Untitled - Tribology in Industry

Untitled - Tribology in Industry

Untitled - Tribology in Industry

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Erpffi<br />

ffimffiffi<br />

PARTICLF QLiANTIFIER<br />

Fig. 1. Contacl geometry<br />

Geometrija kontaWa<br />

Te onef-u pu n rcou t ua x t u a<br />

cast iron with diameters of 68 mm and width of 8 mm.<br />

Diskswere thermally treated by isothermal and classical<br />

procedures. The Thble I shows chemical compositions<br />

and hardness of cast iron NI-500 and NL700 bettered by<br />

classical procedure.<br />

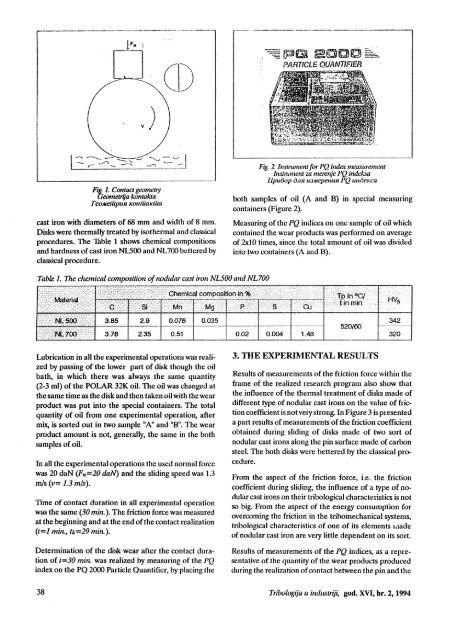

Fig. 2. Instrumentfor PQ <strong>in</strong>der rneasurement<br />

hrstnmrcnt za mercnje PQ <strong>in</strong>deksa<br />

Ilpufiop dnn uaxeperum PQ wtdercca<br />

both samples of oil (A and B) <strong>in</strong> special measur<strong>in</strong>g<br />

conta<strong>in</strong>ers (Figure 2).<br />

Measur<strong>in</strong>g of the PQ <strong>in</strong>dices on one sample of oil which<br />

conta<strong>in</strong>ed the wear products was performed on average<br />

of 2x10 times, s<strong>in</strong>ce the total amount of oil was divided<br />

<strong>in</strong>to two conta<strong>in</strong>ers (A and B).<br />

Table 1. The chemical composition of nodular cast iron NL500 and NL700<br />

,,,,,,,,.'',,'1,..'.';14615 iitdij:: ;:l::::::::::::::: :.::::<br />

:..fi.:.r;.!.i.;;l<br />

v:.:,:::.;<br />

:...'..Si-.i<br />

t.:. ,,:: .:.:i<br />

iMg',..',.'.., : : i l<br />

tt,'P.r.<br />

::it.l<br />

::(!.i::<br />

::r::t_:.<br />

,:cu l<br />

'i,.r::... : ::..t.: .:, I<br />

,::TP.lln,:oCl<br />

':'.,'ti<strong>in</strong> m<strong>in</strong>,<br />

'a,lt:,;,:,,',,a,1:t.i'NLlt$ffi.:t;'.1,:,:',:,:,:,:<br />

3.85 2.9 o.o76 0.035<br />

342<br />

52A1ffi<br />

3.76 2.35 o.51 0.02 0.oo4 1,48 320<br />

HV;<br />

Results of measurements of the PQ <strong>in</strong>dices, as a representative<br />

of the quantity of the wear products produced<br />

dur<strong>in</strong>g the realization of contact between the p<strong>in</strong> and the<br />

Lubrication <strong>in</strong> all the experimental operationswas realizedby<br />

pass<strong>in</strong>g of the lower part of disk though the oil<br />

bath, <strong>in</strong> which there was always the same quantity<br />

(2-3 ml) of the POI-AR 32K oil. The oil was changed at<br />

the same time as the disk and then taken oil with thewear<br />

product was put <strong>in</strong>to the special conta<strong>in</strong>ers. The total<br />

quantity of oil from one experimental operation, after<br />

mB is sorted out <strong>in</strong> two sample "A" and "8". The wear<br />

product amount is not, generally, the same <strong>in</strong> the both<br />

samples of oil.<br />

In all the experimental operations the used normal force<br />

was 20 daN (fz=20 dal,l) and the slid<strong>in</strong>g speed was 1.3<br />

nr/s (v= 1.3 mls).<br />

Time of contact duration <strong>in</strong> all experimental operation<br />

was the same (30 m<strong>in</strong>.), The friction force was measured<br />

at the beg<strong>in</strong>n<strong>in</strong>g and at the end of the contact realization<br />

(t:I m<strong>in</strong>., tk=29 m<strong>in</strong>.),<br />

Determ<strong>in</strong>ation of the disk wear after the contact duration<br />

of t=30 m<strong>in</strong>. was realized by measur<strong>in</strong>g of the PQ<br />

<strong>in</strong>dex on the PQ 2000 Particle Quantifier, by plac<strong>in</strong>g the<br />

3" TIIE BXPERIMBNTAL RESUI,TS<br />

Results of measurements of the friction force with<strong>in</strong> the<br />

frame of the realized research program also show that<br />

the <strong>in</strong>fluence of the thermal treatment of disks made of<br />

different type of nodular cast irons on the value of friction<br />

coefficient is not very strong. In Figure 3 is presented<br />

a part results of measurements of the friction coefficie nt<br />

obta<strong>in</strong>ed dur<strong>in</strong>g slid<strong>in</strong>g of disks made of two sort of<br />

nodular cast irons along the p<strong>in</strong> surface made of carbon<br />

steel. The both disks were bettered by the classical procedure.<br />

From the aspect of the friction force, i.e. the friction<br />

coefficient dur<strong>in</strong>g slid<strong>in</strong>g, the <strong>in</strong>fluence of a type of nodular<br />

cast irons on their tribological characteristics<br />

not<br />

so big. From the aspect of the enerry consumption for<br />

overcom<strong>in</strong>g the friction <strong>in</strong> the tribomechanical systems,<br />

tribological characteristics of one of its elements rrlod€<br />

of nodular cast iron are very little dependent on its sort.<br />

38<br />

Tribologija u <strong>in</strong>drctriji, god. XW rbr.Z,1994