International Operating Engineer - Summer 2019

- Text

- Infrastructure

- Pipeline

- Engineer

- Apprenticeship

- Iuoe

Feature Teamwork Down

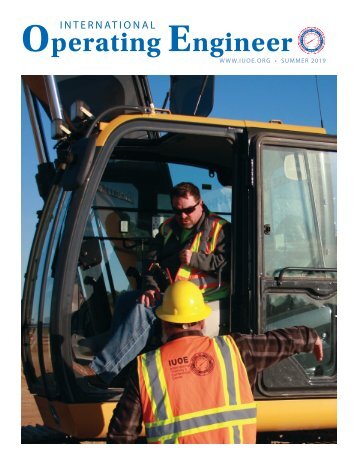

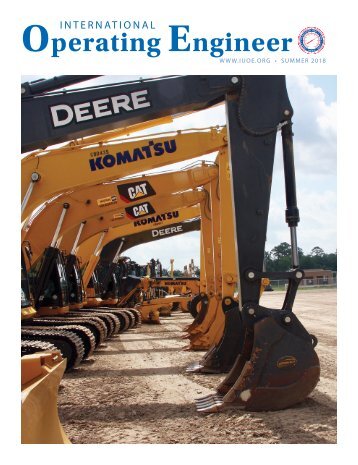

Feature Teamwork Down the Line Local 324 pipeliners take pride in safety & training “WE’RE SPECIALIZED HERE in pipeline. It’s different than anything else you might do – this pipe don’t give at all.” IUOE Local 324 member and longtime pipeliner Tom McEvoy would know. McEvoy has been working in the pipeline and distribution sector as an Operating Engineer 324 member since 1989. Today, he’s showing me around the third phase of the 610 milliondollar Saginaw Trail Pipeline Project in Genesee County. The Saginaw Trail Pipeline Project is just one of several pipeline and distribution jobs being worked on this year by the hard-working and dedicated members of Operating Engineers 324. Phases one and two of this project already saw 37 miles of old pipeline replaced by new sections of 80-foot pipe. Since this pipeline is used for natural gas, it gets special coating and sandblasting, as well as extensive testing before it’s even lowered into the ground. Phase three is the longest section, as it runs outside of downtown Flint. When it’s completed, it will run almost 30 miles from Clio to Grand Blanc, under railroads, streets, highways and the Flint river. It’s a complicated process, and one that is subject to constant supervision and inspection. “When we started, there was about two of us, and 54 inspectors,” notes McEvoy, laughing. “Consumers Energy has very rigid specifications.” This phase will have almost 400 people working on it through the year. The production crew includes boring, the pipe gang, ditch excavation and running the four Horizontal Directional Drills (HDD) that will be used to place the pipe under the river and I-69. Of those 400, about 150 will be Operating Engineers. All 150 are IUOE members, and many of them belong to Local 324. Operating Engineers are joined by union welders, laborers and teamsters. “There are some really congested areas where they are working,” says Greg Kanopka, Project Manager for project contractor Snelson. “They are digging, welding, coating, putting it in, tying it in, backfilling it in four miles of residential areas with utilities, drains, water, etc. Not to mention auto traffic. There are many overhead transmission lines. That’s why communication, spotters, two-way radios, whistles, are so important.” Jeff Sanderson, Supervisor and 20 year Local 324 member adds, “We’re building roads, removing top soil, cutting grade. It’s all about production, with 23 other crews coming in behind you. Laying mats, they keep every crew moving through, with production.” In such a fast-paced and productionminded environment, Sanderson and Kanopka agree that it is the training and safety that Operating Engineers 324 members exhibit that makes all the difference. “The biggest advantage in working with Local 324 to me is the confidence I have in the Operators. They’re safe and I can trust them to do the job,” says Kanopka. “They’re efficient at it, and they know what they’re doing. When I see Local 324 hats and vests, I know they’re looking out for everyone’s safety and interest.” Vince Thompson has been with Local 324 since 2008, and he agrees. “A Local 324 Operator is a lot more safety conscious about everything involved, better in the environment, the neighborhood. A greater attention to detail. The safety orientation is second to none” Thompson has been working on Pipelines for ten years. “I enjoy pipelining. I run the ‘thumper’, the compressor, and the hammer for running stuff through. I’ll operate the track boring machine to go under the road.” A project of this magnitude has heavy equipment around every turn, from the specialty side-boom cranes to excavators, dozers, boring 12 INTERNATIONAL OPERATING ENGINEER SUMMER 2019 13

- Page 1 and 2: Operating Engineer i n t e r n at i

- Page 4: From the General President [James T

- Page 8: Member Spotlight From Bank Teller t

- Page 14: Feature machines and pumps. With th

- Page 18: Politics & Legislation ...Continued

- Page 22: GEB Minutes General Executive Board

- Page 26: GEB Minutes Local Union’s new Bus

- Page 30: Union Death Benefit Benefits paid A

- Page 34: International Union of Operating En

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...

International Operating Engineer

HEADQUARTERS

INTERNATIONAL UNION OF OPERATING ENGINEERS (IUOE)

1125 17th Street, NW

Washington, DC 20036

202 429-9100

CONTACT US

Send us an email here.

©2010 International Union of Operating Engineers. All Rights Reserved.|Terms Of Use|Privacy Statement|Sitemap