Kapittel 1 - Roterende instrumenter - Norsk Orthoform Depot AS

Kapittel 1 - Roterende instrumenter - Norsk Orthoform Depot AS

Kapittel 1 - Roterende instrumenter - Norsk Orthoform Depot AS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1<br />

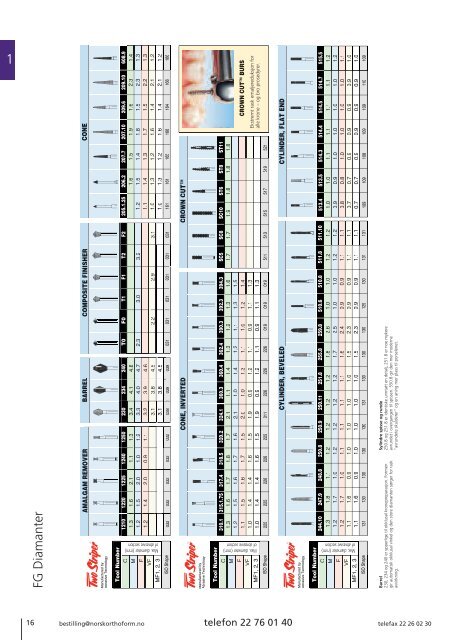

FG Diamanter<br />

16<br />

CONE<br />

BARREL COMPOSITE FINISHER<br />

AMALGAM REMOVER<br />

®<br />

Manufactured by<br />

Abrasive Technology<br />

205.1.25 206.2 207.7 207.10 209.6 209.10 608.9<br />

1.6 1.5 1.9 1.6 2.3 1.4<br />

1.2 1.5 1.4 1.8 1.5 2.3 1.3<br />

1.1 1.4 1.3 1.7 1.5 2.2 1.3<br />

1.0 1.3 1.2 1.6 1.4 2.1 1.2<br />

1.0 1.3 1.2 1.6 1.4 2.1 1.2<br />

161 161 165 166 164 166 166<br />

T0 F0 T1 F1 T2 F2<br />

2.3 3.0 3.2<br />

2.2 2.9 3.1<br />

031 031 031 031 031 031<br />

230 234 240<br />

3.4 4.1 4.8<br />

3.3 4.0 4.7<br />

3.2 3.9 4.6<br />

3.1 3.8 4.5<br />

31 3.1 38 3.8 45 4.5<br />

038 039 039<br />

1210 1220 1225 1240 1250<br />

1.3 1.6 2.1 1.1 1.3<br />

1.2 1.5 2.0 1.0 1.2<br />

1.2 1.4 2.0 0.9 1.1<br />

Tool Number<br />

C<br />

Max. diameter (mm)<br />

of abrasive section<br />

M<br />

F<br />

VF<br />

MF1, 2, 3<br />

032 032 032 032 032<br />

ISO Shape<br />

CROWN CUT<br />

CONE, INVERTED<br />

®<br />

Manufactured by<br />

Abrasive Technology<br />

SC5 SC8 SC10 ST6 ST8 ST11<br />

1.7 1.7 1.9 1.8 1.8 1.8<br />

CROWN CUT BURS<br />

bestilling@norskorthoform.no telefon 22 76 01 40 telefax 22 26 02 30<br />

511 513 515 517 519 521<br />

310.1 315.1.75 317.4 318.5 320.2 324.1 360.3 360.4 362.4 390.3 392.3 394.3<br />

1.3 1.6 1.7 1.8 1.7 2.1 1.1 1.4 1.3 1.2 1.3 1.6<br />

1.2 1.5 1.6 1.7 1.6 2.1 1.0 1.4 1.2 1.1 1.3 1.5<br />

1.1 1.5 1.6 1.7 1.5 2.0 1.0 1.3 1.1 1.0 1.2 1.4<br />

1.0 1.4 1.4 1.6 1.5 1.9 0.9 1.2 1.1 0.9 1.1 1.3<br />

1.0 1.4 1.4 1.6 1.5 1.9 0.9 1.2 1.1 0.9 1.1 1.3<br />

225 225 226 226 225 011 226 226 226 019 019 019<br />

Tool Number<br />

C<br />

Ekstremt rask emaljereduksjon for<br />

alle krone – og bro prosedyrer.<br />

Max. diameter (mm)<br />

of abrasive section<br />

M<br />

F<br />

VF<br />

MF1, 2, 3<br />

ISO Shape<br />

CYLINDER, FLAT END<br />

CYLINDER, BEVELED<br />

®<br />

Manufactured by<br />

Abrasive Technology<br />

513.4 513.5 514.3 514.4 514.5 514.7 515.5<br />

1.0 1.0 1.1 1.1 1.1 1.1 1.2<br />

0.9 0.9 1.0 1.0 1.0 1.0 1.2<br />

0.8 0.8 1.0 1.0 1.0 1.0 1.1<br />

0.7 0.7 0.9 0.9 0.9 0.9 1.0<br />

0.7 0.7 0.9 0.9 0.9 0.9 1.0<br />

109 109 108 109 109 110 109<br />

244.10 247.9 248.8 250.8 250.9 250.11 251.8 255.8 259.8 510.6 510.8 511.8 511.10<br />

1.3 1.8 1.1 1.2 1.2 1.2 1.2 1.8 2.6 1.0 1.0 1.2 1.2<br />

1.2 1.7 1.0 1.2 1.2 1.2 1.2 1.7 2.5 1.0 1.0 1.2 1.2<br />

1.2 1.7 1.0 1.1 1.1 1.1 1.1 1.6 2.4 0.9 0.9 1.1 1.1<br />

1.1 1.6 0.9 1.0 1.0 1.0 1.0 1.5 2.3 0.9 0.9 1.1 1.1<br />

1.1 1.6 0.9 1.0 1.0 1.0 1.0 1.5 2.3 0.9 0.9 1.1 1.1<br />

131 130 130 130 130 131 130 130 130 129 130 131 131<br />

Tool Number<br />

C<br />

Max. diameter (mm)<br />

of abrasive section<br />

M<br />

F<br />

VF<br />

MF1, 2, 3<br />

ISO Shape<br />

Sylindre spisse og runde<br />

250.8 og 251.8 er identiske unntatt en detalj, 251.8 er noe mykere<br />

avrundet i overgangen til spissen. 550.8 gir den mer moderne<br />

”avrundete skulderer” og en aning mer plass til porselenet.<br />

Barrel<br />

230, 234 og 240 er ypperlige til okklusal kronepreparasjon. Formen<br />

gir automatisk okklusal vinkel og den store diamanten sørger for rask<br />

avvirkning.