S A N I TA RY WA R E TUNNEL KILN - Sacmi

S A N I TA RY WA R E TUNNEL KILN - Sacmi

S A N I TA RY WA R E TUNNEL KILN - Sacmi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

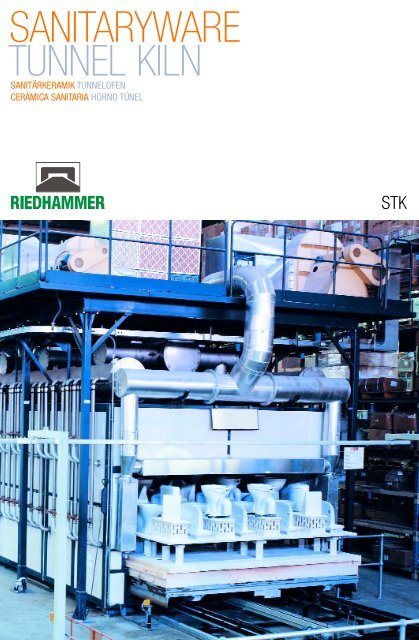

S A N I <strong>TA</strong> <strong>RY</strong> <strong>WA</strong> R E<br />

<strong>TUNNEL</strong> <strong>KILN</strong><br />

SANITÄRKERAMIK T U N N E L O F E N<br />

CERÁMICA SANI<strong>TA</strong> R I A HORNO TÚNEL<br />

STK

<strong>TUNNEL</strong> <strong>KILN</strong> ( S T K )<br />

<strong>TUNNEL</strong>OFEN ( S T K )<br />

HORNO TÚNEL ( S T K )<br />

flue gas section zone<br />

TECHNICAL DA<strong>TA</strong> TECHNISCHE DATEN<br />

Kiln possible dimension<br />

Useful width<br />

Possible car loading height<br />

Car useful volume<br />

Car in the kiln<br />

flue gas<br />

evacuation<br />

Average load on car<br />

(depending on products mix and<br />

loading conditions)<br />

Maximum temperature<br />

Firing temperature<br />

Approximate firing cycle<br />

flue gas<br />

evacuation<br />

Tunnel kiln for fully flexible<br />

production.<br />

Approximate specific net<br />

consumption<br />

(depending on technological and firing<br />

cycle conditions)<br />

roof air combustion air rapid<br />

cooling<br />

Mögliche Ofenmaße<br />

Nutzbreite<br />

Mögliche Ladehöhe d. Wagen<br />

Nutzvolumen d. Wagen<br />

Wagenanzahl im Ofen<br />

Durchschn. Beladung pro Wagen<br />

(abhängig vom Produkt und<br />

Ladebedingungen)<br />

Maximal Temperatur<br />

Brenntemperatur<br />

Brennzyklus (ca.) firing cycle<br />

Spezifischer Nettoverbrauch (ca.)<br />

(abhängig von verwendeter Technologie<br />

und Brennzyklus)<br />

DATOS TÉCNICOS<br />

Posibles dimensiones del horno<br />

Anchura útil<br />

Posible altura de la vagoneta<br />

Volumen útil de vagoneta<br />

No. vagonetas<br />

Carga media en el carro<br />

(depende de la mezcla de productos y<br />

de las condiciones de carga)<br />

Temperatura máxima<br />

Temperatura de cocción<br />

Ciclo de cocción aproximado<br />

Consumo específico neto<br />

aproximado<br />

(depende de las condiciones<br />

tecnológicas y del ciclo de cocción)<br />

gas<br />

piping<br />

Riedhammer GmbH Industrial kiln plants<br />

postal address: 90332 Nürnberg - Germany / address: Klingenhofstraße 72, 90411 Nürnberg - Germany<br />

telephone: +49.911.52180 / fax: +49.911.5218231 / e-mail: mail@riedhammer.de / web: www. r i e d h a m m e r. d e<br />

exhaust<br />

cooling<br />

preheating zone firing zone rapid cooling static cooling final cooling<br />

roof air rapid<br />

cooling<br />

combustion air<br />

Tunnelofen für Höchstflexibilität<br />

beim Brennen.<br />

Horno túnel para en la cocción<br />

máxima flexibilidad.<br />

exhaust<br />

cooling<br />

contravec<br />

46 ÷ 132 m 3<br />

2400 m ÷ 3800 mm<br />

800 mm ÷ 1200 mm<br />

2.52 m 3 ÷ 4.26 m 3<br />

32 ÷ 94<br />

18 ÷ 30 pcs<br />

1300 °C<br />

up to 1260 °C<br />

10 ÷ 20 h<br />

1000 ÷ 1400 Kcal/Kg<br />

cooling air<br />

& contravec<br />

cooling<br />

air