. For side boom training, that ratio is kept at two to one. Our last intake put 18 students through the course. As Training Trust Fund Administrator Darlene Pysyk describes, “The fact that we can train 18 to 20 guys in one training session, that isn’t something that’s available across Canada. We free up our schedule and that’s what we do for that period of time—we do side boom training. Other training providers don’t do things that exclusively and to that extent.” The large capacity of the course is made possible through partnerships with employers, who loan the side booms to Local 955 for the course during the spring breakup season. “It’s in their best interest to provide us with the equipment,” Pysyk says, “because in turn we provide them with trained workers.” Students learn on the same equipment used in the field, both newer hydraulic-draw machines and live-draw models that are still prevalent in the industry. “We have 160 acres so it’s not hard for us to manage nine side booms,” notes Pysyk. Students get ample opportunity to practice skills, and complete the course ready to perform on the job site. Alternatives for side boom training are rare and nowhere near as comprehensive. Focused on profit, these facilities push as many students through a course as possible, sacrificing individual attention and seat time per student. Local 955’s training—offered free of charge to referred and approved members—puts the focus on the student. As Pysyk says, “Members get two-to-one training. They don’t have eight guys that they have to share a side boom with, they’ve got one.” With only two students sharing each machine, it works out to each person getting about 60 hours of actual seat time in the side boom throughout the course. Students gain invaluable experience from all that seat time. They learn to work in tandem, to communicate, to watch for what other operators are doing. They are taught to be aware of their surroundings and practice constant observation. Student Aaron Meunier says, “The whole course was an eye-opener. Learning wrong from right when running live [draw side boom] was a big part of the course and you learn a lot from the hands-on training.” Another successful student, Brett Chern, says the biggest thing he took away from the course was confidence. “When you’re running a side boom there’s always guys and crews around you and you have to be confident operating the machine, because that’s somebody’s life you’re responsible for.” In addition to experience and confidence, students walk away from the course with increased earning potential. All students typically have some experience in the pipeline industry prior to the course, but this training gives them the opportunity to move from laborer positions to actual operating and gain the pay increase that goes along with that. Local 955 views all of our equipment, safety, and skills training as an investment in our membership. A highly trained, safety-conscious work force is the promise we make to industry. The focus and dedication of the staff, employers, and students that participate in our side boom course is the living fulfillment of that promise. [left] A Local 955 student completes a field exercise. [above] Local 955’s side boom class of 2015. [article & photos] Austin Havens, IUOE Local 955 Training Trust NTF Equipment Program Keeps Rolling IN THE INTEREST of keeping our members trained on the latest construction equipment, the IUOE National Training Fund has continued the leasing program with John Deere. There are six sets of construction equipment that are moved following a schedule to different training centers across the United States and Canada. The sets of equipment consist of a 75G Excavator and a 344K Loader with a fork attachment. Pictures shown are courtesy of Local 926 in Georgia where one of the first sets were delivered. 6 INTERNATIONAL OPERATING ENGINEER SUMMER 2015 7

- Page 1 and 2: i n t e r n at i o n a l Operating

- Page 4: International Operating Engineer (I

- Page 10: Politics & Legislation Legislation

- Page 14: HAZMAT Confined Space in Constructi

- Page 18: Canadian News Latest Blow to Labour

- Page 22: In Memorium Death benefits paid May

- Page 26: International Union of Operating En

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...

International Operating Engineer

HEADQUARTERS

INTERNATIONAL UNION OF OPERATING ENGINEERS (IUOE)

1125 17th Street, NW

Washington, DC 20036

202 429-9100

CONTACT US

Send us an email here.

©2010 International Union of Operating Engineers. All Rights Reserved.|Terms Of Use|Privacy Statement|Sitemap