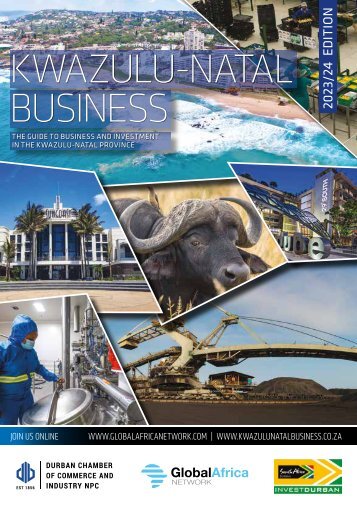

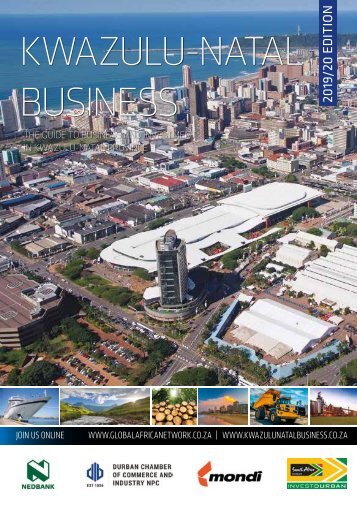

KwaZulu-Natal Business 2021-22

- Text

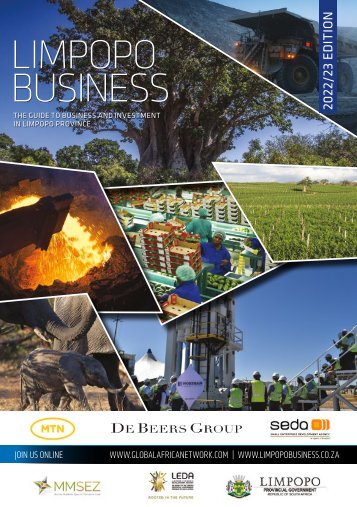

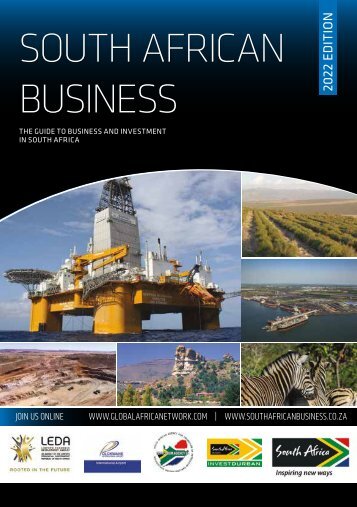

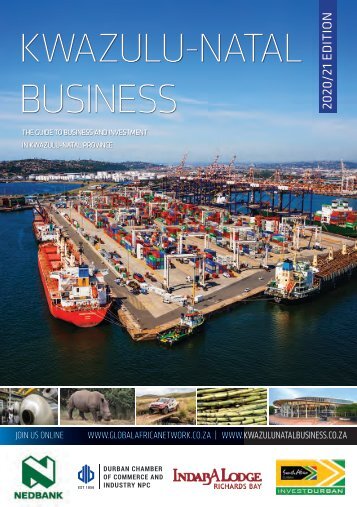

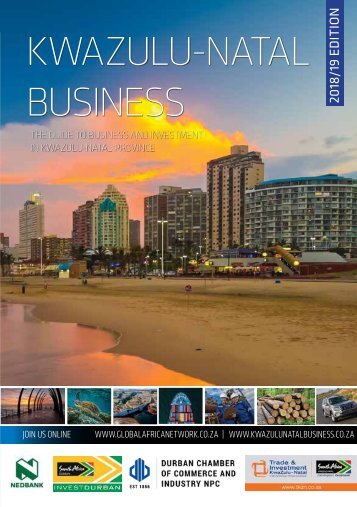

- Harbours

- Ports

- Africa

- Southafrica

- Kwazulunatal

- Business

- Investment

- Infrastructure

- Export

- Ilembe

- Industrial

- Province

- Provincial

- Economic

- Sector

- African

- Municipality

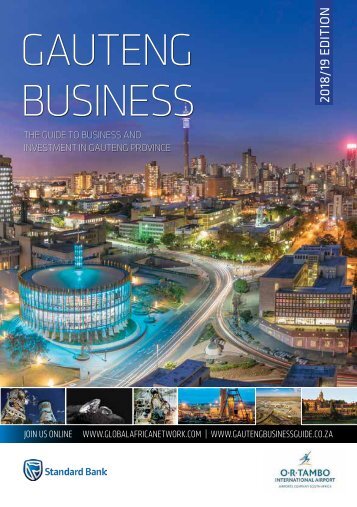

- Durban

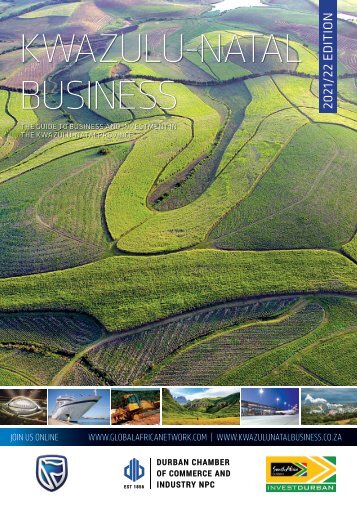

OVERVIEW Forestry and

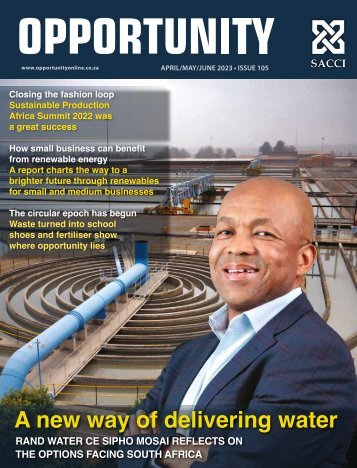

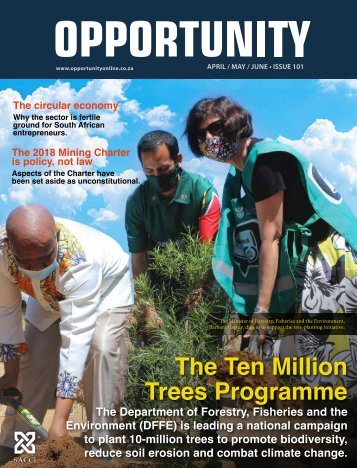

OVERVIEW Forestry and paper A beekeeping project has reduced forest fires. SECTOR INSIGHT Nampak produces crêpe paper at Verulam. Since Sappi started allowing an organisation to place hives in its forests five years ago, the concept has grown into a fully-fledged beekeeping programme that sustains families – and reduces uncontrolled fires. Prior to inviting African Honey Bee onto its properties, Sappi often had to deal with fires caused by people trying to find honey by smoking out hives. A formal training programme has created entrepreneurs who are now reaping the rewards. In 2017, African Honey Bee purchased five tons of honey from 120 beekeepers. This grew to 10 tons from 500 beekeepers in 2019 and training has been offered in vegetable and poultry farming. The honey is packaged and sold throughout South Africa as Sizana traceable honey. Sappi has 19 production facilities on three continents (of which five are in Southern Africa) and 12 800 employees in over 35 countries. Sappi’s Stanger Mill is situated close to sugar fields from which it takes bagasse (dry sugar cane pulp) for use in its production processes. Typek office paper is made at this mill, which has the capacity to produce 80 000 tons of paper and 30 000 tons of tissue. At the company’s Tugela Mill up to 200 000 tons per annum of containerboard (corrugating medium) can be manufactured from recycled and virgin fibre. The giant Sappi Saiccor mill 50km south of Durban is the world’s biggest manufacturer of dissolving wood pulp. The Mondi Group has grown into an international behemoth with 26 000 employees and operations in more than 30 countries. In 2019 Mondi announced that its primary listing would be in London and the JSE will carry the company’s secondary listing. Mondi’s Merebank Mill produces a range of office paper products including the well-known brand, Mondi Rotatrim. Uncoated woodfree reels ONLINE RESOURCES Credit: Sappi Forestry South Africa: www.forestry.co.za Sizana honey: www.peels.co.za South African Institute of Forestry: www.saif.org.za Technical Association of the Pulp and Paper Industry of South Africa: www.tappi.org are manufactured for the South African and Sub-Saharan African markets. At Richards Bay, eucalyptus fibre is used to make a premier-grade bleached hardwood pulp and a white top kraft linerboard is also produced. Major investments at Richards Bay have improved air quality, reduced water consumption and reduced the amount of solid waste. Nampak produces crêpe paper at Verulam and Rafalo produces tissue paper. SA Paper Mills is another paper producer. Mpact’s upgrade of its Felixton mill has increased capacity and improved efficiency. The project cost R765-million and takes overall production up to 215 000 tons and a lightweight containerboard option has been included in the product lines. Mpact has plastics and paper operations, with the paper section divided into three divisions: paper manufacturing, corrugated and converted paper products and recycling efficiency. The project cost R765-million and takes overall production up to 215 000 tons and a lightweight containerboard option has been included in the product lines. Mpact has plastics and paper operations, with the paper section divided into three divisions: paper manufacturing, corrugated and converted paper products and recycling. ■ KWAZULU-NATAL BUSINESS 2021/22 30

