BA ROPULS Umschlag 1110.cdr - Rothenberger

BA ROPULS Umschlag 1110.cdr - Rothenberger

BA ROPULS Umschlag 1110.cdr - Rothenberger

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

5.1 Operation and maintenance<br />

Before you start working, let the compressor run for 10 minutes with the air tap completely<br />

open so that its moving parts can get used to operating.<br />

General information<br />

Important!<br />

Please read!<br />

This compressor is not designed or built for long-term use. It is recommended that it not be<br />

operated at more than 50% and not for more than 15 minutes continuously.<br />

Set-up<br />

Always set up the compressor at least 50 cm from any obstruction that could hinder the<br />

airflow and thereby the cooling.<br />

5.2 Periodic maintenance<br />

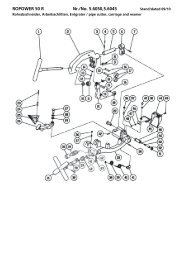

After the first 5 operating hours, check that cap and casing screws fit<br />

tightly (fig. 2).<br />

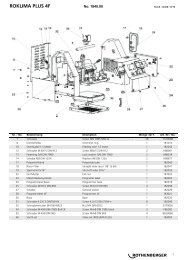

Once per week (Fig. 4)<br />

Drain the condensation water by opening the tap E.<br />

Set the container in such a way that the openings of the drain tap<br />

points downward.<br />

Close the tap as soon as only air begins streaming out.<br />

Because the compressor is lubrication free, the condensation<br />

water can be drained into the sewer.<br />

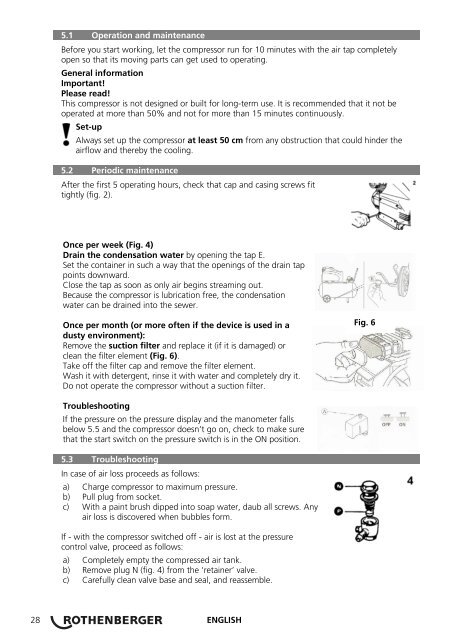

Once per month (or more often if the device is used in a<br />

dusty environment):<br />

Remove the suction filter and replace it (if it is damaged) or<br />

clean the filter element (Fig. 6).<br />

Take off the filter cap and remove the filter element.<br />

Wash it with detergent, rinse it with water and completely dry it.<br />

Do not operate the compressor without a suction filter.<br />

Troubleshooting<br />

If the pressure on the pressure display and the manometer falls<br />

below 5.5 and the compressor doesn’t go on, check to make sure<br />

that the start switch on the pressure switch is in the ON position.<br />

5.3 Troubleshooting<br />

In case of air loss proceeds as follows:<br />

a) Charge compressor to maximum pressure.<br />

b) Pull plug from socket.<br />

c) With a paint brush dipped into soap water, daub all screws. Any<br />

air loss is discovered when bubbles form.<br />

If - with the compressor switched off - air is lost at the pressure<br />

control valve, proceed as follows:<br />

a) Completely empty the compressed air tank.<br />

b) Remove plug N (fig. 4) from the ‘retainer’ valve.<br />

c) Carefully clean valve base and seal, and reassemble.<br />

28 ENGLISH<br />

Fig. 6