You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

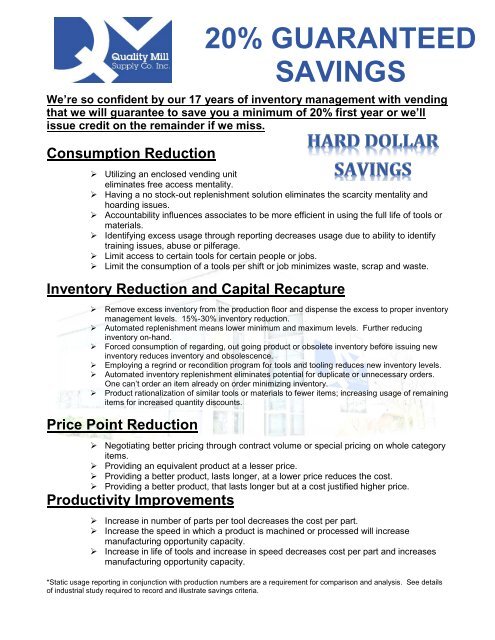

We’re so confident by our 17 years of inventory management with vending<br />

that we will guarantee to save you a minimum of <strong>20%</strong> first year or we’ll<br />

issue credit on the remainder if we miss.<br />

Consumption Reduction<br />

‣ Utilizing an enclosed vending unit<br />

eliminates free access mentality.<br />

‣ Having a no stock-out replenishment solution eliminates the scarcity mentality and<br />

hoarding issues.<br />

‣ Accountability influences associates to be more efficient in using the full life of tools or<br />

materials.<br />

‣ Identifying excess usage through reporting decreases usage due to ability to identify<br />

training issues, abuse or pilferage.<br />

‣ Limit access to certain tools for certain people or jobs.<br />

‣ Limit the consumption of a tools per shift or job minimizes waste, scrap and waste.<br />

Inventory Reduction and Capital Recapture<br />

‣ Remove excess inventory from the production floor and dispense the excess to proper inventory<br />

management levels. 15%-30% inventory reduction.<br />

‣ Automated replenishment means lower minimum and maximum levels. Further reducing<br />

inventory on-hand.<br />

‣ Forced consumption of regarding, out going product or obsolete inventory before issuing new<br />

inventory reduces inventory and obsolescence.<br />

‣ Employing a regrind or recondition program for tools and tooling reduces new inventory levels.<br />

‣ Automated inventory replenishment eliminates potential for duplicate or unnecessary orders.<br />

One can’t order an item already on order minimizing inventory.<br />

‣ Product rationalization of similar tools or materials to fewer items; increasing usage of remaining<br />

items for increased quantity discounts.<br />

Price Point Reduction<br />

<strong>20%</strong> <strong>GUARANTEED</strong><br />

<strong>SAVINGS</strong><br />

‣ Negotiating better pricing through contract volume or special pricing on whole category<br />

items.<br />

‣ Providing an equivalent product at a lesser price.<br />

‣ Providing a better product, lasts longer, at a lower price reduces the cost.<br />

‣ Providing a better product, that lasts longer but at a cost justified higher price.<br />

Productivity Improvements<br />

‣ Increase in number of parts per tool decreases the cost per part.<br />

‣ Increase the speed in which a product is machined or processed will increase<br />

manufacturing opportunity capacity.<br />

‣ Increase in life of tools and increase in speed decreases cost per part and increases<br />

manufacturing opportunity capacity.<br />

*Static usage reporting in conjunction with production numbers are a requirement for comparison and analysis. See details<br />

of industrial study required to record and illustrate savings criteria.