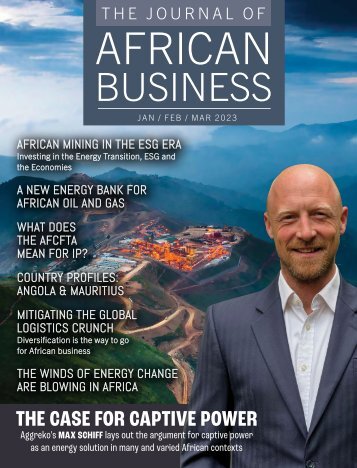

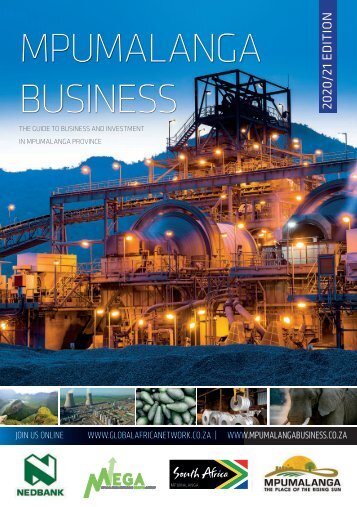

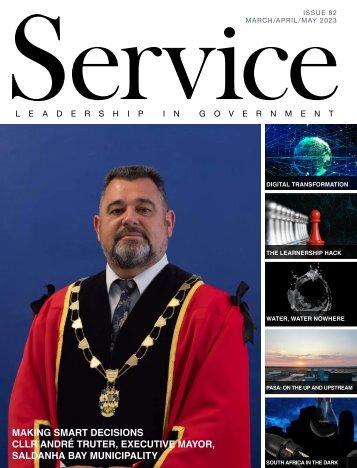

OVERVIEW Mining Coal mining and processing has resumed. South32’s Hillside aluminium smelter at Richards Bay produced a record amount of saleable product in the year to June 2020, despite variable energy supply. The Covid pandemic in 2020 added to the ongoing problem of reliable electricity supply, which is a critical issue for a big energy user like a smelter. The crisis affecting South Africa’s power utility, Eskom, is causing South32, the Australian owner of the Hillside aluminium smelter to rethink their operations there. In 2019 about 400 workers took early retirement or voluntary retrenchment packages. In early 2021, a new contract with Eskom was still under discussion. Most of the product from the smelter (high-quality primary aluminium ingot) is exported but some liquid metal form is sent to Isizinda Aluminium which supplies Hulamin, a company that has had a rolling mill in Pietermaritzburg since 1949. Hulamin is the only major aluminium rolling operator in the region and it makes rolled products and extrusions. Other processing facilities in the province include the steel plant owned by Arcelor Mittal in Newcastle and Safa Steel’s metalcoating factory in Cato Manor. Coal mining resumed in northern KwaZulu-Natal at the start of 2021, after an enforced period under care and maintenance because of the pandemic. Three shafts owned by Zululand Anthracite Colliery (ZAC) are currently functioning and a fourth is expected to come on stream in 2022, when the mine should be able to produce onemillion tons of coal. Some of the coalfields of the province have been revived. Petmin’s Somkhele Anthracite Mine, north of Richards Bay, has one of the biggest reserves of open-pit anthracite in South Africa, with measured and indicated reserves of more than 51-million tons across its four areas. RBM mines the minerals sands of the northern KwaZulu-Natal coast and operates out of Richards Bay. The main products of the RBM mine are zircon, rutile, titania slag, titanium dioxide feedstock and high-purity iron. Luxembourg-based Traxys Africa, which has chrome mines in ONLINE RESOURCES Geological Sciences, University of KZN: www.geology.ukzn.ac.za Minerals Council