SPINSEP⢠Vertical Flotation System

SPINSEP⢠Vertical Flotation System

SPINSEP⢠Vertical Flotation System

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

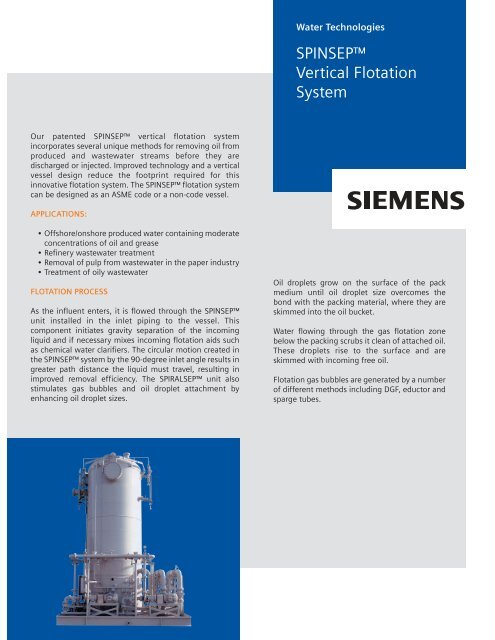

Water TechnologiesSPINSEP<strong>Vertical</strong> <strong>Flotation</strong><strong>System</strong>Our patented SPINSEP vertical flotation systemincorporates several unique methods for removing oil fromproduced and wastewater streams before they aredischarged or injected. Improved technology and a verticalvessel design reduce the footprint required for thisinnovative flotation system. The SPINSEP flotation systemcan be designed as an ASME code or a non-code vessel.APPLICATIONS:• Offshore/onshore produced water containing moderateconcentrations of oil and grease• Refinery wastewater treatment• Removal of pulp from wastewater in the paper industry• Treatment of oily wastewaterFLOTATION PROCESSAs the influent enters, it is flowed through the SPINSEPunit installed in the inlet piping to the vessel. Thiscomponent initiates gravity separation of the incomingliquid and if necessary mixes incoming flotation aids suchas chemical water clarifiers. The circular motion created inthe SPINSEP system by the 90-degree inlet angle results ingreater path distance the liquid must travel, resulting inimproved removal efficiency. The SPIRALSEP unit alsostimulates gas bubbles and oil droplet attachment byenhancing oil droplet sizes.Oil droplets grow on the surface of the packmedium until oil droplet size overcomes thebond with the packing material, where they areskimmed into the oil bucket.Water flowing through the gas flotation zonebelow the packing scrubs it clean of attached oil.These droplets rise to the surface and areskimmed with incoming free oil.<strong>Flotation</strong> gas bubbles are generated by a numberof different methods including DGF, eductor andsparge tubes.