Tehnologia de frezare - EMUGE FRANKEN Tools Romania

Tehnologia de frezare - EMUGE FRANKEN Tools Romania

Tehnologia de frezare - EMUGE FRANKEN Tools Romania

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

________ Tehnologii <strong>de</strong> filetare<br />

________ Tehnologii <strong>de</strong> <strong>frezare</strong><br />

________<br />

Portscule si accesori<br />

<strong>EMUGE</strong> <strong>FRANKEN</strong><br />

<strong>Tools</strong> <strong>Romania</strong> Srl<br />

Str. Tabacarilor 15B/104, Cluj-N., 400139<br />

Tel/Fax: +40-264-597600, +40-364-885544<br />

emuge@emuge.ro, www.emuge.ro<br />

Produse noi care vor fi prezentate in cadrul TIB-2012<br />

PAVILION A, STAND D 01 - 02<br />

- <strong>Tehnologia</strong> <strong>de</strong> fixare -<br />

Softsynchro® Modular cu posibilitatea <strong>de</strong> reglare a<br />

lungimii sculei<br />

Softsynchro®/Modular/IKZ<br />

Softsynchro®/Modular/MQL<br />

Cele mai noi mo<strong>de</strong>le <strong>de</strong> Softsynchro® Modular combina<br />

sistemul patentat si binecunoscut Softsynchro® pentru<br />

compensarea <strong>de</strong> lungime minima, cu necesitiatile <strong>de</strong><br />

portscule flexibile in fabricatia mo<strong>de</strong>rna. Softsynchro®<br />

Modular admite ajustarea <strong>de</strong> lungime a sculei <strong>de</strong> filetat.<br />

Sunt echipate cu con HSK. Sunt concepute atat pentru<br />

ungere minima cu 1 sau 2 canale cat si pentru ungere cu<br />

lichid. Asigura transferul agentului <strong>de</strong> racire/ungere fara<br />

pier<strong>de</strong>re. Datorita acestor avantaje si eficientei sistemului<br />

Softsynchro® imbunatateste substantial procesul <strong>de</strong><br />

filetare, si este un sistem unic <strong>de</strong> port-tarod pe piata.<br />

Press in<br />

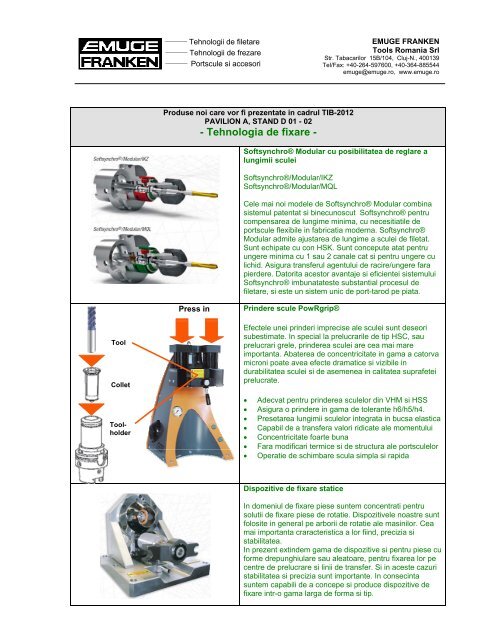

Prin<strong>de</strong>re scule PowRgrip®<br />

Tool<br />

Collet<br />

Toolhol<strong>de</strong>r<br />

Efectele unei prin<strong>de</strong>ri imprecise ale sculei sunt <strong>de</strong>seori<br />

subestimate. In special la prelucrarile <strong>de</strong> tip HSC, sau<br />

prelucrari grele, prin<strong>de</strong>rea sculei are cea mai mare<br />

importanta. Abaterea <strong>de</strong> concentricitate in gama a catorva<br />

microni poate avea efecte dramatice si vizibile in<br />

durabilitatea sculei si <strong>de</strong> asemenea in calitatea suprafetei<br />

prelucrate.<br />

• A<strong>de</strong>cvat pentru prin<strong>de</strong>rea sculelor din VHM si HSS<br />

• Asigura o prin<strong>de</strong>re in gama <strong>de</strong> tolerante h6/h5/h4.<br />

• Presetarea lungimii sculelor integrata in bucsa elastica<br />

• Capabil <strong>de</strong> a transfera valori ridicate ale momentului<br />

• Concentricitate foarte buna<br />

• Fara modificari termice si <strong>de</strong> structura ale portsculelor<br />

• Operatie <strong>de</strong> schimbare scula simpla si rapida<br />

Dispozitive <strong>de</strong> fixare statice<br />

In domeniul <strong>de</strong> fixare piese suntem concentrati pentru<br />

solutii <strong>de</strong> fixare piese <strong>de</strong> rotatie. Dispozitivele noastre sunt<br />

folosite in general pe arborii <strong>de</strong> rotatie ale masinilor. Cea<br />

mai importanta craracteristica a lor fiind, precizia si<br />

stabilitatea.<br />

In prezent extin<strong>de</strong>m gama <strong>de</strong> dispozitive si pentru piese cu<br />

forme drepunghiulare sau aleatoare, pentru fixarea lor pe<br />

centre <strong>de</strong> prelucrare si linii <strong>de</strong> transfer. Si in aceste cazuri<br />

stabilitatea si precizia sunt importante. In consecinta<br />

suntem capabili <strong>de</strong> a concepe si produce dispozitive <strong>de</strong><br />

fixare intr-o gama larga <strong>de</strong> forma si tip.