South Africa: www.mineralscouncil.org.za National Department of Mineral Resources: www.dmr.gov.za SECTOR INSIGHT KZN Sands offers learnerships. Credit: South32 Mpumalanga and Limpopo provinces, runs a high-carbon ferrochrome plant at Richards Bay. The KZN Sands mineral sands operation comprises a central processing complex in Empangeni and the Fairbreeze Mine. Expenditure over several years is expected to rise to R5-billion as it expands. Tronox, which is listed on the New York Stock Exchange, is the major shareholder in KZN Sands. KZN Sands offers learnerships at Mtunzini and Empangeni. Finnish company Metso is spending about R53-million on building a second furnace at its Isithebe foundry in the iLembe District Municipality. This is in response to increased demand for large crusher wear parts. The KwaZulu-Natal foundry is one of five foundries the company runs on four continents. ■ 31 KWAZULU-NATAL BUSINESS 2021/22

- Page 1 and 2: ole in the automotive sector while

- Page 3 and 4: 0 0 11 1 0 1 0 11 0 0 11 1 0 1 0 11

- Page 5 and 6: WHO WE ARE Policy and advocacy are

- Page 7 and 8: Inspiring hope and enabling dreams

- Page 9 and 10: EBH South Africa Trusted ship repai

- Page 11 and 12: SMME VIRTUAL ROADSHOW PRACTICAL AND

- Page 13 and 14: SPECIAL FEATURE A wetland conservat

- Page 15 and 16: SPECIAL FEATURE Geography The mixed

- Page 17 and 18: tourist enterprises. The Lubombo Mo

- Page 19 and 20: Key sectors Our Business Clients se

- Page 21 and 22: SPECIAL FEATURE Donald Trump’s in

- Page 23 and 24: SPECIAL FEATURE year and made up a

- Page 25: FOCUS Sugarcane fields sector depar

- Page 28 and 29: OVERVIEW Agriculture A Value Chain

- Page 30 and 31: Producing crops that feed our count

- Page 34 and 35: OVERVIEW Engineering A respected un

- Page 36 and 37: FOCUS Gas discoveries are a boost t

- Page 38 and 39: OVERVIEW Construction and property

- Page 40 and 41: OVERVIEW Manufacturing Cellphones a

- Page 42 and 43: OVERVIEW Education and training An

- Page 44 and 45: REALISING DREAMS THROUGH QUALITY ED

- Page 46 and 47: OVERVIEW Water Waste-water works ar

- Page 48 and 49: OVERVIEW Banking and financial serv

- Page 50 and 51: OVERVIEW Development finance and SM

Inappropriate

Loading...

Mail this publication

Loading...

Embed

Loading...